Overhead Crane Tonnages and Capacity in the Russian Market

Overhead Crane Tonnages and Capacity in the Russian Market

Overhead cranes serve as the workhorses of industries across Russia, bearing the weight of production, manufacturing, and material handling processes. These vital pieces of equipment come in a wide range of tonnages and lifting capacities, each tailored to meet the unique demands of diverse industrial sectors. In this exploration, we delve into the crucial aspect of tonnages and lifting capacities in the Russian overhead crane market, shedding light on the significance of these considerations when procuring cranes. We will also elucidate how these requirements can vary significantly across different industrial applications, underlining the importance of making informed choices that align with the specific needs of each sector.

Common Tonnages and Capacities

When it comes to overhead cranes in the Russian market, the diversity of tonnages and lifting capacities available is nothing short of impressive. These cranes, designed to shoulder the weight of industrial processes, come in a range of options, each finely tuned to meet the specific needs of various sectors. In this section, we delve into the world of common tonnages and capacities, shedding light on the prevailing choices and the underlying reasons that make them the go-to options for many industries.

Examination of the Most Prevalent Tonnages

In the Russian market, overhead cranes with tonnages ranging from 1 ton to 20 tons reign supreme. These capacities have carved out a niche for themselves as the workhorses of the industry. Here's a closer look at the most prevalent tonnages:

5 ton overhead crane for sale Russia

- 1 to 5 Tons: Overhead cranes in this category are the agile performers of the lot. They excel in tasks that require finesse and precision. Small-scale manufacturing units and workshops often rely on these cranes for tasks such as component assembly, tool handling, and light material transport.

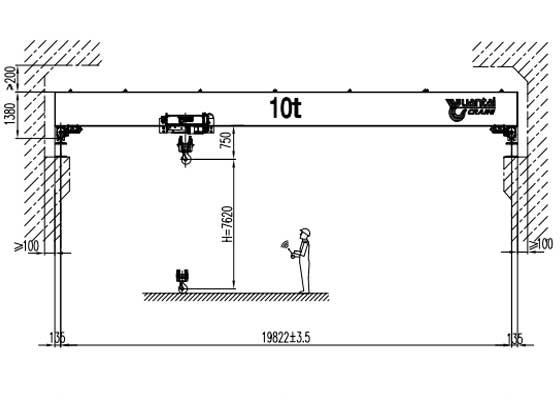

- 10 Tons: The 10-ton capacity is a popular choice for medium-duty lifting operations. Industries, such as automotive manufacturing, where there's a need to handle heavy components like engines or vehicle chassis, frequently employ cranes in this range.

- 20 Tons: Stepping into the realm of heavier lifting, cranes with a 20-ton capacity are a common sight in industries like metallurgy and steel production. These cranes are well-equipped to manage substantial loads, making them essential for the efficient handling of raw materials and steel products.

As for higher crane capapcity or tonnage, please check crane tonnage and specification pages or contact us by leaving a message down below.

Analysis of the Reasons Behind Their Popularity

The popularity of overhead cranes with tonnages between 1 ton and 20 tons can be attributed to several compelling reasons:

- Versatility: These tonnages offer an optimal balance between strength and agility. They are versatile enough to handle a wide range of materials and components, making them adaptable to diverse industrial needs.

- Precision Handling: In many industries, precision is key. Cranes in this tonnage range are well-suited for tasks that demand accuracy, such as positioning delicate components in aerospace manufacturing.

- Cost-Effectiveness: These cranes are often a cost-effective choice for small and medium-sized enterprises. They strike a balance between performance and affordability.

- Compact Design: The design of cranes in this tonnage range is often compact, allowing them to navigate and operate efficiently in limited spaces, which is common in many Russian industrial facilities.

- Ease of Maintenance: Maintaining cranes with these tonnages is generally more straightforward compared to larger, more complex models. This can lead to cost savings in the long run.

- Reliability: Overhead cranes with these tonnages have proven their reliability in a variety of industrial applications, earning the trust of many Russian businesses.

- Safety: These cranes can be engineered with safety features that meet stringent industry standards, ensuring the well-being of workers and the integrity of materials.

