5 Ton Gantry Crane & Custom Gantry Crane System for 5 Ton Workloads

5 ton gantry crane for sale. Custom gantry crane systems for different uses, check features & benefits of gantry crane systems designed for 5 ton capacity.

Enhancing Efficiency and Versatility: Exploring Gantry Crane Systems for 5-Ton Workloads

In the dynamic landscape of industrial operations, efficient material handling plays a pivotal role in ensuring productivity and operational success. Gantry crane systems, characterized by their overhead structure supported by legs or wheels, have become indispensable in various industries for lifting and transporting heavy loads. These systems offer a unique advantage by providing a stable and versatile solution for material handling in diverse environments.

Gantry cranes have proven to be essential in a wide array of industries, ranging from manufacturing and construction to warehousing and shipbuilding. Their ability to lift and move heavy loads with precision and ease makes them a preferred choice for tasks that require reliable and efficient material handling. Gantry cranes contribute significantly to streamlining processes, reducing manual labor, and enhancing overall operational efficiency.

Within the realm of gantry crane systems, a specific focus on those designed for 5-ton workloads is particularly noteworthy. The 5-ton capacity strikes a balance between handling substantial loads and providing the versatility required for diverse applications. This article delves into the applications, features, and benefits of gantry crane systems tailored to meet the demands of 5-ton workloads, shedding light on their crucial role in modern industrial settings. Join us as we explore the intricacies of these systems, uncovering the ways they elevate efficiency and contribute to the success of various industries.

5 ton gantry crane system for outdoor use for stone blocks handling

Applications of 5-Ton Gantry Crane Systems

The adaptability and strength of 5-ton gantry crane systems find applications across a spectrum of industries. These cranes are instrumental in meeting the demands of various sectors that require efficient material handling. From heavy manufacturing plants to expansive construction sites, the versatility of 5-ton gantry cranes has positioned them as indispensable assets in the following key industries.

Specific Use Cases and Applications

Manufacturing

In manufacturing environments, precision and speed are paramount. 5-ton gantry cranes excel in lifting and moving heavy machinery and components with the required accuracy. Whether assembling automobiles, handling steel structures, or managing production lines, these cranes contribute to streamlined processes and enhanced production output.

Construction

Construction sites are dynamic, demanding environments where the ability to lift and place heavy materials is crucial. 5-ton gantry cranes offer the necessary strength and flexibility to assist in tasks such as erecting steel structures, lifting construction materials, and facilitating the assembly of large components with precision.

Indoor gantry crane system for material handling with loadweight of 5 ton

Warehousing

Warehouses are hubs of activity, requiring efficient material handling for storage and retrieval. 5-ton gantry cranes are well-suited for managing palletized goods, heavy equipment, and bulky items within warehouse spaces. Their adaptability makes them ideal for optimizing storage capacity and ensuring smooth logistics operations.

Shipbuilding

Shipbuilding involves the manipulation of large and weighty components, and 5-ton gantry cranes play a vital role in the construction of vessels. These cranes facilitate the movement of ship parts, aiding in the assembly process and ensuring that shipyards operate with maximum efficiency.

Other Relevant Sectors

Beyond the aforementioned industries, 5-ton gantry cranes find application in various sectors where heavy lifting is a routine requirement. This includes sectors such as energy, aerospace, and logistics, where the cranes contribute to seamless operations and safe material handling practices.

The versatile nature of 5-ton gantry crane systems makes them indispensable in addressing the unique challenges presented by each industry, showcasing their adaptability and reliability in diverse operational settings.

Features of 5-Ton Gantry Crane Systems

Structural Components

Frame Design

The frame design of 5-ton gantry crane systems is a critical element that ensures stability and load-bearing capacity. Typically constructed from robust materials such as steel or aluminum, the frame provides the structural integrity needed to withstand the stresses of lifting and moving heavy loads. The design takes into account factors like balance, weight distribution, and overall durability to guarantee safe and efficient crane operation.

