10 to 25 Tons Gantry Cranes for Battery Recycling Operations

Gantry crane for sale. 10 to 25 tons gantry cranes designed for safe and efficient handling in lithium-ion battery recycling operations.

In the sector of renewable energy and electric vehicles, the demand for lithium-ion batteries continues to rise. These batteries are essential for powering everything from smartphones to electric cars, but their growing use poses a significant environmental challenge. Recycling lithium-ion batteries is crucial for several reasons: it reduces the need for raw materials, minimizes hazardous waste, and recovers valuable components like lithium, cobalt, and nickel. Proper recycling not only protects the environment but also supports the circular economy, making resources available for new battery production.

For material handling, the gantry cranes play a vital role in waste management and recycling operations. These cranes are designed to handle heavy loads efficiently, making them ideal for the complex processes involved in battery recycling. Their flexibility allows for the safe and effective transportation of batteries and components throughout recycling facilities, from disassembly to material recovery. With capacities ranging from 10 to 25 tons, gantry cranes can accommodate the significant weight of battery modules and the various equipment used in the recycling process.

This guide aims to provide a comprehensive overview of using 10 to 25 tons gantry cranes specifically for lithium-ion battery recycling operations. We will explore the advantages of these cranes, their specifications, safety features, and best practices for operation and maintenance. By the end of this guide, readers will have a clear understanding of how gantry cranes enhance efficiency and safety in battery recycling, helping to foster a more sustainable approach to waste management.

Overview of Lithium-Ion Battery Recycling

The Recycling Process

Recycling lithium-ion batteries involves several critical steps to ensure that materials are recovered efficiently and safely. The process begins with the collection and sorting of battery materials. This step is crucial, as it involves gathering spent batteries from various sources, including consumer electronics, electric vehicles, and industrial applications. Proper sorting is essential to separate different battery types and ensure that hazardous materials are handled appropriately. Batteries are typically categorized based on their chemistry and size, which helps streamline the recycling process.

Once the batteries are collected and sorted, the next phase is the mechanisms for battery disassembly. This process involves safely dismantling the batteries to access their internal components. Specialized equipment is used to remove the outer casing and separate the battery cells from other materials, such as wiring and electronics. This disassembly can be performed manually or with automated machinery, depending on the facility's capacity and technology. Effective disassembly is vital, as it maximizes material recovery while minimizing risks associated with handling hazardous substances, such as electrolyte leakage.

Importance of Recycling Lithium-Ion Batteries

The importance of recycling lithium-ion batteries cannot be overstated, given the environmental and economic implications. One of the primary environmental benefits of recycling is the reduction of hazardous waste. Lithium-ion batteries contain toxic materials that can harm ecosystems if disposed of improperly. By recycling these batteries, we can prevent harmful chemicals from entering landfills and contaminating soil and water sources.

In addition to environmental protection, recycling contributes to the recovery of valuable materials. Lithium, cobalt, nickel, and other metals used in battery production can be extracted and repurposed for new batteries or other industrial applications. This process reduces the reliance on mining for raw materials, which is often environmentally destructive and resource-intensive. By recycling lithium-ion batteries, we not only conserve natural resources but also support the circular economy, where materials are reused and reprocessed, promoting sustainability in the manufacturing cycle.

Overall, understanding the recycling process and its importance helps to underscore the critical role that lithium-ion battery recycling plays in addressing both environmental challenges and resource conservation.

Gantry Cranes: An Essential Tool

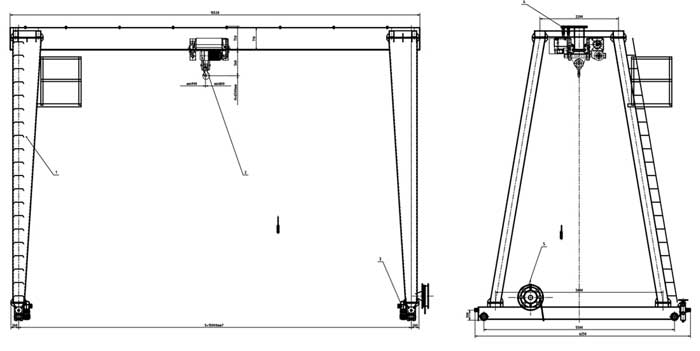

What is a Gantry Crane? A gantry crane is a type of lifting equipment that consists of a bridge supported by vertical legs. This design allows the crane to move freely along a track or rails, making it highly versatile for various applications. The main components of a gantry crane include the bridge, which spans the distance between the legs; the hoist, which is used to lift and lower loads; and the legs, which provide stability and support. Gantry cranes can be made from different materials, typically steel, to ensure durability and strength.

