Overhead Crane Duty Cycles: CMAA, FEM & ASME Crane Standards

Crane duty cycles overview. What are crane duty cycles? And what is the difference between CMAA, FEM & ASME Standard Crane duty Classification? Check now.

There are a variety of things to take into account when choosing an overhead crane for a specific purpose. Duty cycle, which is based on expected usage frequency, load type, and average load weight, is one of the most important factors. That's because the components won't be developed to meet the actual application if the chosen crane is not appropriately specified for these circumstances. As a result, the crane will probably deteriorate more quickly, shortening its lifespan. To achieve a complete return on investment, it is imperative to choose the appropriate crane with the acceptable duty classification and to adhere to the manufacturer's suggested maintenance schedule.

Overhead crane duty classifications - European style single girder overhead crane 5 ton in the pictue for your reference.

When you are getting ready to replace or add an overhead crane or hoist to your building, there are a lot of parameters to consider. Duty level or duty cycle will need to be defined as a crucial specification. There are various organizations that work to standardize the function of overhead cranes and lifting equipment, depending on where you are in the world. We put prepared a summary of the typical regulations and requirements you can encounter for lifting equipment sold in the US and Canada.

Duty cycle of a single girder or double girder overhead crane or hoist assure the product you purchase will be able to perform the job. Think about it like this. You wouldn't pull a semi-trailer with your pickup truck. Your pickup truck would experience excessive wear and tear each time the trailer was pulled. Not only that, but it would also struggle to tow the load of the trailer.

When you're purchasing lifting equipment or an overhead crane in the United States and Canada, there are multiple organizations you may see when shopping equipment. Some manufacturers follow standards organizations within multiple geographies, like Europe and North America. You may work with a manufacturer who calculates both to determine the best product for your application.

Types of Crane and Hoist Duty Cycle Classifications

When a crane builder calculates the duty cycle for your application, they do so using FEM, ASME and CMAA classification systems. FEM classifications are primarily employed in Europe and are the standard for hoist, trolley and bridge duty motion. In North America, crane builders use ASME classifications to provide duty cycle standards for the hoist and CMAA standards for the duty cycle of the trolley and bridge. Each of the following standards are intended to be a guide to manufactures, purchasers or users when defining duty cycles.

CMAA- Crane Manufacturers Association of America

Crane Manufacturers Association of America (CMAA) standards and specifications are followed in the United States and Canada. A crane manufacturer who follows CMAA specifications will determine the crane duty based on calculations of the number of load cycles using specifications detailed in CMAA 70 and CMAA 74.

As you research to prepare for your crane quote, you will likely see the six CMAA crane classes explained below. These are general guidelines to think about as you and your crane manufacturer prepare the quote to meet your requirements for overhead cranes.

- Class A – Standby or infrequent usage, such as those found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts.

- Class B – Light service, such as those used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity.

- Class C – Moderate service, such as those installed in machine shops, including handling an average of 50 percent of the rated capacity up to 10 times per hour.

- Class D – Heavy service, such as those deployed in heavy machine shops, foundries, container yards and more, where loads of 50 percent of the rated capacity are handled constantly.

- Class E – Severe service, such as those found in scrap yards, cement mills, lumber mills and more, where the crane makes 20 or more lifts per hour at or near its rated capacity.

- Class F – Continuous severe service, including custom designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions.

FEM- European Materials Handling Federation

Many crane manufacturers design to European standards because they are based in an European country. Yuantai products meet the European Materials Handling Federation (FEM) standards. FEM is the European Material Handling Federation. Duty classifications of products designed to FEM standards are calculated with input from the load spectrum and operating time. This calculation results in a classification shown below which is applied to the hoist, trolley, and bridge motor use.

FEM Duty Classifications for hoists trolleys, and bridge motors:

- 1Dm/ 1Cm – Standby or infrequent usage

- 1Bm – Light service

- 1Am – Light to medium service

- 2m – Medium to heavy service

- 3m – Heavy service

- 4m/5m – Severe service

FEM Standards for Crane Duty Classifications

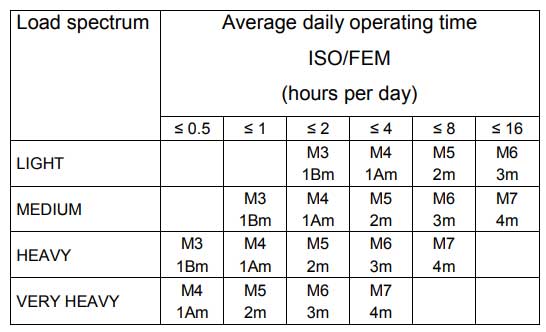

FEM Standards are created by the European Material Handling Society and apply to the mechanical function of hoists, trolleys and bridges with typical metric capacities. According to the FEM 9.511 standard, hoist-duty services application is determined by 1) load spectrum and 2) daily operating time.

