Floor Operated Crane for Sale, Easy Operated Overhead Cranes

Floor operated crane for sale, economical floor operated overhead cranes. Check Yuantai Crane's floor operated cranes for high precision & safety.

In the world of heavy-duty lifting and industrial excellence, a groundbreaking innovation has reshaped the landscape of handling massive loads and streamlining operations. Enter the realm of Yuantai Crane's floor-operated cranes – the unsung heroes that bring precision, safety, and efficiency to various industries. Embarking on this journey, we'll closely examine these mechanical marvels within the Yuantai Crane family, gaining insights into their significance across diverse sectors and uncovering the reasons behind their surging popularity.

Defining Yuantai Floor-Operated Crane

Imagine a crane that operates with the operator's feet planted firmly on the ground, yet holds the power to hoist, move, and place heavy materials with precision. Yuantai floor-operated cranes, as the name suggests, are a category of cranes that are controlled and maneuvered from the same level as the loa Unlike traditional crane setups that require operators to be stationed in elevated cabs, Yuantai floor-operated cranes empower operators to orchestrate movements while maintaining proximity to the load and their surroundings.

The brilliance of Yuantai floor-operated cranes lies in their versatility. They come in various forms, including overhead cranes that traverse on rails, gantry cranes that straddle wide spaces, and jib cranes that extend from walls or columns. What unites them is the ability to provide operators with a front-row seat to the action, enhancing safety, efficiency, and control.

The Pivotal Role of Crane Operations Across Industries

Cranes are the backbone of industries that deal with heavy materials, intricate assembly, and efficient material handling. From manufacturing plants that create massive machinery to construction sites that raise skyscrapers, the importance of cranes cannot be overstate Consider the task of moving tons of raw materials within a factory or positioning large components for assembly – these tasks demand precision, strength, and above all, safety.

In the realm of manufacturing, Yuantai floor-operated cranes enable operators to oversee the movement of materials and parts, ensuring seamless workflow and minimizing the risk of accidents. Construction sites, often characterized by their dynamic and evolving environments, benefit from the agility of Yuantai floor-operated cranes, allowing operators to adapt to changing conditions swiftly. Warehouses and distribution centers, where efficient storage and retrieval of goods are paramount, leverage these cranes to streamline operations and optimize spac

Unveiling the Purpose of Yuantai Floor-Operated Cranes

At the heart of the popularity of Yuantai floor-operated cranes lies their purpose – to bridge the gap between power and precision. These cranes offer a range of advantages that make them indispensable assets across industries. The proximity of operators to the load enhances visibility, enabling them to make informed decisions while maneuvering heavy objects. The intuitive controls of Yuantai floor-operated cranes translate to quicker training and reduced learning curves for operators.

Flexibility in operator positioning is another key advantag Operators can easily adjust their position relative to the load, responding promptly to changing requirements on the groun Additionally, the reduced need for dedicated operator cabs or control rooms translates to cost savings and efficient use of spac

In the next segments of this exploration, we'll delve deeper into the types of Yuantai floor-operated cranes, explore their intricate control systems, and discuss their applications in various industries. Join us as we uncover the inner workings and undeniable benefits of these ground-level giants.

Types of Yuantai Floor-Operated Cranes

When it comes to heavy lifting and efficient material handling, Yuantai floor-operated cranes offer a diverse range of configurations, each tailored to specific needs and environments. Let's explore the various types of floor-operated cranes by Yuantai that have become the workhorses of modern industry.

Overhead Cranes

Single Girder Overhead Cranes:

Yuantai's single girder floor operated overhead cranes are characterized by their simplicity and cost-effectiveness. They consist of a single horizontal beam (girder) that spans the width of the workspace, supported by end trucks on either sid These cranes are ideal for moderate lifting tasks and environments with limited headroom. Single girder overhead cranes are well-suited for manufacturing facilities, warehouses, and assembly lines where precision and efficiency are paramount.