In summary, the common tonnages and capacities in the Russian overhead crane market, ranging from 1 ton to 20 tons, have solidified their positions due to their versatility, cost-effectiveness, precision, and reliability. These cranes serve as the backbone of various industries, offering the strength and adaptability required to support a wide array of material handling operations.

Variations Across Industrial Sectors

The Russian industrial landscape is a tapestry of diverse sectors, each with its own unique demands and intricacies. When it comes to overhead crane tonnages, one size certainly does not fit all. The requirements for these lifting champions can vary significantly from one sector to another. In this section, we embark on a journey to explore how tonnage requirements differ across different industrial sectors in Russia. By examining sectors such as energy, manufacturing, and construction, we will unveil the diverse needs that drive the selection of crane capacities.

Energy Sector: Powering Up with Heavy Lifts

In the energy sector, particularly in power generation and transmission, the demand for overhead cranes with substantial tonnages is unmistakable. This sector relies on massive machinery, equipment, and components that require cranes with extraordinary lifting capacities. Here are specific examples:

- Nuclear Power Plants: The construction and maintenance of nuclear power plants call for cranes with capacities exceeding 100 tons. These behemoths are tasked with the precise handling of heavy reactor components, shield walls, and fuel assemblies, emphasizing the utmost precision and safety.

- Hydroelectric Facilities: Cranes used in the assembly and maintenance of hydroelectric turbines are often rated at 50 tons or more. They play a pivotal role in positioning massive turbines and generators with unwavering accuracy.

- Oil and Gas Industry: In offshore oil and gas installations, cranes with high tonnages are essential for handling drilling equipment, pipeline components, and subsea infrastructure. Tonnages in the 20 to 50-ton range are commonly employed in this sector.

Manufacturing Sector: Precision Meets Power

Manufacturing, a diverse sector in its own right, relies on overhead cranes for an array of material handling tasks. The choice of tonnages here depends on the precision and scale required:

- Automotive Manufacturing: In the assembly of vehicles, cranes with tonnages around 10 tons are frequently utilized. These cranes assist in the positioning of heavy vehicle components, such as engines and chassis frames, with exacting precision.

- Aerospace Industry: Precision is the name of the game in aerospace manufacturing. Cranes with lower tonnages, typically in the 5 to 10-ton range, are employed for transporting delicate and intricate aircraft components.

- Steel Mills and Metallurgy: In the steel and metallurgy sector, where heavy materials are commonplace, overhead cranes with tonnages ranging from 20 to 50 tons are instrumental. They handle the heavy lifting of raw materials and finished steel products with efficiency and power.

Construction Sector: Building Foundations with Versatile Cranes

Construction, marked by its dynamic and often confined workspaces, demands overhead cranes that are both robust and nimble. Here, versatility is the key:

- Construction Sites: Cranes in the 10 to 20-ton range are a common sight on construction sites. Their capacities strike a balance between strength and maneuverability, making them ideal for lifting construction materials like steel beams and concrete blocks.

- Bridge Construction: Overhead cranes are vital in the construction of bridges. Cranes with tonnages of 10 to 20 tons are often employed for lifting and positioning bridge segments and components.

- Skyscraper Construction: When it comes to constructing skyscrapers, cranes with higher tonnages, such as 50 tons or more, are necessary for hoisting substantial materials and structural components to towering heights.

In each of these sectors, the tonnage requirements for overhead cranes reflect the distinct demands and intricacies of the industry. The energy sector relies on sheer power and precision, manufacturing emphasizes the precision of smaller tonnages, and the construction sector necessitates versatility in handling materials in varying work environments. The selection of tonnage is a critical decision that ensures the seamless functioning of industrial processes across the Russian landscape.

10 ton single girder overhead crane for sale Russia

Factors Influencing Tonnage Selection

The selection of tonnage for overhead cranes is far from arbitrary; it is a decision influenced by a complex interplay of factors. These factors extend beyond the mere weight of materials being lifted and encompass various considerations that impact the safe and efficient operation of cranes. In this section, we discuss the key factors that influence tonnage selection and delve into how material handling demands, safety considerations, environmental factors, and working conditions shape these decisions.

