Overhead Cranes in Hot Rolling Mills for Slabs to Sheets Handling

Slabs to Sheets: Overhead Cranes in Hot Rolling Mills

Introduction

In the grand symphony of steel production, hot rolling mills occupy a crucial stage. These mammoth industrial facilities play a pivotal role in transforming raw steel slabs into a wide range of products, including sheets, coils, and plates, which serve as the backbone of countless industries. At the heart of this intricate process lies the art of efficient material handling, and one of the unsung heroes in this realm is the overhead crane.

Hot rolling mills are the forge of the steel industry, where metal takes shape through a process that involves heating it to high temperatures and then rolling it between massive, heavy-duty rollers. The result is steel that boasts a myriad of applications, from construction materials to automotive components.

Hot Rolling Mills: An Overview

Hot rolling mills stand as the fiery heart of the steel industry, where raw steel slabs undergo a profound transformation. In this section, we will delve into the fascinating world of hot rolling mills, exploring the intricate process that takes place within their walls and the critical role they play in shaping steel.

The Hot Rolling Process

At its core, the overhead crane for the hot rolling process is a marvel of metallurgical engineering. It's a mechanical method that dramatically alters the properties and dimensions of steel, primarily through the application of heat and pressure. The fundamental steps of hot rolling can be summarized as follows:

- 1. Heating: Steel slabs are heated to extreme temperatures, often exceeding 1,700 degrees Celsius (3,092 degrees Fahrenheit). This intense heat renders the steel malleable, allowing it to be reshaped.

- 2. Rolling: The heated slabs are then subjected to the relentless pressure of massive rollers. These rollers exert tremendous force on the slabs, causing them to deform and change shape.

- 3. Reduction: As the slabs pass through successive sets of rollers, they progressively reduce in thickness. The precise control over this reduction is essential for achieving the desired product dimensions.

Types of Steel Products Produced

Hot rolling mills are the crucible where steel is reborn into various forms, each with distinct properties and applications. Some of the most common steel products produced in hot rolling mills include:

- - Sheets: Thin, flat pieces of steel with a broad range of applications, from automotive body panels to roofing materials.

- - Coils: Continuous lengths of steel wound into tight coils. These are often further processed into various shapes and sizes, making them versatile for a wide array of applications.

- - Plates: Thick, flat steel pieces used in structural applications, such as building construction and heavy machinery.

These steel products are the backbone of industries spanning construction, manufacturing, infrastructure development, and more. They serve as the canvas upon which countless innovations and structures are built.

Coil handling overhead cranes

With this understanding of hot rolling mills and the products they yield, we venture further into the realm of steel production, where the role of overhead cranes becomes paramount in ensuring the seamless flow of operations. In the subsequent sections, we will explore how specialized overhead cranes facilitate the handling of steel slabs in this challenging environment.

The Role of Overhead Cranes in Hot Rolling Mills

Within the pulsating heart of hot rolling mills, where steel is transformed into sheets, coils, and plates, overhead cranes stand as indispensable workhorses. In this section, we will uncover the pivotal role played by overhead cranes in the intricate choreography of handling steel slabs during the hot rolling process.

- Integral Equipment in Hot Rolling Mills Overhead cranes are not mere bystanders but rather essential partners in the production dance of hot rolling mills. Their towering presence and robust capabilities are integral to the seamless execution of operations. These cranes are designed and engineered with precision to withstand the extreme conditions of a hot rolling mill and perform with unwavering reliability.

- Handling and Movement of Slabs At the heart of their mission is the expert handling of steel slabs, the raw canvas from which sheets, coils, and plates are born. Overhead cranes deftly hoist these scorching slabs, a feat that requires not only strength but also finesse. Here's how overhead cranes aid in the artful handling and movement of slabs within the mill:

- - Precision Lifting: Overhead cranes are equipped with lifting mechanisms capable of handling the immense weight of steel slabs with pinpoint accuracy. This precision is crucial as it ensures the slabs are manipulated without distortion or damage.

- - Maneuverability: The cranes' versatility shines as they navigate through the labyrinthine pathways of the mill. They seamlessly transport slabs from one station to another, effortlessly adjusting to the ever-changing demands of the rolling process.

- - Safety: In the scorching and challenging environment of a hot rolling mill, safety is paramount. Overhead cranes are designed with robust safety features to protect both the equipment and the workforce. From redundant safety mechanisms to advanced control systems, these cranes are engineered for the highest standards of safety.

