Gantry Crane Specifications Explained: A Guide to Technical Details

Explore essential technical details of gantry cranes, i.e, load capacity, span, height, speed, controls, and safety features in this comprehensive guide.

Gantry Crane Specifications Explained: A Comprehensive Guide to Technical Details

The technical specifications of gantry cranes is crucial for anyone involved in purchasing or operating these essential lifting tools. Whether you're a project manager, engineer, or procurement specialist, knowing these specifications ensures you choose the right crane for the job and maximize operational efficiency.

Whether you're considering a gantry crane for a manufacturing facility, construction site, or warehouse operation, this guide will provide the insights needed to choose wisely. By empowering you with knowledge, we aim to enhance your ability to select and utilize gantry cranes effectively, meeting your operational needs with confidence and clarity.

Basics of Gantry Crane Specifications

Gantry cranes are versatile lifting devices characterized by their overhead structure supported by legs or wheels that run on tracks or flat surfaces. They are used across various industries, including manufacturing, logistics, construction, and shipbuilding, to lift heavy loads horizontally and vertically within a specified area.

Definition of Gantry Cranes and Typical Applications:

Gantry cranes, also known as portal cranes or gantry bridge cranes, are designed for handling heavy materials and goods in locations where overhead cranes are not feasible or practical. Unlike overhead cranes that are ceiling-mounted, gantry cranes have their supporting structure on the ground, making them suitable for outdoor applications and facilities with high ceilings where overhead clearance is limited.

Typical applications of gantry cranes include:

- Loading and unloading shipping containers in ports and terminals.

- Moving heavy equipment and materials in manufacturing plants and warehouses.

- Constructing and assembling large structures in construction sites.

- Handling and maintaining boats and yachts in shipyards.

Importance of Technical Specifications in Crane Selection:

Technical specifications are critical in selecting the right gantry crane for a specific application. Each specification—such as load capacity, span, lifting height, duty cycle, lifting speed, and power requirements—directly influences the crane's performance, safety, and operational efficiency.

- Ensure the crane can lift and move loads of the required weight and dimensions safely.

- Determine the reach and coverage area of the crane to match the operational space available.

- Assess the crane's durability and reliability under expected operating conditions.

- Optimize energy consumption and operational costs by choosing appropriate power requirements.

By grasping the technical nuances of gantry crane specifications, stakeholders can make informed decisions that align with operational needs, enhance workplace safety, and maximize productivity. This guide will delve into each specification, providing clarity and practical insights to aid in effective gantry crane selection and utilization.

Key Technical Specifications Explained

Understanding the technical specifications of gantry cranes is essential for selecting the right equipment that meets operational requirements. Here's an in-depth look at the key specifications:

Load Capacity

- Definition and Significance: Load capacity refers to the maximum weight a gantry crane can lift safely. It ensures that the crane can handle the heaviest loads without compromising safety or performance.

- Factors Influencing Load Capacity: The load capacity is influenced by factors such as the crane's structural design, span (distance between the legs or supports), lifting height (vertical distance from the ground to the hook), and the type of load (uniform or concentrated).

- Examples of Common Load Capacities: Gantry cranes commonly range in load capacities from smaller units handling around 1 ton to larger models capable of lifting 100 tons or more. Common capacities include 5 tons, 10 tons, and 20 tons, tailored to specific industrial applications.

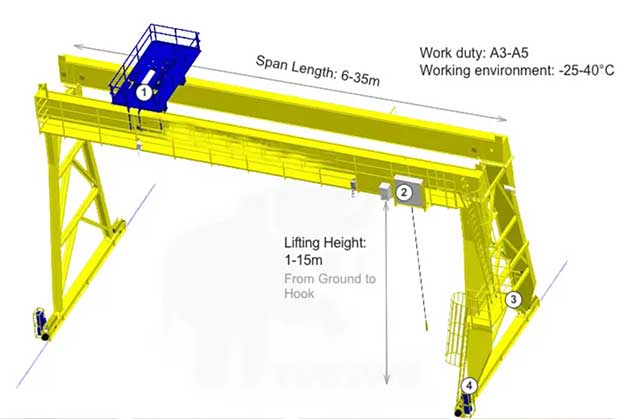

Span and Lifting Height

- Explanation of Span and Lifting Height Measurements: Span refers to the distance between the legs or supports of the gantry crane. Lifting height denotes the maximum vertical distance from the ground to the hook when fully extended. These measurements determine the crane's coverage area and reach.

