Double Girder 20 Ton Overhead Cranes for Steel Fabrication

20 ton steel mill crane, custom double girder overhead crane 20 ton for handling steel beams, plates, coils, and structural components. Heavy duty crane 20 ton for sale.

Maximizing Efficiency in Steel Fabrication with European Style Double Girder 20 Ton Overhead Cranes

In steel fabrication, efficiency reigns supreme. Every cut, weld, and assembly must be executed with precision and speed to meet tight deadlines and maintain quality standards. At the heart of this process lies the crucial need for efficient material handling. Without the ability to swiftly and safely transport heavy steel materials, fabrication shops and metalworking plants would struggle to keep up with demand.

This is where specialized equipment like double girder overhead cranes come into play. These heavy-duty workhorses are designed to handle the toughest lifting tasks with ease, making them indispensable in steel fabrication industries. With their robust construction and impressive lifting capacity, double girder cranes are capable of moving steel beams, plates, coils, and structural components with precision and efficiency.In this blog, we'll explore the vital role that double girder 20-ton overhead cranes play in maximizing efficiency and productivity in steel fabrication operations. From their diverse applications to practical considerations for optimizing their use, we'll delve into the world of heavy-duty material handling and uncover the benefits of utilizing these powerful lifting machines. So, let's dive in and discover how double girder overhead cranes are revolutionizing the steel fabrication industry!

Overview of Euroepan Style Double Girder Overhead Crane 20 Ton for Steel Fabrication

The European Style Double Girder Overhead Crane 20 Ton is a sophisticated and versatile lifting solution tailored for the demanding needs of steel fabrication industries. Characterized by its sleek design, advanced features, and precision performance, this crane offers unparalleled efficiency and reliability in handling heavy steel materials for fabrication processes.

Key Features:

- Advanced Design: European-style cranes are engineered with a focus on compactness, efficiency, and modern aesthetics. Their lightweight yet sturdy construction ensures optimal performance while minimizing structural strain.

- High Lifting Capacity: With a lifting capacity of 20 tons, these cranes are capable of handling heavy steel beams, plates, coils, and structural components with ease, facilitating seamless production workflows.

- Precision Control: Equipped with advanced control systems, including variable speed drives and frequency control, European-style cranes offer precise load handling and positioning, ensuring accuracy and efficiency in fabrication operations.

- Enhanced Safety Features: Safety is paramount in steel fabrication environments, and European-style cranes are equipped with comprehensive safety features such as overload protection, emergency stop buttons, and anti-sway technology to prevent accidents and protect personnel and equipment.

- Adaptability and Customization: These cranes can be tailored to specific application requirements, with options for specialized hoists, attachments, and control systems. Whether it's handling raw materials, transporting finished products, or maneuvering within tight spaces, European-style cranes offer versatility and adaptability.

European Style Double Girder Overhead Crane 20 Ton is an ideal solution for steel fabrication industries seeking to enhance productivity, efficiency, and safety in material handling operations. With its advanced design, precision control, and versatile capabilities, this crane delivers optimal performance and reliability in demanding industrial environments.

Advantages

Double girder overhead cranes are indispensable tools in steel fabrication, offering a wide range of functions and benefits that contribute to efficient material handling and streamlined workflow. Let's delve into the specific functions and advantages of these powerful lifting machines:

- Efficient Lifting and Transport: One of the primary functions of double girder overhead cranes in steel fabrication is the efficient lifting and transport of heavy loads. With their robust construction and high lifting capacity, these cranes are capable of handling steel beams, plates, coils, and structural components with ease. They can quickly and safely move materials to and from workstations, supporting fabrication, welding, and assembly processes while minimizing downtime and increasing productivity.

- Versatile Handling Capabilities: Double girder overhead cranes offer versatile handling capabilities to accommodate various shapes and sizes of steel materials. Whether lifting long steel beams, wide steel plates, or bulky structural components, these cranes can adjust to the specific requirements of each load. Their adjustable hoisting mechanisms, trolleys, and lifting attachments allow for precise positioning and manipulation of steel materials, ensuring smooth and efficient material handling operations.

- Enhanced Safety Features: Safety is paramount in steel fabrication, and double girder overhead cranes are equipped with enhanced safety features to ensure secure lifting and precise positioning of heavy components. These cranes are designed with features such as overload protection systems, emergency stop buttons, and limit switches to prevent accidents and protect both personnel and equipment. Additionally, advanced control systems and safety interlocks provide operators with real-time feedback and ensure safe operation in all conditions.

In summary, double girder overhead cranes play a crucial role in steel fabrication by efficiently lifting and transporting heavy loads, accommodating various shapes and sizes of steel materials, and ensuring safe and precise material handling operations. With their robust construction, versatile handling capabilities, and enhanced safety features, these cranes are indispensable assets in steel fabrication shops, metalworking plants, and construction sites, helping businesses maximize efficiency, productivity, and safety in their material handling processes.