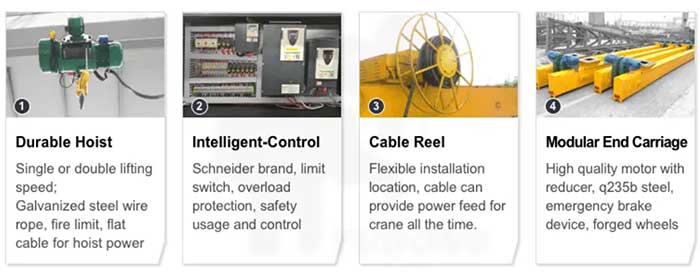

Lifting Mechanism

The heart of any gantry crane lies in its lifting mechanism. 5-ton gantry cranes are equipped with powerful hoists and winches designed to handle substantial weights with precision. The lifting mechanism incorporates advanced features such as variable speed controls and smooth acceleration and deceleration, ensuring the safe and controlled movement of loads.

Trolley System

The trolley system of a gantry crane facilitates lateral movement along the crane's beam, allowing for precise positioning of the load. In 5-ton gantry cranes, the trolley system is engineered for efficiency and reliability, often featuring adjustable speeds and programmable controls. This adaptability is crucial in meeting the diverse demands of different applications.

Controls and Automation

Modern 5-ton gantry crane systems leverage advanced control systems and automation technologies. Remote control options, programmable logic controllers (PLCs), and sophisticated monitoring systems enhance the precision and safety of crane operations. Automation features contribute to increased productivity and reduced reliance on manual intervention.

Material Considerations

High-Strength Steel

The use of high-strength steel in the construction of gantry crane components is a key factor in ensuring durability and load-bearing capacity. High-strength steel alloys provide the necessary strength-to-weight ratio, allowing for the construction of lightweight yet robust crane structures capable of handling 5-ton workloads.

Corrosion-Resistant Materials

Given the often challenging environments in which gantry cranes operate, the incorporation of corrosion-resistant materials is crucial for longevity. Components exposed to the elements or harsh industrial conditions are often coated or constructed from materials such as galvanized steel to prevent corrosion and extend the crane's lifespan. 2

Mobility and Flexibility

Rail-Mounted vs. Wheel Travelling Gantry Cranes

The mobility of gantry cranes is a significant consideration, and 5-ton gantry cranes offer flexibility in their mobility options. Rail-mounted gantry cranes are ideal for fixed applications along a specific path, while wheel gantry cranes provide the versatility to move freely within a designated area. The choice between these options depends on the specific requirements of the application.

Adjustable Height and Span Options

To accommodate varying work environments, 5-ton gantry crane systems often feature adjustable height and span options. This adaptability ensures that the crane can be tailored to the specific needs of a given task, allowing for efficient use of space and optimal load positioning.

The combination of these structural components, material considerations, and mobility features makes 5-ton gantry crane systems robust, versatile, and well-suited to meet the demands of diverse industrial applications.

Benefits of Using 5-Ton Gantry Crane Systems

Increased Efficiency in Material Handling

One of the primary advantages of utilizing 5-ton gantry crane systems is the significant increase in efficiency in material handling processes. The precision and speed with which these cranes can lift, move, and position loads contribute to streamlined operations. Whether in manufacturing, construction, or warehousing, the ability to swiftly and accurately handle materials enhances overall productivity and reduces downtime.

Enhanced Safety Features

Safety is paramount in any industrial setting, and 5-ton gantry crane systems are equipped with advanced safety features to mitigate risks. These features may include overload protection mechanisms, emergency braking systems, and collision avoidance technology. The incorporation of state-of-the-art safety measures ensures not only the protection of personnel but also safeguards against potential damage to the crane itself and the surrounding infrastructure.

Versatility in Handling Various Loads

The versatility of 5-ton gantry crane systems is a key attribute that sets them apart. These cranes are designed to handle a wide range of loads, from heavy machinery components to bulk materials. The flexibility in load capacity and adaptability to different load shapes and sizes make them ideal for environments where the variety of materials being handled is diverse.

Cost-Effectiveness Compared to Alternative Solutions

In the realm of material handling equipment, cost-effectiveness is a crucial consideration. 5-ton gantry crane systems offer a favorable balance between capacity and cost. Compared to alternative solutions such as larger cranes or manual labor, these systems provide a cost-effective option for businesses seeking efficient material handling without compromising on load capacity.