Material Handling Demands

- Weight and Size of Materials - One of the most fundamental factors is the weight and size of the materials being handled. The tonnage of the crane must match or exceed the weight of the heaviest load it will lift. For example, in steel mills, where enormous steel coils or billets are moved, cranes with high tonnages, often exceeding 50 tons, are utilized to ensure safe and efficient material handling.

- Load Distribution - The distribution of the load is another critical consideration. Irregularly shaped or unbalanced loads may require cranes with higher tonnages to maintain stability and prevent tipping or load shift during lifting.

- Load Dynamics - The dynamics of load movement play a role in tonnage selection. If a load needs to be accelerated or decelerated rapidly or if it undergoes frequent starts and stops, a crane with a higher tonnage may be needed to handle the additional stresses and ensure safe and controlled movements.

Safety Considerations

- Factor of Safety - Safety is of paramount importance in crane operations. Engineers and crane operators must consider a factor of safety when selecting the tonnage. This factor provides a margin for error and helps prevent overloading, which can lead to equipment failure or accidents.

- Stability and Balance - Maintaining the stability and balance of the crane is crucial for safe operation. Cranes should be rated to handle loads without exceeding their tipping or structural limits. Selecting the right tonnage helps ensure the crane operates within its safe working range.

- Safety Devices - Incorporating safety devices and features, such as overload protection systems and anti-sway mechanisms, may be necessary when dealing with heavy or sensitive loads. These additional safety measures can influence the choice of tonnage.

Environmental Factors

- Extreme Weather Conditions - In regions with extreme weather conditions, such as Russia's harsh winters, the tonnage of overhead cranes must account for environmental factors. Cranes operating in high winds, heavy snow, or temperature extremes may require higher capacities to maintain stability and safety.

- Corrosive Environments - Environments with high levels of humidity or chemical exposure can lead to corrosion. Overhead cranes used in such settings may require additional tonnage to support protective coatings and materials that mitigate corrosion.

Working Conditions

- Space Constraints - The physical layout and dimensions of the workspace can affect tonnage decisions. Cranes used in tight spaces may require lower capacities to navigate and operate efficiently.

- Crane Mobility - If a crane needs to move around a facility, the tonnage is an essential factor. Larger cranes may require wider access paths, while smaller cranes can maneuver more easily in confined spaces.

- Accessibility and Reach - Considerations related to the accessibility and reach of the crane, especially in industrial facilities with complex layouts, can influence tonnage selection. Cranes must be able to reach and lift materials in various locations efficiently.

In summary, the selection of tonnage for overhead cranes is a multi-faceted decision that integrates material handling demands, safety considerations, environmental factors, and working conditions. These factors collectively shape the capacity of the crane and ensure that it operates safely, efficiently, and effectively within the unique demands of its industrial setting.

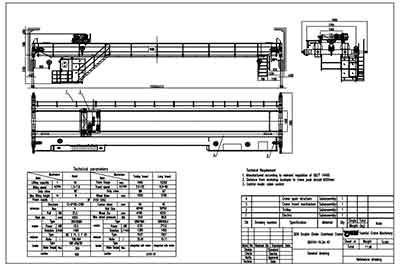

10 ton double girder bridge crane for sale Russia

Customization and Adaptation

Overhead cranes are not one-size-fits-all solutions. The dynamic nature of industrial processes in Russia often necessitates the ability to tailor cranes to specific requirements. Customization is the key to meeting the unique demands of industries or projects. In this section, we delve into the possibilities of customizing crane tonnages and provide examples of successful adaptations, showcasing how they impact operational efficiency and safety.

Tailoring Crane Tonnages

Customizing crane tonnages involves matching the crane's lifting capacity to the exact needs of a particular application. This can be particularly beneficial in several scenarios:

- Precision Handling - In industries such as aerospace and pharmaceuticals, where the handling of delicate and precise components is critical, cranes with lower tonnages are often customized to provide the required level of precision and control. These adaptations ensure that materials are handled with the utmost care, minimizing the risk of damage.

