5 Ton & 10 Ton Overhead Crane Costs: A Comprehensive Guide

Overhead cranes come in various types and configurations, each designed to suit specific applications and load capacities. From the commonly seen single-girder and double-girder cranes to more specialized gantry and jib cranes, these machines play a crucial role in enhancing efficiency and productivity across diverse industries.

Understanding the costs associated with overhead cranes is pivotal for businesses and industries seeking to acquire, maintain, or optimize their material handling capabilities. The financial implications involved in purchasing, renting, installing, and maintaining these cranes necessitate a comprehensive understanding to make informed decisions.

Overhead crane costs encompass a spectrum of factors, from the initial purchase or rental expenses to installation, operational, and maintenance costs. Knowing the intricacies of these expenses enables businesses to plan budgets effectively, assess return on investment, and make strategic choices aligning with their operational needs.

In this comprehensive guide, we delve into the various facets of overhead crane costs, exploring different types of cranes and their associated expenses. We’ll dissect the factors influencing costs, understand the components contributing to overall expenses, and provide practical strategies for managing and optimizing crane-related expenditures.

Types of Overhead Cranes and Their Costs

Overhead cranes come in various load capacities and configurations, each tailored to specific industrial needs. Understanding the costs associated with different tonnages and functionalities is crucial in selecting the most suitable crane for your operations while aligning with your budget.

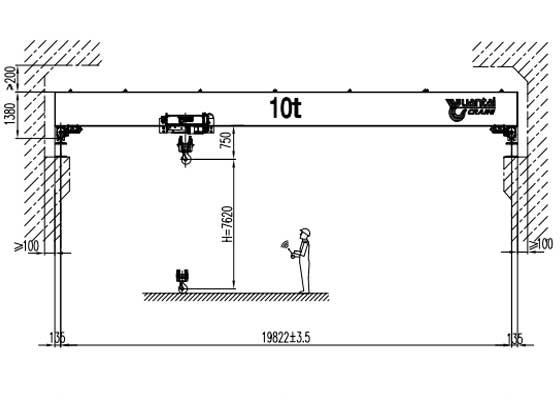

10 ton overhead cranes

10 Ton Overhead Crane Cost

A 10-ton overhead crane, designed to handle heavier loads, is a robust solution for industrial environments requiring substantial lifting capacities. The cost of a 10-ton overhead crane typically varies based on several factors:

Type and Configuration:Single-girder, double-girder, gantry, or custom-engineered cranes come with differing price points.

Manufacturer and Quality:Renowned brands or those offering advanced features may have higher initial costs but often ensure reliability and longevity.

Customization and Additional Features:Optional features like remote control operation, specialized hooks, or automation systems can impact the overall cost.

Installation Requirements:Factors such as site preparation, structural modifications, and installation complexity contribute to the final expenses.

While the upfront cost of a 10-ton overhead crane might seem significant, it’s essential to assess the long-term benefits, including enhanced productivity and minimized downtime, to justify the investment.

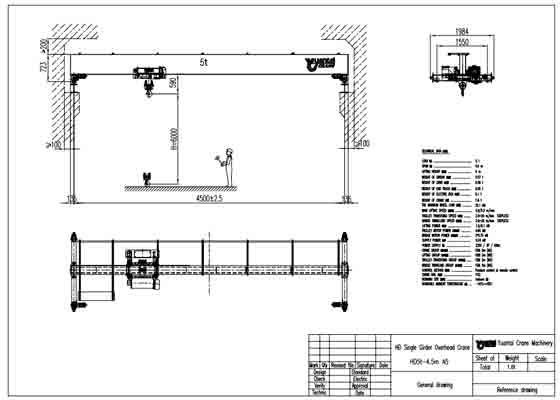

Types of 5 ton overhead crane, with single girder and double girder design

5 Ton Overhead Crane Cost

In comparison, a 5-ton overhead crane caters to lighter load capacities while offering versatile handling capabilities. The cost considerations for a 5-ton crane mirror those of a 10-ton crane, albeit with adjustments for the lower load capacity:

- Type and Configuration:Similar to the 10-ton crane, different configurations and types influence the price.