Adaptability to Different Work Environments

The adaptability of 5-ton gantry crane systems to various work environments is a significant advantage. Whether operating in confined spaces or expansive industrial facilities, these cranes can be customized to suit specific needs. The ability to adjust height, span, and mobility options ensures that the crane can seamlessly integrate into different work environments, optimizing space utilization and operational workflows.

In summary, the use of 5-ton gantry crane systems offers a multitude of benefits, ranging from increased efficiency and enhanced safety features to versatility, cost-effectiveness, and adaptability to diverse work environments. These advantages make them indispensable tools in modern industrial settings, contributing to improved overall operational performance.

Case Studies

Highlight Specific Projects or Instances Where 5-Ton Gantry Crane Systems Proved Beneficial

Manufacturing Excellence:

In a leading automotive manufacturing plant, a 5-ton gantry crane system played a pivotal role in the assembly line. The crane efficiently lifted and positioned heavy engine components, reducing manual handling and enhancing production speed. This resulted in a significant increase in overall manufacturing efficiency, with a measurable reduction in production time.

Efficient Construction Operations:

A construction project involving the erection of steel structures benefitted from the use of a 5-ton gantry crane. The crane's adaptability allowed for precise positioning of steel beams and other construction materials, contributing to the project's timely completion. The ability to navigate tight construction sites and lift heavy loads with ease showcased the crane's effectiveness in dynamic environments.

Gantry Crane 5 Ton for Sale Singapore,Singapore

5 ton portable gantry crane system for mold handling in Qatar

5 ton gantry crane system customized for container handling

European style single girder gantry crane 5 ton for marble manufacturing workshop

5 Ton Portable Gantry Crane for Construction Company Brunei

These case studies underscore the versatility and effectiveness of 5-ton gantry crane systems in diverse industries. From manufacturing and construction to warehousing and aerospace, these cranes have proven to be indispensable tools, contributing to increased efficiency, improved safety, and successful project outcomes.

Technological Advancements

Recent years have witnessed significant advancements in the technology powering 5-ton gantry crane systems, transforming the landscape of industrial material handling. These innovations have focused on enhancing efficiency, safety, and adaptability, making these cranes more indispensable than ever.

Integration of Smart Features and Automation

Remote Control and Monitoring:

Modern 5-ton gantry cranes are equipped with remote control capabilities, allowing operators to manage crane movements from a safe distance. This not only improves operator safety but also provides a vantage point for precise load positioning. Additionally, remote monitoring systems enable real-time tracking of crane performance, facilitating proactive maintenance and minimizing downtime.

Automated Positioning Systems:

The integration of automated positioning systems has revolutionized load handling precision. These systems utilize sensors and cameras to analyze the environment, enabling the crane to automatically position loads with high accuracy. This feature is particularly beneficial in applications where precise load placement is critical, such as in manufacturing and construction.

Load Sensing Technology:

Load sensing technology has become a standard feature in many 5-ton gantry crane systems. This innovation allows the crane to continuously monitor the load weight and adjust its operations accordingly. It not only prevents overloading but also optimizes energy consumption, contributing to both safety and operational efficiency.

Impact of Technological Advancements on Performance and Safety

Enhanced Performance:

The integration of smart features and automation has significantly enhanced the overall performance of 5-ton gantry crane systems. Automated positioning, precision controls, and variable speed capabilities contribute to faster and more efficient material handling processes. This, in turn, translates to increased productivity and reduced lead times.

Improved Safety Measures:

Technological advancements have had a profound impact on crane safety. Load sensing technology, collision avoidance systems, and emergency braking features work together to create a safer working environment. Automated controls reduce the margin of error, and real-time monitoring allows for the early detection of potential issues, minimizing the risk of accidents.

Efficient Energy Utilization:

The implementation of smart technologies has led to more energy-efficient operations. Cranes can optimize power usage based on load requirements, contributing to reduced energy consumption. This not only aligns with sustainability goals but also results in cost savings for businesses operating 5-ton gantry crane systems.

In conclusion, the continuous evolution of technology has propelled 5-ton gantry crane systems to new heights of performance, safety, and efficiency. The integration of smart features and automation not only meets the demands of modern industrial applications but also positions these cranes as crucial components in the era of smart and connected manufacturing.