- Heavy-Duty Operations - On the opposite end of the spectrum, heavy-duty industries like mining and metallurgy may require cranes with higher tonnages. In such cases, cranes can be customized with reinforced structures, larger hoists, and increased load capacities to efficiently handle heavy materials, such as ore, steel, or bulk goods.

- Versatility - Some industries require versatile cranes that can adapt to a variety of tasks. For example, a 10-ton crane used in a manufacturing facility may be customized with specialized attachments and controls to handle various loads, from small components to larger machinery.

Examples of Successful Adaptations

Automotive Manufacturing: In the automotive industry, where precision is crucial, cranes have been customized to meet the needs of assembly lines. Cranes with capacities around 5 tons are adapted with precision controls and end effectors to precisely position engine components and vehicle bodies. This customization ensures a smooth and efficient manufacturing process.

Mining Operations: In the mining sector, where heavy materials are the norm, cranes with higher tonnages, often exceeding 50 tons, are common. These cranes are further customized with features like reinforced structures, advanced load monitoring systems, and anti-sway mechanisms to handle large volumes of ore and rock efficiently and safely.

Pharmaceutical Industry: Cleanroom environments in the pharmaceutical industry require cranes with specific tonnages and cleanliness standards. Customized cranes with lower tonnages and specialized coatings are used to meet strict cleanliness and precision requirements while handling sensitive pharmaceutical equipment.

Bridge Construction: In the construction of bridges, cranes with tonnages between 10 and 20 tons are often adapted to meet the unique needs of bridge construction sites. These cranes may be equipped with extended reach booms and specialized lifting attachments to position bridge segments with precision.

Impact on Operational Efficiency and Safety

Customizing crane tonnages can have a profound impact on operational efficiency and safety. These adaptations:

- Improve Precision: Tailoring cranes to meet the precise requirements of an application enhances precision and reduces the risk of errors.

- Enhance Safety: Customized features, such as anti-sway mechanisms and load monitoring systems, contribute to improved safety during lifting operations.

- Increase Productivity: Cranes that are customized to handle specific loads efficiently can boost productivity and reduce downtime.

- Adapt to Unique Environments: Customized cranes can be engineered to withstand challenging environmental conditions, ensuring reliability in extreme settings.

- Reduce Maintenance Costs: Customizations that align the crane with the exact demands of an application can result in reduced wear and tear, leading to lower maintenance costs.

In summary, customizing crane tonnages to meet the unique requirements of specific industries or projects is a common practice in Russia. Successful adaptations not only enhance operational efficiency and productivity but also play a pivotal role in ensuring the safety of workers and the integrity of materials. Customization is the key to optimizing the performance of overhead cranes in a wide array of industrial settings.

Future Trends and Considerations

The world of industrial technology is constantly evolving, and the realm of overhead cranes is no exception. In Russia, as in many parts of the world, the requirements for overhead crane tonnages and capacities are subject to shifts and trends driven by changing industrial needs and technological advancements. In this section, we take a peek into the crystal ball to explore the future trends in overhead crane tonnages and capacity requirements, as well as how technology and automation might shape the choices of tomorrow.

Emerging Trends in Tonnages and Capacities

- Greater Precision: As industries like electronics and pharmaceuticals demand ever-increasing levels of precision, there is a growing trend towards cranes with lower tonnages. These cranes are adapted with cutting-edge controls and automation, allowing for meticulous handling of fragile components.

- Miniaturization: In industries where smaller components are the norm, there's a shift towards miniaturized cranes with extremely low tonnages, sometimes even below 1 ton. These miniature cranes can access tight spaces and provide micro-level precision.

- Heavy-Duty Automation: For heavy-duty industries like mining and metallurgy, the future may bring even more advanced automation, reducing the need for human intervention. This could lead to the development of cranes with exceptionally high tonnages and smart, autonomous systems.

- Energy-Efficiency: Energy-efficient cranes that can handle heavy loads while minimizing power consumption are becoming increasingly popular. These cranes are designed to lower operating costs and environmental impact.

- Multi-Functional Cranes: The trend towards multi-functional cranes is likely to continue. These cranes are adaptable and can handle a wide range of tasks within a single facility, reducing the need for multiple crane installations.

