10 Ton Semi Gantry Cranes Applications & Benefits

Maximizing Load Handling 10 ton Semi Gantry Cranes Applications & Benefits

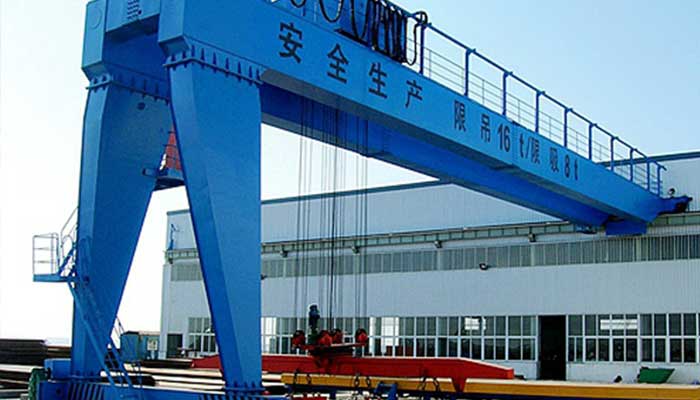

In the world of heavy industry, the term "10 ton semi gantry crane" carries a weight of its own. These impressive machines are a vital part of modern manufacturing, construction, and logistics, designed to handle substantial loads with precision and efficiency. A 10 ton semi gantry crane is a heavy-duty lifting device characterized by its gantry frame that runs on wheels along a track or rail, supported on one side by a fixed structure such as a wall or column, while the other side is mobile. It is equipped with a hoist and trolley system, which allows for the vertical and horizontal movement of loads, making it an indispensable tool in various industrial applications.

Efficient load handling is the lifeblood of industries across the spectrum. From manufacturing to construction, warehousing to shipbuilding, the ability to safely and effectively lift, move, and position heavy objects is a critical component of productivity and profitability. Whether it's assembling intricate machinery, transporting construction materials, or managing inventory in a warehouse, the reliability and precision of load handling equipment play a central role in determining the success of operations.

Types of Semi Gantry Cranes 10 Ton

The semi gantry cranes come in different configurations to suit various industrial needs. The choice of type depends on factors such as the specific application, available space, and load requirements.

Single Girder Semi Gantry Crane

The single girder semi gantry crane is characterized by a single horizontal beam or girder on the trolley. It's an excellent choice when there is a need for efficient load handling in a more confined space. This type is known for its cost-effectiveness and versatility, making it suitable for tasks such as light manufacturing and maintenance operations.

single girder semi gantry crane for sale 1 ton -20 ton

Double Girder Semi Gantry Crane

In contrast, the double girder semi gantry crane features two horizontal beams or girders on the trolley. This design provides enhanced stability and allows for the handling of heavier loads. Double girder cranes are commonly used in industrial settings that require precision and control, such as heavy manufacturing, construction, and shipping. Their capacity to handle substantial weights makes them a vital asset in these applications.

Double girder semi gantry crane for outdoor use with capacity from 3 ton to 32 ton

Structural Components

To understand the versatility and effectiveness of 10 ton semi gantry cranes, it's essential to familiarize ourselves with their key structural components. These elements work in harmony to make load handling a seamless process.

- 1. Gantry Frame-The gantry frame serves as the backbone of a semi gantry crane. It consists of two vertical legs connected by a horizontal beam or girder. One of the legs is fixed to the ground or a structural support, while the other is mobile and rides on wheels along a track or rail. This configuration provides stability and mobility, allowing the crane to reach loads in various locations. The gantry frame is often made of robust materials such as steel to ensure strength and durability.

- 2. Trolley-Mounted on the horizontal beam of the gantry frame, the trolley is responsible for horizontal movement. It is equipped with wheels or a similar mechanism that enables it to travel along the beam. The trolley serves as the bridge between the fixed and mobile parts of the crane, ensuring that loads can be moved with precision.

- 3. Hoist-The hoist is the part of the crane responsible for vertical lifting. It is attached to the trolley and is equipped with a hook, cable, or other lifting mechanism. The operator can control the hoist to raise, lower, and position heavy loads accurately. The hoist's design and capacity determine the crane's overall lifting capabilities.

Understanding the structural components and the types of 10 ton semi gantry cranes sets the stage for exploring their wide-ranging applications across various industries. These components, coupled with the crane's mobility and lifting capabilities, form the foundation for their effectiveness in load handling tasks. Whether it's a single girder or double girder design, these cranes are integral to the productivity and efficiency of many industrial processes.

10 ton semi gantry crane for indoor material handling save your space

Applications of 10 ton Semi Gantry Cranes

10 ton semi gantry cranes are versatile pieces of heavy equipment, and their applications span across various industries. Their ability to efficiently handle substantial loads makes them indispensable in a wide range of industrial processes.