In recycling operations, several variants of gantry cranes are commonly used. These include single girder gantry cranes, which are lighter and suitable for lower capacity needs, and double girder gantry cranes, which offer greater strength and can handle heavier loads. Additionally, portable gantry cranes are popular for their flexibility, allowing operators to reposition them easily within the facility as needed. Each variant is designed to meet specific operational requirements, making gantry cranes a key asset in battery recycling processes.

signle girder gantry crane 1 ton to 20 ton for sale

Advantages of Using Gantry Cranes in Recycling

Gantry cranes provide numerous advantages that make them ideal for recycling operations, especially in the context of lithium-ion battery recycling. One of the primary benefits is their flexibility and mobility. Unlike fixed cranes, gantry cranes can be easily relocated within a facility, allowing operators to adapt to changing workflows and optimize space usage. This mobility is particularly useful in recycling facilities where various processes may require different setups.

Another significant advantage is their high load capacity and efficiency. Gantry cranes are designed to handle substantial weights, typically ranging from 10 to 25 tons, which is essential for managing the heavy components of lithium-ion batteries. Their robust design enables them to lift and transport large battery modules and associated materials with ease, minimizing the risk of accidents or damage. Furthermore, the efficiency of gantry cranes helps streamline operations, reducing downtime and improving overall productivity.

In summary, the flexibility, mobility, high load capacity, and efficiency of gantry cranes make them an essential tool in lithium-ion battery recycling operations. Their ability to adapt to various tasks and handle substantial weights contributes significantly to the effectiveness and safety of recycling processes.

Specialized Features of Gantry Cranes Used for Lithium-Ion Battery Recycling

In lithium-ion battery recycling operations, gantry cranes are not just used for heavy lifting; they come equipped with specialized features tailored to the unique challenges of handling batteries, which can be hazardous due to their chemical composition. These features enhance safety, precision, and efficiency in battery recycling facilities.

Anti-Spark and Explosion-Proof Design

Lithium-ion batteries pose a significant fire and explosion risk due to their volatile chemicals, especially when damaged or improperly handled. Gantry cranes used in these operations often incorporate anti-spark and explosion-proof designs. This includes the use of non-sparking materials, such as copper alloys for hoists and other components, and specialized coatings on electrical systems to prevent ignition of any flammable gases or dust present in the recycling facility.

Additionally, explosion-proof motors and wiring systems are commonly installed to comply with stringent safety standards in hazardous environments. This is crucial for protecting both workers and the facility itself from potential hazards posed by damaged or leaking batteries.

Precision Load Handling and Control Systems

Battery recycling often involves disassembling and sorting various components of the batteries, which requires precise handling. Gantry cranes designed for these operations are equipped with precision control systems that allow for smooth, controlled lifting and lowering of materials. Features like variable frequency drives (VFD) provide operators with the ability to adjust the speed of the crane to ensure delicate handling of sensitive components.

Moreover, advanced load control systems help in maintaining balance during lifting, preventing sudden jerks or sways that could damage the battery components or create unsafe conditions.

Non-Magnetic and Non-Conductive Materials

Lithium-ion batteries contain ferrous materials, and in some cases, residual charge, posing the risk of magnetic interference or electrical conductivity during handling. Gantry cranes used in these operations are often designed with non-magnetic and non-conductive materials to prevent unwanted interactions between the crane and the materials being handled. This can include non-magnetic hooks, chains, and structural components, ensuring that the crane does not interfere with or affect the battery materials.

These materials also reduce the risk of short circuits or electrical shocks, especially in environments where battery components might still carry residual charge.

Enhanced Weight Capacity and Customization

In a lithium-ion battery recycling facility, the weight of the materials being handled can vary greatly depending on the stage of recycling, from entire battery packs to individual cells. Gantry cranes for these operations come with customizable weight capacities, typically ranging from 10 to 25 tons. These cranes are built to handle not only the heavy battery packs but also the equipment and machinery involved in disassembling and sorting the materials.

The crane design can also be customized with additional attachments and lifting tools, such as special clamps or vacuum lifts, to securely handle irregularly shaped battery modules or containers, improving the safety and efficiency of the recycling process.

Automated and Remote Control Systems

Automation plays a key role in improving the efficiency and safety of battery recycling operations. Automated gantry cranes equipped with remote control systems allow operators to control crane movements from a safe distance, reducing direct exposure to potentially hazardous materials. This is particularly useful when handling large battery packs or materials that may pose a chemical or electrical risk if mishandled.

Remote control systems also enable greater precision in tight spaces, such as when maneuvering around other equipment or navigating crowded recycling areas. In some cases, semi-automated or fully automated systems can be integrated to streamline repetitive tasks, such as loading and unloading battery materials from conveyor systems or disassembly lines.

