Industrial Overhead Cranes for Metalworking Plants 3 Ton to 50 Ton

Overhead Cranes for Metalworking Plants 3 Ton to 50 TonOverhead cranes represent a vital component within the metalworking industry, playing a pivotal role in material handling and production processes. These cranes are elevated structures that traverse horizontally along a runway system, allowing for the efficient movement and positioning of heavy loads within metalworking facilities.

Equipped with lifting mechanisms and sturdy configurations, overhead cranes are engineered to handle various metal materials, machinery parts, and products across different stages of metalworking operations. They provide essential support in lifting, transporting, and positioning materials, aiding in assembly, fabrication, storage, and other crucial tasks within metalworking facilities.

Overhead cranes are tailored to suit different capacities, from light-duty handling to heavy-duty lifting, catering to the diverse needs of metalworking applications. Their adaptability, precision, and capacity to navigate across workspaces make them indispensable assets, optimizing workflow efficiency and ensuring safety in metalworking operations.

Types of Overhead Cranes for Metalworking Plants

As the heartbeat of a metalworking facility, overhead cranes come in diverse forms, each tailored to address specific demands and applications within the bustling environment of metalworking. Let's delve into the myriad types of overhead cranes and their distinctive attributes, finely crafted to meet the intricate needs of this industrious domain.

Bridge Cranes (EOT)

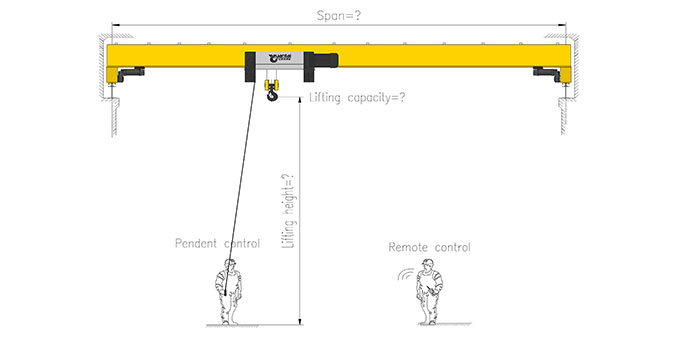

Single and Double Girder Configurations of Bridge Cranes

These workhorses of the metalworking industry, available in single or double girder setups, offer unparalleled versatility and strength. The single girder variant is adept at handling moderate loads efficiently, while the double girder configuration is the epitome of robustness, lifting heavy loads with seamless ease. These cranes span the workshop width, showcasing remarkable precision and control, making them indispensable for moving materials in metalworking processes.

Features: Bridge cranes, available in both single and double girder configurations, are characterized by their expansive span, allowing them to traverse the workshop width with ease. They exhibit precise load control and exceptional lifting capacities, making them versatile assets in metalworking facilities.

Benefits: The robustness of bridge cranes ensures efficient handling of heavy materials. Their ability to precisely position loads and navigate across workspaces makes them indispensable in various metalworking processes, including material handling, machining, and assembly.

Applications: Bridge cranes are utilized extensively in metalworking for tasks such as moving raw materials, transporting components between workstations, and aiding in assembling structures within the facility.

Types of bridge cranes for metal working

In metalworking, various types of bridge cranes are employed to facilitate material handling and streamline processes. Some common types include:

- Design: Single girder bridge cranes feature a single beam or girder that supports the hoist and trolley, spanning the width of the workspace.

- Features: These cranes are known for their cost-effectiveness, lighter weight, and ease of installation compared to double girder cranes.

- Applications: Ideal for lighter loads and smaller metalworking workshops, such as in machine shops or fabrication units.

- Design: Double girder bridge cranes utilize two parallel girders to support the hoist and trolley, providing increased stability and lifting capacity.

- Features: Offers higher lifting capacities and greater durability, suitable for heavy-duty applications in large-scale metalworking facilities.