Manufacturing Industry

- 1. Material Handling in Workshops-In manufacturing, time is money, and efficiency is paramount. 10 ton semi gantry cranes are often used for transporting raw materials and components within workshops. They play a pivotal role in minimizing production downtime by swiftly and safely moving materials to where they are needed. This application is particularly crucial in industries like automotive manufacturing, where precision and timeliness are essential.

- 2. Assembly Line Operations-For assembly line operations, the precision and control offered by semi gantry cranes are invaluable. These cranes are used to lift and position heavy components, machinery, and products during the assembly process. The ability to precisely place these items ensures that production runs smoothly and that the end product meets high-quality standards.

Construction Industry

- 1. Lifting Heavy Construction Materials-In the construction industry, where massive steel beams, concrete slabs, and heavy construction materials are commonplace, 10 ton semi gantry cranes shine. They excel at lifting and relocating these heavy items, contributing to faster construction times and enhanced safety. This application streamlines the process of getting materials to where they are needed on construction sites.

- 2. Assisting in Structural Erection-When erecting large structures like bridges, industrial buildings, and towers, the role of semi gantry cranes is critical. They assist in positioning and connecting structural components with precision, ensuring the safety of construction workers and the integrity of the final structure. Their mobility and lifting capacity make them indispensable in these scenarios.

Warehousing and Logistics

- 1. Efficient Loading and Unloading of Goods-Efficient warehousing and logistics operations are essential for businesses dealing with large volumes of goods. 10 ton semi gantry cranes are utilized to load and unload heavy shipments, such as containers and pallets. This streamlines the logistics process, reduces handling times, and minimizes the risk of damage to goods during transit.

- 2. Inventory Management-In large warehouses, inventory management is a complex task. Semi gantry cranes help manage and organize inventory by moving heavy pallets and goods to designated storage locations. Their precision ensures that the right items are placed in the right spots, reducing errors and improving inventory control.

Shipbuilding and Ports

- 1. Loading and Unloading Cargo-Ports and shipyards handle colossal cargo containers and materials daily. Semi gantry cranes are instrumental in efficiently loading and unloading cargo from ships. Their mobility allows them to reach multiple points along the dock, ensuring a swift transfer of goods to and from vessels.

- 2. Ship Maintenance and Repairs-Even after ships are in the water, they require maintenance and repair. Semi gantry cranes are used to lift and position heavy components for ship maintenance, including engines, hull sections, and equipment. Their reliability and precision are crucial for keeping vessels in operational condition.

The widespread applications of 10 ton semi gantry cranes illustrate their versatility and the substantial impact they have on various industries. Whether it's the manufacturing of products, the construction of structures, the management of goods in a warehouse, or the maintenance of ships, these cranes are essential in enhancing efficiency, safety, and overall productivity.

Benefits of 10 ton Semi Gantry Cranes

10 ton semi gantry cranes offer a multitude of advantages that make them indispensable in various industries. These benefits range from improved efficiency and safety to versatility and long-term cost savings.

Improved Efficiency

- 1. Faster Loading and Unloading-One of the most significant benefits of 10 ton semi gantry cranes is their ability to expedite the loading and unloading of materials and goods. Their precise control and swift movement mean that heavy loads can be handled more quickly, reducing turnaround times in manufacturing, warehousing, and logistics operations. This efficiency translates into increased productivity and profitability for businesses.

- 2. Reduced Downtime-Semi gantry cranes contribute to reduced downtime in industrial processes. They minimize the time spent waiting for materials or components to be in the right place, ensuring that machinery and workers are continuously engaged. This reduction in downtime equates to higher output, making them a key asset in industries where every minute counts.

Safety Advantages

- 1. Operator Safety-The safety of workers is paramount in any industrial setting. 10 ton semi gantry cranes are equipped with advanced safety features and controls that protect crane operators. These include features like emergency stop buttons, overload protection, and advanced control systems that allow operators to perform their tasks with precision and minimal risk.

- 2. Load Safety- Ensuring the safety of the loads being handled is equally important. These cranes offer precise control over load placement, reducing the risk of accidents or damage to goods. Load safety features such as anti-sway systems and secure fastening mechanisms contribute to accident prevention.

Versatility

- 1. Adaptable to Various Industries-10 ton semi gantry cranes are versatile, adaptable tools that find applications in a wide range of industries. Whether it's manufacturing, construction, warehousing, or shipbuilding, their mobility and lifting capacity make them a valuable asset in diverse settings. This adaptability ensures that a single investment can serve multiple purposes.