Corrosion-Resistant and Heavy-Duty Materials

The recycling environment, particularly with the chemicals present in lithium-ion batteries, can be harsh and corrosive. Gantry cranes used in these operations are often made with corrosion-resistant materials, such as stainless steel or specially coated metals, to withstand the effects of chemical exposure. This ensures the long-term durability of the crane and reduces the frequency of maintenance or replacement.

For cranes operating in outdoor environments or near facilities handling large volumes of batteries, weather-resistant features are also included, protecting the crane from the effects of moisture, dust, and temperature fluctuations.

Integrated Safety Monitoring Systems

Many modern gantry cranes for battery recycling come equipped with real-time safety monitoring systems that track the condition and performance of the crane. These systems provide data on load limits, stress levels, and potential mechanical issues, allowing operators to intervene before a failure occurs. By integrating these systems with facility management software, recycling plants can ensure that their cranes are operating safely and efficiently at all times.

Multi-Directional Mobility and Flexibility

Given the diverse layout of recycling facilities, gantry cranes designed for lithium-ion battery recycling often feature multi-directional mobility. This means the crane can move both along fixed tracks and be repositioned as needed to service different areas of the facility. The flexibility provided by rubber-tired or track-mounted systems allows the crane to navigate complex spaces and adapt to different workflows, enhancing overall operational efficiency.

The specialized features of gantry cranes used for lithium-ion battery recycling are designed to meet the specific demands of this critical industry. From safety mechanisms that prevent accidents in hazardous environments to precision control systems that enable delicate handling of valuable battery components, these cranes are essential tools for efficient, safe, and sustainable recycling operations.

double girder gantry crane for sale 5 ton to 550 ton

Specifications for 10 to 25 Tons Gantry Cranes

Load Capacity and Performance

In lithium-ion battery recycling, understanding the load capacity and performance of gantry cranes is crucial. Typical load weights in battery recycling can vary widely, depending on the size and type of batteries being processed. For instance, individual battery packs from electric vehicles can weigh several hundred pounds, while larger assemblies may exceed a ton. Therefore, gantry cranes with capacities ranging from 10 to 25 tons are well-suited for these operations.

When comparing 10, 15, 20, and 25-ton cranes, it's essential to consider not only the weight they can lift but also their operational efficiency. A 10-ton crane may suffice for handling smaller battery modules or components, while a 15-ton crane might be ideal for more significant assemblies. The 20-ton model offers enhanced versatility for varied tasks, including disassembly and material handling. Meanwhile, the 25-ton crane provides the most substantial lifting power, essential for larger batteries or when multiple components need to be moved simultaneously. Each step up in capacity allows for increased flexibility in operations and greater efficiency in material handling.

Design and Build Considerations

When selecting gantry cranes for battery recycling, several design and build considerations come into play to ensure durability and safety. One of the primary factors is the materials used in construction. High-quality steel is commonly used for the crane's frame due to its strength and resistance to deformation under heavy loads. Additionally, components like the hoist and wheels must be engineered to withstand rigorous use, minimizing wear and ensuring reliability.

Customization options are also vital for specific recycling operations. Facilities may require specialized features, such as adjustable height settings to accommodate various loads or enhanced safety mechanisms like overload protection systems. Some operations may benefit from additional accessories, such as lifting slings or attachments designed for specific battery types, enhancing the crane's versatility. Customizable cranes allow recycling facilities to tailor equipment to their unique needs, optimizing efficiency and safety in their processes.

In summary, the specifications of 10 to 25 tons gantry cranes play a significant role in their performance in lithium-ion battery recycling. Understanding load capacities and the importance of robust design ensures that these cranes meet the demanding requirements of the recycling process while maintaining safety and efficiency.

Safety Features in Gantry Cranes

Safety Regulations and Standards

Safety is a paramount concern in any industrial operation, particularly in recycling facilities where heavy lifting and handling hazardous materials occur. There are several applicable industry standards that govern the use of gantry cranes, including the Occupational Safety and Health Administration (OSHA) regulations and the American National Standards Institute (ANSI) guidelines. These standards provide essential guidelines on crane design, operation, and maintenance, ensuring that equipment is safe for use in the workplace.

In the context of compliance requirements for waste management operations, facilities must adhere to specific regulations that address both worker safety and environmental protection. This includes conducting regular inspections and maintenance of the cranes, implementing training programs for operators, and ensuring that all safety features are functional. Compliance with these standards not only protects workers but also minimizes the risk of accidents and liabilities for the facility.

Built-in Safety Mechanisms

To enhance safety during operation, gantry cranes are equipped with several built-in safety mechanisms. One of the most critical features is the emergency stop system. This system allows operators to halt crane operations immediately in case of an emergency, preventing potential accidents or injuries. Emergency stop buttons should be easily accessible from the operator's position, ensuring that quick action can be taken when needed.