- Applications: Well-suited for handling heavier loads, such as in steel mills, foundries, or areas dealing with larger metal components.

- Design: Underslung bridge cranes have the crane rails mounted on the bottom flange of the runway beams, allowing the hoist to be positioned underneath the beams.

- Features: Offers increased hook height and flexibility, as the hoist can operate close to the floor level, ideal for handling materials in tight spaces.

- Applications: Often used in metalworking workshops with limited headroom or in areas where floor space needs to be maximized.

Customized Specialty Bridge Cranes:

- Design: Specialty bridge cranes are customized to meet specific requirements, integrating unique features or adaptations tailored to particular metalworking processes.

- Features: Designed based on specialized needs, such as integrating magnet systems for handling ferrous metals or adapting to work in high-temperature environments.

- Applications: Used in specialized metalworking environments with unique demands, such as foundries, forging operations, or clean rooms.

Each type of bridge crane offers distinct features and advantages, catering to the varied demands and requirements of different metalworking applications and facilities. Choosing the most suitable type depends on factors such as load capacities, workspace layout, and specific operational needs within the metalworking environment.

Gantry Cranes

Gantry Crane sfor Flexibility and Heavy Load Handling:

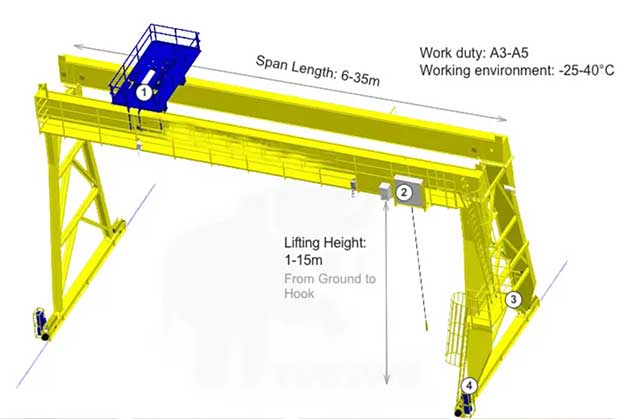

Gantry cranes, with their towering frames and exceptional flexibility, stand tall as the stalwarts of heavy load handling within metalworking environments. These cranes operate on tracks or wheels, providing the flexibility to navigate diverse terrain, lifting and moving substantial loads effortlessly. Their adaptability makes them the go-to solution for handling immense materials and products in metalworking settings.

Benefits: Gantry cranes, with their flexible mobility on tracks or wheels, offer unmatched versatility and strength in handling heavy loads within metalworking environments. They provide the agility to maneuver diverse terrains while effortlessly managing substantial materials.

Applications: These cranes find crucial applications in metalworking plants for loading and unloading materials, organizing storage yards, and handling large components or products during manufacturing processes.

Types of gantry cranes for metal working

In metalworking operations, several types of gantry cranes are utilized to efficiently handle materials and aid in various tasks. Here are some common types:

- Design: Single girder gantry cranes feature a single beam running along the width of the crane, supporting the hoist and trolley system.

- Features: Known for their cost-effectiveness, lightweight design, and ease of installation compared to double girder models.

- Applications: Suitable for lighter loads and smaller metalworking operations where space might be limited, such as workshops or smaller fabrication units.

- Design: Double girder gantry cranes employ two parallel girders to support the hoist and trolley, providing enhanced stability and increased lifting capacities.

- Features: Offer superior strength and durability, making them suitable for heavy-duty applications in larger metalworking facilities.

- Applications: Used in heavy lifting tasks, such as moving larger metal components or handling heavy materials in steel mills, foundries, or large fabrication shops.

- Design: Semi-gantry cranes have one end supported by a building structure or support beam, while the other end operates on a rail or wheels on the floor.

- Features: Offer flexibility in movement and are suitable for handling loads where only partial coverage of the workspace is required.

- Applications: Used in metalworking setups where mobility and partial coverage are needed, such as loading/unloading docks or storage yards.