- Manufacturer and Quality:Quality components, albeit for lower load capacities, are essential for safety and efficiency.

- Customization and Additional Features:Optional features and add-ons might differ based on the crane’s specifications.

- 4. Installation Costs:Though potentially lower than a heavier crane, installation expenses remain a significant factor in overall costs.

Varied Costs Based on Different Tonnages and Functionalities

It's important to note that the costs associated with overhead cranes span a broad spectrum beyond just 5 and 10-ton capacities. Cranes with higher tonnages, specialized functionalities, or custom-built solutions will exhibit diverse cost structures, allowing businesses to select the most appropriate crane meeting their specific operational needs.

General-purpose Single Girder Overhead Crane, Cheaper Price

Single Girder Overhead Crane For Sale

It is a light small lift equipment with the capacity of 1to 32 tons, which is the most commonly used small material handling equipment, suitable for most factories, warehouses, etc.

- Lifting Capacity: 1~32t

- Lifting Height: 6-30m

- Span: 7.5~28.5m

- Working Duty: A3, A4

- Ambient Temperature: -20~40℃

Overhead Crane Span(m) Lifting Height(m) Power Supply(V) Price(USD)

1 ton 7.5~35 6~30 220-480/3/50 $2200~40000

2 ton 7.5~35 6~30 220-480/3/50 $2500~40800

3 ton 7.5~35 6~30 220-480/3/50 $2600~41000

5 ton 7.5~35 6~30 220-480/3/50 $3000~41500

10 ton 7.5~35 6~30 220-480/3/50 $4000~45000

16 ton 7.5~35 6~30 220-480/3/50 $5000~48000

20 ton 7.5~35 6~30 220-480/3/50 $6000~50000

25 ton 7.5~35 6~30 220-480/3/50 $8000~56000

The price of the above overhead bridge cranes will change with the market, without further notice, for reference only. If you need an accurate price in the near future, please contact us.

Double Girder Overhead Crane for Sale Good Price

The crane can lift loads from 5 to 63 ton, which is widely used in machinery fabrication, metallurgical plant auxiliary workshop, storage, stock ground, and power station, textile industry and food industry.

- Lifting Capacity: 1~63t

- Lifting Height: 6-30m

- Span: 7.5~28.5m

- Working Duty: A3, A4, A5

- Ambient Temperature:-20~40℃

Capacity Span(m) Lifting Height(m) Power Supply(V) Price(USD)

1 ton overhead crane 7.5~35 6~30 220-480/3/50 $4000-60000

2 ton overhead crane 7.5~35 6~30 220-480/3/50 $4500-62000

3 ton overhead crane 7.5~35 6~30 220-480/3/50 $ 5000-66000

5 ton overhead crane 7.5~35 6~30 220-480/3/50 $5800-72000

10 ton overhead crane 7.5~35 6~30 220-480/3/50 $6500-79000

16 ton overhead crane 7.5~35 6~30 220-480/3/50 $7800-86000

20 ton overhead crane 7.5~35 6~30 220-480/3/50 $8600-95000

25 ton overhead crane 7.5~35 6~30 220-480/3/50 $9800-110000

Factors Affecting Overhead Crane Costs

When considering the procurement or operation of an overhead crane, numerous factors contribute to the overall cost. Understanding these influential elements helps in making informed decisions while assessing the investment and ongoing expenses.

The type and specifications of an overhead crane play a pivotal role in determining its cost. Different crane types, such as single-girder, double-girder, gantry, or jib cranes, come with varied price points. Specifications like load capacity, span, lifting height, and speed also influence the overall cost, as cranes tailored for higher capacities or greater precision tend to be more expensive.