Another essential safety feature is the incorporation of anti-collision sensors and alarms. These systems detect obstacles or other equipment in the crane's path, preventing collisions during operation. Alarms can alert operators to potential hazards, allowing them to take corrective action before an incident occurs. Some advanced models even include automated systems that can adjust the crane's movements to avoid collisions, further enhancing operational safety.

In summary, the safety features of gantry cranes are critical to ensuring a secure working environment in lithium-ion battery recycling operations. By adhering to industry regulations and implementing effective safety mechanisms, facilities can significantly reduce the risks associated with heavy lifting and handling of hazardous materials.

Operational Efficiency

Optimizing Crane Usage

Maximizing the operational efficiency of gantry cranes in recycling facilities is essential for maintaining productivity and safety. To optimize crane usage, several best practices can be implemented. First, it’s crucial to ensure that all operators are properly trained in the specific features and capabilities of the crane they will be using. Training should cover safe operating procedures, load handling techniques, and emergency protocols.

Additionally, establishing clear techniques to enhance throughput can significantly improve efficiency. This includes planning the layout of the recycling facility to minimize the distance that loads must be moved. Positioning the gantry crane strategically near high-traffic areas can reduce travel time and facilitate quicker handling of materials. Utilizing effective communication tools, such as radios or hand signals, can also streamline operations, ensuring that all team members are aware of ongoing tasks and can coordinate effectively.

Moreover, implementing a systematic approach to scheduling crane usage can prevent bottlenecks. Designating specific times for routine tasks can help to distribute workloads evenly and reduce idle time. Encouraging teamwork and collaboration among operators can foster a culture of efficiency, further enhancing overall performance in the facility.

Maintenance and Inspection Protocols

To keep gantry cranes operating at peak performance, establishing maintenance and inspection protocols is critical. Regular maintenance schedules should be set up to ensure that all components are functioning correctly and safely. This includes routine checks of the hoist, wheels, and structural integrity of the crane. Lubrication of moving parts and replacement of worn components should be part of a scheduled maintenance plan to prevent unexpected breakdowns.

In addition to scheduled maintenance, operators should be trained to conduct common issues and troubleshooting checks. Awareness of potential problems, such as unusual noises, vibrations, or performance declines, can help identify issues before they escalate. Implementing a logbook for maintenance activities and inspections can track the history of repairs and help identify patterns that may indicate recurring problems.

Finally, establishing a clear protocol for reporting issues or malfunctions is essential. Prompt reporting ensures that any concerns are addressed quickly, reducing downtime and maintaining safety standards. By following rigorous maintenance and inspection protocols, facilities can enhance the longevity and reliability of their gantry cranes, contributing to overall operational efficiency.

Case Studies and Applications

Successful Implementations of Gantry Cranes

The effectiveness of gantry cranes in lithium-ion battery recycling is evident through various successful implementations in leading recycling facilities. For instance, one prominent facility in California integrated a 20-ton gantry crane into its operations to handle the increasing volume of battery recycling. By optimizing the crane's positioning and streamlining workflows, the facility reported a 30% increase in throughput. The crane's flexibility allowed operators to quickly move large battery packs from collection points to processing areas, significantly reducing handling times.

Another example is a facility in Germany that utilized a double girder gantry crane for its disassembly line. This setup enabled the efficient separation of battery components, leading to improved recovery rates of valuable materials. The facility noted that with the enhanced lifting capacity and operational efficiency provided by the gantry crane, they could process 40% more batteries daily, translating to higher overall productivity and profitability.

These case studies highlight that by adopting gantry cranes, recycling facilities can realize substantial operational improvements and efficiency gains. The ability to handle heavier loads safely and swiftly not only enhances productivity but also contributes to a safer working environment, minimizing the risk of injuries and accidents.

Conclusion

In conclusion, the use of 10 to 25 tons gantry cranes in lithium-ion battery recycling offers numerous benefits that significantly enhance operational efficiency and safety. These cranes provide the necessary load capacity to handle the heavy demands of battery processing, facilitating the safe and efficient movement of materials throughout recycling facilities. Their flexibility and mobility allow for quick adjustments to workflows, ultimately leading to increased throughput and productivity.

Moreover, the built-in safety features of gantry cranes, combined with adherence to industry standards, ensure that operations remain compliant and safe for workers. The case studies presented highlight the tangible improvements achieved by facilities that have integrated these cranes into their operations, showcasing their critical role in the recycling process.

As the recycling industry continues to evolve, the importance of selecting the right equipment cannot be overstated. Investing in high-quality gantry cranes tailored to specific operational needs is essential for achieving successful recycling outcomes. By doing so, facilities can not only improve their efficiency and safety but also contribute to a more sustainable future through effective resource recovery and waste management practices.