Before we immerse ourselves in the dynamic world of overhead cranes available in the Spanish market, let's start with the basics. This chapter will lay the foundation for your journey by unraveling the essence of overhead cranes, their core components, and the primary types you can find in Spain.

Jib Cranes

A jib crane is a type of crane that is designed to lift and move heavy loads in a small area, typically within a radius of a few meters. It consists of a vertical mast or post, which is supported by a base or foundation, and a horizontal boom or jib that extends out from the mast.

The main components of a jib crane include:

- 1. Mast: This is the vertical support structure that holds up the jib and supports the load being lifted. It can be made of steel or other materials, and is typically designed to withstand the weight and forces involved in lifting heavy loads.

- 2. Boom or jib: This is the horizontal arm that extends out from the mast and supports the hoist and load. It can be fixed or adjustable, depending on the needs of the application.

- 3. Hoist: This is the mechanism that actually lifts and lowers the load. It consists of a motorized drum that winds and unwinds a cable or chain, allowing the load to be moved up and down.

- 4. Trolley: This is the mechanism that moves the hoist along the length of the boom or jib, allowing it to position the load precisely where it needs to be.

- 5. Foundation or base: This is the structure that supports the mast and keeps the crane stable during operation. It can be bolted to the floor or attached to a mobile platform, depending on the needs of the application.

Wall-Mounted Jib Cranes:

These cranes are attached to walls and are commonly seen in workshops and manufacturing cells.

Wall mounted jib cranes are a type of jib crane that is mounted on a wall or column. They are used for lifting and moving loads in a smaller area.

Features of wall mounted jib cranes:

- Can be mounted on walls or columns, saving floor space

- Can rotate 180 degrees, providing greater coverage

- Can be customized with different hoist and trolley configurations to meet specific lifting needs

- Can be powered by electricity, air, or other sources

Benefits of wall mounted jib cranes:

- Save floor space, making them useful in facilities with limited space

- Can rotate 180 degrees, providing greater coverage than floor mounted jib cranes

- Can be more cost-effective than other types of cranes

- Easy to install and maintain

Applications for wall mounted jib cranes include manufacturing, warehouses, and assembly lines. They are especially useful for lifting and moving loads in a smaller area, such as loading and unloading materials from machines or transporting materials between workstations. They can also be used for outdoor lifting and moving operations.

Floor-Mounted Jib Cranes:

Anchored to the floor, they offer increased lifting capacity and range, making them versatile for various tasks.

Floor mounted jib cranes are a type of jib crane that is mounted on a floor or foundation. They are used for lifting and moving loads in a smaller area.

Features of floor mounted jib cranes:

- Can be easily moved around the floor as needed

- Can rotate 360 degrees, providing complete coverage

- Can be customized with different hoist and trolley configurations to meet specific lifting needs

- Can be powered by electricity, air, or other sources

Benefits of floor mounted jib cranes:

- Can be used in facilities with limited space

- Can rotate 360 degrees, providing complete coverage of the work area

- Can be more cost-effective than other types of cranes

- Easy to install and maintain

Applications for floor mounted jib cranes include manufacturing, warehouses, and assembly lines. They are especially useful for lifting and moving loads in a smaller area, such as loading and unloading materials from machines or transporting materials between workstations. They can also be used for outdoor lifting and moving operations.

These fundamental types of overhead cranes lay the groundwork for your exploration. Each type possesses unique characteristics and strengths, making them suitable for specific applications across diverse industries in Spain. As we delve deeper into this guide, we will provide comprehensive insights into each type, empowering you to make informed decisions tailored to your material handling needs in Spain's industrial landscape.

Assessing Your Material Handling Needs in Spain

Crafting the Perfect Crane Solution for Your Spanish Operations

Now that we've laid the groundwork on understanding overhead cranes, it's time to dive deeper. In this chapter, we'll guide you through the crucial process of assessing your material handling needs, tailored to the unique landscape of Spain. This step-by-step approach will ensure you choose the ideal crane solution for your specific requirements.

- Step 1: Defining Load Capacity -The first and foremost consideration when selecting an overhead crane is load capacity. In Spain, where industries span from heavy steel production to precision manufacturing, it's vital to have a clear understanding of the heaviest loads you intend to lift. Consider both the maximum weight and the typical weight of the materials or products you handle. This insight will guide you in choosing a crane with the appropriate lifting capacity.

- Step 2: Evaluating Span -The span, or the distance between the crane's runways, is another critical factor influenced by the layout and dimensions of your workspace. In the diverse Spanish industrial landscape, you may find facilities with expansive open areas as well as those with limited space. Understanding your span requirements will help you select a crane that fits seamlessly within your workspace while maximizing operational efficiency.