The FEM classification best suited to your application is determined by first identifying the appropriate load spectrum. Cranes are split into four categories by load spectrum: light, medium, heavy and very heavy.

After load spectrum is determined, the expected daily operating time of the equipment is calculated using the following equation:

- H = average hoisting height (m)

- N = hoisting cycles per hour

- T = daily working time (hrs.)

- V = hoisting speed (m/min)

Once both load spectrum and daily operating time are identified, the chart below identifies the appropriate classification. For example, when R&M equipment is used exactly to the appropriate duty cycle, it consumes 10 percent of its Safe Working Period annually, which translates to a 10-year equipment lifecycle. This equation also serves as a starting point for calculating the Safe Working Period of your equipment.

ASME- The American Society of Mechanical Engineers

Primarily used in the United States and Canada, the American Society of Mechanical Engineers (ASME) develops standards applicable to the hoist marked in typical US capacities. ASME standards are approved by another organization, the American National Standards Institute (ANSI). To determine hoist duty, ASME calculates the maximum number of starts per hour, maximum on-time minutes per hour and the mean effective load to determine the hoist rating below.

ASME Standards for C rane Duty Clas sifica tions

ASME standards are developed by the American Society of Mechanical Engineers and approved by the American National Standards Institute (ANSI). While FEM covers the mechanical standards of hoist, trolley and bridge motion, ASME covers the mechanics of the hoist only. ASME hoist duty ratings (H3, H4, etc.) apply to hoists marked with typical U.S. capacities (for example, 1 ton = 2000 lbs. = 907 kg) and do not apply to hoists marked with typical metric capacities (for example, 1 metric ton = 1,000 kg = 2,200 lbs.) for R&M equipment.

The ASME hoist-duty classification is determined by three main factors:

- 1. Max no. of starts per hour , defined as the maximum number of motor starts per hour uniformly distributed over a given work period.

- 2. Max on-time minutes per hour , which equals the maximum number of minutes per hour of run time.

- 3. Mean effective load , a theoretical single load value that has the same effect on the equipment as various loads applied to the equipment over a period of time.

Typical applications for ASME standards are:

- H1 = Idle one to six months, used for installation and/or maintenance

- H2 = Light maintenance, fabrication; capacity loads infrequently handled; randomly distributed loads; low running time

- H3 = General machining; randomly distributed loads; total running time ≤ 25 percent of work period

- H4 = High volume handling of heavy loads near rated capacity; steel warehousing, machining, foundries; total running time ≤ 50 percent of work period

- H5 = Bulk material handling with attachments; approaching continuous operation

Defining the correct ASME standard for an application requires referencing the ASME publication catalog ASME HST-4 (latest edition) for electric wire rope hoists and B30.16 for overhead, underhung and stationary hoists.

Duty classification is a critical calculation for your lifting project. There are different organizations that set standards and specifications to match the product with your requirements. Assuring your lifting equipment is sized properly makes your lifting operations safer, more reliable, and efficient. Working with an experienced crane manufacturer or dealer will assure your project requirements will be met.

Comparison Of FEM And ASME Hoist Duty Service Classifications

There are three important differences to note between FEM and ASME duty classifications. First, FEM is one of the most stringent classification systems, meaning if your crane is covered by FEM, it is held to one of the highest standards. Second, FEM and ASME cover different parts of a crane. FEM covers the mechanical standards of hoist, trolley and bridge motion, while ASME covers the hoist only and relies on CMAA specifications for the bridge and trolley motions. Finally, ASME takes the number of starts/stops per hour into account.

Conversion between FEM and ASME is possible using the following conversion charts:

CSA C/US Certification For Electronic O verhead Cranes And Hoists

CSA International is a Nationally Recognized Testing Laboratory (NRTL) accredited by the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) to test and certify products. All CSA requirements for overhead cranes, gantry cranes, monorails, hoists, and jib cranes are found in CSA B167-16.

Certification from CSA International indicates that a trolley or bridge conforms to a range of electrical safety compliance measures and are subject to periodic follow-up inspections to verify conformance. CSA certification is an important factor because it ensures protection against electric shock and fire hazard. CSA Certification is required in Canada.

Determining Overhead Crane and Electric Hoist Duty Service Rating

One of the top five things you should ask your crane builder before making a purchase is about the durability and duty rating of your equipment. Duty service classifications are quite specialized and technical. If you're looking to purchase a new crane or hoist, it is beneficial to speak with knowledgeable experts about duty ratings.