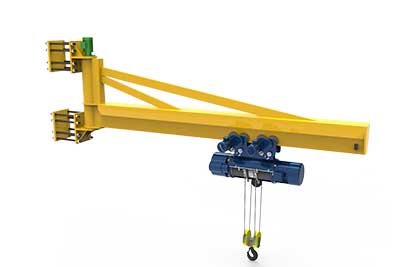

Types of cranes for sale Uzbekistan good price. Customized gantry cranes, overhead cranes, & light jib cranes and hoists for sale good price. Check crane for sale Uzbekistan now.

Types of cranes for sale Uzbekistan good price. Customized gantry cranes, overhead cranes, & light jib cranes and hoists for sale good price. For Uzbekistan's various industries, the industrial gantry cranes and overhead cranes either heavy duty or light duty can be provided to improve material handling efficiency in places and applications such as the building construction, components & parts manufacturing factory , precast concrete factory, drainage pipes plants,steel mills,, as well as mining, textile, and other industries and workshops, etc.

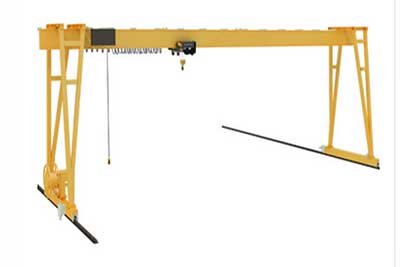

Gantry crane for sale Uzebistan

A gantry crane system is a type of overhead material handling crane in which two support legs are attached beneath the main beam or main girder and directly extend onto the ground, travelling or moving on the ground rails. Gantry cranes are available in a variety of styles and designs to meet various lifting needs. There are Full gantry cranes, semi gantry cranes / single leg gantry cranes , and cantilever gantry cranes depending on the gantry frame structure.

Truss girder gantry crane for sale Uzbekistan

They can be classified as single girder gantry cranes or double girder gantry cranes depending on the primary beam structure. And also based on your lifting requirement and application conditions, the gantry steel structure can be option between a truss structure and a box-shaped construction.

There are general purpose gantry cranes, container gantry cranes, shipyard gantry cranes, and hydro-power station gantry cranes, depending on the use.

Structure of Gantry Cranes

The metal framework, lifting mechanism, running mechanism, and safety protection system are the four essential components of gantry cranes.

Single Girder Gantry Crane Structure, box girder design for your refernece

Main Beam of single girder gantry crane

support legs of rail travelling gantry cranes

travelling ground beam

- Metal structure of gantry crane - The main beam, end beam, support legs, and lower beams make up the metal framework. It comes in two varieties: truss structures and box-shaped structures. The main beam can form a cantilever and extend past the legs to one or both sides to increase the crane's working range.

- Lifting system of gantry crane - Electric hoists or are the lifting mechanism for light duty gantry crane and open winch trolley are used for heavy duty material handling. To handle different materials, the picking tool can be a hook, a grab bucket, or an electromagnetic chuck.

- Travelling mechaism of rail travelling gantry crane - Trolley and crane running mechanisms are examples of running mechanisms. The hoist trolley's integrated three-in-one motor typically powers the trolley's operating mechanism. Typically, a three-in-one motor or a two-in-one motor with an independent brake is used to power the crane's operating mechanism.

- Safety devices - The lifting limitation, overload limiter, stroke limiter, bumper, and wind-resistant anti-skid device are some of the components of the safety protection system.

- Gantry cranes are perfect for both indoor and outdoor applications thanks to their high site utilization, extensive working range, broad adaptability, and powerful versatility. Contact us right away for more details about our gantry cranes!

Types of Gantry Cranes for sale Uzbekistan

Gantry cranes are very versatile material handling cranes for indoor and outdoor use. Gantry cranes come in a variety of designs and can be categorized into many groups based on various standards.

Gantry crane types based on gantry frame designs

The gantry frame can be classified as full gantry cranes, semi-gantry cranes, cantilever gantry cranes, etc. depending on its various forms. The portion of the main beam that extends outside the legs and is not more than one third of the inner side of the main beam is referred to as the cantilever.

Gantry crane types based on main beams

The gantry cranes can be separated into single beam gantry cranes and double beam gantry cranes depending on the shape of the main beam.

- Single girder gantry crane - The single girder crane has a simpler structure and costs less than a twin main beam gantry crane. When the load capacity is less than 20t, this crane is typically employed.

- Double girder gantry crane - The two beam gantry crane is advised for heavier-duty applications due to its robust bearing capacity, wide span, good overall stability, and variety.

Gantry crane classifications in terms of crane uses or purpose

Gantry crane can be classified as a general gantry crane, a shipbuilding gantry crane, a container gantry crane, a gantry crane for a hydropower station, etc. depending on its intended function.