- Step 3: Duty Cycle Matters -Spain's industries operate with varying degrees of intensity, from continuous production lines to occasional heavy lifting tasks. Therefore, it's crucial to assess the duty cycle – the frequency and duration of crane use. This consideration ensures that your chosen crane is designed to withstand the demands of your specific industry in Spain, whether it's 24/7 operation or intermittent use.

- Step 4: Typical Load Types -Different Spanish industries handle a wide array of materials and products. Assessing the types of loads you commonly encounter is essential. Whether it's raw materials in steel mills, automotive components, or delicate manufacturing parts, knowing the characteristics of your loads – such as their shape, size, and fragility – will guide you in selecting the appropriate hoisting mechanisms and attachments for your crane.

- Step 5: Environmental Factors -Spain's diverse geography and climate can impact your overhead crane's performance and longevity. If your operations are situated in coastal regions, for example, you may need to consider corrosion-resistant materials. Conversely, if you're operating in extreme temperatures, such as found in mining operations, crane components should be selected to withstand these conditions.

By meticulously assessing these material handling needs specific to Spain, you'll be equipped with the knowledge necessary to choose the perfect overhead crane for your operations. Our guide will continue to lead you through the intricacies of overhead crane types, customization options, and the sourcing process, ensuring you're fully prepared to make informed decisions tailored to the Spanish industrial landscape.

Selecting the Ideal Crane for Spanish Industries

Navigating the Maze: Finding Your Perfect Overhead Crane Match in Spain

In the vast Spanish industrial landscape, finding the ideal overhead crane can be a complex task. But fret not, for in this chapter, we will guide you through the process of selecting the most appropriate crane type based on your industry or application within Spain. We'll highlight the sectors where each crane type frequently shines and provide you with real-world examples of successful crane installations in Spanish industries.

Single Girder Bridge Cranes

- Light to medium-duty lifting tasks.

- Industries: Manufacturing, warehousing, and maintenance.

- Success Story: A mid-sized auto parts manufacturer in Valencia, Spain, improved its efficiency by installing single girder bridge cranes in its assembly area. These cranes allowed for precise material handling, reducing production time and ensuring product quality.

Double Girder Bridge Cranes

- Heavy-duty applications requiring high lifting capacity.

- Industries: Steel manufacturing, automotive, and shipbuilding.

- Success Story: A steel mill in Asturias, Spain, increased its production output by implementing double girder bridge cranes. These cranes effortlessly handled heavy steel coils, reducing downtime and boosting productivity.

Gantry Cranes

- Outdoor projects and versatile material handling.

- Industries: Construction, shipyards, and lumber yards.

- Success Story: A construction company in Barcelona, Spain, utilized single leg gantry cranes for its large-scale projects. These cranes provided mobility and efficiency in handling construction materials, improving project timelines.

Jib Cranes

- Localized lifting and precise positioning.

- Industries: Workshops, manufacturing cells, and material transfer.

- Success Story: A machinery workshop in Madrid, Spain, installed wall-mounted jib cranes for efficient machine tool loading and assembly. These cranes maximized workspace utilization and reduced manual labor.

Monorail Cranes

- Linear material handling within defined routes.

- Industries: Manufacturing assembly lines and logistics.

- Success Story: An electronics manufacturer in Zaragoza, Spain, implemented monorail cranes for transporting components along its production line. These cranes improved workflow efficiency and product assembly precision.

Ladle Cranes

- Handling ladles of molten metal in extreme conditions.

- Industries: Steel and metallurgical.

- Success Story: A steel mill in Bilbao, Spain, relied on ladle cranes to safely transport molten metal from the furnace to the casting area. These cranes ensured operational safety and consistency.