Double Girder Overhead Cranes:

Yuantai's double girder floor operated overhead cranes offer enhanced lifting capacity and versatility. They feature two horizontal girders that provide increased stability and load-bearing capacity. These cranes are well-equipped to handle heavy loads and longer spans, making them suitable for industries that demand robust lifting solutions. Double girder overhead cranes find applications in steel mills, foundries, and construction sites where heavy materials need to be moved with precision.

Gantry Cranes

Rail-Mounted Gantry Cranes:

Rail-mounted gantry cranes, often referred to as RMGs, are commonly used in container terminals and shipping yards. These cranes run on tracks embedded in the ground, enabling them to efficiently move along the length of the storage are RMGs are capable of stacking containers vertically, optimizing space utilization and streamlining container handling operations.

Rubber-Tired Gantry Cranes:

Yuantai's rubber-tired gantry cranes, or RTGs, offer the advantage of mobility and flexibility. These cranes are equipped with rubber tires and are capable of moving around on paved surfaces within terminals and yards. RTGs are known for their agility and speed in handling containers and other heavy loads. Their ability to navigate through various terrains makes them a valuable asset in container handling and logistics operations.

Jib Cranes

Wall-Mounted Jib Cranes:

Yuantai's wall-mounted jib cranes are fixtures attached to walls or columns, allowing for precise lifting and positioning within a limited are These cranes are excellent for workstations where materials need to be maneuvered within a specific radius. Wall-mounted jib cranes are often found in workshops, manufacturing cells, and maintenance facilities.

Freestanding Jib Cranes:

Yuantai's freestanding jib cranes are independent structures with a vertical post or column that supports a horizontal jib arm. These cranes offer a greater range of movement compared to wall-mounted jib cranes. Freestanding jib cranes are commonly used in outdoor environments, loading docks, and areas where overhead space is limite

These diverse types of floor-operated cranes by Yuantai cater to a wide spectrum of industrial needs, providing solutions that range from delicate precision to heavy-duty lifting. As we delve further into our exploration, we'll uncover the intricate control systems that empower operators to orchestrate these mechanical giants with finesse and accuracy.

Features and Components

In the intricate world of floor-operated cranes, the seamless orchestration of movements is made possible by a combination of finely engineered features and components. These elements come together to transform these mechanical giants into versatile tools capable of tackling a wide array of lifting challenges.

Control Panel: The Nerve Center of Precision

Functions and Buttons:

The control panel of a Yuantai floor-operated crane serves as the nerve center, enabling operators to execute precise movements. Rows of buttons and switches allow operators to control crane motions including hoisting, trolley movement, and bridge traversal. Emergency stop buttons provide an instant way to halt operations in critical situations, ensuring safety remains paramount.

Remote Control Options:

The advent of technology has brought about the evolution of crane control systems. Remote control options, including handheld transmitters or radio frequency devices, offer operators the freedom to maneuver the crane from a distanc This enhanced flexibility is particularly valuable in scenarios where visibility and safety are priorities.

Hoist Mechanism: Lifting Power in Motion

Wire Rope Hoists:

Yuantai's wire rope hoists are versatile and commonly used for various lifting applications. They utilize a system of wire ropes wound around a drum to lift heavy loads with precision. Wire rope hoists are known for their durability, resistance to wear, and smooth lifting motions.

Chain Hoists:

Yuantai's chain hoists employ a chain loop to lift loads. They are compact, reliable, and capable of handling a broad range of weights. Chain hoists are often favored for their simplicity and ease of maintenanc

Trolley System: Seamless Movement Across the Span

Manual Trolley:

Yuantai's manual trolley systems allow operators to move the crane horizontally along the beam manually. These systems are straightforward and require physical effort from operators. They are commonly used in scenarios with lighter loads and limited horizontal travel.

Electric Trolley:

Yuantai's electric trolley systems enhance operator convenience by enabling motorized horizontal movement. Operators can control the trolley's position from the control panel, facilitating smoother and more precise load positioning.

Lifting Mechanism: Precision Placement

Hook Block:

The hook block is the primary attachment for lifting loads. It consists of a hook suspended from a pulley system. Operators can attach various lifting accessories to the hook block, allowing for precise positioning and secure attachment of loads.