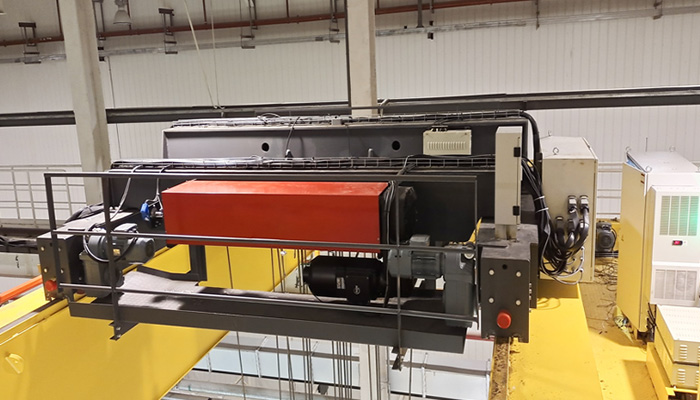

Main hoist and Auxiliary Hoist Overhead Crane

Crane Application

Double girder 20-ton overhead cranes find versatile applications across a range of industrial settings, where heavy steel materials need to be efficiently handled and moved. Let's explore the diverse environments where these powerful lifting machines are utilized:

- Steel Fabrication Shops: Within steel fabrication shops, double girder 20-ton overhead cranes serve as indispensable assets, supporting critical processes such as cutting, bending, and assembly. These cranes excel in lifting and transporting steel beams, plates, and structural components to and from various workstations. By seamlessly moving materials, they enhance workflow efficiency, boost productivity, and contribute to the timely completion of fabrication projects.

- Metalworking Plants: Double girder 20-ton overhead cranes play a crucial role in material movement within metalworking plants, where machining and finishing operations are carried out. These cranes facilitate the transportation of raw materials, workpieces, and finished products between different production stages. By ensuring the smooth flow of materials, they enable efficient processing and timely delivery of metal components, thereby supporting the overall operational efficiency of metalworking facilities.

- Construction Sites: At construction sites, double girder 20-ton overhead cranes are indispensable for assisting in the erection of steel structures and infrastructure. They are deployed to lift and position heavy steel beams, columns, and trusses during construction projects, providing crucial support for the assembly of buildings, bridges, and other steel-based structures. By offering precise control and high lifting capacity, these cranes contribute to the safe and efficient execution of construction tasks, ultimately accelerating project timelines and ensuring structural integrity.

In each of these environments, double girder 20-ton overhead cranes play a pivotal role in enhancing efficiency, productivity, and safety in material handling operations. Their robust construction, precise control, and high lifting capacity make them indispensable assets in the steel fabrication industry and beyond. With these cranes, businesses can streamline their operations, meet project deadlines, and navigate the challenges of today's dynamic industrial landscape with confidence.

Typical Loads

In steel fabrication, a wide array of heavy steel materials is handled on a daily basis. Let's take a closer look at some of the typical loads commonly encountered in steel fabrication shops and metalworking plants:

- Steel Beams: These sturdy structural members are essential components in construction projects, providing support and stability to buildings, bridges, and other structures. Steel beams come in various shapes and sizes, including I-beams, H-beams, and W-beams, and are often used for framing and support applications.

- Steel Plates: Steel plates are flat sheets of steel used in a multitude of applications, from manufacturing machinery components to constructing ship hulls and pressure vessels. Available in different thicknesses and widths, steel plates offer strength, durability, and versatility in a wide range of industrial applications.

- Steel Coils: Steel coils are continuous, long strips of steel wound into coils for transportation and storage. These coils are commonly used in manufacturing processes such as stamping, roll forming, and tube production. Steel coils come in various grades and thicknesses, making them suitable for diverse manufacturing applications across industries.

- Structural Components: In addition to beams, plates, and coils, steel fabrication involves handling various structural components such as angles, channels, and tubes. These components are used to create frameworks, supports, and enclosures in buildings, machinery, and infrastructure projects. With their strength and versatility, structural steel components form the backbone of many industrial structures and assemblies.

These are just a few examples of the heavy steel materials that are routinely handled and processed in steel fabrication operations. With their formidable lifting capacity and precision control, double girder 20-ton overhead cranes are well-equipped to handle these typical loads with ease, ensuring smooth and efficient material handling in steel fabrication shops and metalworking plants.