The selection of an overhead crane type and its specifications is a fundamental step in the acquisition process, significantly impacting the associated costs. Here's a closer look at how various crane types and specifications influence overall expenses:

Different Crane Types and Varied Price Points:

- Single-Girder Cranes:These cranes feature a single bridge girder supporting the hoist and trolley. Known for their cost-effectiveness, they suit applications where moderate load capacities and span lengths are sufficient.

- Double-Girder Cranes:In contrast, double-girder cranes have two bridge girders, offering increased stability and higher lifting capacities. While more expensive than single-girder counterparts, they are suitable for heavier loads and longer spans.

- Gantry Cranes:Gantry cranes, with legs supporting the bridge, provide mobility and versatility. Their costs vary based on design complexities, spanning capabilities, and functionalities tailored for specific industries like shipping, manufacturing, or construction.

- Jib Cranes:Jib cranes have a horizontal arm (jib) mounted to a vertical mast or wall, offering localized lifting solutions. Their cost factors include load capacity, span, and rotation capability, typically used for specific applications within workshops or manufacturing facilities.

Influence of Specifications on Costs:

- Load Capacity:The crane's load capacity stands as a primary determinant of its cost. Cranes designed to handle heavier loads necessitate more robust structures, powerful motors, and specialized components, contributing to higher costs.

- Span and Lifting Height:Longer spans and higher lifting heights increase material requirements and engineering complexity, affecting crane costs. Customizing cranes for specific spans and heights involves additional design and manufacturing expenses.

- Speed and Precision:Cranes engineered for increased speed or precision in load handling often incorporate advanced control systems and specialized components, leading to higher initial costs due to their enhanced functionalities.

Manufacturer and Quality

The choice of manufacturer and crane quality significantly impacts costs. Renowned manufacturers often offer higher quality components and advanced features, ensuring durability, safety, and reliability. While initial costs might be higher with reputable brands, they often translate into reduced maintenance and longer service life, potentially offsetting initial expenses in the long run.

Manufacturer and Quality

The selection of a manufacturer plays a crucial role in the overall cost and performance of an overhead crane. The quality, reliability, and durability of a crane are directly influenced by the manufacturer's reputation and the standards they adhere to. Here's a deeper insight into how these factors impact costs:

Reputation and Quality Standards:

- Renowned Manufacturers:Established manufacturers with a history of delivering high-quality cranes often incorporate superior materials, advanced engineering techniques, and stringent quality control measures. Their products conform to industry standards and are often equipped with innovative features, ensuring reliability and longevity.

- Quality Components:Cranes from reputable manufacturers are constructed using top-grade components, such as high-strength steel for structural elements, advanced electrical systems, and precision-engineered mechanical parts. These components contribute to higher initial costs but ensure enhanced performance and reduced maintenance requirements.

Cost Implications of Quality:

- Initial Costs vs. Long-Term Benefits:While the upfront costs of cranes from renowned manufacturers might be higher, they offer significant long-term benefits. Their reliability and durability translate into reduced downtime, lower repair and maintenance expenses, and longer service life, ultimately offsetting the initial investment.

- Reduced Maintenance and Repairs:Quality cranes are built to withstand rigorous operational conditions. Their robust construction and use of quality components minimize wear and tear, leading to fewer breakdowns and repair needs. This results in lower ongoing maintenance expenses over the crane's lifespan.

- Safety and Compliance:Cranes from reputable manufacturers often meet or exceed industry safety standards and regulatory requirements. Investing in these cranes ensures compliance with safety norms, potentially reducing liability risks associated with accidents or non-compliance.

Choosing a reputable manufacturer and prioritizing crane quality may involve higher initial costs but leads to a more reliable, safer, and cost-effective solution over the crane's operational life cycle.

Customization and Additional Features

Customization and additional features contribute to the overall cost of an overhead crane. Businesses might require specialized functionalities like remote control operation, anti-sway systems, or specialized hooks tailored to specific applications. These customized features add to the initial cost but can significantly enhance productivity and safety in certain operational settings.