Cantilever Gantry Cranes:

- Design: Cantilever gantry cranes have a horizontal beam extending beyond the supporting legs, allowing for lateral movement and increased reach.

- Features: Provide extended reach and access to difficult-to-reach areas, offering versatility in material handling.

- Applications: Utilized in metalworking facilities where specific reach and access to different work zones are required, such as handling materials around obstacles or machinery.

Adjustable Height Gantry Cranes:

- Design: These gantry cranes are equipped with adjustable legs or a telescoping structure, allowing for varying height adjustments.

- Features: Versatile in adapting to different height requirements, enabling lifting and moving materials at various levels.

- Applications: Ideal for metalworking environments where variable height requirements are essential, like handling materials on different floor levels or varying workstations.

Customized Specialty Gantry Cranes:

- Design: Specialty gantry cranes are tailor-made to suit specific requirements or integrate specialized features based on unique metalworking processes.

- Features: Customized with specific features such as magnet systems, specialized lifting attachments, or adaptations for high-temperature environments.

- Applications: Used in specialized metalworking operations with unique demands, such as foundries, high-temperature processing areas, or clean rooms.

Each type of gantry crane offers distinct advantages and applications, catering to diverse needs and requirements within the metalworking industry. Selecting the most suitable type depends on factors like load capacities, workspace layout, mobility needs, and the specific operational demands of the metalworking facility.

Jib Cranes

Jib Cranes for Localized Lifting Capabilities:

In the intricate tapestry of metalworking facilities, jib cranes emerge as the precision artists. With their vertical mast and horizontal boom, these cranes boast localized lifting capabilities, seamlessly maneuvering smaller components or tools with pinpoint accuracy. They find their niche in specific workstations, offering unparalleled precision and control in handling smaller yet critical elements of the metalworking process.

Functions: Jib cranes, with their vertical mast and horizontal boom, excel in localized lifting and positioning tasks. They offer precision and control, making them ideal for specific workstations where meticulous handling of smaller components or tools is required.

Applications: Jib cranes play a pivotal role in metalworking setups, aiding in the precise handling of components during forging, machining, welding, or assembly processes.

Types of jib cranes for metal working

In the metalworking industry, various types of jib cranes are employed to facilitate material handling and improve productivity. Here are some common types:

- Design: Free standing jib cranes are standalone units with a vertical support column, providing 360-degree rotation for material handling.

- Features: Offer flexibility in movement and easy maneuverability across a broad area, enabling efficient load positioning.

- Applications: Suitable for small to medium-sized metalworking workshops, assembly lines, or machining areas where precise material handling is required.

- Design: Wall-mounted jib cranes are fixed to existing building structures or walls, providing 180 to 270-degree rotation depending on the mounting location.

- Features: Space-saving design that maximizes floor space, ideal for material handling along a specific wall or work area.

- Applications: Used in metalworking facilities where floor space is limited, providing localized material handling capabilities.

- Design: Articulating jib cranes have a movable arm that pivots or articulates, offering increased flexibility and maneuverability.

- Features: Provide precise load positioning and access to confined spaces, allowing for a wider range of motion.

- Applications: Commonly used in metalworking facilities where precise material placement or access to tight spaces is essential, such as in machining centers or assembly stations.

- Design: Floor-mounted jib cranes are anchored directly to the floor, providing stability and a fixed range of motion for material handling.

- Features: Offer robustness and durability, suitable for handling moderate to heavy loads within a specific area.

- Applications: Used in metalworking environments where a fixed lifting point is required, such as loading/unloading stations or specific work zones.

Customized Specialty Jib Cranes:

- Design: Specialty jib cranes are custom-designed to meet unique requirements, integrating specialized features or adaptations for specific metalworking processes.

- Features: Customized with specific functionalities like specialized hooks, attachments, or adaptations for unique material handling needs.

- Applications: Deployed in specialized metalworking operations with distinct requirements, such as foundries, fabrication units, or clean rooms.

