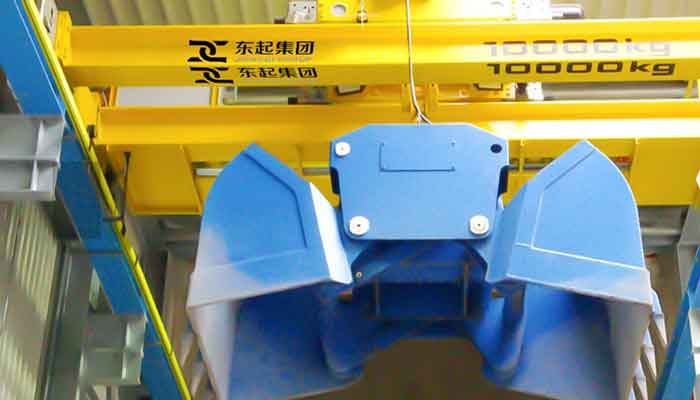

Cement Bucket Grab Overhead Cranes 1 Ton to 80 Ton for Sale

Cement Bucket Grab Overhead Cranes 1 Ton to 80 Ton for Sale

A cement bucket grab overhead crane efficiently handles and transports bulk cement, enhancing productivity and safety in construction and manufacturing.

Cement bucket grab overhead cranes are specialized lifting devices designed to handle and transport bulk materials like cement, sand, and gravel in construction and industrial settings. These cranes feature a bucket or grab mechanism that can securely hold and release heavy loads, making them essential for efficient material handling.

In the construction and cement industry, timely and safe material handling is crucial. Cement bucket grab overhead cranes play a vital role in streamlining operations by facilitating the quick movement of bulk materials from storage areas to mixing stations or directly to construction sites. Their ability to lift heavy loads minimizes manual labor and reduces the risk of accidents, thereby enhancing productivity and safety on job sites. Moreover, these cranes help optimize workflow, ensuring that materials are available when needed, which is essential for meeting project deadlines.

Cement bucket grab overhead cranes come equipped with several key features that enhance their performance. These include:

- Durable Construction: Built from robust materials, these cranes are designed to withstand the harsh conditions often found in construction environments.

- High Load Capacity: They can handle significant weights, making them suitable for transporting large volumes of cement and other materials.

- Precision Control: Operators can maneuver the crane with precision, allowing for accurate placement of materials and reducing waste.

- Versatile Operation: Many models offer various operational modes, including automatic and manual controls, to adapt to different tasks.

- Safety Features: Equipped with safety mechanisms such as overload protection and emergency stop functions, these cranes ensure safe operation in busy work environments.

By integrating these features, cement bucket grab overhead cranes significantly improve the efficiency and safety of material handling in the construction and cement industries.

double girder grab bucket overhead cranes for sale

Load Types

Types of Cement

Powdered Cement

- Characteristics: Powdered cement, commonly known as Portland cement, is a fine, gray powder that hardens when mixed with water. It is the primary ingredient in concrete and mortar, known for its strength and durability. Powdered cement is highly reactive, which means it can set quickly when exposed to moisture.

- Handling Requirements: Due to its fine particle size, powdered cement can be prone to dust generation during handling. This necessitates the use of enclosed systems or dust suppression measures to maintain a safe work environment. The handling equipment must be designed to prevent spillage and ensure efficient loading and unloading. Cement bucket grabs should have smooth edges and sealing mechanisms to minimize dust release.

Granular Cement

- Characteristics: Granular cement consists of larger particles compared to powdered cement, often resembling sand or fine gravel. This type of cement may include additives that enhance specific properties, such as workability or setting time. Granular cement is often used in applications where a coarser texture is beneficial.

- Handling Requirements: Handling granular cement requires equipment that can manage bulk materials effectively. The cranes and buckets used should have larger openings to accommodate the coarser texture and allow for efficient flow. Additionally, because granular cement can settle and compact, it's important to ensure that the handling system allows for easy discharge without clogging.

Other Materials

Additives and Aggregates

- Additives such as plasticizers, accelerators, and retarders are often mixed with cement to enhance performance characteristics. Aggregates, which include sand, gravel, and crushed stone, are also crucial for creating concrete. These materials vary in size and composition, requiring careful handling to prevent segregation and ensure a uniform mix.