Customizing overhead cranes with additional features tailored to specific operational needs or applications introduces variations in costs. While these customizations add to the initial investment, they often provide substantial benefits in terms of productivity, efficiency, and safety.

Specialized Functionalities:

- Remote Control Operation:Implementing remote control functionality allows operators to control the crane from a safe distance. While this customization incurs additional costs, it enhances operator safety and provides flexibility in maneuvering the crane, especially in hazardous or confined spaces.

- Anti-Sway Systems:Anti-sway systems minimize load swing during lifting, ensuring precise load placement. Though they increase the initial cost, they significantly improve operational efficiency by reducing load handling times and minimizing the risk of accidents.

- Specialized Hooks and Attachments:Tailoring hooks or attachments to specific load types or handling requirements incurs extra costs but enhances the crane's versatility. Customized hooks optimized for various loads or applications improve overall efficiency and safety during lifting operations.

Productivity and Safety Enhancements:

- Increased Productivity:Custom features often streamline processes, leading to increased productivity. For instance, automated functions or specialized controls can speed up operations, reducing handling time and enhancing overall productivity.

- Enhanced Safety Measures:Customizations focused on safety, such as specialized sensors, warning systems, or additional safety devices, reduce the risk of accidents or mishaps. The added initial cost is offset by the improved safety standards and potential reductions in liability risks.

Tailored Solutions for Specific Applications:

- Industry-Specific Requirements:Certain industries or applications require specific crane functionalities. Customizing cranes to meet these requirements ensures optimal performance in specialized environments, but these customizations may add to the initial cost.

- Efficiency and Precision:Tailoring cranes to handle unique loads or operate in specific environments optimizes efficiency and precision, potentially reducing operational costs and increasing overall throughput.

While customization and additional features elevate the initial cost of an overhead crane, these tailored solutions often result in enhanced operational efficiency, increased safety, and improved adaptability, providing long-term benefits that outweigh the initial investment.

Installation Requirements and Costs

Installation expenses are a crucial aspect of overhead crane costs. Factors such as site preparation, structural modifications, crane assembly, and commissioning contribute to installation costs. Complex installations involving intricate structural designs or specific safety measures might incur higher expenses.

The installation phase of an overhead crane involves several factors that significantly influence overall expenses. Understanding these factors is crucial for accurate budgeting and planning for crane installation.

Site Preparation and Structural Considerations:

- Site Assessment:Before installation, conducting a comprehensive site assessment is essential. Factors such as ground stability, space availability, floor load-bearing capacity, and clearances are assessed to ensure the site is suitable for crane installation.

- Structural Modifications:In many cases, structural modifications to the building or facility are necessary to support the crane. This might involve reinforcing floors, installing support beams, or modifying the building's structure to accommodate the crane's load-bearing requirements.

Crane Assembly and Commissioning:

- Assembly Process:Crane assembly involves skilled labor and specialized equipment for erecting the crane structure, installing hoists, trolleys, and electrical components, and connecting all necessary parts for operation.

- Commissioning and Testing:After assembly, the crane undergoes commissioning, including thorough testing and calibration to ensure all components function correctly and meet safety standards. This phase ensures the crane operates efficiently and safely.

Factors Influencing Installation Expenses:

- Complexity of Installation:The complexity of the installation significantly impacts costs. More intricate structural designs or installations requiring specific safety measures, such as hazardous environments or restricted spaces, might lead to higher expenses.

- Regulatory Compliance:Adhering to safety regulations and industry standards often involves additional costs for ensuring compliance, such as acquiring permits, conducting safety audits, and implementing safety protocols.

- Geographic Location:Installation costs might vary based on the geographic location due to factors like labor rates, accessibility, transportation of equipment, and local regulations affecting the installation process.

Accurate assessment and planning for installation expenses are critical to avoid cost overruns and delays. Engaging experienced professionals familiar with crane installations helps in estimating and managing these expenses effectively.

