Overhead Crane with Grab for Sludge Handling, Custom Bridge Crane

Grab overhead crane for sludge handling. Customized double girder bridge crane with grab bucket for sludge handling in sewage treatment plants & others, etc.

Sludge Handling Overhead Cranes:

Sludge handling overhead cranes, also known as sludge cranes or sludge grab cranes, are specialized material handling machines used in sewage treatment plants and other industrial facilities where sludge is generated as a byproduct of the wastewater treatment process. These cranes are designed to efficiently and safely handle sludge, which is a semi-solid material containing solid particles, organic matter, and water.

Key features and characteristics of sludge handling overhead cranes:

- 1. Sludge Grab: The defining feature of sludge handling overhead cranes is the sludge grab or clamshell grab attachment. This specialized grab allows the crane to scoop up sludge from containers, drying beds, or treatment tanks, and securely hold the material during lifting and transport operations.

- 2. Heavy Lifting Capacity: Sludge can be dense and have a high moisture content, making it quite heavy. Sludge handling overhead cranes are designed with high lifting capacities to safely lift and move these heavy loads.

- 3. Precise Control: Sludge handling cranes offer precise control during material handling, allowing operators to open and close the grab smoothly and accurately position it for efficient loading and unloading.

- 4. Corrosion Resistance: Sludge handling cranes are often constructed with materials and coatings that provide corrosion resistance, ensuring their durability and longevity in challenging environments where sludge may contain corrosive substances.

- 5. Environmentally Friendly Features: Some sludge handling cranes may be equipped with additional environmental features, such as dust suppression systems, to minimize the release of airborne particles during handling.

- 6. Safety Features: Safety is of utmost importance when dealing with heavy loads and potentially hazardous materials. Sludge handling cranes are equipped with safety features such as overload protection, emergency stop buttons, and limit switches to prevent accidents and ensure operator safety.

- 7. Adaptable and Flexible: Sludge handling cranes are adaptable to different types of sludge handling tasks within the treatment plant. They may be used for lifting and moving sludge containers, positioning sludge drying beds, or assisting in sludge dewatering processes.

- 8. Supportive Role: While sludge handling overhead cranes are crucial for sludge management, they typically work in conjunction with other equipment and systems in the sewage treatment plant to efficiently handle sludge throughout the treatment process.

The efficient management of sludge is essential for responsible and sustainable sewage treatment. Sludge handling overhead cranes play a critical role in the proper handling and disposal of sludge, contributing to the effectiveness of the treatment plant and meeting environmental compliance standards. These specialized cranes ensure that sludge is handled efficiently, reducing manual labor, optimizing the treatment process, and supporting the overall goals of sewage treatment plants for clean water discharge and environmental protection.

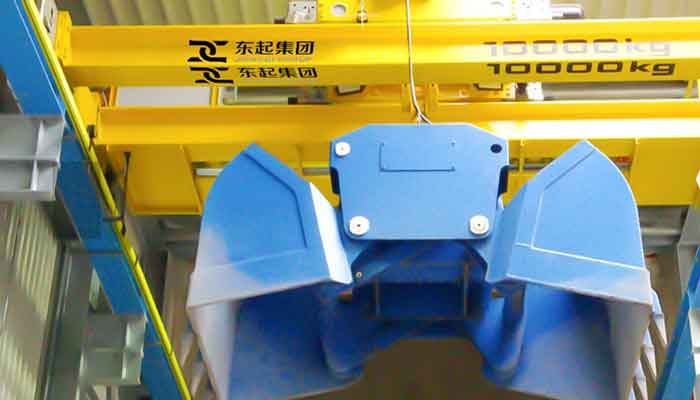

Sludge handling grab bucket

The type of grab used on a sludge handling overhead crane is typically a sludge grab or clamshell grab. These specialized grabs are designed to efficiently and securely handle sludge, which is a semi-solid material with high moisture content and varying consistency. The sludge grab is an essential attachment for the crane, allowing it to grasp and hold the sludge during lifting and transport operations.

Key features of a sludge grab for a sludge handling overhead crane:

- 1. Clamshell Design: The sludge grab is typically of a clamshell design, resembling two hinged shells or buckets that open and close. This design allows the grab to scoop up sludge from a container or sludge drying bed and then close to securely hold the material during lifting.