- The handling of additives and aggregates often involves separate storage and transport systems to maintain their integrity. Cranes and bucket grabs must be versatile enough to accommodate different materials without contamination.

Compatibility with Other Bulk Materials

- Cement and its additives must be compatible with other bulk materials used in construction, such as aggregates and chemical admixtures. Proper compatibility ensures optimal performance of the final concrete mix. When handling multiple materials, it is essential to use cranes and buckets that can be easily cleaned or are designed to minimize cross-contamination.

- Additionally, the handling systems should be adaptable to various material types, allowing for efficient transitions between different loads. This flexibility is crucial in construction environments where multiple materials are processed simultaneously.

Design Features

Structure of the Bucket Grab

- Material Construction: Cement bucket grabs are typically constructed from high-strength steel or other durable materials to withstand the heavy loads and harsh conditions of construction environments. The choice of material ensures longevity and resistance to wear and tear, which is essential for maintaining operational efficiency. Some models may also incorporate corrosion-resistant coatings to protect against moisture and chemical exposure.

- Dimensions and Capacity: The dimensions of the bucket grab are designed to accommodate various load sizes, with capacities ranging from a few hundred kilograms to several tons. The design must balance size and weight, ensuring that the grab can lift heavy loads without compromising the crane's stability. Custom sizes can be developed to meet specific project requirements, allowing for flexibility in handling different materials.

Sealing Mechanism

- Purpose of Preventing Dust Leakage: - A key feature of cement bucket grabs is their sealing mechanism, which is crucial for preventing dust leakage during transport. This is important not only for maintaining a clean work environment but also for complying with safety regulations. Dust can pose health risks to workers and can also affect the quality of the materials being handled.

- Types of Sealing Mechanisms Used: - Various sealing mechanisms may be employed, including rubber gaskets, flaps, or sliding doors that close tightly when the bucket is in a closed position. These mechanisms ensure that the contents remain secure and minimize dust emissions, enhancing both safety and efficiency during operation.

Interior Design

- Smooth Surfaces for Easy Flow: - The interior of the bucket grab is designed with smooth surfaces to facilitate the easy flow of materials. This design reduces friction and prevents material buildup, ensuring that the contents can be discharged quickly and efficiently. Smooth interiors also make cleaning easier, which is vital for maintaining the integrity of the materials being handled.

- Shape and Configuration for Optimal Loading/Unloading: - The shape and configuration of the bucket grab are engineered to optimize loading and unloading processes. A tapered design can help guide materials into the bucket more easily, while a wide opening allows for quick discharge. The overall design aims to minimize the time spent on each load cycle, thereby improving productivity on the job site.

Safety Features

- Load Sensors:Load sensors are integrated into the crane system to monitor the weight of the materials being lifted. These sensors provide real-time feedback to operators, helping to prevent overloading and ensuring safe operation. By alerting the operator to any potential overload conditions, these sensors play a critical role in maintaining safety standards.

- Emergency Stop Mechanisms:Emergency stop mechanisms are essential for ensuring the safety of personnel and equipment. These systems allow operators to quickly halt operation in case of an emergency, preventing accidents and potential injuries. Emergency stops can be activated from multiple locations, providing flexibility and immediate response capabilities in critical situations.

Applications

Construction Sites

- Role in Transporting Cement to Various Locations: Cement bucket grabs are crucial on construction sites for efficiently transporting cement from storage areas to mixing stations or directly to where it is needed. Their ability to lift and move heavy loads quickly helps maintain a steady supply of materials, which is essential for keeping projects on schedule. This mobility allows for flexibility in operations, as the grabs can reach different parts of the site without the need for multiple handling systems.

- Efficiency in Managing Large Volumes: These cranes significantly enhance the efficiency of managing large volumes of cement and other bulk materials. By using cement bucket grabs, construction teams can minimize downtime and reduce the manual labor required for material handling. This efficiency leads to faster project completion times and helps control costs by reducing labor expenses and material waste.

Cement Plants

- Integration in Production Lines: In cement plants, bucket grabs are integrated into production lines to facilitate the movement of raw materials such as limestone, clay, and additives. They play a vital role in the continuous flow of materials needed for cement production, ensuring that the manufacturing process runs smoothly. Their ability to handle bulk materials efficiently helps optimize the overall production cycle.