- Impact on Crane Performance and Usability: A wider span allows the crane to cover a larger area, while a greater lifting height enables it to reach higher elevations. These specifications directly affect the crane's operational flexibility and suitability for specific tasks, such as loading trucks or stacking materials.

Duty Cycle

- Definition of Duty Cycle: Duty cycle refers to the percentage of time a crane operates at or near its maximum capacity during a specific period, usually an hour. It reflects the crane's capability to handle continuous or intermittent operations without overheating or mechanical stress.

- Different Duty Cycles and Their Implications: Cranes are categorized by duty cycles (e.g., light, moderate, heavy) based on their intended usage patterns. Higher duty cycle cranes are designed for continuous use in demanding environments, whereas lower duty cycle cranes are suitable for intermittent operations with sufficient cooldown periods.

Lifting Speed

- Importance of Lifting Speed: Lifting speed affects operational efficiency and productivity. It refers to how quickly the crane can raise or lower a load, minimizing downtime and optimizing workflow.

- Factors Affecting Lifting Speed: Lifting speed is influenced by the crane's load capacity, power source (e.g., electric, diesel), and mechanical design (e.g., motor type, gear ratio). Higher load capacities and power sources typically result in faster lifting speeds, enhancing overall crane performance.

Power Requirements

- Types of Power Sources: Gantry cranes can be powered by various sources, including electric (AC or DC), diesel, or hydraulic systems. Each power source offers distinct advantages in terms of efficiency, environmental impact, and operational cost.

- Calculating Power Requirements: Power requirements are calculated based on the crane's operational specifications, including load capacity, lifting height, duty cycle, and lifting speed. Matching the crane's power source to its operational demands ensures optimal performance and energy efficiency.

These key technical specifications empowers decision-makers to select the most suitable gantry crane for their specific operational needs, ensuring safety, efficiency, and cost-effectiveness in industrial lifting applications.

Hot Sale Gantry Cranes Main Specifications

Single girder gantry crane specifications

|

Technical Specification of MH Single Girder Gantry Crane with Electric Hoist |

||||||

|

Capacity |

t |

3.2 |

5 |

10 |

16 |

20 |

|

Span |

S(m) |

8~35 |

8~35 |

8~35 |

8~35 |

8~35 |

|

Lifting height |

m |

6~12 |

6~12 |

6~12 |

6~12 |

6~12 |

|

Lifting speed |

m/min |

0.8/5 |

0.8/5 |

0.8/5 |

0.66/4 |

0.66/4 |

|

Trolley speed |

m/min |

2~20 |

2~20 |

2~20 |

2~20 |

2~20 |

|

Crane speed |

m/min |

3~30 |

3~30 |

3~30 |

3~30 |

3~30 |

|

Work duty |

A5 |

A5 |

A5 |

A5 |

A5 |

|

|

Track type |

P24 |

P24 P30 |

P30 P38 |

P30 P38 |

P38 P43 |

|

|

Technical Specification of NMH European Style Single Girder Gantry Crane with Electric Hoist |