Each type of jib crane presents unique features and advantages, catering to different lifting capacities, spatial constraints, and material handling requirements within metalworking facilities. The choice of jib crane type depends on factors such as load capacities, available space, maneuverability needs, and specific operational demands of the metalworking environment.

Specialized Cranes (Magnet, Grab Bucket, Ingot Handling, etc.)

The specialized cranes are provided for particular applications, including the magnet cranes,rab bucket cranes, or ingot handling cranes. These specialized cranes cater to unique needs, whether it's handling ferrous materials with magnetic cranes or efficiently managing bulky ingots with ingot handling cranes, becoming indispensable assets in the metalworking realm.

- Unique Features: Equipped with powerful electromagnets or permanent magnets designed to lift ferrous materials like steel plates, sheets, or bars without the need for slings or hooks.

- Applications: Ideal for handling materials in metalworking operations where magnetic materials need to be lifted and transported efficiently, such as steel mills, metal fabrication units, or scrapyards.

- Unique Features: Employ a grab bucket attachment to grip and transport bulk materials or irregularly shaped objects, enhancing efficiency in loading and unloading processes.

- Applications: Used for handling loose bulk materials like scrap metal, raw materials, or waste in metalworking facilities, recycling centers, or ports.

- Unique Features: Specifically designed for handling heavy and bulky ingots or metal blocks, offering specialized lifting mechanisms and supports for safe and precise handling.

- Applications: Deployed in metal foundries, forging plants, or manufacturing units dealing with molten metal or large castings to facilitate the movement and storage of ingots.

- Unique Features: Equipped with specialized fixtures like coil grabs or hooks to handle and transport metal coils, ensuring stability and safety during lifting and movement.

- Applications: Used in steel mills or manufacturing facilities dealing with metal coils, facilitating safe loading/unloading, storage, or transportation of these heavy and bulky materials.

These specialized cranes play pivotal roles in various metalworking operations, addressing unique challenges and ensuring efficient, safe, and precise material handling in specific industrial settings. The choice of specialized crane depends on the nature of materials handled, the operational environment, and the specific requirements of the metalworking application.

Industrial Applications of Overhead Cranes in Metalworking

In the vibrant landscape of metalworking, the application spectrum of overhead cranes is as diverse as the myriad stages of production. These mechanical marvels weave seamlessly through the intricate tapestry of material handling, machining, assembly, and safety, becoming indispensable allies in the pursuit of efficiency and precision.

Material Handling -Detailing Material Movement: Overhead cranes emerge as stalwarts in material handling, orchestrating the seamless movement of raw materials and components across various stages of metalworking processes. Whether it's transporting steel coils, sheets, or ingots, these cranes navigate the workshop expanse with precision, optimizing material flow and ensuring efficient handling at every step.

- Machining and Processing -Transporting Materials: Within metalworking facilities, overhead cranes play a crucial role in material transportation to machining centers, lathes, milling machines, or CNC units. Their precision and lifting capabilities aid in positioning materials with finesse, allowing for precise machining and processing operations essential for creating intricate components.

- Assembly and Finishing -Assembling Large Structures: The prowess of overhead cranes extends to assembly processes, where they come into play in lifting, positioning, and maneuvering large structures or heavy components during welding, assembly, or finishing stages. Their ability to handle substantial loads with ease ensures the seamless construction of metal structures.

- Transporting Finished Products: Beyond assembly, these cranes serve as reliable transporters, ferrying finished products within the facility. Whether it's transporting finished machinery parts or delivering final products for quality checks, their efficiency ensures the smooth flow of finished goods.

- Safety Measures -Ensuring Safety and Compliance: Paramount in any industrial setting, safety is woven into the fabric of overhead crane functionality. These cranes are equipped with an arsenal of safety features—limit switches, anti-collision systems, emergency braking—to ensure the safety of both materials and personnel. Compliance with industry standards and safety protocols is inherent in the design and operation of overhead cranes, establishing them as guardians of safety within metalworking environments.

