Construction site of the Iconic Tower in Egypt New Administrative Capital, Source -Wu Huiwo/Xinhua via ZUMA Wire

Egypt is a country located in North Africa and the Middle East. It is the third most populous country in Africa and has a rich history dating back thousands of years. Egypt is known for its ancient civilization, including the pyramids and the Sphinx, as well as its modern cities such as Cairo and Alexandria.

Egypt's economy is diverse and includes a range of industries. The country's main industries include tourism, agriculture, manufacturing, and natural resources such as oil and gas. Egypt is also a major exporter of goods such as textiles, chemicals, and food products. The Suez Canal, which connects the Mediterranean Sea to the Red Sea, is an important shipping route and a key source of revenue for the country. Additionally, Egypt has been investing in renewable energy sources such as wind and solar power in recent years.

Overhead crane market in Egypt

The overhead crane market in Egypt is expected to grow steadily in the coming years. The increasing demand for material handling equipment in various industries such as construction, automotive, and manufacturing is driving the growth of the overhead crane market in Egypt. Additionally, the government's focus on infrastructure development and investments in various sectors such as oil and gas, power, and transportation is expected to create a significant demand for overhead cranes in the country.

Types of overhead bridge cranes and main components for sale Egypt

A Bridge crane, also referred to as an overhead crane, overhead travelling crane, or industrial crane, is a type of material handling equipment that is used to lift, lower, and transport loads horizontally. This heavyduty equipment typically utilizes a hookandline mechanism that moves along a horizontal beam which travels on a runway beam, which serves as the supporting structure.

Bridge cranes are capable of handling high lifting capacities and their travel is directed by an operator, either manually or with a wired pendant station or wireless controls. They are commonly used for multidirectional movement of materials to aid in manufacturing, storing, loading or unloading works inside a facility or outside in a yard, railway, shipping port, and other application environments.