Considerations for Selecting a 5-Ton Gantry Crane

Workload Requirements

Determining the specific workload requirements is a foundational step in selecting an appropriate 5-ton gantry crane. Understanding the weight and dimensions of the loads to be handled ensures that the crane's capacity aligns with operational needs. It's essential to consider both current and future workload projections to guarantee that the crane system remains efficient and relevant as operational demands evolve.

Space Constraints and Layout Considerations

The physical layout of the workspace and any space constraints play a crucial role in selecting the right 5-ton gantry crane. Factors such as ceiling height, available floor space, and the overall layout of the facility influence the type of gantry crane system that is most suitable. Additionally, considerations for aisle width and the crane's ability to navigate within the available space are vital for seamless integration into the operational environment.

Environmental Factors

The operating environment significantly impacts the longevity and performance of a 5-ton gantry crane. For outdoor applications, exposure to the elements necessitates the use of materials with corrosion-resistant properties. Indoor environments may require adherence to cleanliness standards, influencing the choice of crane components. Understanding the environmental conditions ensures that the selected gantry crane can withstand challenges posed by factors such as humidity, temperature variations, and exposure to corrosive substances.

Budget Considerations

Budget considerations are integral to the decision-making process when selecting a 5-ton gantry crane. The initial investment cost, including the crane system itself and any necessary infrastructure modifications, should be evaluated against the expected returns in terms of increased productivity and operational efficiency. Additionally, ongoing maintenance costs, energy consumption, and potential future upgrades or expansions should be factored into the budgetary considerations to ensure a comprehensive financial analysis.

Careful evaluation of these considerations allows businesses to make informed decisions when selecting a 5-ton gantry crane, aligning the chosen system with specific operational requirements and long-term strategic goals. By addressing workload needs, spatial constraints, environmental factors, and budget considerations, businesses can optimize their material handling capabilities and contribute to overall operational success.

Maintenance and Safety Practices

Routine Maintenance Guidelines

To ensure the continued efficiency and safety of a 5-ton gantry crane system, adherence to routine maintenance guidelines is paramount. Regular inspections and maintenance tasks should be carried out according to the manufacturer's recommendations. Key areas of focus include:

Inspecting Structural Components:

Regularly check the crane's structural components, such as the frame, trolley, and lifting mechanism, for signs of wear, corrosion, or damage. Address any issues promptly to prevent further deterioration.

Checking Electrical Systems:

Inspect electrical components, wiring, and control systems to identify any potential issues. Ensure that connections are secure and that there are no exposed wires that could pose a safety hazard.

Examining Load-Bearing Parts:

Pay close attention to load-bearing parts, such as hooks, slings, and chains. Regularly assess their condition and replace any components showing signs of wear or fatigue.

Lubricating Moving Parts:

Keep all moving parts well-lubricated to reduce friction and prevent premature wear. This includes gears, bearings, and any joints in the crane's structure.

Testing Emergency Systems:

Regularly test emergency features, such as emergency brakes and limit switches, to ensure they function correctly. This is crucial for immediate response in the event of a malfunction or emergency situation.

Importance of Operator Training

Operator training is a fundamental aspect of maintaining a safe working environment when utilizing a 5-ton gantry crane. Well-trained operators contribute to the overall efficiency of material handling operations and significantly reduce the risk of accidents. Training programs should cover:

Safe Operation Procedures:

Operators should be thoroughly trained on safe operating procedures, including load capacity limits, proper load attachment, and correct maneuvering techniques.

Emergency Response Protocols:

Familiarize operators with emergency response protocols, ensuring they know how to react in case of equipment malfunctions or unforeseen events.

Equipment Familiarization:

Operators should be well-versed in the specific features and controls of the 5-ton gantry crane they operate. This includes understanding the crane's load chart, operational limits, and emergency stop procedures.

Regular Refresher Courses:

Conduct regular refresher courses to update operators on any changes in equipment or safety regulations. Ongoing training helps reinforce safety practices and keeps operators informed about the latest industry standards.