Grab Bucket (for specific applications):

In applications that involve bulk material handling, such as in mining or construction, grab buckets are use These specialized attachments allow the crane to grip and release bulk materials like sand, gravel, or debris.

Load Capacity and Specifications: Engineering Excellence

The load capacity of a Yuantai floor-operated crane depends on its design and components. Manufacturers specify the maximum weight a crane can safely lift and mov This information guides operators in making informed decisions about load management and ensures that operations remain within safe parameters.

As we venture deeper into the realm of floor-operated cranes, we'll explore the advantages they offer, their real-world applications, and the vital role they play in shaping the efficiency and safety of industries worldwid

Advantages of Yuantai Floor-Operated Cranes

In the dynamic landscape of industrial operations, the utilization of Yuantai floor-operated cranes has ushered in a new era of efficiency, safety, and precision. These mechanical marvels come with a host of advantages that make them indispensable assets across various sectors. Let's explore the key advantages that have positioned Yuantai floor-operated cranes at the forefront of modern lifting solutions.

Improved Visibility and Line of Sight

One of the standout features of Yuantai floor-operated cranes is the direct line of sight they offer to operators. Unlike traditional cranes that require operators to peer down from elevated cabs, Yuantai floor-operated cranes keep operators at ground level, enabling them to maintain an unobstructed view of the load, the surroundings, and potential obstacles. This heightened visibility translates to enhanced accuracy in load positioning, minimizing the risk of collisions and accidents.

Ease of Operation and Control

The intuitive nature of Yuantai floor-operated crane controls plays a pivotal role in their widespread adoption. Operators can quickly grasp the functions of buttons, switches, and levers, enabling them to operate the crane with confidenc This ease of operation not only reduces the learning curve for new operators but also contributes to faster task execution and seamless coordination of movements.

Flexibility in Operator Positioning

Yuantai floor-operated cranes empower operators with the flexibility to move around the crane and the load as neede This adaptability is particularly valuable in scenarios where the load needs to be accurately positioned in confined spaces or where obstacles need to be navigate The ability to position oneself in close proximity to the load fosters a hands-on approach to crane operations, resulting in increased control and efficiency.

Enhanced Safety and Communication

Safety is paramount in industrial environments, and Yuantai floor-operated cranes contribute significantly to creating a secure workspac Operators' presence at ground level facilitates direct communication with ground personnel, enabling them to relay instructions and receive real-time feedback. The reduced distance between operators and the ground also enables quicker response to emergencies, as operators are closer to emergency stop buttons and can take immediate action if neede

Reduced Infrastructure Requirements

Unlike traditional cranes that often require the construction of operator cabs or control rooms at elevated heights, Yuantai floor-operated cranes have reduced infrastructure demands. This translates to cost savings and efficient space utilization. The absence of dedicated cabs also means that operators are more integrated with the work environment, fostering better communication and collaboration with colleagues.

The advantages presented by Yuantai floor-operated cranes extend their influence across industries, from manufacturing and construction to logistics and heavy equipment maintenanc As we continue our exploration, we'll delve into the diverse applications that harness these advantages to streamline operations and elevate industrial efficiency.

Applications of Yuantai Floor-Operated Cranes

Yuantai floor-operated cranes, with their unique features and advantages, find their niche across a wide spectrum of industries, transforming the way heavy lifting and material handling are accomplishe Let's explore how these versatile mechanical giants play a crucial role in various industrial landscapes.

Manufacturing Industries: Precision at the Heart

In manufacturing plants, where precision and efficiency are paramount, Yuantai floor-operated cranes rise to the occasion. They enable operators to effortlessly move heavy components, position intricate machinery, and facilitate seamless assembly processes. Whether it's lifting raw materials, positioning large workpieces, or aiding in complex manufacturing operations, these cranes ensure that the manufacturing floor operates like a well-oiled machin

Construction Sites: Building the Future

The dynamic and evolving environment of construction sites demands flexible and adaptable lifting solutions. Yuantai floor-operated cranes step up to the challenge by providing operators with the tools to move heavy materials, transport equipment, and assist in erecting structures. Their ability to navigate tight spaces and handle various load types makes them indispensable assets in shaping the skylines of cities around the worl

Warehouses and Distribution Centers: Efficient Storage and Retrieval

In the realm of logistics, Yuantai floor-operated cranes contribute to the smooth operation of warehouses and distribution centers. They play a vital role in stacking, organizing, and retrieving goods from shelves and storage racks. With their agility and precision, these cranes optimize space utilization, reduce handling times, and ensure timely delivery of products to end customers.

