Overhead Cranes for Sale in Portugal Guide : Finding the Perfect Solution for Your Industry

In the heart of Portugal's diverse industrial landscape, overhead cranes have emerged as indispensable workhorses, elevating the efficiency, precision, and safety of material handling across a multitude of sectors. From manufacturing plants churning out heavy machinery to bustling ports orchestrating the intricate dance of cargo, the applications of overhead cranes are as diverse as the industries they serve. However, in the quest for optimal performance and safety, the key to success often lies in choosing the right overhead crane for your specific needs.

This comprehensive guide serves as a beacon for those navigating the labyrinth of overhead crane options in the Portuguese market. Whether you represent a thriving industrial sector or are an individual buyer looking for a customized crane solution, our guide is designed to provide invaluable insights, practical advice, and the tools to make informed decisions. In a country where the industrial tapestry is as rich and varied as Portugal, finding the perfect overhead crane tailored to your industry's unique requirements can be a game-changer.

Overviw of Overhead Cranes

In the bustling industrial landscape of Portugal, where the rhythm of manufacturing, logistics, and various sectors never seems to pause, overhead cranes have emerged as essential tools for elevating material handling processes. These towering giants of industry gracefully glide above factory floors, construction sites, and ports, effortlessly lifting and positioning heavy loads with precision and ease. They are the workhorses that make it all happen, from manufacturing the components of a new bridge to unloading containers from ships.

An overhead crane, also known as a bridge crane or a suspended crane, is a material handling device that operates on an elevated runway system. These systems consist of a hoist and trolley that move along the bridge, allowing for the lifting and movement of heavy loads horizontally. Overhead cranes are capable of handling a diverse range of materials, from steel beams and machinery components to shipping containers and more. They are designed to make material handling tasks efficient, precise, and, most importantly, safe.

The primary functions of overhead cranes are:

- Lifting: Overhead cranes are designed to lift heavy objects and materials, transporting them from one location to another within a facility or between different parts of a production process.

- Transporting: Overhead cranes can move loads horizontally along the runway system, ensuring materials are precisely positioned at the required destination.

- Positioning: These cranes are crucial for accurately placing heavy components during assembly processes, ensuring that each piece fits perfectly into its designated location.

- Safety: Overhead cranes are equipped with advanced safety features to protect both the crane operators and the materials being handled.

The Importance of Selecting the Right Type of Crane

Choosing the right type of overhead crane is paramount to the success of any project. The industrial landscape in Portugal is rich and varied, encompassing sectors as diverse as manufacturing and engineering, ports and shipping, construction, and more. The selection of the most suitable crane type depends on the unique requirements and challenges of each industry and application.

For instance, while a double-girder bridge crane may be the ideal choice for a manufacturing facility that deals with heavy machinery components, a jib crane might be more appropriate for localized lifting tasks within a workshop or loading dock. Selecting the wrong type of crane can lead to inefficiencies, increased safety risks, and operational disruptions. It's imperative to align the crane's characteristics with the specific needs of the industry or application.

Introducing the Concept of Customized Specifications

One of the key advantages of overhead cranes is their adaptability. These cranes can be customized to meet the unique needs of different industries and projects. Customization allows buyers to tailor crane specifications, including load capacity, span, lifting height, and additional features, to precisely match the requirements of their applications.

For example, an overhead crane used in the steel and metalworking industry may have a significantly higher lifting capacity and specialized equipment for handling molten metal, whereas a crane in a woodworking facility may be designed with features to handle large timber logs with precision.

Customization ensures that overhead cranes are not just tools but strategic assets, capable of optimizing the efficiency and safety of material handling processes in various industrial sectors. In Portugal's dynamic industrial landscape, the ability to customize crane specifications offers a competitive edge and a pathway to operational excellence. The journey to finding the perfect overhead crane begins with a deep understanding of their functions and the unique demands of your industry.