- - Efficiency: Time is money, and overhead cranes understand this well. Their efficient handling of slabs optimizes the production flow, reducing downtime and increasing the mill's overall productivity.

- - Customization: Not all steel slabs are born equal. Overhead cranes are often customized to match the specific dimensions and characteristics of the slabs they handle. This adaptability ensures that each crane is tailored to the unique needs of the mill.

As the slabs journey through the intricate ballet of the hot rolling process, overhead cranes stand as silent sentinels, ensuring that each step is executed with precision and efficiency. They are the unsung heroes of steel production, playing a pivotal role in shaping the world around us. In the following section, we will delve into the specialized types of overhead cranes employed in hot rolling mills and uncover their unique capabilities.

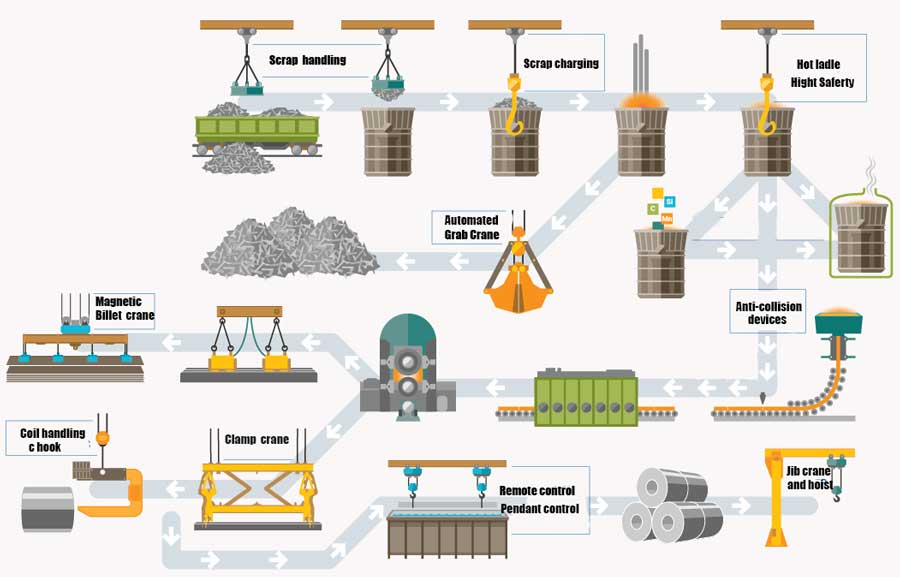

Specialized Overhead Cranes for Slab Handling

In the intricate world of hot rolling mills, where steel slabs are transformed into sheets, coils, and plates, specialized overhead cranes take center stage. These cranes are meticulously designed and tailored to handle the unique challenges posed by the hot rolling process. In this section, we will embark on a detailed exploration of the specialized overhead cranes that shoulder the responsibility of slab handling, unveiling their configurations and capacities.

Tailored to Perfection

Specialized overhead cranes for slab handling are not one-size-fits-all machines; they are precision instruments, custom-crafted to meet the exacting demands of the hot rolling mill environment. Here's a closer look at their key features:

- - Robust Structure: These cranes are constructed with a focus on durability, with heavy-duty materials that can withstand the punishing heat and conditions of the mill.

- - High Heat Tolerance: Operating in a hot rolling mill means exposure to extreme temperatures. These cranes are equipped with specialized insulation and cooling systems to ensure their longevity and performance under such conditions.

- - Unique Lifting Mechanisms: Slabs come in various sizes and weights, and specialized lifting mechanisms are tailored to handle this diversity. From powerful electromagnets to custom hooks and clamps, these cranes are armed with the right tools for the job.

- - Maneuverability: Navigating through the bustling mill is no small task. Specialized cranes are designed for maximum maneuverability, with precision controls that allow for intricate movements in tight spaces.

- - Load Stability: Maintaining the stability of the load, especially when handling red-hot slabs, is paramount. These cranes are equipped with advanced load control systems to prevent accidents and material damage.

- - Safety First: Safety is woven into the DNA of these cranes. Multiple safety features, such as emergency stop systems and load monitoring, ensure the well-being of both the equipment and the workforce.

Configurations and Capacities

The diversity of steel slabs demands a range of crane configurations and capacities. Specialized overhead cranes for slab handling come in various forms, each designed for specific roles within the hot rolling mill:

- - Single Girder Cranes: These cranes are known for their versatility and are often used for lighter slab handling tasks. They offer excellent control and precision.