Shipping Yards and Ports: Managing Cargo with Finesse

Shipping yards and ports form the backbone of global trade, and the efficiency of cargo handling is of utmost importanc Yuantai floor-operated cranes, whether rail-mounted or rubber-tired gantry cranes, excel in the management of shipping containers. They facilitate the loading and unloading of vessels, arrange containers in precise stacks, and contribute to the rapid turnover of cargo, ensuring that goods reach their destinations efficiently.

Heavy Equipment Maintenance: Keeping Operations Running

Maintaining heavy equipment, whether in construction, mining, or industrial plants, requires careful handling and precise positioning. Yuantai floor-operated cranes provide the necessary lifting power to hoist heavy machinery and components, allowing maintenance teams to carry out repairs, inspections, and replacements with accuracy. These cranes contribute to minimizing downtime and maximizing operational uptim

The applications of Yuantai floor-operated cranes extend beyond these sectors, permeating industries that rely on the efficient movement of heavy loads. As we venture further, we'll explore the diverse control options that empower operators to orchestrate these cranes with finesse and navigate them through complex operational landscapes.

Safety Considerations

In the realm of industrial operations, safety stands as a cornerstone that cannot be compromise Yuantai floor-operated cranes, despite their efficiency and capabilities, must be operated with a steadfast commitment to safety. Let's delve into the essential safety considerations that ensure the well-being of operators, equipment, and the entire work environment.

Operator Training and Certification: The First Line of Defense

The skill and competence of crane operators are paramount to safe operations. Proper training and certification ensure that operators are well-versed in crane controls, maneuvers, emergency procedures, and load management. Ongoing training keeps operators updated with best practices, safety regulations, and the latest technological advancements, equipping them to handle the complexities of crane operations with confidenc

Load Capacity Awareness: Staying Within Safe Limits

One of the cardinal rules in crane operation is respecting load capacity limits. Operators must be acutely aware of the crane's rated load capacity and never exceed it. Overloading a crane can lead to catastrophic failure, endangering personnel and property. It's imperative to consider not only the weight of the load but also its size, shape, and potential dynamic forces during lifting and movement.

Adherence to Safety Protocols: Operating by the Book

Safety protocols and procedures are in place to prevent accidents and ensure the consistent application of safe practices. Operators must adhere to established protocols, including proper rigging techniques, load securing, and communication procedures. Regular safety briefings and toolbox talks foster a safety-conscious mindset among the entire team, promoting a culture of responsibility and accountability.

Regular Maintenance and Inspections: Ensuring Mechanical Integrity

A well-maintained crane is a safe cran Regular maintenance and inspections are crucial to identifying potential issues before they escalat Components such as wire ropes, chains, brakes, and electrical systems require routine checks to detect wear, corrosion, or malfunction. Prompt repairs and proactive maintenance contribute to the longevity and reliability of the crane while minimizing the risk of accidents.

As we continue to marvel at the capabilities of Yuantai floor-operated cranes, let's remember that their power must be harnessed within a framework of unwavering commitment to safety. By embracing these considerations, industries can ensure that these cranes remain steadfast allies in the pursuit of efficient and secure operations.