Types of Overhead Cranes

In the diverse industrial landscape of Portugal, where versatility is the key to success, selecting the right type of overhead crane is of paramount importance. Understanding the various types of overhead cranes, their features, and benefits is crucial to making an informed choice that aligns with the unique requirements of different industries and applications. In this chapter, we'll explore the rich tapestry of overhead cranes, shedding light on their characteristics and real-world applications.

Bridge Cranes (Single Girder and Double Girder Cranes)

Features and Benefits:

- Bridge cranes, characterized by one or two main bridge beams, are highly versatile and used in a wide range of applications.

- Single girder cranes have a single bridge beam, making them more cost-effective and suitable for lighter loads.

- Double girder cranes feature two bridge beams, providing enhanced load capacity and stability.

- Bridge cranes offer precision in material handling, making them ideal for industries requiring precise positioning of heavy components.

Commonly Used Applications:

- Manufacturing and Engineering: Heavy equipment handling, material transport, and assembly.

- Automotive: Vehicle assembly, component positioning, and material handling.

Gantry Cranes

Features and Benefits:

- Gantry cranes, similar to bridge cranes, are supported by legs or columns on the floor and can move along rails on the ground.

- Their mobility makes them suitable for outdoor or semi-outdoor applications, such as shipyards and construction sites.

- Gantry cranes offer high lifting capacities and flexibility in various industrial environments.

Commonly Used Applications:

- Ports and Shipping: Cargo handling, container loading and unloading.

- Construction: Lifting and positioning heavy construction materials.

Jib Cranes

Features and Benefits:

- Jib cranes have a vertical mast with a horizontal boom that can rotate, providing localized lifting and movement.

- They are ideal for workstations, workshops, and loading docks where precision is crucial.

- Jib cranes offer a compact and versatile solution for specific material handling needs.

Commonly Used Applications:

- Manufacturing and Engineering: Precision positioning of components in assembly lines.

- Warehousing and Logistics: Efficient handling of goods within confined spaces.

Underslung Cranes

Features and Benefits:

- Underslung cranes are installed beneath an existing bridge or runway, making them an effective solution when there's limited overhead space.

- They offer efficient lifting and transport capabilities without the need for extensive structural modifications.

- Underslung cranes are adaptable to various industries and space constraints.

Commonly Used Applications:

- Manufacturing and Engineering: Handling heavy machinery components in limited-space environments.

- Warehousing: Efficient material handling in confined spaces.

Wall-Mounted Cranes

Features and Benefits:

- Wall-mounted cranes are attached to a wall or vertical structure and are suitable for lifting and moving loads in a specific area.

- They offer versatility and can be customized to suit specific requirements.

- Wall-mounted cranes are ideal for applications with limited floor space.

Commonly Used Applications:

- Automotive: Handling vehicle components during assembly.

- Warehousing and Logistics: Precise material handling in confined spaces.

Specialized Overhead Cranes

Features and Benefits:

- Certain industries may require specialized cranes designed to meet unique challenges.

- Examples include foundry cranes for molten metal handling and explosion-proof cranes for hazardous environments.

- Specialized cranes are engineered for safety, reliability, and performance in demanding conditions.

Commonly Used Applications:

- Steel and Metalworking: Foundry cranes for handling molten metal.

- Chemical and Petrochemical: Explosion-proof cranes for hazardous material handling.

Each type of overhead crane has its own set of features and benefits that cater to specific industrial needs. Understanding these distinctions is essential for selecting the right crane that aligns with your project requirements. The versatility of overhead crane types ensures that there is a perfect solution for every application in Portugal's vibrant industrial landscape.

Tailoring Your Overhead Crane

In the ever-evolving industrial landscape of Portugal, the demand for overhead cranes that seamlessly integrate into specific applications has never been higher. One of the key advantages of overhead cranes is their remarkable flexibility and adaptability. The concept of customization in overhead crane design is an essential tool for ensuring that the crane aligns perfectly with the unique needs of different industries and projects. In this chapter, we'll delve into the world of tailored solutions, exploring the intricacies of customization and the factors to consider when crafting the perfect crane for your specific needs.