- General use gantry crane - The most adaptable type is the general use gantry crane. With a lifting capacity of up to several hundred tons, it can manage a variety of materials or weights. The gantry cranes can be fitted with a variety of picking tools, including as hooks, electromagnetic chucks, and others.

- Shipbuilding gantry crane - The hull is assembled using a shipbuilding gantry crane, which frequently has two lifting trolleys: one with two major hooks that runs on the rail of the upper flange of the bridge, and the other with a main hook and a sub hook that flips and hoists big hulls.

- Container gantry cranes -In order to speed up the turnaround of container carriers or other cranes, container gantry cranes are used to stack containers, load them, and carry them away from container ports. There are two types of container cranes: rail-mounted and rubber-tired.

- Hydropower station gantry crane - The primary functions of a gantry crane at a hydroelectric plant include lifting, opening and closing gates, as well as installation operations.

Overhead Crane Systems & Overhead Crane Solutions

We offer overhead cranes and material handling systems that are effective, safe, and affordable for rapid and simple lifting and moving in industrial operations. Heavy loads can be lifted and moved by overhead cranes without being hindered by obstructions on the ground, minimizing product damage and worker injuries. To satisfy various facility circumstances and lifting requirements, the overhead bridge cranes are available in four basic configurations: single girder, double girder, top running, and underhung system.

Hoist, winch & trolley overhead crane for sale Uzbekistan Crane Lifting system : Electric hoist 0.25 - 80 ton, winch trolley hoist up to 550 ton

It is crucial to comprehend your lifting requirements when choosing an overhead crane and to pick one that will offer an effective and affordable solution for your particular application. Depending on your particular use, overhead cranes come in a variety of sizes, capacities, and levels of complexity. Depending on the kind of cargo, load or material being hoisted, they can employ conventional rigging or special below-the-hook attachments. A trolley or more are transported across the crane bridge.

With a lifting capacity ranging from one ton to several hundred tons, the electric hoist that latches onto the cargo uses single-, double-, and variable-speed electric motors. Depending on the user's taste, the working conditions for the crane, the load capacity, the particular application, etc., the crane control mechanism may be a handheld push button pendant, wireless remote control, or cabin control.

Overhead Crane Structure and Main Parts

The typical components of an overhead crane include a bridge, a lifting mechanism, a crane and trolley traveling mechanism, a control room, a trolley conductive device, a main power conductive device, etc.

Main Beam of double girder overhead crane

End Beam or end carriage of double girder bridge crane

Open winch trolley for heavy duty overhead crane

Cabin control

- Bridge - The bridge, which is made up of the main beam, the end beam, and the platform, is the overhead crane's fundamental part. The primary beam often has a box-like form. A pedestrian platform with safety railings is constructed outside the two main beams, which are joined at both ends by end beams. A device that delivers power to the trolley's electric components, the auxiliary sliding wire, is installed on the platform opposite the side of the cab where the crane operating mechanism is located. The overhead crane is moved along the guide rail throughout the workshop by the crane running mechanism.

- Lifting mechanism - The components of a lifting mechanism include a motor, reducer, drum, brake, etc. Through the connection and braking wheel, the motor is connected to the reduction, and the reducer's output shaft is attached to the drum wrapped in steel wire rope. A hook is attached to the wire rope's opposite end. The hook rises or falls when the drum rotates due to the drum's wire rope being wound or unwound. There are two sets of lifting mechanisms for overhead cranes with a lifting capacity of 15 tons or more, known as the main hook and the auxiliary hook.

- Overhead bridge crane travelling mechanism -The components of the crane's moving mechanism include the motor, transmission shaft, reducer, wheel, and brake. Driving can be done in either centralized or separate modes.

- Crane trolley travelling mechanism- A trolley that can go the length of the workplace is mounted on the bridge rail. It has a trolley frame, a trolley running mechanism, and a lifting mechanism on it and is primarily built of welded steel plates.

- There are two transmission configurations for the trolley's drivetrain: one places the reduction gearbox between the two driving wheels, while the other places it on one side of the trolley. With the former, the torque applied to the transmission shaft is more evenly distributed; with the latter, installation and maintenance are easier.

- Control room or cabin of bridge cranes -In the control room, there are crane protection devices, lifting mechanism control devices, and running mechanism control devices for cranes and trolleys.

- Most of the time, the cab is fastened to one end of the main beam, while some are mounted below the trolley so they can move with it. When maintaining crane and trolley mechanisms and electrical equipment, a hatch above the cab is opened to allow maintenance employees to enter and exit.