Maintenance and Operational Expenses

Beyond the initial purchase or installation, maintenance and operational expenses are ongoing factors influencing overhead crane costs. Regular maintenance, inspections, spare parts, and repairs contribute to the crane's total cost of ownership. Operational expenses encompass energy consumption, operator training, and, if applicable, rental costs for short-term use.

Once an overhead crane is in operation, ongoing maintenance and operational expenses become critical factors that contribute significantly to the crane's total cost of ownership. Understanding and budgeting for these expenses are essential for effective financial planning.

Regular Maintenance and Inspections:

- Scheduled Maintenance:Implementing a routine maintenance schedule is crucial to ensure the crane operates at optimal efficiency. This includes lubrication, component checks, and calibration to prevent premature wear and maintain peak performance.

- Inspections and Compliance:Periodic inspections, as mandated by industry regulations, are vital to identify potential issues and ensure compliance with safety standards. Compliance inspections help in detecting faults early, minimizing risks, and avoiding costly penalties.

Spare Parts and Repairs:

- Spare Parts Inventory:Maintaining an inventory of critical spare parts allows for timely repairs, reducing downtime in case of component failure. Costs associated with purchasing spare parts are part of the ongoing operational expenses.

- Repair Costs:Unexpected breakdowns or wear-related issues may necessitate repairs. Costs for repairs, especially those not covered under warranties, contribute to the crane's total cost of ownership.

Operational Expenses:

- Energy Consumption:The energy required to operate overhead cranes, including electricity or fuel costs, is a significant operational expense. Optimizing energy use through efficient operational practices can lead to cost savings.

- Operator Training:Investing in continuous training for crane operators is vital for safe and efficient crane operation. Operator training programs incur costs but can significantly reduce the likelihood of accidents and costly repairs caused by operator error.

- Rental Costs (If Applicable):For intermittent or short-term needs, renting cranes might be a cost-effective option. However, rental costs incurred per usage contribute to operational expenses.

Understanding Different Cost Components

Understanding the various components contributing to overhead crane costs is vital for businesses to make informed decisions regarding acquisition, rental, installation, and overall management.

Average Cost of a Crane – Variations and Industry Standards

The average cost of a crane varies significantly based on factors such as crane type, capacity, brand, specifications, and additional features. Industry standards play a crucial role in setting benchmarks for crane costs. Businesses can gain insights into prevailing market rates by comparing quotes from multiple suppliers, studying industry reports, or consulting with experts. Understanding these variations helps in setting realistic budget expectations.

Crane Cost to Buy – Analyzing Purchase Expenses

The cost to buy an overhead crane encompasses various expenses beyond the crane's base price. It includes expenses for transportation, taxes, warranties, and potential customization. Analyzing the breakdown of these expenses is essential to determine the total acquisition cost accurately. Additionally, comparing quotes from different suppliers and negotiating terms can help in optimizing the purchase cost.

Average Crane Rental Cost – Evaluating Short-term Options

For short-term or project-based needs, renting an overhead crane might be a more viable option than purchasing. The average crane rental cost depends on factors like crane type, duration of rental, additional services provided, and geographic location. Understanding the rental cost structure, including terms and conditions, insurance coverage, and maintenance responsibilities, aids in making cost-effective decisions for temporary or intermittent usage.

Overhead Crane Installation Cost – Factors Influencing Installation Expenses

The installation of an overhead crane involves various factors that impact overall expenses. Site preparation, structural modifications to accommodate the crane, labor costs, specialized equipment, and safety measures are key contributors to installation expenses. The complexity of installation, including height, location, and regulatory compliance, can significantly influence costs. Understanding these factors helps in budgeting and planning for the installation phase accurately.

By comprehending the breakdown of different cost components related to overhead cranes, businesses can strategize their financial allocation effectively, whether opting for purchase or rental, and anticipate the comprehensive expenses involved in installation and operation.

Cost-Effective Strategies for Overhead Crane Acquisition

In the realm of overhead crane procurement, implementing effective strategies can lead to optimized investments and long-term cost savings.