||||||

|

Capacity |

t |

3.2 |

5 |

10 |

16 |

20 |

|

Span |

S(m) |

8~35 |

8~35 |

8~35 |

8~35 |

8~35 |

|

Lifting height |

m |

6~12 |

6~12 |

6~12 |

6~12 |

6~12 |

|

Lifting speed |

m/min |

0.8/5 |

0.8/5 |

0.8/5 |

0.66/4 |

0.66/4 |

|

Trolley speed |

m/min |

2~20 |

2~20 |

2~20 |

2~20 |

2~20 |

|

Crane speed |

m/min |

3~30 |

3~30 |

3~30 |

3~30 |

3~30 |

|

Work duty |

A5 |

A5 |

A5 |

A5 |

A5 |

|

|

Track type |

P24 |

P24 P30 |

P30 P38 |

P30 P38 |

P38 P43 |

|

Double girder gantry crane specifications

|

Technical Specification of MG Double Girder Gantry Crane with A Fame Legs |

||||||

|

Capacity |

t |

5 |

10 |

16 |

20 |

32 |

|

Span |

S(m) |

18~35 |

18~35 |

18~35 |

18~35 |

18~35 |

|

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

|

Lifting speed |

m/min |

11.5 |

8.5 |

7.9 |

7.2 |

6 |

|

Trolley speed |

m/min |

37.2 |

37.4 |

40.1 |

40 |

37 |

|

Crane speed |

m/min |

37.7 |

37.7 |

40.1 |

40.1 |

38 |

|

Work duty |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

|

|

Track type |

P43 |

P43 |

P43 QU70 |

P43 QU70 |

P50 QU80 |

|

|

Capacity |

t |

50 |

75 |

100 |

160 |

200 |

|

Span |

S(m) |

18~35 |

18~35 |

18~35 |

18~35 |

18~35 |

|

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

|

Lifting speed |

m/min |

5.9 |

4.7 |

3.9 |

3.5 |

3.5 |

|

Trolley speed |

m/min |

31.3 |

38.2 |

33.9 |

22.5 |

29 |

|

Crane speed |

m/min |

44 |

38.3 |

32.3 |

28 |

28 |

|

Work duty |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

|

|

Track type |

QU80 |

QU80 |

QU100 |

QU100 |

QU100 |

|

Capacity |

t |

250 |

320 |

400 |

450 |

500 |

|

Span |

S(m) |

18~35 |

18~35 |

18~35 |

18~35 |

18~35 |

|

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

|

Lifting speed |

m/min |

2.2 |

2.3 |

1.5 |

1.5 |

1.5 |

|

Trolley speed |

m/min |

28 |

16.6 |

10 |

10 |

11.5 |

|

Crane speed |

m/min |

50 |

28 |

18 |

18 |

16 |

|

Work duty |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

A3-A7 |

|

|

Track type |

QU120 |

QU120 |

QU120 |

QU120 |

QU120 |

|

Technical Specification of Double Girder Gantry Crane with U Fame Leg |

|||||||

|

Capacity |

t |

10 |

16 |

20 |

32 |

40 |

50 |

|

Span |

S(m) |

18~35 |

18~35 |

18~35 |

18~35 |

18~35 |

18~35 |

|

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

|

Lifting speed |

m/min |

13.3 |

7.9 |

7.2 |

6 |

5.9 |

5.9 |

|

Trolley speed |

m/min |

37.4 |

40.1 |

40 |

37 |

31.3 |

31.3 |

|

Crane speed |

m/min |

41 |

40.1 |

44 |

40.1 |

40.1 |

40.1 |

|

Work duty |

A5-A6 |

A5-A6 |

A5-A6 |

A5-A6 |

A5-A6 |

A5-A6 |

|

|

Track type |

P43 |

P43 QU70 |

QU70 |

QU80 |

QU80 |

QU100 |

|

Semi gantry crane specification

Specification s of BMH Semi Gantry Crane with Single Girder Design

|

Capacity |

t |

3 |

5 |

10 |

16 |

20 |

|

Span |

S(m) |

8~30 |

8~30 |

8~30 |

8~30 |

8~30 |

|

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

|

Lifting speed |

m/min |

8(0.8/8) |

8(0.8/8) |

7(0.7/7) |

3.5(0.35/3.5) |

3.3(0.33/3.3) |

|

Trolley speed |

m/min |

20(30) |

20(30) |

20(30) |

18 |

14 |

|

Crane speed |

m/min |

20(30) |

20(30) |

20(30) |

20(30) |

20(30) |

|

Work duty |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

|

|

Track type |

P24 |

P24 P30 |

P30 P38 |

P30 P38 |

P38 P43 |

|

Technical Specification of BMG Double Girder Semi Gantry Crane |

||||||

|

Capacity |

t |

5 |

10 |

16 |

20 |

32 |

|

Span |

S(m) |

12~30 |

12~30 |

12~30 |

12~30 |

12~30 |

|

Lifting height |

m |

6~12 |

6~12 |

6~12 |

6~12 |

6~12 |

|

Lifting speed |

m/min |

11.5 |

8.5 |

7.9 |

7.2 |

6 |

|

Trolley speed |

m/min |

37.2 |

37.4 |

40.1 |

40 |

37 |

|

Crane speed |

m/min |

37.7 |

37.7 |

40.1 |

40.1 |

38 |

|

Work duty |

A3~A6 |

A3~A6 |

A3~A6 |

A3~A6 |

A3~A6 |

|

|

Track type |

P43 |

P43 |

P43 QU70 |

P43 QU70 |

P50 QU80 |

|

Additional Technical Details

In addition to fundamental specifications, certain technical aspects significantly influence the performance, safety, and usability of gantry cranes:

Control System