Operation of Overhead Crane

In general, an overhead crane is made up of a bridge frame with a traveling crane mechanism, a hoist trolley with a lifting mechanism and a travelling trolley mechanism, an electrical device, a driver's cabin, etc. The bridge is supported at both ends by parallel runways. The hoist trolley and the load can move longitudinally thanks to the crane's traveling mechanism. The cargoes are raised and lowered using the lifting mechanism, and moved laterally using the crane trolley.

Typically, electric overhead travelling cranes are controlled electrically from a driver's cabin that is connected to the crane, a wireless remote control, or a control pendant. The user's preference, the particular program, the surroundings, etc. all have a role in the operating method choice. The operator must be able to handle any emergencies that arise on-site, and the coordinator and operator must work together skillfully to complete the job.

Gantry Crane & Overhead Crane Working Environment And Conditions

The crane's power source is three-phase AC with a frequency of 50Hz and 60Hz and a voltage of 1000V. (can also be 3kV, 6kV, or 10kV according to your needs). The power supply system's voltage fluctuation at the crane feeder's entrance shouldn't be more than 10% of the rated voltage.

The crane's track installation must adhere to GB/T tolerance standards.

The crane is mounted and used at a height of no more than 1000 meters (if it exceeds 1000m, the capacity of the motor should be checked according to the provisions of GB 755, and when it exceeds 2000m, the capacity of the electrical components should be checked.)

When the crane is operating indoors, the temperature must not be higher than +40 °C and must not rise over +35 °C on average over the course of a 24-hour period.

There is no ambient temperature below -5 °C.

At +40 °C, the relative humidity does not rise above 50%.

When the crane is operating outside, the temperature must not be higher than +40 °C and must not rise above +35 °C on average over the course of a 24-hour period.

The surrounding temperature is at least -20 °C.

Relative humidity is permitted to momentarily reach 100% when the outside temperature is less than or equal to +25 °C.

The working wind pressure shouldn't be more than: 150 Pa in the interior and 250 Pa along the coast. In a non-working state, the maximum wind pressure is typically 800Pa.

Contact us at any moment for additional details on the overhead crane equipment.

Overhead cranes and gatnry crane for different industrial sectors

Yuantai gantry crane and overhead cranes are widely used in various industrial sectors in Uzbekistan from light industries to heavy industries. For different industrial use and applications, our industrial gantry cranes and industrial overhead cranes will be customized to meet your particular needs.

Heavy Industry

The most successful heavy industries in Uzbekistan have been coal mining, ferrous metallurgy, chemical, and electrical power production, as well as natural gas and oil extraction, oil refining, mining and mineral processing, machine building, particularly textile and cotton farming equipment, and mining and processing of minerals. Fertilizer production is the primary emphasis of the chemical manufacturing sector.

Steel industries

Tundish cranes, slab cranes, scrap cranes, ladle cranes, billet cranes, coil and plate handling cranes, etc. are examples of industrial cranes used in the steel industry.

Technology gives the sector a benefit when it comes to steel mill industrial crane. Because of this, Yuantai industrial cranes for the steel industry combine our intelligent lifting solutions with cutting-edge technologies to solve your routine maintenance problems. Additionally, our adaptable service plans raise your productivity as a whole.

Custom steel mill cranes for metal & steel industries

For the steel industry, Yuantai Crane offers specially developed industrial crane for the steel industry, which includes the following steel industrial crane types in addition to standard utilized overhead crane, gantry crane, and jib crane:

- Tundish crane,

- Slab crane,Scrap crane,

- Ladle crane,

- Billet and ingot handling industrial crane,

- Coil handling industrial crane,

- 5 -74 ton Charging crane ,

- 20 -600 ton foundry crane

- ,Carrier beam crane,etc.

Lifting devices and tools for steel industrial cranes

For different types of steel materials or steel loads handling,Yuantai Crane as a professional industrial steel mill crane manufacturer offers the following crane attachment or below hook devices for different steel loads handling , such as, steel scraps, hot ladle, billets, plates, pipe, coils, and beams, etc.

Lifting devices for different steel loads handling

- Types of devices for general material handling :Crane hook,

- Steel coil and steel roll handling devices and tools:Crane c hook ,Roll lifter,Lifting tongs

- Ladle handling devices and tools:Ladle hook

- For steel sheet, plate, slab, coil, roll , pipe handling:Sheet lifter & plate lifter,Crane electromagnet,Round electromagnet,Carrier beam,Permanent lifting magne

- For steel scraps handling :Grab bucket

Cement, glass, bricks, concrete handling

Industrial crane for cement, glass, bricks, concrete handling.Yuantai industrial cranes offers cost-effective material handling for Cement works/production of lime and gypsum, Precast concrete parts, Glass industry, etc.