Typical Below Hook Devices for The Loads Handling

Below hook devices play a crucial role in handling heavy loads in steel fabrication and metalworking environments. Let's explore some typical below hook devices commonly used for handling the various steel materials mentioned above:

- C-Hooks: C-hooks are specialized lifting attachments designed to securely grip and transport steel coils. They feature a curved, C-shaped design that cradles the coil's outer circumference, providing stability and preventing slippage during lifting and transport operations. C-hooks come in various sizes and configurations to accommodate different coil dimensions and weights.

- Lifting Magnets: Lifting magnets utilize electromagnetic technology to lift and transport ferrous materials such as steel plates and structural components. These powerful magnets create a strong magnetic field that attracts and holds onto the steel material, allowing for safe and efficient lifting without the need for additional slings or attachments. Lifting magnets are available in different sizes and lifting capacities to suit various material handling requirements.

- Vacuum Lifters: Vacuum lifters are ideal for handling smooth, flat steel plates and panels. They use suction cups or vacuum pads to create a vacuum seal on the surface of the material, securely gripping and lifting it with minimal contact. Vacuum lifters are especially useful for delicate or sensitive materials that may be prone to scratching or damage from traditional lifting methods.

- Clamps and Grabs: Clamps and grabs are versatile below hook devices used for lifting and transporting steel beams, plates, and structural components. They feature adjustable jaws or arms that securely grip the material, providing a reliable lifting solution for a wide range of shapes and sizes. Clamps and grabs come in various configurations, including plate clamps, beam clamps, and coil grabs, to accommodate different material handling requirements.

- Spreader Beams: Spreader beams are lifting beams with multiple attachment points, designed to distribute the load evenly and prevent overloading of the crane or lifting equipment. They are commonly used for lifting long or oversized steel materials such as beams, tubes, and pipes. Spreader beams help ensure safe and stable lifting by providing a balanced support structure for the load.

By utilizing these below hook devices, steel fabrication shops and metalworking plants can safely and efficiently handle a wide range of heavy steel materials, improving productivity and enhancing workplace safety.

Practical Considerations

Optimizing the use of double girder overhead cranes in steel fabrication requires careful attention to practical tips and considerations to ensure safe and efficient operations. Here are some key factors to keep in mind:

- Proper Load Estimation and Weight Distribution: Before lifting any load, it's crucial to properly estimate its weight and distribute it evenly across the crane's lifting mechanism. Overloading the crane can lead to equipment damage, accidents, and injuries. By accurately assessing load weights and ensuring proper weight distribution, you can prevent overloading and maintain safe lifting practices.

- Regular Maintenance Routines: To ensure the reliability and longevity of double girder overhead cranes, it's essential to implement regular maintenance routines. This includes inspecting crane components for signs of wear and damage, lubricating moving parts, and testing safety features. By adhering to a scheduled maintenance program, you can identify and address potential issues before they escalate, minimizing downtime and extending the lifespan of the crane.

- Operator Training Programs: Proper operator training is crucial for safe and efficient crane operation. Training programs should focus on teaching operators how to safely operate the crane controls, perform pre-operational checks, and use proper lifting techniques. Operators should also be trained to recognize and respond to potential hazards and emergency situations. By investing in comprehensive operator training programs, you can ensure that operators have the skills and knowledge to operate the crane safely and efficiently.

By considering these practical tips and considerations, steel fabrication businesses can optimize the use of double girder overhead cranes, improve safety, and enhance productivity in their material handling operations. Implementing proper load estimation practices, adhering to regular maintenance routines, and providing thorough operator training are essential steps in maximizing the efficiency and effectiveness of double girder overhead cranes in steel fabrication environments.

Conclusion

In conclusion, the advantages of utilizing double girder 20-ton overhead cranes for material handling in steel fabrication are undeniable. These powerful lifting machines offer a multitude of benefits that contribute to increased efficiency, productivity, and safety in steel fabrication operations.

By efficiently lifting and transporting heavy loads for fabrication, welding, and assembly processes, double girder overhead cranes streamline workflow and minimize downtime. Their versatile handling capabilities enable them to accommodate various shapes and sizes of steel materials, ensuring smooth and efficient material handling operations.

Furthermore, double girder overhead cranes are equipped with enhanced safety features to ensure secure lifting and precise positioning of heavy components, protecting both personnel and equipment from accidents and injuries.

Investing in quality equipment and practices is paramount to maximizing efficiency and productivity in steel fabrication operations. By choosing double girder 20-ton overhead cranes and implementing proper load estimation, regular maintenance routines, and comprehensive operator training programs, businesses can optimize their material handling processes and stay ahead in today's competitive market landscape.

In essence, double girder 20-ton overhead cranes are indispensable assets in steel fabrication, offering a reliable and efficient solution for heavy-duty material handling tasks. By harnessing the capabilities of these powerful lifting machines, steel fabrication businesses can achieve greater efficiency, productivity, and success in their operations.