- 2. Flexible Load Handling-Semi gantry cranes offer flexibility in load handling. Their ability to move loads both horizontally and vertically means that they can be used for various tasks within an industry. From precision assembly to heavy lifting, these cranes are versatile enough to tackle a wide array of challenges, reducing the need for multiple specialized machines.

Cost Savings

- 1. Reduced Labor Costs-By automating and streamlining the process of load handling, 10 ton semi gantry cranes reduce the labor required for such tasks. This results in significant cost savings over time, as businesses can achieve the same or greater productivity with fewer human resources. In addition, the reduced physical strain on workers minimizes the risk of workplace injuries, further decreasing labor-related costs.

- 2. Long-term Durability and Low Maintenance-Semi gantry cranes are built to withstand heavy use and harsh industrial environments. Their robust construction and quality materials ensure long-term durability, reducing the need for frequent replacements. Moreover, these cranes typically require low maintenance, which translates to further cost savings and operational efficiency over their lifespan.

The benefits of 10 ton semi gantry cranes extend beyond their immediate impact on load handling. They enhance efficiency, safety, and versatility while simultaneously contributing to long-term cost savings. These advantages underscore the integral role that semi gantry cranes play in various industries, driving productivity and ensuring the well-being of both workers and businesses.

Applications of 10 ton semi gantry cranes

Successful Implementations

To truly appreciate the impact of 10 ton semi gantry cranes, let's explore some real-world examples of their successful implementation across various industries:

- 1. Automotive Manufacturing: In an automotive manufacturing plant, a 10 ton semi gantry crane has revolutionized the process of moving heavy car parts along the assembly line. This crane's precise handling capabilities have not only increased production speed but also reduced errors in the assembly process, resulting in significant cost savings and improved product quality.

- 2. Shipyard Operations: Shipyards have adopted 10 ton semi gantry cranes for both building and maintaining ships. These cranes efficiently move massive ship components and engines, expediting the construction process. In ship maintenance, they have improved safety by providing a stable platform for workers during repair and maintenance tasks.

- 3. Warehouse Logistics: In a large e-commerce fulfillment center, semi gantry cranes have streamlined the loading and unloading of cargo containers. By reducing handling time, they've improved the efficiency of the entire logistics chain, from receiving goods to shipping customer orders. The cranes' adaptability to various load sizes and types has made them an essential part of the facility's operation.

Highlight Efficiency and Safety Gains

- 1. Construction Site Safety: In the construction industry, the implementation of 10 ton semi gantry cranes has significantly improved safety. By replacing manual labor for lifting heavy construction materials, the risk of worker injuries has been reduced. Workers can now focus on more complex tasks, while the cranes handle the heavy lifting with precision.

- 2. Manufacturing Precision: Within manufacturing facilities, the use of semi gantry cranes has led to remarkable gains in production precision. These cranes offer the exactitude needed to ensure that complex machinery and products are assembled with minimal error. The reduction in assembly errors not only increases product quality but also minimizes costly rework.

- 3. Dramatic Time Savings: Across industries, the introduction of 10 ton semi gantry cranes has resulted in substantial time savings. For instance, in the shipbuilding sector, they have reduced the time it takes to load and unload cargo ships, enhancing overall port efficiency. Similarly, in the manufacturing and warehousing sectors, faster load handling translates into shorter turnaround times and increased production rates.

Maintenance and Safety Considerations

Implementing 10 ton semi gantry cranes in industrial settings is accompanied by a responsibility to ensure the safety of personnel and the longevity of the equipment. Maintenance and adherence to safety protocols are crucial for safe and efficient operations.

Regular Inspection and Maintenance

- 1. Scheduled Inspections: Regular inspections are essential to identify wear and tear on critical components. These inspections should include checks on the gantry frame, trolley, hoist, cables, and controls. Inspections should be carried out at scheduled intervals, and any issues should be addressed promptly.

- 2. Preventative Maintenance: Implementing a preventative maintenance program is key to extending the lifespan of the equipment. This includes lubricating moving parts, adjusting tension in cables, and replacing worn-out components. By addressing potential problems before they become critical, businesses can avoid costly downtime.

- 3. Emergency Repairs: It's imperative to have a plan for addressing unexpected issues. This may involve having spare parts readily available and a team of maintenance professionals on call for emergency repairs. The ability to quickly respond to breakdowns is essential for minimizing disruptions to operations.

Operator Training and Safety Protocols

- 1. Operator Training: Operators of 10 ton semi gantry cranes must receive proper training. Training programs should cover the safe operation of the equipment, emergency procedures, and the use of safety features and controls. Operators should be certified to ensure they have the necessary skills and knowledge.

- 2. Safety Protocols: Establishing safety protocols is paramount. This includes clear guidelines for load limits, safe operating speeds, and load securing. Operators should adhere to these protocols rigorously to prevent accidents. The protocols should also detail safety measures such as the use of personal protective equipment.