Exploring the Concept of Customization in Overhead Crane Design

Customization is the art of transforming an overhead crane from a mere tool into a strategic asset. It involves tailoring the crane's specifications to meet the unique requirements of a particular industry or project. The ability to customize overhead cranes is a valuable feature that allows businesses to optimize their material handling processes and maximize efficiency.

By customizing your overhead crane, you can:

- Enhance Performance: Adjust the crane's load capacity to precisely match the weight of the materials you need to lift, ensuring optimal performance and efficiency.

- Optimize Space Utilization: Tailor the span and lifting height of the crane to suit the layout and dimensions of your facility, making the most of available space.

- Adapt to Special Requirements: Customize the crane to accommodate special requirements, such as hazardous environments or unique material handling challenges.

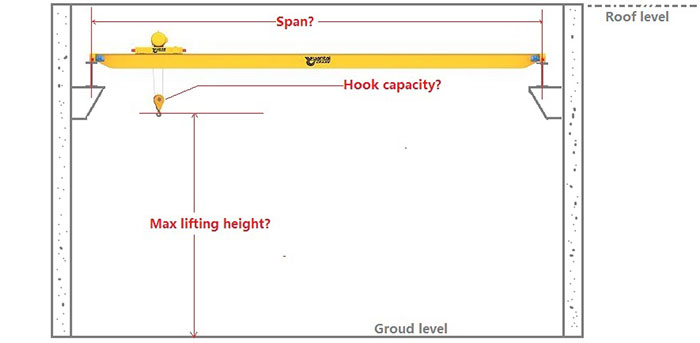

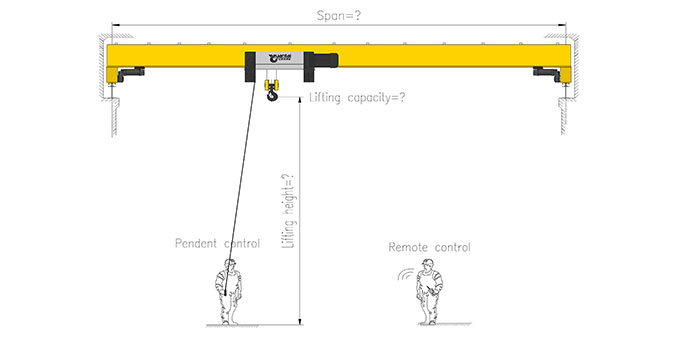

Factors to Consider When Customizing Your Overhead Crane

When considering the customization of an overhead crane, it's essential to take various factors into account to ensure it meets the specific needs of your industry or project. Some of the key factors to consider include:

- Load Capacity: Determine the maximum weight your crane needs to lift. Customizing the load capacity ensures that your crane can handle the heaviest materials without strain.

- Span: The span of the crane defines the distance between the runways. Customizing the span allows you to adapt the crane to the layout of your facility, optimizing space usage.

- Lifting Height: Customize the lifting height to match the vertical requirements of your application. Whether you're working in a confined space or handling materials at significant heights, tailored lifting height is essential.

- Special Requirements: Consider any special conditions or requirements in your industry. For instance, if you're operating in a hazardous environment, customization may include explosion-proof features or special materials for crane components.

- Automation: If your industry benefits from automation, consider customizing your crane to include automation features. Automated overhead cranes can significantly enhance productivity and precision.

- Material Handling Accessories: Customize your crane with specialized hooks, magnets, or other accessories that are tailored to the materials you handle.

Highlighting the Flexibility of Overhead Crane Design

The flexibility of overhead crane design ensures that you can have a crane that meets your specific industrial needs. The customization process is a collaborative effort between crane manufacturers, suppliers, and the end users, resulting in a crane that becomes an integral part of your operations. Portugal's industrial landscape is rich and varied, and the ability to customize overhead cranes to suit its diverse sectors and unique projects is a testament to the adaptability and innovation in the world of material handling. The journey to find the perfect overhead crane continues with the ability to tailor it to your specific requirements, making it an indispensable asset in your industrial toolkit.