- - Double Girder Cranes: When heavier slabs need to be transported, double girder cranes step up to the plate. Their robust construction and higher lifting capacities make them indispensable in many mills.

- - Tundish Handling Cranes: In the continuous casting process, tundishes play a vital role in delivering molten steel to the molds. Specialized cranes are designed exclusively for the precise handling of tundishes.

- - Scrap Handling Cranes: Efficient handling of scrap materials is essential in maintaining the cleanliness of the mill. These cranes are tailored for scrap collection and disposal.

The capacities of these cranes can vary widely, from smaller units capable of handling a few tons to massive overhead behemoths with capacities reaching well over 100 tons. This diversity ensures that hot rolling mills have the right tool for the job, no matter the scale of their operations.

In our next section, we will journey deeper into the heart of the hot rolling mill and explore the crucial role these cranes play in the transformation of steel slabs into the versatile materials that shape our world.

Ladle handling overhead crane for sale

Advantages of Using Overhead Cranes in Hot Rolling Mills

The utilization of overhead cranes in hot rolling mills is not merely a matter of convenience; it's a strategic choice driven by a host of compelling advantages. These towering mechanical marvels elevate the efficiency, safety, and productivity of the hot rolling process to unprecedented heights. In this section, we'll delve into the benefits that make overhead cranes indispensable in this challenging industrial setting.

Enhanced Safety First

Safety is paramount in any industrial environment, and hot rolling mills are no exception. The extreme temperatures, heavy loads, and fast-paced operations present inherent risks. Overhead cranes are engineered with safety in mind and provide several critical safety advantages:

- - Precise Load Control: Overhead cranes offer meticulous control over slab movement, ensuring that loads are maneuvered with precision and care, reducing the risk of accidents and material damage.

- - Emergency Stop Systems: In the event of unforeseen circumstances, overhead cranes are equipped with emergency stop systems that can halt operations instantly, preventing potential disasters.

- - Load Monitoring: Advanced load monitoring systems continuously assess load stability, allowing operators to make real-time adjustments to ensure safety.

- - Reduced Manual Labor: By mechanizing the handling of slabs, overhead cranes reduce the need for manual labor in high-risk areas, minimizing the exposure of workers to potential hazards.

Efficiency Amplified

In the dynamic world of hot rolling mills, efficiency is the linchpin of success. Overhead cranes inject efficiency into the process through the following means:

- - Swift Handling: Overhead cranes swiftly and precisely move slabs from one station to another, minimizing downtime and ensuring a seamless production flow.

- - Flexible Maneuverability: Their ability to navigate tight spaces and reach elevated positions means that overhead cranes can access every nook and cranny of the mill, optimizing material handling.

- - Increased Throughput: By reducing the time required for material handling, overhead cranes contribute to higher throughput and increased production capacity.

- - Versatile Load Handling: The adaptability of overhead cranes means they can handle slabs of various sizes and weights, accommodating the diverse needs of the mill.

Productivity Soared

Productivity in hot rolling mills is the ultimate barometer of success, and overhead cranes are instrumental in elevating it to new heights:

- - Continuous Operation: Overhead cranes facilitate the continuous operation of the mill by efficiently handling slabs, reducing bottlenecks, and maintaining a steady workflow.

- - Resource Optimization: The efficient use of overhead cranes minimizes resource wastage, whether it's time, energy, or materials, contributing to cost savings.

- - Reliability: These cranes are designed for rugged, high-temperature environments, ensuring uninterrupted operation and minimal downtime.

- - Customized Solutions: Overhead cranes can be customized to match the specific needs of the mill, providing tailor-made solutions that enhance productivity.

In the high-stakes world of hot rolling mills, where precision, safety, and productivity are non-negotiable, overhead cranes emerge as the champions of efficiency. They navigate the challenges of the environment with ease, ensuring that the transformation of steel slabs into versatile products proceeds seamlessly.

In our next section, we will immerse ourselves in real-world examples of how these specialized cranes empower hot rolling mills to achieve their production goals and, in turn, shape the future of steel.

Common Applications of Overhead Cranes in Slab Handling

Overhead cranes in hot rolling mills are the unsung heroes that orchestrate the intricate ballet of transforming steel slabs into a wide array of valuable products. Their versatility and precision make them indispensable in various critical applications within the mill. In this section, we will uncover the common tasks and applications where these overhead cranes shine.