- 3. Emergency Procedures: In the event of an emergency, operators should be well-versed in procedures for shutting down the crane, evacuating the area, and responding to potential hazards. Having a clear and rehearsed emergency plan is crucial for minimizing risks.

Compliance with Regulations and Standards

- 1. Adherence to Regulatory Standards: Complying with local, national, and international safety and operational regulations is non-negotiable. Regulations may cover crane design, operation, maintenance, and operator certification. Businesses must stay up-to-date with these standards and ensure compliance at all times.

- 2. Regular Audits and Compliance Checks: Periodic audits and compliance checks should be conducted to verify adherence to regulations and industry standards. These audits can identify areas of improvement and help ensure that the equipment and operations meet safety requirements.

- 3. Continual Improvement: A commitment to safety includes a culture of continual improvement. Businesses should actively seek ways to enhance safety measures, whether through equipment upgrades, training enhancements, or the adoption of new safety technologies.

By emphasizing maintenance, operator training, and compliance with regulations, businesses can create a safer and more efficient working environment. 10 ton semi gantry cranes, when operated and maintained correctly, can be a boon to productivity and safety in various industries.

Future Trends and Innovations

As technology continues to advance, the world of 10 ton semi gantry cranes is not exempt from innovation. The future of these cranes promises to be characterized by advancements in technology, increased automation, and a growing emphasis on sustainability.

Advancements in Gantry Crane Technology

- 1. Precision and Control: Future 10 ton semi gantry cranes are likely to incorporate advanced control systems and sensors, further enhancing their precision and control. This will enable more delicate and intricate handling of loads, expanding their utility in industries like electronics manufacturing and pharmaceuticals.

- 2. Lightweight Materials: The use of lightweight and durable materials, such as advanced composites, may reduce the overall weight of the crane's structural components. This will improve energy efficiency and reduce wear and tear on the equipment.

- 3. Enhanced Safety Features: Anticipate the integration of additional safety features, including real-time monitoring of load stability, predictive maintenance alerts, and collision avoidance systems. These features will further reduce the risk of accidents and downtime.

Integration of Automation

- Remote Operation: Semi gantry cranes may increasingly be operated remotely, allowing for greater flexibility and reducing the need for operators to be physically present. This can be especially beneficial for applications in hazardous or hard-to-reach environments.

- Automation and Robotics: The automation of semi gantry cranes may become more prevalent, with the ability to automate repetitive tasks, such as loading and unloading, in a variety of industries. This will not only increase efficiency but also reduce the need for human intervention in potentially hazardous situations.

Sustainable Practices in Load Handling

- 1. Electric and Eco-friendly Solutions: The adoption of electric or hybrid power sources in semi gantry cranes can reduce emissions and environmental impact. These environmentally friendly solutions align with the growing demand for sustainability in industries.

- 2. Energy Recovery Systems: Innovations in energy recovery systems will become more common. These systems capture and store energy during braking or lowering of loads, which can then be used to power the crane, resulting in energy savings.

- 3. Material and Energy Efficiency: Sustainable practices in manufacturing and using 10 ton semi gantry cranes will focus on the use of eco-friendly materials and efficient energy consumption. These practices will reduce the carbon footprint associated with crane production and operation.

The future of 10 ton semi gantry cranes is exciting, with technology poised to enhance their capabilities, safety, and environmental sustainability. These innovations will not only make load handling more efficient but also contribute to a greener and safer industrial landscape.

Wrap it up,

In conclusion, 10 ton semi gantry cranes have proven to be vital assets in modern industry. Their unique design and capabilities offer a solution to the essential task of load handling, impacting a broad spectrum of sectors. These cranes provide the precise control, efficiency, and safety necessary for managing heavy materials and goods in the industrial landscape.

We have explored their applications in various industries, from manufacturing and construction to warehousing and shipbuilding. In each context, 10 ton semi gantry cranes have demonstrated their value by improving efficiency, reducing downtime, enhancing safety, and ensuring the flexibility required to meet diverse load handling needs. The real-world examples we've seen underscore their role in achieving efficiency and safety gains.

The importance of these cranes in enhancing industrial productivity cannot be overstated. They provide a pathway to faster operations, reduced labor costs, and long-term durability. In an ever-evolving industrial landscape, we've also glimpsed into the future, where advancements in technology, automation, and sustainability will further elevate the impact and value of 10 ton semi gantry cranes.

As industry continues to evolve, these cranes will remain a cornerstone of efficient load handling, enabling businesses to thrive in a competitive global marketplace. The legacy of 10 ton semi gantry cranes is one of innovation, adaptability, and a commitment to safety and efficiency – qualities that will continue to drive industrial progress in the years to come.