Selecting the Right Overhead Crane for Your Industry

In the diverse and dynamic industrial landscape of Portugal, the importance of selecting the right type of overhead crane for a specific industry cannot be overstated. Each sector, from manufacturing and construction to ports and shipping, has its unique set of challenges and needs when it comes to material handling. In this chapter, we'll provide guidance on how to make informed decisions when choosing the perfect overhead crane for your industry. We'll offer insights into the common requirements and challenges of various sectors, and we'll showcase real-world case studies and success stories of customized overhead crane solutions in Portugal.

Guidance on Choosing the Right Overhead Crane for Your Industry

Selecting the ideal overhead crane for your industry begins with a clear understanding of your operational requirements, challenges, and goals. Here are some essential steps to guide you through the decision-making process:

- Industry Assessment: Start by conducting a comprehensive assessment of your industry's material handling needs. Consider factors such as the weight and dimensions of the materials you handle, the frequency of lifting, and the layout of your facility.

- Safety Considerations: Prioritize safety in your industry. Identify potential hazards and ensure that the selected crane type and specifications align with safety regulations and best practices.

- Load Capacity: Determine the maximum weight that your crane needs to lift. This factor will influence your choice of crane type and specifications, ensuring it can handle your materials without strain.

- Space Constraints: Evaluate the available space in your facility. Customizing the span and lifting height of your crane will allow you to make the most efficient use of your space.

- Application Specifics: Consider the specific applications where the crane will be used. Whether it's in manufacturing, construction, or another industry, the crane's functions must align with the tasks it will perform.

- Special Requirements: If your industry has unique demands, such as working in hazardous environments, consider customization options to meet these special requirements.

Insights into Common Needs and Challenges in Various Sectors

Understanding the common needs and challenges of different sectors in Portugal is crucial for selecting the right overhead crane. Here are insights into a selection of industries and their specific requirements:

Manufacturing and Engineering:

- Needs: Heavy equipment handling, assembly, and material transport.

- Challenges: Precision positioning of components, high load capacities, and safety during manufacturing processes.

- Real-world success: Customized double-girder bridge cranes for precise component positioning in an aerospace manufacturing facility.

Ports and Shipping:

- Needs: Efficient cargo handling, container loading and unloading.

- Challenges: High load capacities, precision, and continuous operation.

- Real-world success: Mobile gantry cranes for container handling at busy ports, optimizing cargo operations.

Construction:

- Needs: Lifting and positioning heavy construction materials.

- Challenges: Compact spaces, versatility, and efficient material transport.

- Real-world success: Jib cranes customized for confined construction sites, offering precise material handling.

Automotive:

- Needs: Vehicle assembly, component positioning, and material handling.

- Challenges: Efficient production, precision in assembly, and space optimization.

- Real-world success: Customized monorail cranes for efficient material transport in automotive assembly lines.

Steel and Metalworking:

- Needs: Handling molten metal, heavy steel components, and material positioning.

- Challenges: Extreme temperatures, high load capacities, and safety in handling molten materials.

- Real-world success: Specialized foundry cranes designed for the safe handling of molten metal in steel production.

Power and Energy:

- Needs: Lifting and positioning heavy machinery in power plants.

- Challenges: High load capacities, precision, and reliability for continuous operation.

- Real-world success: Double-girder bridge cranes customized for the efficient handling of heavy machinery in power generation facilities.

Warehousing and Logistics:

- Needs: Streamlined material handling within warehouses and distribution centers.

- Challenges: Space optimization, efficient storage, and quick material transport.

- Real-world success: Monorail cranes customized for the efficient movement of goods within a busy warehouse.

Chemical and Petrochemical:

- Needs: Handling chemicals and equipment in hazardous environments.

- Challenges: Safety in hazardous conditions, reliable operation, and material handling within restricted spaces.

- Real-world success: Explosion-proof overhead cranes designed to meet safety requirements in chemical plants.