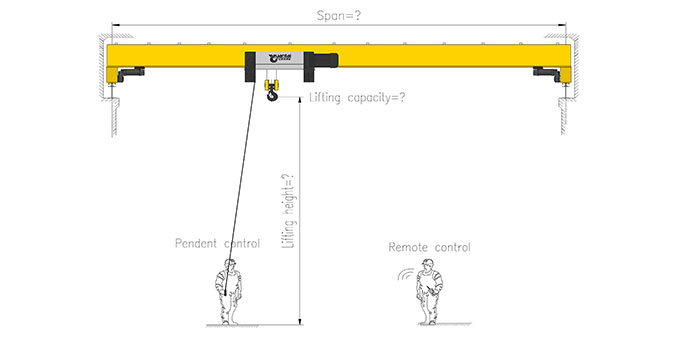

Floor operated crane main specification needed for quotation

Factors Influencing Selection

Selecting the right Yuantai floor-operated crane for a specific application involves careful consideration of several factors. From the nature of the loads to be lifted to the available budget, these elements play a pivotal role in determining the optimal crane solution. Let's explore the key factors that guide the selection process and ensure that the chosen crane aligns with operational needs.

Types of Loads to Be Lifted: Tailoring the Crane to the Task

The diversity of loads within an industry necessitates a crane that can handle various weights, sizes, and shapes. Different types of cranes are suited for specific load profiles. For instance, single girder overhead cranes may be ideal for lighter loads, while double girder overhead cranes excel in handling heavier materials. Understanding the characteristics of the loads to be lifted allows for a crane selection that aligns with lifting requirements.

Available Space and Layout: Maximizing Utilization

The spatial configuration of the operational area influences the choice of crane design. Overhead cranes are optimal when vertical space is abundant, while gantry cranes prove advantageous in wide and open spaces. The crane's footprint, travel path, and clearance requirements must harmonize with the available space to ensure seamless movement and efficient material handling.

Operational Environment and Conditions: Adapting to Challenges

The environment in which the crane will operate is a critical consideration. Factors such as temperature extremes, humidity, exposure to corrosive agents, and outdoor use impact the choice of materials, coatings, and design features. Crane manufacturers offer options that cater to different environmental conditions, ensuring the crane's durability and longevity.

Lifting Height and Span: Reaching New Heights

The lifting height and span determine the crane's reach and coverage are Different types of cranes have varying capabilities when it comes to lifting height and span. It's essential to choose a crane with the appropriate lifting height and span to ensure that it can effectively maneuver loads within the desired operational rang

Operator Experience and Training: Ensuring Competence

The proficiency of crane operators is a crucial factor in safe and efficient operations. The complexity of crane controls, load management, and maneuvering demands skilled operators who are well-trained and certifie The chosen crane should align with the experience level of the operators, with more straightforward systems for beginners and more advanced controls for seasoned professionals.

Budget Considerations: Balancing Investment and Returns

Investing in a Yuantai floor-operated crane is an investment in operational efficiency and productivity. While considering budget constraints, it's important to evaluate the long-term returns that a well-selected crane can provid Opting for a crane that meets operational needs and offers durability and reliability ensures that the investment pays off over tim

By carefully analyzing these factors and collaborating with crane experts, industries can select the perfect Yuantai floor-operated crane that elevates their operational capabilities and supports their growth journey. As we conclude our exploration, let's reflect on the transformative impact of these mechanical giants on industries around the worl

Conclusion: Elevating Industrial Efficiency

The realm of heavy lifting and material handling has been forever transformed by the introduction of Yuantai floor-operated cranes. These mechanical marvels have emerged as stalwarts of precision, safety, and efficiency across a spectrum of industries. Their unique advantages, diverse applications, and pivotal role in shaping modern industrial operations underscore their significance in today's dynamic landscap

From manufacturing plants that orchestrate complex assembly processes to construction sites that shape skylines, Yuantai floor-operated cranes offer the power of precision from a ground-level vantage point. The seamless control, enhanced visibility, and adaptability of these cranes empower operators to navigate challenging environments and execute tasks with finess

As industries continue to evolve and innovate, the reliance on Yuantai floor-operated cranes as indispensable tools of progress remains unwavering. Through a commitment to safety, operator training, and the intelligent selection of crane solutions, industries can harness the full potential of these mechanical giants and propel themselves toward new heights of operational excellenc

In the grand tapestry of modern industry, Yuantai floor-operated cranes have woven a thread of efficiency and innovation that leaves an indelible mark. As they continue to lift, move, and position heavy loads with precision, these cranes serve as reminders of the boundless possibilities that emerge when engineering ingenuity meets industrial prowess.