Main components of overhead bridge crane kits

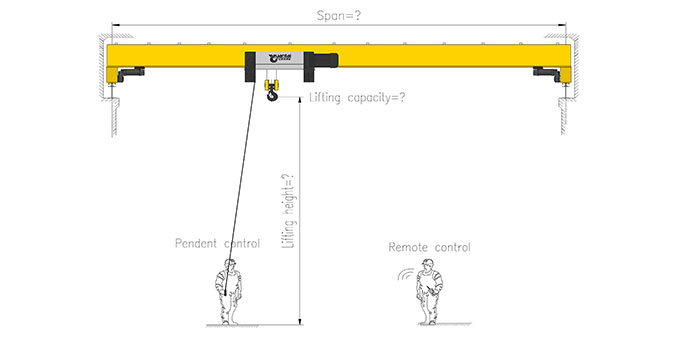

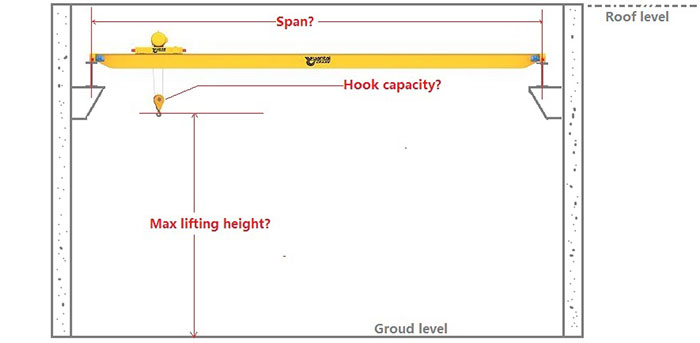

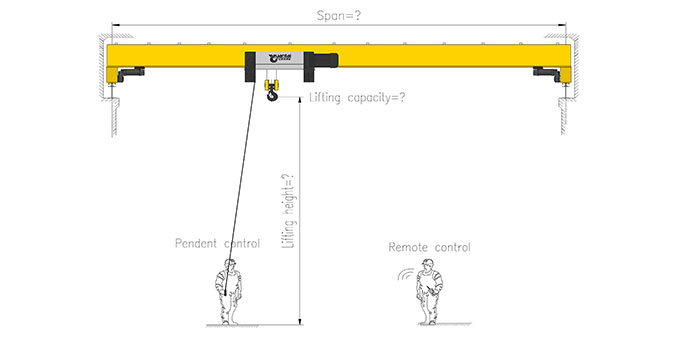

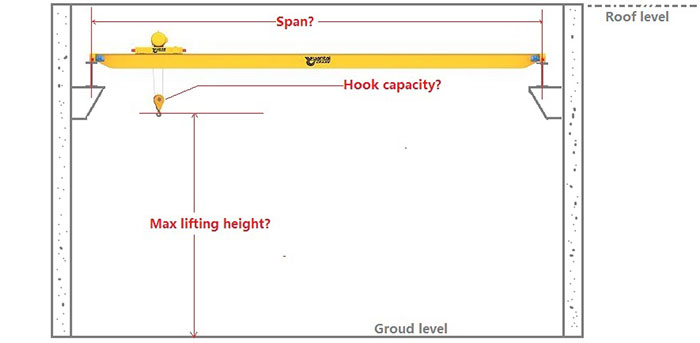

The Bridge crane consists of three main components, namely the crane bridge, the hoist or trolley, and the runway. The crane bridge traverses across the runway while the hoist or trolley is the lifting mechanism that moves across the crane bridge and lifts loads vertically. The runway is tied to the building structure. Other parts are also involved in the system, as shown in the following diagram for your reference.

- Crane capacity: maximum weight the Bridge crane is required to handle.

- Crane span: horizontal distance between the rails of runway on which the crane travels.

- Lift or hook height: distance from the floor to the crane hook, which determines the height of the runway from the floor and is subject to the clear inside height of the building.

- Bridge, trolley and lift speeds: rate at which the bridge or trolley runs or at which the hoist lifts; dual speeds are available.

- Crane bridge: main travelling structure of Bridge crane consisting of two end trucks and one or two bridged girders varying with the type of crane.

- End trucks: located on both sides of the span, they house the wheels on which the crane runs.

- Bridge girder(s): principal horizontal beam of the crane bridge supported by the end trucks and meant to support the trolley.

- Trolley hoist: consists of hoist and trolley frame; one or more hoists can be installed according to lifting requirements, which can be supplied on the same trolley or on separate trolleys.

- Trolley: takes the hoist across the bay along bridge girder(s) traversing the span.

- Hoist: mounted to the trolley and is the main lifting equipment together with the crane hook or other lifting attachment.

Overhead crane configuration:

Overhead cranes mainly have two configurations: Top running overhead cranes and under running overhead cranes.

Top running single girder overhead crane under construction

Top running overhead cranes:

The top running overhead crane refers to the crane which has the bridge travel on the top of rails mounted on a runway beam supported by either the building columns or columns specifically engineered for the crane. The top running overhead crane is the most common crane configuration with the feature that the crane loads are transmitted to the supporting columns or freestanding structure and with the advantage of minimum headroom and maximum height of lift.

Classification of top running overhead cranes:

Top running overhead cranes can be further classified into single girder, double girder, and box girder overhead crane in terms of girder types.

Single girder overhead crane is consisted of two end trucks, trolley hoist unit, and a single bridge girder, on the bottom flange of which the trolley runs on. A single girder overhead crane designed for your application can be costeffective. It has lower wheel loads so that it will save on new support structures and it will also allow you to add more lifting capabilities to your runway structure without upgrading.

Double girder overhead crane is consisted of two end trucks, trolley hoist unit, and two bridge girders, on the top of which located the rails on which the trolley runs. A double girder overhead crane provides better hook height for the hoist of the double girder overhead crane is mounted on top of the bridge rather than underneath.

Box girder overhead crane is a crane equipped on a girder formed by multiple walls in the shape of an enclosed tube, rather than on an Ibeam or Hbeam. It is used for heavyduty material handling with the feature of extremely rigidity and durability.

Under running overhead cranes:

Underrunning or underhung overhead crane has the end trucks ride on the bottom flange of the runway, which is usually suspended from the roof, with no need for extra floor columns for the support of the runway. The underrunning or underhung overhead crane has the advantage of taking no floor space and saving cost for supporting systems. Moreover, it can be applied to sloped ceilings or multiple crane systems.

Underhung overhead crane for sale Egypt with capacity up to 10 ton

Classification of underrunning or underhang overhead crane

In terms of crane girder, the underrunning or underhang or under slung overhead cranes can be grouped into single girder, double girder and box girder overhead cranes.

Single girder under running Overhead crane

Single girder under running overhead crane provides you a costeffective material handling solution as it can save new support structure because of its reduced wheel loads. This also makes it possible to add more lifting capabilities without upgradation.