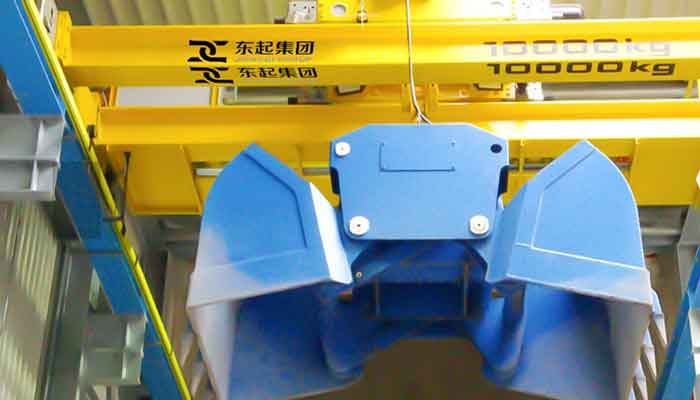

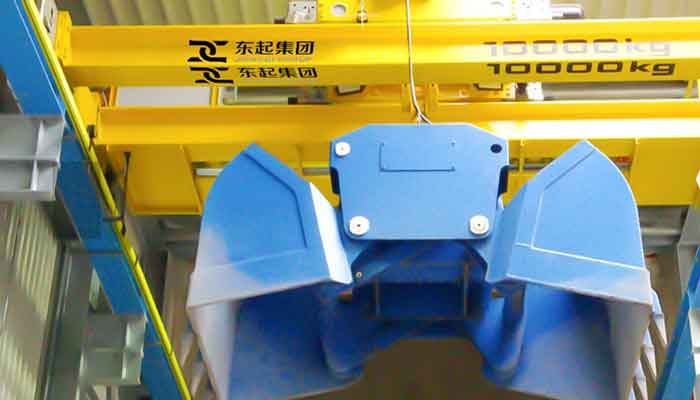

Grab Bucket Cranes

- Bulk material handling in ports and recycling facilities.

- Industries: Shipping and material recycling.

- Success Story: A port facility in Valencia, Spain, employed grab bucket cranes to efficiently load and unload loose materials from ships. These cranes reduced turnaround times and increased port capacity.

Magnetic Cranes

- Handling magnetic materials like steel sheets.

- Industries: Steel production and metalworking.

- Success Story: A metal fabrication plant in Seville, Spain, utilized magnetic cranes to precisely position and transport steel components. These cranes improved production accuracy and reduced material wastage.

Explosion-Proof Cranes

- Hazardous environments in chemical, oil and gas, and mining.

- Industries: Ensuring safety in explosive atmospheres.

- Success Story: An oil refinery in Tarragona, Spain, installed explosion-proof cranes for material handling in potentially hazardous areas. These cranes enhanced safety compliance and minimized operational risks.

Each crane type has its domain of excellence in the diverse Spanish industrial spectrum. By aligning your choice with your industry and application needs, you can harness the full potential of these overhead cranes. As we progress through this guide, we'll delve deeper into customization options, sourcing strategies, and best practices for successful crane implementation within your specific sector in Spain.

Customization for the Spanish Market

Tailoring Excellence: Customizing Overhead Cranes to Spanish Needs

In the diverse tapestry of Spanish industries, one size rarely fits all. That's where customization comes into play. In this chapter, we'll emphasize the significance of customization to meet the unique requirements of the Spanish market. We'll explore available options for tailoring overhead cranes, including load attachments, control systems, safety features, and environmental considerations. Plus, we'll underscore the importance of adhering to Spanish regulations and safety standards.

The Significance of Customization

While standard overhead cranes offer a solid foundation, customization allows you to fine-tune your crane solution to your exact needs. In the dynamic world of Spanish industries, this flexibility is invaluable.

Load Attachments and Lifting Devices

Customization Options:

- Choice of hooks, magnets, or specialized lifting devices.

- Adjustable spreader bars for different load shapes.

- Customized grabs and buckets for bulk material handling.

Spanish Relevance:

- Adapt your crane to the unique shapes and materials found in Spanish industries.

- Enhance safety and efficiency with specialized lifting tools.

- Optimize crane performance for your specific loads, whether it's automotive components or raw materials for steel production.

Control Systems

Customization Options:

- Selection of control methods: pendant, radio remote, or cabin controls.

- Integration of automation and programmable logic controllers (PLCs).

- Customized control interfaces and software.

Spanish Relevance:

- Tailor your crane's control system to match your operational preferences.

- Enhance safety and precision with advanced control options.

- Seamlessly integrate your crane into Spanish industrial automation processes.

Safety Features

Customization Options:

- Additional safety devices such as load limiters and anti-collision systems.

- Explosion-proof components for hazardous environments.

- Specialized safety training and operator certifications.

Spanish Relevance:

- Prioritize safety in accordance with Spanish regulations.

- Ensure compliance with industry-specific safety standards.

- Customize safety measures to mitigate the unique risks of your Spanish operations.

Environmental Considerations

Customization Options:

- Corrosion-resistant coatings for cranes exposed to coastal environments.

- Climate-controlled cabins for extreme temperature conditions.

- Energy-efficient components and regenerative braking systems.

Spanish Relevance:

- Protect your crane against the corrosive effects of coastal regions.