Impact of Technology and Automation

- Dynamic Load Monitoring: Technology will play a pivotal role in the development of dynamic load monitoring systems. These systems can adjust the crane's tonnage and capacity in real-time based on the weight and dynamics of the load, enhancing safety and efficiency.

- Automation and Robotics: The integration of automation and robotics with overhead cranes is expected to increase. Automated cranes with the ability to independently select tonnages and optimize material handling processes will become more prevalent.

- IoT and Predictive Maintenance: The Internet of Things (IoT) will enable overhead cranes to communicate their tonnage and capacity needs as well as maintenance requirements in real-time. This will lead to proactive maintenance, reducing downtime.

- Load Balancing: Overhead cranes will increasingly utilize load balancing algorithms, distributing loads optimally across multiple cranes to improve efficiency and safety.

- Sustainability: Technology will drive the development of sustainable overhead cranes that can handle heavy loads using renewable energy sources and innovative materials, potentially reducing the tonnages required for lifting.

- Advanced Material Handling: Overhead cranes will be equipped with advanced sensors and imaging technologies to enhance material handling processes, potentially influencing tonnage requirements.

Considerations for the Future

As industries in Russia and around the world continue to evolve, it's essential for businesses to remain agile and open to embracing emerging trends and technologies. Considerations for the future of overhead crane tonnages and capacities include:

- Investing in Automation: Businesses should evaluate the potential benefits of automation and consider how it can impact tonnage requirements. Automated cranes may require less human intervention and can adjust their tonnages as needed.

- Monitoring Technological Advances: Staying informed about the latest advancements in crane technology and tonnage optimization is essential. Regularly updating crane systems can lead to increased efficiency and cost savings.

- Sustainability and Energy Efficiency: As sustainability becomes a top priority, businesses should explore energy-efficient cranes and sustainable materials that can reduce the tonnages required for lifting.

- Adapting to Precision Needs: Industries with a growing need for precision, such as electronics and pharmaceuticals, should assess their tonnage requirements and consider cranes with lower capacities but advanced control systems.

- Safety First: Safety should always be a top priority. When adopting new technologies and adjusting tonnages, businesses must ensure that safety standards and practices are rigorously maintained.

In conclusion, the future of overhead crane tonnages and capacity requirements in Russia is intertwined with technological advancements and evolving industrial needs. By embracing emerging trends and considering the impact of automation and sustainability, businesses can remain at the forefront of efficient and safe material handling practices.

5 -80 ton double girder overhead crane

Conclusion

In the dynamic landscape of industrial applications in Russia, the choice of tonnage and capacity for overhead cranes plays a pivotal role in the seamless flow of operations. It's a decision that should not be taken lightly, as it directly impacts efficiency, safety, and the bottom line. As we draw the curtains on our exploration of overhead crane tonnages and capacities in the Russian market, it's crucial to recap the significance of this choice and extend an encouraging hand to all the buyers navigating this complex terrain.

The selection of the right tonnage is not a mere formality; it's a decision that reflects the unique demands of your industry. Whether you find yourself in the precision-centric world of electronics or the heavy-duty realm of metallurgy, tonnage matters. It's the force that powers your operations, the precision that safeguards your materials, and the balance that ensures safety.

The prevailing tonnages in the Russian overhead crane market, from 1 to 20 tons, are not arbitrary choices. They represent the essence of adaptability, cost-effectiveness, and reliability that industries across the nation value. As you step into the future, it's essential to remember that the trends in tonnage selection are not set in stone. Emerging technologies and changing industrial needs will continue to reshape this landscape.

So, whether you're embarking on a journey to select an overhead crane or you're already a seasoned player in the field, consider the uniqueness of your industry. Think about precision, heavy-duty performance, versatility, and sustainability. Embrace customization, and adapt your cranes to meet the exact demands of your applications. Keep an eye on technological advancements and the potential for automation.

The significance of tonnage selection lies not only in the lifting capacity but also in the efficiency, safety, and profitability it brings to your industrial processes. Let it be a reflection of your commitment to excellence and innovation. As you navigate the ever-evolving world of overhead cranes in Russia, choose your tonnage wisely, and may your operations rise to new heights.