Double girder under running Overhead crane

Double girder under running overhead crane is usually used for handling loads over 25 tons and is usually provided with a complete material handling solution. Double girder cranes provide a higher lifting height for the crane hook travels between the beams, comparing with that of the single girder overhead crane.

Overhead crane comparison top running Vs. under running

To choose the top running overhead crane or under running overhead crane is mainly determined by two factors:

- Capacity: Even though the under running overhead crane can be up to 25 ton capacity, the practical limit is more like 15 tons.

- Support structure: Under running overhead crane can be suspended directly from the overhead steel for the lighter duty crane. Top running overhead cranes need a bracket off the building support steel (up to 10 tons capacity) or independent columns for larger capacities.

Top running overhead crane configuration is best used when headroom is an issue. Double girder top running configuration is the most spaceefficient one. Whereas when the headroom is not an issue a top or under running configuration can be either single girder or double girder.

Overhead crane application

Overhead crane can be applied for material handling in various situations and industries, such as Automotive, Beverage, Chemicals, Commercial printing, Manufacturing, Newspaper, Paper, Steel and warehousing and distribution, etc.

Assembly

Overhead cranes are used to move the products through production processes.

Transportation

Overhead cranes are used to transport the finished products onto open trailers or other vehicles.

Staging

Holding workinprocess for additional production processes.

Storage

Overhead crane also can be used to transport heavy item into or out of the storage area.

Warehousing

Heavy items can be moved with overhead cranes to and from docks.

Overhead crane advantages

Overhead crane is the most applied material handling equipment for the following advantages:

Adaptable

Due to overhead crane can be operated on any plant floor surface and also because they can be modified to accommodate changing needs, overhead cranes provide high adaptability.

Customizable

Customized overhead cranes are available. The below hook attachments, riggings, and other special material handling tool to deal with the variety of loads.

Comfortableness

The design of overhead cranes takes the comfortableness of crane operators into consideration, which would improve the efficiency and safety in the working area.

Efficiency

Overhead cranes lift loads up and over obstacles with high efficiency without navigating back and forth through aisles.

Load control

Radio remote control, pendant pushbutton control, and driver’s cabin control are also at your choice for your overhead cranes.

Lower maintenance costs

Adopting with advanced technologies and offered in a variety of usage of capacity ratings, overhead cranes need less maintenance comparing with other lifting equipment.

Positioning

The overhead cranes can place the loads to an exact location with high precision.

Reduce labor cost

A set of single overhead crane can replace many forklifts and cover a large work area.

Lower damage to loads

With soft start features, wide selection of speed options, and a variety of handling tools or riggings, the loads can be safely handled.

Safety

Variety of safety measures are installed on overhead cranes to ensure the safety of your lifting equipment, crane operator and loads, etc.

Higher lifting height

Overhead cranes can provide you a higher lifting height with higher efficiency.

Overhead crane controls

Crane pendant control

crane cab control

inside of crane cabin

Overhead crane control controls your crane safety and reliability. Flexible and reliable control for overhead crane are very important. Usually, the following controls are frequently used on overhead cranes.

Pendant control

The pendant overhead control can give the crane operator precise control over the motion of the crane. According to the different functions, the pendant control has different configurations. The pendant control could be either suspended from the Trolley Hoist, which requires the crane operator to walk with and beside the load or on a separate sliding track system allowing the operator to move independently of the load.

VFD

A pendant overhead crane control can also be used in conjunction with a Variable Frequency Drive, which controls the motion for smooth acceleration and deceleration by varying the frequency of motors. The VFD controls could be highly customized.

Radio control

The radio control for overhead crane is just like the pendant control except the operator uses a radio frequency instead of pendant. The radio control has higher safety feature and also provides the operator a wider range of operating motions that a pendant.

Power supply

The electrical power supply in the building should be matched with the designed rate of overhead crane.

Electrical cabin

The electrical components of overhead crane could be placed and protected in the control cabin.

Safety

The safety of the overhead crane is ensured by protection against accidental contact, electrical shock, enclosed equipment, and indoor protection against dirt, dust, oil and water, etc.

Overhead crane runways

The runway of overhead cranes structure refers to the rails, beams and columns on which the crane operates.

Crane rails

The crane rails are where the end trucks travel and are fixed on the runway beam.