Reheating Furnace Operations

- - Slab Charging: Overhead cranes play a pivotal role in loading steel slabs into the reheating furnace. Their ability to handle heavy loads with precision ensures a seamless and efficient charging process.

- - Batch Control: Advanced overhead cranes are equipped with batch control systems that optimize the arrangement of slabs within the furnace, ensuring uniform heating and reducing energy consumption.

- Transportation to Rolling Stands

- - Mill Entry: Once slabs are heated to the desired temperature, overhead cranes transport them to the rolling stands. This is a critical juncture where precision is essential to ensure a smooth transition.

- - Rolling Line Feeding: Overhead cranes continue to shine as they feed the rolling line with a constant supply of slabs, maintaining the rhythm of the rolling process.

Slab handling overhead crane

Material Handling Within the Mill

- - Billet Storage: Overhead cranes are responsible for transporting slabs to storage areas within the mill. Their precision and load control capabilities ensure safe stacking and retrieval of slabs.

- - Inter-Process Transfers: The hot rolling process often involves multiple stages. Overhead cranes facilitate the movement of slabs between these stages, ensuring a continuous workflow.

- Quality Control and Inspection

- - Load Positioning: Overhead cranes are employed for precise positioning of slabs during inspection and quality control procedures. This allows mill operators to identify and address any defects or irregularities.

Loading and Shipping

- - Loading onto Transport Vehicles: Overhead cranes are instrumental in loading processed slabs onto trucks or railcars for transportation to downstream processing facilities or customers.

- - Material Dispatch: They also play a key role in dispatching finished products, ensuring timely deliveries and maintaining an efficient supply chain.

- Maintenance and Repairs

- - Equipment Maintenance: Overhead cranes are utilized for maintenance and repair tasks within the mill. Their load capacity and versatility enable the safe handling of machinery and components.

- - Emergency Response: In cases of equipment breakdown or emergencies, overhead cranes can swiftly move heavy components, expediting repair processes and minimizing downtime.

Custom Applications

- Specialized Tasks: Some mills have unique requirements that demand specialized overhead crane solutions. These custom applications can include tasks such as slab flipping or turning for specific rolling processes.

The applications of overhead cranes in slab handling within hot rolling mills are multifaceted. They not only ensure the smooth flow of operations but also enhance safety, precision, and productivity. As versatile workhorses, these cranes are at the heart of the mill's ability to shape steel into sheets, coils, and plates that fuel various industries.

In the next section, we will delve into real-world examples of how hot rolling mills have harnessed the power of overhead cranes to achieve remarkable results and maintain their competitive edge in the steel industry.

Safety Measures and Challenges

Safety is paramount in any industrial setting, and hot rolling mills are no exception. In this section, we will delve into the safety measures and challenges associated with the operation of overhead cranes in hot rolling mills.

High-Temperature Environment:

- - Heat Protection: Hot rolling mills operate in extremely high-temperature environments. To protect crane operators and ensure crane longevity, specialized heat-resistant materials and insulation are employed.

- - Operator Safety Gear: Crane operators are equipped with heat-resistant personal protective equipment (PPE) such as suits, gloves, and face shields to mitigate the risk of exposure to extreme temperatures.

- Load Control and Stability:

- - Load Monitoring: Overhead cranes in hot rolling mills are equipped with load monitoring systems to ensure that the load remains within safe limits. Any deviation can trigger alarms and automatic shutdowns.

- - Load Balance: Maintaining the balance of heavy slabs during lifting and transport is crucial. Overhead cranes use advanced control systems to ensure load stability, reducing the risk of accidents.

Emergency Response:

- - Emergency Shutdown: Overhead cranes are equipped with emergency shutdown mechanisms that can be activated in the event of a malfunction or unsafe conditions.

- - Emergency Training: Operators undergo rigorous training to respond quickly and effectively to emergencies, including the safe evacuation of the crane cab.

- Maintenance and Inspection:

- - Regular Inspections: Routine inspections are conducted to identify any wear and tear on crane components. Preventive maintenance is carried out to address issues before they become safety hazards.

- - Equipment Replacement: Aging components are replaced to maintain the reliability and safety of the cranes.

Challenges and Solutions:

- - Handling High-Temperature Slabs: One of the primary challenges in hot rolling mills is the safe handling of high-temperature slabs. Specialized equipment, including heat-resistant hooks and lifting devices, is used to address this challenge.