Compliance with Safety Standards and Regulations

Adhering to safety standards and regulations is non-negotiable for the operation of a 5-ton gantry crane. This includes compliance with local, national, and industry-specific safety standards. Key aspects of compliance include:

Regular Inspections and Certifications:

Schedule regular inspections and certifications to ensure that the gantry crane meets or exceeds safety standards. Compliance with certification requirements is essential for legal and operational purposes.

Documentation and Record-Keeping:

Maintain comprehensive documentation of inspections, maintenance activities, and operator training records. This documentation serves as evidence of compliance and is crucial in the event of audits or investigations.

Stay Informed on Regulatory Updates:

Keep abreast of any changes in safety regulations and standards applicable to gantry crane operations. Adjust safety practices and procedures accordingly to remain in compliance with the latest requirements.

Collaboration with Regulatory Authorities:

Foster collaboration with regulatory authorities to ensure a proactive approach to safety compliance. Regular communication with relevant agencies helps maintain a safe and compliant working environment.

Implementing thorough routine maintenance practices, providing comprehensive operator training, and ensuring strict compliance with safety standards are integral components of a holistic approach to maintaining the efficiency and safety of 5-ton gantry crane systems. These practices not only contribute to the longevity of the equipment but also prioritize the well-being of personnel and the overall workplace safety culture.

Conclusion

Throughout this exploration of 5-ton gantry crane systems, several key points have been highlighted:

- Versatility and Efficiency: 5-ton gantry crane systems have proven to be versatile solutions across diverse industries, from manufacturing and construction to warehousing and shipbuilding. Their capacity to handle various loads with precision and efficiency has emerged as a cornerstone of modern industrial material handling.

- Structural Components and Materials: The structural components, materials, and innovative features of 5-ton gantry crane systems play a pivotal role in their performance. High-strength steel, advanced lifting mechanisms, and automation technologies contribute to their reliability and adaptability.

- Benefits to Industries: The benefits of using 5-ton gantry crane systems extend beyond increased efficiency to encompass enhanced safety features, cost-effectiveness, and adaptability to different work environments. Case studies have illustrated their successful applications in real-world industrial settings.

- Technological Advancements: Recent technological advancements, including smart features and automation, have propelled 5-ton gantry cranes into the era of connected manufacturing. These innovations have not only improved performance but also elevated safety standards and energy efficiency.

- Considerations for Selection: Selecting the right 5-ton gantry crane involves careful consideration of workload requirements, space constraints, environmental factors, and budget considerations. Each of these factors contributes to the successful integration of the crane into specific operational contexts.

- Maintenance and Safety Practices: Routine maintenance guidelines, operator training, and compliance with safety standards are crucial for ensuring the continued efficiency and safety of 5-ton gantry crane systems. These practices contribute to the longevity of the equipment and create a safer working environment.

The versatility and advantages of 5-ton gantry crane systems underscore their importance as indispensable tools in modern industrial settings. Their ability to efficiently handle various loads, coupled with adaptability to diverse work environments, positions them as key contributors to increased productivity and operational success.

Future Trends and Developments in the Gantry Crane Industry

Looking ahead, the gantry crane industry is poised for continuous evolution. Future trends may include:

- Integration of Artificial Intelligence (AI):

The integration of AI technologies could further enhance automation and decision-making processes in gantry crane operations, contributing to increased efficiency and precision. - Advanced Materials and Design:

Continued advancements in materials and design may lead to the development of lighter yet stronger gantry crane structures, improving performance and energy efficiency. - IoT and Connectivity:

The Internet of Things (IoT) and increased connectivity may play a crucial role in data-driven maintenance, allowing for predictive analytics and minimizing downtime through proactive interventions. - Eco-Friendly Initiatives:

With an increased focus on sustainability, future developments in gantry crane technology may prioritize eco-friendly features, such as energy-efficient systems and environmentally conscious materials. - Enhanced Safety Technologies:

The gantry crane industry is likely to witness further advancements in safety technologies, including real-time monitoring, enhanced collision avoidance systems, and improved emergency response features.

As 5-ton gantry crane systems continue to evolve and adapt to the changing needs of industries, they are poised to remain at the forefront of efficient and safe material handling solutions. Businesses that leverage these advancements will not only benefit from increased productivity but also contribute to the ongoing progress of the industrial landscape.