- Adapt to Spain's varied climate conditions, from scorching summers to chilly winters.

- Promote sustainability by reducing energy consumption in your operations.

Compliance with Spanish Regulations and Safety Standards

Customization doesn't mean compromising on safety and compliance. It means tailoring your crane to meet, and often exceed, Spanish regulations and safety standards. Whether it's CE marking for European conformity or specific industry regulations, your customized crane should align seamlessly with Spanish requirements.

By embracing customization, you empower your crane to excel in the unique challenges posed by the Spanish industrial landscape. It becomes a finely tuned instrument, enhancing efficiency, safety, and performance. As we progress in this guide, we'll dive deeper into sourcing strategies and best practices, ensuring your customized overhead crane is a perfect fit for your Spanish operations.

Sourcing Overhead Cranes in Spain

Finding Your Crane Partner: Navigating the Spanish Overhead Crane Market

Now that you've defined your material handling needs, explored various crane types, and considered customization options, it's time to embark on the journey of sourcing the perfect overhead crane for your Spanish operations. In this chapter, we'll provide you with invaluable insights into locating reputable overhead crane suppliers and manufacturers in Spain. We'll also share tips for assessing Spanish suppliers and obtaining competitive quotations to ensure a successful crane procurement process.

Locating Reputable Overhead Crane Suppliers and Manufacturers

- Industry Networks and Associations -- Tap into industry-specific networks and associations in Spain. These organizations often have directories of reputable suppliers and manufacturers.

- Online Directories -- Utilize online business directories and platforms to search for overhead crane suppliers based in Spain. Websites like Kompass and Europages can be valuable resources.

- Trade Shows and Exhibitions -- Attend trade shows and exhibitions related to your industry in Spain. These events provide opportunities to meet crane suppliers, view product demonstrations, and establish contacts.

- Referrals and Recommendations -- Seek recommendations from industry peers or colleagues who have experience with overhead cranes in Spain. Personal referrals can be a reliable source of information.

Assessing Spanish Suppliers

- Reputation and Experience -- Evaluate the supplier's reputation and track record in the Spanish market. Look for longevity and successful project references.

- Certifications and Compliance -- Ensure the supplier complies with Spanish and European regulations, including CE marking for crane equipment.

- Customization Expertise -- Assess the supplier's capabilities in customization. Do they have a history of tailoring crane solutions to meet specific Spanish requirements?

- Support and Service -- Inquire about the supplier's after-sales support and maintenance services. A reliable service network is essential for crane longevity.

Obtaining Competitive Quotations

- Detailed Specifications - Provide suppliers with comprehensive specifications based on your material handling needs and customization requirements. The more detailed your specifications, the more accurate the quotations will be.

- Request Multiple Quotes - Reach out to multiple reputable suppliers to obtain competitive quotations. This allows you to compare pricing, terms, and conditions.

- Consider Total Cost of Ownership - Look beyond the initial purchase price. Consider the total cost of ownership, including maintenance, energy efficiency, and longevity.

- Negotiation - Don't hesitate to negotiate with suppliers. There may be room for adjustments in pricing or terms.

- Warranty and Service Agreements - Review warranty and service agreements carefully. Ensure they align with your expectations for crane maintenance and support in Spain.

By effectively sourcing overhead cranes from reputable suppliers and carefully assessing your options, you can secure the right crane solution for your Spanish operations at a competitive price. In the following chapters, we'll delve into installation, maintenance, and safety considerations to ensure your crane functions optimally within the Spanish industrial landscape.

Installation, Maintenance, and Safety in Spain

Setting Up for Success: Overhead Crane Installation and Safety

As you embark on the journey of acquiring an overhead crane for your Spanish operations, it's crucial to pay close attention to the installation, maintenance, and safety aspects. In this chapter, we'll provide you with essential guidance on the installation process, routine maintenance considerations tailored to the Spanish climate, and an overview of safety practices and regulations specific to Spain.

Installation Process

Site Preparation

- Ensure your facility's infrastructure is capable of supporting the crane's load, including the overhead runway structure and runway beams.

- Verify the foundations or columns are engineered to withstand the crane's weight and the loads it will lift.

- Make necessary adjustments to the building structure, if required, to accommodate the crane's clearances and runway span.

Structural Considerations

- Collaborate closely with your crane supplier to ensure proper structural design.

- Consider the wind and seismic loads specific to your location in Spain and incorporate structural reinforcements as needed.

- Ensure the installation complies with Spanish building codes and regulations.

Maintenance and Inspections

Routine Maintenance

- Establish a regular maintenance schedule to keep your crane in optimal working condition.