Runway beam

The runway beam is supported on the columns of top running overhead crane or from the roof structure of under running overhead crane.

Design of crane runway system

During the design of crane runway system, the existing building columns can be taken advantages. By then, it is important to provide the down shop center to center spacing between them.

Conductors

The conductors are mounted to the runway beam, which supply power to the overhead crane.

How to choose your overhead crane

Generally, the lifting capacity of the overhead cranes decides the types of crane girders: single, double and box girder. The single girder overhead is designed for handling loads of about 20 tons and the double girder and box girder overhead crane can be used to handling materials above 20 tons.

To choose the right material handling solution is critical. Therefore the customized or tailored overhead cranes are manufactured. However, how to find out the best type of overhead crane for your application? The most suitable overhead crane should be selected based on the specific application conditions and your building dimensions if the building has been constructed. The following tips are given for your reference to find your best cranes.

Load capacity

The maximum weight of your loads should not exceed the rated lifting capacity of your crane.

Crane span

The span or width of the crane system is important to decide the size of the overhead crane.

Working frequency

The operational frequency of your crane will be used to define the crane classification needed for your application.

Supporting systems

Usually, the overhead crane is supported by runway structures, attached to workshop building or the overhead crane could be supported on a freestanding runway set up specifically for the crane.

In order to give you a better understanding of what should be considered on choose an overhead crane, top running double girder overhead crane is taken as an example for your references.

Ask for single girder overhead crane price

Ask for double girder overhead crane price

Overhead crane cost in Egypt

The cost of an overhead crane in Egypt can vary depending on several factors such as the type of crane, lifting capacity, span length, and other specifications. Generally, overhead cranes can cost anywhere from a few thousand dollars to hundreds of thousands of dollars.

It is recommended to contact a reputable crane supplier or manufacturer in Egypt to get a more accurate estimate based on your specific needs and requirements. They can provide you with a detailed quotation that includes all the necessary components and installation costs.

Some popular crane suppliers in Egypt include Misr Crane & Engineering, El Masreya for Trading and Supplies, and El Helal for Engineering Industries.

Safety regulations for operating an overhead crane in Egypt

The safety regulations for operating an overhead crane in Egypt are governed by the Ministry of Manpower. These regulations include the requirement for a licensed operator, regular inspections and maintenance of the crane, proper training for operators and riggers, and adherence to safety protocols such as the use of personal protective equipment and proper signaling during operation. It is important to ensure that the crane is designed and installed according to local regulations and that all safety requirements are met before operating the crane. Failure to comply with these regulations can result in serious accidents and legal consequences.

Overhead crane maintenance

As there are many parts of the overhead crane, for different technical characteristics of the various components, in the actual work they will generally be maintained into periodic check in weeks.

Check the brake

Check the nut, cotter pins, positioning plate on the brakes whether it is complete, lose or not, lever and spring is free of cracks, pin bolts on the wheel and the brake washer is loose cushion, or complete; if it is reliable when the brake is open. The opening of the movable tiles should be less than 1.0mm and the distance across the gap between the brake drum should be equal, each axle pin may not have stuck phenomenon.

Checking the rope

Checking the rope on the winding drum and the pulley is normal or not, is there any phenomenons such as jumping from slot, channeling, knotting, twisting and so on. Whether rope plate bolts are tightened and has a double nut locking device or not.

Checking safety switch

Checking the installation of the safety switch and limit switch are accurate, flexible and reliable, especially the rise limit is reliable.

Lubrication points

Checking all lubrication points are in good condition.

Fastening screws

Check if it is lost or shortage of the fastening screws on coupling closures of the lifting mechanism.

Track

Checking the track to confirm that no foreign body to obstruct running of overhead crane.

Transmission

If there is any abnormal noise on the transmission of overhead crane.

Types of Cranes for sale Egypts and Featured projects

Construction site of the Iconic Tower in Egypt New Administrative Capital, Source -Wu Huiwo/Xinhua via ZUMA Wire

Construction site of the Iconic Tower in Egypt New Administrative Capital, Source -Wu Huiwo/Xinhua via ZUMA Wire

Crane pendant control

Crane pendant control  crane cab control

crane cab control  inside of crane cabin

inside of crane cabin

Ask for single girder overhead crane price

Ask for single girder overhead crane price  Ask for double girder overhead crane price

Ask for double girder overhead crane price