- - Material Flow Optimization: To ensure the safety of personnel and equipment, hot rolling mills employ advanced material flow simulations and process optimization techniques. This helps in streamlining operations and reducing the risk of accidents.

- - Operator Training: Extensive operator training programs are in place to ensure that crane operators are well-versed in safe operating procedures and emergency response protocols.

- - Environmental Controls: Adequate ventilation and environmental controls are implemented to minimize the impact of high-temperature conditions on both equipment and personnel.

Safety in hot rolling mills is a multifaceted endeavor that encompasses equipment design, operator training, and a proactive approach to maintenance. The combination of advanced technology and a safety-first mindset ensures that overhead cranes play a pivotal role in maintaining a secure work environment within these challenging industrial settings.

In the following section, we will explore real-world success stories that demonstrate how the seamless integration of overhead cranes in hot rolling mills has not only improved safety but also elevated efficiency and productivity.

Case Studies and Success Stories

To provide a deeper understanding of the impact of overhead cranes in hot rolling mills, we'll delve into some real-world case studies and success stories. These examples underscore the pivotal role that specialized cranes play in enhancing efficiency and cost-effectiveness in steel production.

Streamlining Slab Handling in a Large Steel Mill

*In a major steel mill that produces a substantial volume of slabs daily, the need for efficient material handling was paramount. By implementing state-of-the-art overhead cranes designed specifically for slab handling, the mill achieved several noteworthy outcomes:*

- - Enhanced Throughput: The new overhead cranes significantly reduced the time required to move slabs from the reheating furnace to the rolling stands. This led to a substantial increase in production throughput.

- - Reduced Downtime: The advanced control systems of the cranes, along with predictive maintenance, minimized unexpected breakdowns. This reduction in downtime translated to cost savings and improved reliability.

- - Improved Safety: The use of specialized equipment designed for high-temperature environments ensured the safety of crane operators and other personnel involved in slab handling.

Optimizing Material Flow in a Mid-Sized Rolling Mill

*In a mid-sized rolling mill that produces sheets and coils, the efficient flow of materials from the furnace to the rolling stands was critical. The adoption of overhead cranes tailored for slab and sheet handling had a transformative impact:*

- - Precise Positioning: The cranes' precision control allowed for accurate positioning of slabs and sheets, reducing material waste and enhancing the quality of the final product.

- - Versatility: The flexibility of the overhead cranes allowed for the handling of various sizes and types of slabs and sheets, making the mill more versatile in responding to market demands.

- - Cost Savings: The optimized material flow, coupled with reduced labor requirements due to automation, resulted in substantial cost savings for the mill.

Safety and Efficiency in a Smaller Rolling Facility

*Even in smaller rolling facilities, the safety and efficiency benefits of overhead cranes were evident. A case study of a smaller steel mill highlighted the following advantages:*

- - Space Optimization: Overhead cranes made efficient use of limited floor space, allowing for streamlined operations within the compact facility.

- - Quick Turnaround: The ability to rapidly move materials, particularly slabs, between production stages minimized production lead times, ensuring timely order fulfillment.

- - Reduced Manual Handling: The cranes reduced the need for manual material handling, lowering the risk of workplace injuries and fatigue among workers.

These case studies serve as compelling examples of how overhead cranes tailored for hot rolling mill applications can make a substantial difference in efficiency, safety, and overall operational success. The versatility and adaptability of these cranes, along with their capacity to handle high-temperature materials, continue to drive innovation in the steel industry.

In the following section, we will address common questions and concerns related to the use of overhead cranes in hot rolling mills, offering valuable insights for those considering their implementation.

Future Trends and Innovations

As technology continues to advance, the steel industry is experiencing a wave of innovations that promise to further enhance the efficiency and sustainability of hot rolling mills. Overhead crane design is no exception to this trend, with several promising developments on the horizon. In this section, we'll explore some of the future trends and innovations in overhead crane design for hot rolling mills and their potential impact on the steel production process.

Automation and Robotics Integration:

One of the most significant trends in overhead crane design is the integration of automation and robotics. Advanced control systems and sensors enable cranes to operate autonomously, performing tasks with precision and efficiency. In hot rolling mills, this automation can streamline material handling, reduce human intervention in high-temperature environments, and optimize production processes.