Top Concerns and Solutions for Overhead Crane Users

While overhead cranes stand as pillars of efficiency and safety within metalworking facilities, addressing certain key concerns is paramount to ensuring their optimal performance and longevity.

Maintenance and Inspections

Smooth and uninterrupted crane operation relies heavily on meticulous maintenance and regular inspections. These practices form the cornerstone of ensuring the longevity and performance of overhead cranes within metalworking facilities.

Scheduled Inspections: Regularly scheduled inspections, adhering to manufacturer guidelines, are pivotal in identifying potential issues before they escalate. These checks encompass structural integrity, electrical systems, and mechanical components, enabling early detection of wear, damage, or malfunction.

- Preventive Maintenance: Implementing comprehensive preventive maintenance routines involves tasks like lubrication, parts replacement, and adjustments. These measures are essential in preventing unexpected breakdowns, reducing downtime, and optimizing the crane's reliability and functionality.

- Adherence to Protocols: Strict adherence to prescribed maintenance protocols by trained personnel ensures that maintenance tasks are executed accurately and in accordance with industry standards, guaranteeing optimal crane performance.

Operator Training

The safe and efficient operation of overhead cranes hinges on well-trained and proficient crane operators. Investing in comprehensive training programs is fundamental in equipping operators with the requisite skills and knowledge.

- Skill Development: Training programs encompass theoretical knowledge combined with practical hands-on experience, offering insights into crane functionalities, load handling techniques, and safety procedures.

- Risk Mitigation: A well-trained operator is adept at recognizing potential hazards and employing appropriate safety protocols. Through continuous training, operators are equipped to respond effectively to challenging scenarios, minimizing risks and ensuring a safe working environment.

Load Capacity and Handling

Efficient load management is paramount for both safety and operational efficiency in metalworking environments.

Understanding Load Capacities: Thorough comprehension of the crane's load capacities and adherence to these limitations prevent overloading, a major cause of crane accidents. Operators must be well-versed in the crane's load charts and limitations.

- Rigging Techniques: Proper rigging techniques play a crucial role in ensuring load stability and even distribution, reducing stress on crane components. Training on rigging practices helps maintain safety standards while handling various loads.

- Compliance with Guidelines: Adhering to established load handling guidelines, including securing loads properly, conducting trial lifts, and using appropriate lifting accessories, is pivotal in safeguarding the crane's longevity and preventing accidents.

Q&A: Addressing User Concerns and Queries

Q: How do I select the right overhead crane for my metalworking facility?

A: Choosing the appropriate crane involves assessing your facility's specific needs—consider factors like lifting capacity, span, height, and the type of materials to be handled. Consultation with crane experts aids in selecting the ideal crane for your operations.

Q: What is the installation process for overhead cranes?

A: Crane installation involves meticulous planning, structural assessments, and compliance with safety standards. Trained professionals handle the installation, ensuring structural integrity and adherence to safety protocols.

Q: How do I ensure efficient crane operation?

A: Efficient operation involves regular maintenance, operator training, and adherence to load capacity guidelines. Routine inspections, lubrication, and following manufacturer guidelines are pivotal for optimum performance.

Troubleshooting

Issue: Crane malfunction during operation

Solution: Immediate stoppage and inspection are crucial. Identify the issue—whether mechanical or electrical—and enlist the assistance of qualified technicians to rectify the problem promptly.

Issue: Abnormal noises during crane movement

Solution: Unusual noises might indicate mechanical issues. Cease crane operation, conduct a visual inspection, and seek professional assistance to diagnose and rectify the underlying problem.

Issue: Overload or exceeding load capacity

Solution: Overloading poses significant risks. Implement strict load capacity guidelines, provide proper operator training, and incorporate warning systems to prevent potential overloading incidents.

If you have any other needs, please feel free to contact us.