- Overview of Control Options: Gantry cranes utilize various control systems to manage lifting operations effectively. Common options include pendant controls, which feature handheld devices with buttons for crane movement and lifting functions. Radio remote controls offer wireless operation, allowing operators to manage crane functions from a distance, enhancing safety and visibility during operations.

- Impact on Crane Operation Efficiency: The control system directly impacts crane efficiency by enabling precise movement control and operational flexibility. Advanced control systems contribute to smoother load handling, faster response times, and reduced downtime, thereby optimizing overall productivity in industrial settings.

Safety Features

- Essential Safety Features: Gantry cranes are equipped with essential safety features to protect personnel, materials, and equipment during operations. These include:

- Overload Protection: Sensors and systems that prevent the crane from lifting loads exceeding its rated capacity, reducing the risk of structural damage or accidents.

- Emergency Stop: A critical safety mechanism that halts all crane movements immediately in emergency situations, ensuring swift response to potential hazards.

- Limit Switches: Devices that restrict crane movement within predefined operational limits, preventing collisions and enhancing operational safety.

- Compliance with Industry Standards and Regulations: Gantry cranes must adhere to stringent industry standards and regulations to ensure safe operation. Compliance involves periodic inspections, maintenance of safety features, and adherence to load testing requirements. Regulatory compliance not only mitigates risks but also enhances workplace safety and operational reliability, meeting legal obligations and industry best practices.

Understanding these additional technical details ensures that gantry cranes are not only efficient in operation but also safe and compliant with regulatory standards. By incorporating advanced control systems and robust safety features, stakeholders can optimize crane performance while prioritizing personnel safety and operational integrity.

Choosing the Right Gantry Crane

Selecting the appropriate gantry crane involves aligning its specifications with specific operational requirements. Here are key factors to consider and the significance of matching specifications to application needs:

Factors to Consider When Matching Crane Specifications with Operational Needs:

Load Capacity and Size Requirements:

- Assess the maximum weight and dimensions of the loads to be lifted.

- Ensure the crane's load capacity and lifting dimensions can accommodate operational demands without exceeding safety limits.

Span and Lifting Height:

- Determine the required span and lifting height based on the operational area and lifting tasks.

- Optimize coverage and reach to effectively handle materials within the designated workspace.

Duty Cycle and Operational Intensity:

- Evaluate the frequency and duration of crane use (duty cycle).

- Select a crane with a duty cycle that matches operational intensity to ensure reliable performance and longevity.

Environmental Conditions:

- Consider the operating environment, including temperature variations, humidity levels, and exposure to corrosive elements.

- Choose materials and coatings that withstand environmental challenges for sustained performance and durability.

Power Source and Efficiency:

- Evaluate power availability and cost considerations (e.g., electric, diesel).

- Optimize energy efficiency and operational costs by selecting a crane with an appropriate power source for the application.

Control System and Safety Features:

- Prioritize user-friendly control systems (e.g., pendant control, radio remote) that enhance operator efficiency and safety.

- Ensure the crane is equipped with essential safety features (e.g., overload protection, emergency stop) to mitigate operational risks and comply with safety regulations.

Conclusion

In conclusion, understanding the technical specifications of gantry cranes is key for making informed decisions that enhance operational efficiency and safety. Throughout this guide, we've explored various critical aspects that influence the performance and suitability of gantry cranes in industrial applications. If you have any need of gantry cranes, please feel free to contact us to check what we can do to save your cost.