Showcasing Real-World Case Studies in Portugal

To further illustrate the value of customized overhead crane solutions, let's look at some real-world case studies and success stories in Portugal:

- Automotive Manufacturing: A prominent automotive manufacturing facility in Lisbon sought to enhance its assembly line efficiency. By customizing monorail cranes, they achieved streamlined material transport, precise positioning of vehicle components, and a significant boost in production output.

- Port Operations: A bustling port in Setúbal faced challenges with container handling and storage. By investing in mobile gantry cranes customized to their specific needs, the port optimized cargo operations, reducing turnaround times and increasing overall efficiency.

- Steel Production: A steel and metalworking plant in Porto required a solution for safely handling molten metal. Specialized foundry cranes were designed to withstand extreme temperatures, ensuring the secure and efficient transport of molten metal within the facility.

These real-world case studies demonstrate how customized overhead crane solutions have been instrumental in addressing the unique challenges and needs of various industries in Portugal. By tailoring overhead cranes to specific requirements, businesses can achieve greater efficiency, safety, and success in their material handling operations.

The selection of the right overhead crane is a critical decision that can significantly impact the productivity and safety of your industry. By understanding the common needs and challenges of different sectors and learning from real-world success stories, you can make an informed choice that elevates your operations to new heights. In the vibrant and diverse industrial landscape of Portugal, the right overhead crane is the key to unlocking your industry's full potential.

Buying Overhead Cranes in Portugal

The process of purchasing overhead cranes in Portugal is a pivotal step in optimizing material handling operations across various industries. To make an informed and successful purchase, it's essential to navigate the procurement process with care. In this chapter, we will explore the key steps in buying overhead cranes in Portugal, discuss factors to consider during the purchasing journey, including budget, local regulations, and vendor selection, and provide a checklist to guide buyers towards a well-informed decision.

Exploring the Procurement Process for Overhead Cranes in Portugal

- Needs Assessment: Begin by conducting a comprehensive needs assessment to determine the specific requirements of your project or industry. Identify load capacity, lifting height, span, and any special features or accessories necessary for your overhead crane.

- Budgeting: Establish a clear budget for your overhead crane purchase. Consider not only the upfront costs but also ongoing maintenance expenses. Ensure your budget aligns with the quality and features you require.

- Regulatory Compliance: Familiarize yourself with local regulations and safety standards related to overhead cranes in Portugal. Compliance with safety and operational regulations is paramount.

- Vendor Selection: Research and select reputable overhead crane manufacturers or suppliers in Portugal. Look for companies with a proven track record, experience in your industry, and the capacity to provide customized solutions.

- Request for Proposals (RFPs): If your project is of significant scale, consider issuing a request for proposals to potential vendors. This document should outline your specific needs, budget constraints, and expectations for the crane.

- Customization: Work closely with your chosen vendor to customize the crane to your exact specifications. Ensure the crane is designed to meet the unique requirements of your industry.

- Installation and Training: Coordinate the installation of the crane with your vendor. Once installed, ensure that your personnel receive proper training on crane operation, safety procedures, and maintenance.

- 8. Maintenance and Support: Establish a maintenance schedule with your vendor to ensure the ongoing reliability and safety of your overhead crane. Quick access to support and spare parts is crucial.

Factors to Consider When Purchasing Overhead Cranes

When purchasing overhead cranes in Portugal, consider the following factors to make an informed decision:

- Budget: Determine your budget constraints and ensure that the chosen crane aligns with your financial capacity. Balance cost considerations with the quality and features required for your industry.

- Load Capacity: Select a crane with the appropriate load capacity to handle the materials in your industry efficiently. Overloading a crane can lead to operational issues and safety risks.

- Local Regulations: Comply with local safety and operational regulations. Ensure that the crane is designed and installed to meet Portuguese standards and requirements.

- Vendor Reputation: Choose a vendor with a strong reputation for quality, reliability, and after-sales support. Check references, reviews, and testimonials to gauge their track record.