Industrial gantry cranes and overhead cranes are also widely used for handling cement, glass, bricks, and concrete, etc. Yuantai industrial cranes provides economical material handling for the glass sector, precast concrete components, cement works/production of lime and gypsum, etc.

Industrial cranes for Cement, glass, bricks, concrete handling

- Overhead crane for indoor material handling

- Gantry crane for outdoor and heavy duty concrete beam, pipe, and section handlinge,wich can be grouped into truss girder gantry crane and box girder gantry crane, etc.

- Jib hoist and cranes for light glass handling with vaccum lifter, etc.

More information on

industrial cranes for construction industries.

Automotive industry

Automotive industry hoist and industrial crane. The hoist and industrial cranes are utilized for car handling in the automotive sectors. For handling cars, the Yuantai hoist and industrial crane are frequently employed.

Industrial cranes for Automotive industry

- Overhead crane

- Gantry crane

- Jib crane

- Electric chain hoist and wire rope hoist

- For automotive parts and component assembly, stamping mold handling, and machinery maintenance, etc.

Mining industry

Mining industrial cranes protect your safety and live your loads. Industrial cranes used in mining are designed to handle materials efficiently in an aggressive environment while maintaining worker safety and preventing accidents. Industrial cranes from Yuantai Mining and Industrial lift and protect you!

Industrial cranes for mining industry

For material handling in the industry, the most commonly used industrial hoists include wire rope hoists and industrial chain hoists, as well as the basic industrial overhead crane, gantry crane, and jib cranes.

Types of specially engineered industrial cranes include grab cranes, explosion-proof single girder cranes, explosion-proof double girder cranes, and explosion-proof hoists.

Light and textile industry

The development and expansion of the Uzbekistan's industrial complex has been significantly aided by the light and textile industries. The provided sector accounts for more than a third of all industrial firms in Uzbekistan and provides the majority of the nation's financial resources, employment opportunities, foreign trade surplus, and foreign exchange earnings. Given the unique characteristics of the nation and its extensive farming economy, a varied light industry was established that produced cotton fiber, cotton and silk fabrics, raw silk, ambary fiber, hosiery, upper and linen knitted apparel, ready-made clothing, footwear, and other items. The production of carpets, haberdashery, and china-faience goods is seen to fall under the category of the nation's light industry.

Food industry

The food business mostly relies on processing locally grown agricultural raw materials. One of the crucial subsectors of the specified industry is the production of oil from cottonseeds. The implementation of nationwide flour grinding, dairy and meat production, non-alcoholic beverage production, bakery production, and confectionery production. There are numerous businesses that specialize in producing cans, oils, macaroni, tobacco, wine, liqueur, and cognac, as well as fresh and dry fruits, vegetables, melons, watermelons, and other high-demand goods.

Buying The Right Type of Crane for Your Business

Are you looking to buy a new overhead crane or gantry crane? The experts at Yuantai Crane are available to assist you in choosing the ideal material handling crane for your application. You can email us your request or use the contact form to let us know what you need, including:

- Rating for load capacity.

- Length of the crane

- Lifting height; the object or load that needs to be raised.

- Working conditions for cranes.

- How far does the crane travel in a day?

- Or any other lifting requirement?

Customized Gantry Crane Projects & Overhead Crane Cases

With more thant 34 years experiences, we have been provided types of cranes for clients from Uzbekistan and many other countries and regions around world. Based on your particular applications and uses, the most suitable overhead crane solution will be provided. In the following, some of the featured crane projects and cases will be presented for your reference. If you have any need or do not find the crane and hoist your need, please feel free to contact us by leaving a message below.

Truss girder gantry crane for sale Uzbekistan

Truss girder gantry crane for sale Uzbekistan

Single Girder Gantry Crane Structure, box girder design for your refernece

Single Girder Gantry Crane Structure, box girder design for your refernece Main Beam of single girder gantry crane

Main Beam of single girder gantry crane support legs of rail travelling gantry cranes

support legs of rail travelling gantry cranes travelling ground beam

travelling ground beam

Hoist, winch & trolley overhead crane for sale Uzbekistan Crane Lifting system : Electric hoist 0.25 - 80 ton, winch trolley hoist up to 550 ton

Hoist, winch & trolley overhead crane for sale Uzbekistan Crane Lifting system : Electric hoist 0.25 - 80 ton, winch trolley hoist up to 550 ton Main Beam of double girder overhead crane

Main Beam of double girder overhead crane End Beam or end carriage of double girder bridge crane

End Beam or end carriage of double girder bridge crane Open winch trolley for heavy duty overhead crane

Open winch trolley for heavy duty overhead crane Cabin control

Cabin control