- 2. Robust Construction: Sludge grabs are built with durable materials, such as high-strength steel, to withstand the abrasive nature of sludge and resist corrosion from the chemicals present in wastewater treatment processes.

- 3. Enhanced Sealing: To prevent sludge from leaking out during handling, sludge grabs often have enhanced sealing features, such as rubber gaskets or reinforced edges, to create a tight seal when the grab is closed.

- 4. Teeth or Cutting Edges: Some sludge grabs are equipped with teeth or cutting edges on the bucket's leading edge to help penetrate and break apart dense or compacted sludge for easier lifting.

- 5. Large Capacity: Sludge grabs have a relatively large capacity to handle significant amounts of sludge in one grab, minimizing the number of lifts required for efficient material handling.

- 6. Precise Control: The sludge grab is designed for precise control during operation, allowing the crane operator to open and close the grab smoothly and accurately position it for efficient loading and unloading.

- 7. Easy Maintenance: Sludge grabs are designed with accessibility in mind, making it easier for maintenance personnel to inspect, clean, and service the grab when needed.

- The use of a dedicated sludge grab on a sludge handling overhead crane ensures efficient and safe handling of sludge, contributing to the overall effectiveness of the sewage treatment process. The grab's design and capabilities are tailored to the unique challenges of handling sludge, making it an essential tool in sewage treatment plants and other industrial facilities where sludge is generated.

Double girder overhead crane with grab bucket for sale for efficient sluding handling

Double girder overhead crane with grab bucket for sale for efficient sluding handling

Applications of sludge handling overhead cranes

Sludge handling overhead cranes have various applications in sewage treatment plants and other industrial settings where sludge is generated as a byproduct of the wastewater treatment process. These specialized cranes are designed to efficiently and safely handle sludge, which is a semi-solid material with high moisture content and varying consistency. Some of the key applications of sludge handling overhead cranes include:

- 1. Sludge Transfer and Transport: Sludge handling cranes are used to lift and transport sludge from various treatment stages to different areas within the treatment plant. They can move sludge from collection points to drying beds, sludge thickeners, or sludge digesters.

- 2. Loading and Unloading Sludge Containers: Sludge is often collected and stored in large containers or bins. Sludge handling cranes are used to lift and unload these containers, positioning them at the appropriate treatment or storage locations.

- 3. Sludge Dewatering Processes: Some treatment plants use sludge dewatering equipment, such as belt filter presses or centrifuges, to reduce the moisture content of sludge. Sludge handling cranes assist in handling and positioning the sludge for dewatering.

- 4. Sludge Drying Beds: Sludge handling cranes are used to load and unload sludge onto drying beds where the material is allowed to dry and reduce its moisture content.

- 5. Sludge Digesters: In larger sewage treatment plants, sludge may be treated in anaerobic digesters to break down organic matter. Sludge handling cranes are used to manage the feeding and removal of sludge from the digesters.

- 6. Sludge Mixing and Aeration: Sludge handling cranes may be used to position mixers or aeration equipment within treatment tanks to facilitate biological treatment processes.

- 7. Sludge Disposal: Once sludge has been treated or concentrated to meet specific standards, sludge handling cranes are used to load the sludge into trucks for transportation to dedicated sludge treatment or disposal facilities.

- 8. Maintenance and Cleaning: Sludge handling cranes are also used for maintenance and cleaning activities within sludge handling areas. They can lift and remove components or parts for repair or replacement, ensuring the reliable operation of sludge handling equipment.

- 9. Sludge Transfer Stations: In larger treatment plants, sludge handling cranes may be used in sludge transfer stations where sludge from different parts of the treatment plant is collected and transported to central storage or disposal areas.

- 10. Other Material Handling Tasks: While primarily used for sludge handling, these cranes may also assist in handling other materials, such as equipment and tools used in sewage treatment processes.

Overall, sludge handling overhead cranes play a critical role in sewage treatment plants, helping to efficiently manage sludge throughout the treatment process and ensuring compliance with environmental regulations for responsible sludge handling and disposal.