- Customization: Work closely with the vendor to customize the crane to your industry's unique needs. Ensure it is tailored to meet your specific requirements.

- Maintenance Plans: Establish a maintenance plan with the vendor to ensure the crane's ongoing reliability. Quick access to support and spare parts is crucial to minimizing downtime.

- Training and Operator Certification: Ensure that your crane operators receive proper training on crane operation, safety procedures, and maintenance. Operator certification may be required.

- Warranty: Inquire about the warranty and service agreements offered by the vendor. A comprehensive warranty can provide peace of mind and cost savings in case of unexpected issues.

- Space and Layout: Consider the layout of your facility and available space when selecting the crane type, span, and lifting height. Optimize space utilization for efficient material handling.

- Special Features: If your industry has unique requirements, such as handling hazardous materials or operating in extreme conditions, make sure the crane is equipped with the necessary special features and safety measures.

Checklist for Buyers: Making an Informed Decision

To ensure that you make an informed decision when buying overhead cranes in Portugal, use this checklist:

- [ ] Define your project's specific needs, including load capacity, span, and lifting height.

- [ ] Establish a clear budget for your overhead crane purchase.

- [ ] Research and select reputable overhead crane manufacturers or suppliers in Portugal.

- [ ] Ensure compliance with local safety and operational regulations.

- [ ] Consider issuing a request for proposals (RFPs) for large-scale projects.

- [ ] Collaborate with your chosen vendor to customize the crane to your exact specifications.

- [ ] Coordinate the installation and training of your personnel.

- [ ] Establish a maintenance schedule with your vendor for ongoing support and reliability.

- [ ] Verify the vendor's reputation, including references and testimonials.

- [ ] Check the warranty and service agreements offered by the vendor.

- [ ] Optimize space utilization in your facility by selecting the right crane type and specifications.

- [ ] Ensure the crane includes special features or safety measures if your industry requires them.

By following this checklist and considering the key factors, you can confidently navigate the process of buying overhead cranes in Portugal. Whether you represent a thriving industrial sector or are an individual buyer seeking a customized solution, making an informed decision will ensure that your overhead crane aligns perfectly with your unique needs and elevates your operations to new heights of efficiency and safety.

Overhead Crane Manufacturers and Suppliers in Portugal

Selecting the right overhead crane for your industry or project in Portugal is not only about the crane itself but also the manufacturer or supplier you choose to partner with. This chapter focuses on listing and describing reputable overhead crane manufacturers and suppliers in Portugal. We'll also highlight the advantages of working with local suppliers, including proximity and after-sales support, and provide tips on how to research and choose the right supplier to meet your crane needs.

Reputable Overhead Crane Manufacturers and Suppliers in Portugal

- MoviCarga, Lda: MoviCarga is a prominent Portuguese manufacturer and supplier of lifting and handling equipment, including overhead cranes. They offer a range of standard and customized solutions to meet various industrial requirements. With a strong commitment to quality and safety, MoviCarga has earned a reputation for delivering reliable and efficient crane systems.

- PCE Portugal: PCE Portugal specializes in the design, manufacture, and installation of material handling equipment, including overhead cranes. They offer tailored solutions for a variety of industries, from manufacturing to logistics. PCE Portugal's extensive experience and commitment to customer satisfaction make them a reliable partner.

- GRUA-TEC - Engenharia e Equipamentos, Lda: GRUA-TEC is a well-established Portuguese company specializing in the design, manufacturing, and installation of various types of cranes, including overhead cranes. They focus on delivering high-quality, customized solutions to meet specific industry needs.

- Fergruas, Lda: Fergruas is a company with extensive experience in the sale, maintenance, and repair of lifting equipment, including overhead cranes. They provide a wide range of crane solutions and prioritize safety and efficiency in their offerings.

Advantages of Working with Local Suppliers

Working with local overhead crane manufacturers and suppliers in Portugal offers several advantages:

- Proximity: Local suppliers are easily accessible for consultations, inspections, and maintenance. Proximity can lead to quicker response times and reduced downtime in case of issues.