- Address lubrication, electrical, and mechanical components to prevent wear and tear.

- Conduct inspections for signs of corrosion, especially in coastal regions, and address promptly.

Climate-Specific Maintenance

- In regions with extreme temperatures, take precautions to protect electrical components from overheating or freezing.

- Use appropriate lubricants that perform well in the specific climate conditions of your location in Spain.

Safety Inspections

- Implement a comprehensive safety inspection program for your crane.

- Regularly check load-bearing components, controls, and safety devices.

- Conduct load tests and functional tests to ensure proper crane operation.

Safety Practices and Regulations

Compliance with CE Marking

- Ensure your crane equipment bears the CE marking, signifying compliance with European safety standards.

- Verify that all components, from electrical systems to safety devices, adhere to applicable regulations.

Operator Training

- Provide thorough training for crane operators, emphasizing safe operation, load handling, and emergency procedures.

- Ensure operators are certified and competent to operate the specific crane type in your Spanish facility.

Safety Devices

- Regularly inspect and maintain safety devices such as limit switches, overload protection, and emergency stop systems.

- Replace any malfunctioning safety components promptly to prevent accidents.

Environmental Considerations

- Adapt safety practices to environmental factors, such as ensuring adequate ventilation in areas with potential gas or fume emissions.

- Comply with any additional environmental regulations specific to your industry in Spain.

By meticulously following the installation process, implementing routine maintenance practices tailored to the Spanish climate, and adhering to safety regulations, you can ensure the longevity and safe operation of your overhead crane in the dynamic and diverse industrial landscape of Spain. In the final chapter of this guide, we'll explore the benefits and potential ROI of your overhead crane investment in the Spanish market.

Spanish Success Stories and Case Studies

Realizing Potential: Overhead Crane Triumphs in Spanish Industries

In this final chapter of our guide, we'll dive into real-world case studies that showcase the successful implementation of overhead cranes in Spanish industries. These stories illustrate the transformative impact of selecting the right crane for specific applications, providing tangible evidence of the benefits and potential return on investment (ROI) that overhead cranes can deliver in the diverse Spanish industrial landscape.

Case Study 1: Automotive Assembly Efficiency

Industry: Automotive Manufacturing

Location: Barcelona, Spain

- Challenge: A leading automotive manufacturer in Spain sought to optimize its assembly line efficiency. The challenge was to reduce production time and enhance worker safety while maintaining stringent quality standards.

- Solution: The implementation of double girder bridge cranes with precision control systems allowed for seamless material handling. Customized lifting devices and automation integration improved workflow efficiency.

- Results: The automotive manufacturer achieved a 20% reduction in production time, translating to significant cost savings. The precise control systems reduced errors and improved safety. The investment in overhead cranes demonstrated a quick ROI through increased productivity.

Case Study 2: Shipyard Productivity Boost

Industry: Shipbuilding

Location: Cadiz, Spain

- Challenge: A shipyard in Cadiz faced challenges in handling massive ship components efficiently. The need was to enhance productivity and reduce manual labor in moving and positioning these components.

- Solution: Double leg gantry cranes with specialized lifting equipment were installed to handle the large ship sections. The cranes provided the required stability and lifting capacity for the task.

- Results: The shipyard witnessed a 30% increase in productivity, allowing for faster ship construction and delivery. The reduced manual handling also led to improved worker safety and reduced downtime due to injuries.

Case Study 3: Steel Mill Transformation

Industry: Steel Manufacturing

Location: Asturias, Spain

- Challenge: A steel mill in Asturias needed to handle heavy steel coils efficiently and minimize downtime during material handling processes.

- Solution: Double girder bridge cranes with ladle attachments were deployed to move the heavy steel coils safely and precisely. These cranes also featured advanced control systems for accurate positioning.

- Results: The steel mill reported a 25% reduction in downtime, leading to increased production capacity. The ladle cranes significantly improved safety by minimizing manual handling of heavy materials.

Case Study 4: Port Logistics Enhancement

Industry: Shipping and Ports

Location: Valencia, Spain

- Challenge: A busy port facility in Valencia aimed to optimize its cargo handling operations. The goal was to reduce turnaround times for loading and unloading ships.

- Solution: Grab bucket cranes were installed to efficiently handle bulk materials such as coal and ore. These cranes featured automation integration for precise material positioning.

- Results: The port facility achieved a 40% reduction in turnaround times for ships, enhancing its capacity and attracting more cargo traffic. The investment in grab bucket cranes contributed significantly to the port's economic growth.