Predictive Maintenance:

Predictive maintenance, powered by data analytics and sensor technology, is becoming increasingly prevalent. Overhead cranes equipped with sensors can monitor their own condition in real-time, detecting signs of wear, stress, or potential malfunctions. This data-driven approach allows for proactive maintenance, reducing downtime and extending crane lifespan.

Energy Efficiency and Sustainability:

With growing emphasis on sustainability, future overhead crane designs are likely to focus on energy efficiency. This includes the use of regenerative braking systems, energy-efficient motors, and lightweight materials to reduce power consumption. Such innovations align with the broader goal of reducing the environmental footprint of steel production.

Enhanced Safety Features:

Safety remains a top priority in hot rolling mills. Future overhead cranes may incorporate advanced safety features, such as collision avoidance systems, improved operator interfaces, and augmented reality tools to enhance situational awareness. These innovations aim to further reduce the risk of accidents and injuries.

Customization and Adaptability:

The ability to tailor overhead crane designs to specific mill requirements will continue to be a key trend. Manufacturers are expected to offer a wide range of configurations and capabilities, allowing mills to choose cranes that precisely meet their needs. This customization enhances overall efficiency and productivity.

Remote Monitoring and Control:

Remote monitoring and control capabilities are likely to expand. Hot rolling mills can benefit from real-time monitoring of crane operations, allowing for remote adjustments and troubleshooting. This not only improves operational efficiency but also reduces the need for on-site personnel in hazardous environments.

Artificial Intelligence (AI) Integration:

AI-powered algorithms can optimize crane operations by analyzing data on material flow, crane performance, and environmental conditions. These algorithms can make real-time decisions to maximize efficiency, such as adjusting crane speeds or rerouting material flow to prevent bottlenecks.

Sustainability Initiatives:

Many steel producers are committing to sustainability goals. Overhead crane manufacturers are responding by developing eco-friendly crane solutions. This includes the use of recyclable materials in crane construction and the implementation of technologies that reduce emissions.

These emerging trends and innovations represent an exciting future for overhead cranes in hot rolling mills. They not only promise to improve efficiency and safety but also contribute to the broader goal of sustainable steel production. As steel mills continue to embrace these advancements, we can expect to see remarkable transformations in the way steel is manufactured, further solidifying its role as a foundational material in our modern world.

In the final section, we will wrap up our exploration of overhead cranes in hot rolling mills with a recap of key takeaways and insights.

Conclusion

In the world of steel production, where efficiency, precision, and safety are paramount, the role of overhead cranes in hot rolling mills is nothing short of indispensable. These powerful machines, designed to handle the intense heat and heavy loads of steel slabs, play a vital role in the transformation of slabs into the sheets, coils, and plates that are the building blocks of our modern infrastructure.

Throughout this journey, we've explored the significance of hot rolling mills in the steel industry, delving into the intricacies of the hot rolling process and the diverse range of steel products it yields. We've witnessed how overhead cranes, purpose-built for the demands of slab handling, have become the workhorses of these mills, ensuring the efficient movement of materials and contributing to the precision and quality of the final product.

The specialized overhead cranes used in hot rolling mills are a testament to engineering innovation. Their configurations and capacities are tailored to the unique challenges posed by the extreme temperatures and substantial weights involved in slab handling. These cranes not only increase efficiency but also enhance safety, minimizing risks in an environment where precision is paramount.

We've examined the advantages of using overhead cranes in hot rolling mills, from improved productivity and reliability to enhanced safety measures. We've explored the common applications of these cranes, from transporting slabs from reheating furnaces to precisely positioning them in rolling stands.

Safety, a paramount concern in any steel mill, has been addressed, with insights into the measures and challenges associated with overhead crane operations in the high-temperature environment of hot rolling mills. Real-world case studies have underscored the tangible benefits and success stories that result from the integration of advanced overhead crane solutions.

Looking ahead, we've glimpsed into the future of overhead crane design, where automation, predictive maintenance, energy efficiency, and sustainability take center stage. These innovations promise not only to further improve the efficiency and safety of hot rolling mills but also to align steel production with global sustainability initiatives.

As we conclude our exploration of overhead cranes in hot rolling mills, one message resounds: the choice of the right overhead crane solutions is pivotal to optimizing steel production. Whether it's achieving higher throughput, ensuring the safety of workers, or contributing to a more sustainable future, overhead cranes are at the forefront of innovation in the steel industry.