- Knowledge of Local Regulations: Local suppliers are well-versed in Portuguese safety regulations and standards, ensuring that the cranes they provide comply with local requirements.

- After-Sales Support: Local suppliers can offer more responsive after-sales support, including maintenance, repairs, and spare parts availability. This ensures the long-term reliability of your crane.

- Customization and Adaptability: Local suppliers can better understand the unique needs of Portuguese industries and tailor crane solutions accordingly.

Tips on Researching and Choosing the Right Supplier

When researching and choosing an overhead crane supplier in Portugal, consider the following tips:

- Reputation and Experience: Investigate the supplier's reputation and years of experience in the industry. Look for customer reviews and case studies to assess their track record.

- Customization Capabilities: Ensure the supplier can customize crane solutions to meet your specific needs.

- Compliance and Certification: Verify that the supplier's products adhere to safety standards and regulations. They should provide relevant certifications.

- Customer Support: Inquire about the supplier's after-sales support, including maintenance and repair services. Prompt and reliable support is essential.

- References: Ask for references from previous clients or projects to gain insights into the supplier's performance and reliability.

- Budget Considerations: Compare quotes and proposals from different suppliers to ensure that their pricing aligns with your budget.

By thoroughly researching and choosing the right overhead crane supplier in Portugal, you can build a strong and reliable partnership that contributes to the success of your material handling operations. Whether you're a part of Portugal's thriving industrial sectors or an individual buyer seeking customized solutions, working with a reputable local supplier is a strategic decision that can significantly impact your project's efficiency and safety.

Installation, Maintenance, and Safety

In the world of overhead cranes, proper installation, regular maintenance, and unwavering safety measures are the cornerstones of efficient and secure material handling operations. This chapter emphasizes the critical role of these aspects and provides guidance on finding experienced installation and maintenance services in Portugal. Additionally, we offer tips for ensuring safety compliance in different industrial sectors, underlining their significance for businesses and projects.

Importance of Proper Installation, Regular Maintenance, and Safety

- Proper Installation: The correct installation of an overhead crane is the foundation for its reliable and efficient operation. A well-installed crane ensures load stability, precision in movement, and safety for personnel and materials.

- Regular Maintenance: Routine maintenance is essential to prolong the lifespan of your crane and prevent unexpected breakdowns. Regular inspections, lubrication, and component checks are necessary to keep the crane in optimal condition.

- Safety Measures: Overhead cranes, due to their heavy lifting capabilities, can pose significant safety risks if not used and maintained properly. Ensuring safety measures are in place and adhered to is a non-negotiable aspect of crane operation.

Guidance on Finding Experienced Installation and Maintenance Services in Portugal

- Local Suppliers: Reach out to local overhead crane manufacturers and suppliers in Portugal, as they often provide installation and maintenance services. These suppliers are familiar with their equipment and can offer specialized support.

- Certified Technicians: Ensure that the technicians responsible for installation and maintenance are certified and have the necessary expertise in overhead crane systems. Look for certifications from recognized organizations.

- References and Case Studies: Ask for references and case studies from service providers to assess their track record in handling crane installations and maintenance.

- After-Sales Support: Choose service providers who offer comprehensive after-sales support, including 24/7 emergency services, spare parts availability, and rapid response to technical issues.

Tips for Ensuring Safety Compliance in Different Industrial Sectors

Manufacturing and Engineering:

- Conduct regular safety training for personnel involved in crane operation.

- Implement safety measures for material handling, including securing loads and maintaining clear safety zones.

Ports and Shipping:

- Follow international safety standards for cargo handling and container operations.

- Conduct regular equipment inspections and maintain safety protocols for personnel working near cranes.

Construction:

- Ensure that cranes used in construction meet safety standards and are regularly inspected.

- Implement safety guidelines for crane operators and workers on construction sites.

Automotive:

- Provide safety training to crane operators in automotive assembly facilities.

- Enforce safety measures for handling vehicle components and materials.

Warehousing and Logistics:

- Create safety protocols for material handling and storage in warehouses.