- Importance in Bulk Handling of Raw Materials: Cement bucket grabs are essential for bulk handling operations within cement plants. They allow for the rapid loading and unloading of materials from trucks or storage silos, reducing the time and labor involved in these processes. This capability is critical for maintaining high production rates and ensuring that raw materials are always available for processing.

Bulk Storage Facilities

- Managing Inventory and Distribution: In bulk storage facilities, cement bucket grabs are used to manage inventory effectively. They enable operators to load and unload large quantities of cement and other materials quickly, facilitating efficient distribution to various locations. This capability helps maintain accurate inventory levels and ensures that materials are readily available for delivery or further processing.

- Automation and Operational Efficiency: Many bulk storage facilities are increasingly adopting automation technologies, and cement bucket grabs can be integrated into automated systems to enhance operational efficiency. Automated grabs can operate with minimal human intervention, allowing for faster and more precise handling of materials. This automation reduces the risk of human error, increases safety, and maximizes throughput, ultimately leading to improved productivity in material handling operations.

Customized Options for Different Loads Handling

Cement grab bucket cranes are designed with various features tailored to handle different loads and objects efficiently. The specific features can vary based on the type of material being handled, the operational environment, and the crane's intended use. Here are some common features for different types of cement grab bucket cranes:

Bucket Design

Shape and Size: Buckets can be designed in various shapes (e.g., rectangular, trapezoidal) and sizes to accommodate different volumes and types of cement or bulk materials.

Capacity: Different buckets have varying capacities to handle small, medium, or large loads, ensuring optimal performance based on the specific application.

Opening Mechanism

Clamshell Design: Commonly used for handling loose materials like cement, clamshell buckets can open and close to scoop up and release materials effectively.

Single or Double Acting: Some grabs operate with a single acting mechanism (one hydraulic cylinder) while others use double acting (two cylinders) for better control over the opening and closing actions.

Material Composition

High-Wear Resistant Materials: Buckets may be constructed from high-strength steel or wear-resistant alloys to withstand the abrasion caused by handling cement and other abrasive materials.

Corrosion Resistance: In environments where moisture is present, buckets may be coated or constructed from corrosion-resistant materials to prolong lifespan.

Weight Distribution and Center of Gravity

Counterweights: Some cranes are equipped with adjustable counterweights to maintain stability when handling heavy loads or when the load is unevenly distributed.

Design for Load Balance: Features that ensure proper weight distribution help prevent tipping or swaying during operation.

Hydraulic Systems

Variable Speed Controls: Advanced hydraulic systems allow for variable speed controls during the opening and closing of the grab, providing better precision in handling different loads.

Pressure Sensors: Some cranes are equipped with pressure sensors to monitor load weight and prevent overloading, enhancing safety.

Operational Controls

Remote Control Systems: Many modern cranes offer remote control capabilities, allowing operators to maneuver the crane from a safe distance, which is particularly useful when handling hazardous or heavy loads.

Automated Controls: Automated systems can optimize the handling process, reducing the need for manual intervention and increasing efficiency.

Safety Features

Load Limit Indicators: These indicators alert operators when the load exceeds the safe working limit, preventing potential accidents.

Emergency Stop Mechanisms: Safety systems that allow for immediate shutdown in case of malfunction or emergency situations.

Adaptability and Versatility

Interchangeable Buckets: Some cranes are designed to accommodate interchangeable buckets for handling different materials, such as aggregates, sand, or other bulk materials, in addition to cement.

Modular Designs: Modular designs allow for easy upgrades or modifications to adapt to specific handling requirements or to enhance capabilities.

Environmental Considerations

Dust Control Features: Buckets may include features designed to minimize dust generation during operation, such as sealed edges or dust suppression systems.

Temperature Resistance: For handling heated materials or operating in high-temperature environments, buckets may be designed to withstand elevated temperatures.

These features collectively enhance the functionality and safety of cement grab bucket cranes, making them suitable for a wide range of applications in the construction and cement industries. By selecting the appropriate features based on the specific handling requirements, operators can optimize performance and efficiency.