- Regularly inspect cranes used in logistics to prevent accidents and equipment failure.

Chemical and Petrochemical:

- Follow strict safety standards for crane operation in hazardous environments.

- Regularly inspect explosion-proof cranes and maintain safety features.

Power and Energy:

- Implement safety measures for crane operation in power generation facilities.

- Regularly inspect cranes used in power plants and ensure safety protocols are followed.

Safety compliance is paramount in all industrial sectors, and the implementation of safety measures is not only a regulatory requirement but also a moral responsibility. Proper installation and maintenance, coupled with rigorous adherence to safety measures, ensure the seamless and secure operation of overhead cranes in diverse industries. In Portugal's ever-evolving industrial landscape, these practices are not just guidelines but pillars of success.

Future Trends in Overhead Crane Technology

As industries in Portugal continue to evolve, so too does the technology that supports their material handling processes. In this chapter, we'll explore emerging technologies and trends in the overhead crane industry, including automation, the Internet of Things (IoT), and digital monitoring. We'll discuss how these innovations have the potential to impact various industries in Portugal and encourage readers to stay updated on advancements in crane technology.

Emerging Technologies and Trends in Overhead Crane Industry

- Automation: The integration of automation in overhead crane systems is a game-changer for industries in Portugal. Automated cranes can perform repetitive tasks with precision and efficiency, reducing the need for manual labor. These cranes can be programmed for various applications, including material handling in manufacturing and logistics.

- Internet of Things (IoT): IoT technology allows for real-time data collection and monitoring of crane performance. Sensors and connected devices on cranes can provide valuable insights into equipment health, safety, and efficiency. By analyzing this data, industries can make informed decisions about maintenance and optimization.

- Digital Monitoring: Digital monitoring systems provide operators and maintenance teams with instant access to vital crane information. This technology enables remote diagnostics, predictive maintenance, and the tracking of equipment usage. By monitoring the crane's condition and performance, industries can reduce downtime and extend the crane's lifespan.

Impact on Various Industries in Portugal

- Manufacturing and Engineering: Automation and digital monitoring will enhance efficiency and precision in manufacturing processes. Cranes with IoT capabilities can provide real-time data on equipment performance, leading to proactive maintenance and minimized downtime.

- Ports and Shipping: IoT technology can optimize cargo handling operations at ports by monitoring crane performance and scheduling maintenance during downtime. This can lead to increased throughput and reduced operational costs.

- Construction: Automation in cranes can improve the handling of construction materials on job sites, increasing productivity and safety. Real-time monitoring can help ensure the integrity and safety of construction equipment.

- Automotive: Automation in assembly processes will enhance vehicle manufacturing. IoT-enabled cranes can provide insights into production line efficiency, enabling continuous improvement.

- Warehousing and Logistics: Automation in warehouses can streamline material handling operations, particularly in e-commerce fulfillment centers. IoT technology can track goods and manage inventory more efficiently.

- Chemical and Petrochemical: Automation and digital monitoring can enhance safety in hazardous environments. Cranes equipped with advanced technology can perform tasks that may be dangerous for humans.

The future of overhead crane technology is bright, with innovations aimed at improving efficiency, safety, and overall performance. We encourage readers to stay updated on these advancements by regularly following industry news, attending seminars, and networking with professionals in the field. By embracing new technology and staying informed, industries in Portugal can continue to optimize their material handling operations and adapt to the ever-changing industrial landscape.

In the vibrant and diverse industrial landscape of Portugal, the importance of overhead cranes cannot be overstated. These remarkable pieces of machinery play a pivotal role in material handling across various sectors, from manufacturing and construction to shipping and logistics. As we conclude this guide to overhead cranes for sale in Portugal, let's recap some key takeaways and emphasize the significance of tailored solutions in the world of cranes.

In Portugal's ever-evolving industrial landscape, the right overhead crane is more than a piece of equipment; it's a strategic asset. We wish you success in your crane endeavors and the continued growth of your industry.