Operational Considerations

Training and Safety Protocols

Operator Training Requirements: Proper training for operators is essential to ensure safe and efficient use of cement bucket grabs. Operators should undergo comprehensive training programs that cover the following:Equipment Familiarization: Understanding the specific features and functions of the bucket grab.

- Load Handling Techniques: Learning safe practices for loading, lifting, and unloading materials to prevent accidents and damage.

- Emergency Procedures: Training on how to respond to emergencies, including using emergency stop mechanisms and handling equipment failures.

- Health and Safety Regulations: Familiarity with relevant safety regulations and best practices to minimize risks associated with dust and heavy lifting.

Safety Measures During Operation: Implementing safety measures is crucial for protecting operators and personnel in the vicinity. Key safety measures include:Personal Protective Equipment (PPE): Ensuring operators wear appropriate PPE, such as hard hats, gloves, safety goggles, and respiratory protection to mitigate dust exposure.

- Pre-Operation Checks: Conducting thorough inspections of the bucket grab before use to identify any potential issues.

- Clear Communication: Establishing clear communication protocols among team members to coordinate operations and alert personnel of any hazards.

- Designated Work Zones: Creating designated areas for operation to keep non-essential personnel at a safe distance from the lifting activities.

Maintenance and Inspection

Regular Maintenance Schedules: To ensure the longevity and reliability of cement bucket grabs, a regular maintenance schedule should be established. This schedule typically includes:Daily Inspections: Checking for visible wear, damage, or loose components before each use.

- Weekly Maintenance: Lubricating moving parts, inspecting seals and gaskets, and ensuring that all safety mechanisms are functional.

- Monthly and Annual Checks: Conducting more thorough inspections that may involve checking structural integrity, load sensors, and electrical systems. These inspections can help identify potential issues before they lead to equipment failure.

Common Issues and Solutions: Several common issues may arise with cement bucket grabs, along with their solutions:Wear and Tear: Over time, the edges of the bucket can become worn due to abrasive materials. Regularly inspect and replace worn components to maintain efficiency.

- Dust Leakage: If dust leakage occurs, check the integrity of sealing mechanisms. Replace damaged gaskets or seals to prevent further leakage.

- Hydraulic Failures: Hydraulic systems may experience leaks or loss of pressure. Regularly inspect hydraulic lines and connections, and replace any damaged components.

- Electrical Malfunctions: Issues with load sensors or control systems can disrupt operation. Conduct routine checks of electrical systems and ensure that connections are secure and free from corrosion.

By adhering to proper training, safety protocols, and maintenance practices, operators can ensure safe and efficient operation of cement bucket grabs, ultimately contributing to the overall success of material handling operations.

Conclusion

Cement bucket grab overhead cranes play a vital role in the construction and cement industries by facilitating the efficient handling and transportation of bulk materials. Their robust design and specialized features enable them to manage heavy loads while minimizing dust leakage and ensuring safety on job sites. The combination of their structural integrity, operational efficiency, and adaptability makes them indispensable tools for managing the complexities of material handling in various applications, from construction sites to cement plants and bulk storage facilities.

Cement bucket grab overhead cranes are essential for enhancing productivity in the cement industry. By streamlining the handling and transportation of bulk materials, they contribute to faster project completion times and improved operational efficiency. As the industry adapts to new challenges and technological advancements, the continued evolution of these cranes will further optimize material handling processes, ultimately driving growth and sustainability in the cement sector. Their role in ensuring safe, reliable, and efficient operations cannot be overstated, making them a critical component of modern cement production and construction practices.

References

Industry Standards and Regulations

- Occupational Safety and Health Administration (OSHA) Standards:OSHA regulations provide guidelines for safe operation and maintenance of cranes and material handling equipment, including cement bucket grabs. Specific standards can be found in OSHA's 29 CFR Part 1910 and Part 192

- American National Standards Institute (ANSI):ANSI B30.2: "Overhead and Gantry Cranes" outlines safety standards for the design, construction, and operation of overhead cranes, including those used for handling cement.

- International Organization for Standardization (ISO):ISO 4301-1: "Cranes – Classification" provides a classification system for cranes, including overhead cranes, which helps ensure compliance with safety and operational standards.