Comparative Cost Analysis between Buying and Renting

Performing a comparative cost analysis between purchasing and renting overhead cranes is pivotal. For short-term or specific project needs, renting might prove to be a more cost-effective option, eliminating upfront purchase expenses and reducing maintenance and ownership responsibilities. Conversely, for long-term and continuous usage, purchasing might offer greater cost efficiencies in the long run.

Long-Term Cost Benefits of Quality and Reliable Cranes

Investing in quality and reliable cranes might involve higher initial costs but offers substantial long-term benefits. Quality cranes often require less frequent maintenance, experience fewer downtimes, and have longer service lives, resulting in reduced overall ownership costs. Additionally, they contribute to enhanced safety, productivity, and operational efficiency.

Negotiating Pricing and Exploring Financing Options

Negotiating pricing with suppliers or manufacturers can significantly impact acquisition costs. Seeking multiple quotes, leveraging competitive pricing, and exploring flexible financing options or leasing agreements can provide financial advantages. Tailoring payment structures or exploring financing options can help businesses manage cash flow effectively while acquiring necessary equipment.

Importance of Regular Maintenance and Its Impact on Overall Costs

Regular maintenance is crucial in mitigating unforeseen repair expenses and extending the lifespan of overhead cranes. Implementing a proactive maintenance schedule not only ensures optimal performance but also reduces the likelihood of costly breakdowns. Scheduled inspections, preventive maintenance, and promptly addressing minor issues can prevent more extensive and expensive repairs in the future, thereby positively impacting overall costs.

Employing these cost-effective strategies allows businesses to make informed decisions regarding overhead crane acquisition, emphasizing a balance between upfront expenses and long-term savings.

Tips for Cost Management and Optimization

Effective cost management and optimization strategies go beyond the initial acquisition or rental phase. Implementing measures to enhance efficiency, reduce operational costs, and prolong crane lifespan are critical for overall cost optimization.

Efficient Utilization and Scheduling of Crane Operations

Optimizing crane utilization by scheduling operations effectively can lead to significant cost savings. Planning and organizing tasks to minimize idle time, optimizing load handling processes, and streamlining workflows contribute to improved operational efficiency. This reduces energy consumption and wear and tear on the crane, ultimately lowering operational costs.

Training Programs for Operators to Minimize Accidents and Repair Costs

Investing in comprehensive training programs for crane operators is essential for accident prevention and cost reduction. Well-trained operators are adept at handling cranes safely and efficiently, reducing the likelihood of accidents and minimizing repair costs associated with operator-related errors. Ongoing training and certifications ensure operators stay updated with best practices and safety protocols.

Upgrading or Retrofitting Existing Cranes for Improved Efficiency

Instead of investing in new cranes, upgrading or retrofitting existing ones can enhance efficiency at a reduced cost. Upgrades like installing modern control systems, adding safety features, or replacing obsolete components can improve performance, safety, and energy efficiency. This approach often proves cost-effective compared to purchasing new equipment.

Monitoring and Assessing Total Cost of Ownership Over Time

Regularly monitoring and assessing the total cost of ownership (TCO) of overhead cranes over their lifespan is crucial. Tracking maintenance expenses, repair costs, energy consumption, and other operational expenditures allows businesses to identify areas for cost reduction and optimization. Analyzing TCO provides insights into the actual expenses associated with crane ownership, aiding in making informed decisions regarding maintenance, repairs, or replacements.

By implementing these cost management and optimization tips, businesses can maximize the efficiency, safety, and longevity of their overhead cranes while minimizing operational expenses.

Wrap it Up,

The cost considerations for overhead cranes encompass various elements, including crane type and specifications, manufacturer quality, customization, installation requirements, and ongoing maintenance expenses. Each factor plays a pivotal role in determining the overall cost of acquiring, operating, and maintaining these indispensable industrial tools.

Making informed decisions regarding crane investments is imperative for businesses. Assessing various options, such as buying versus renting, considering long-term benefits of quality cranes, and exploring financing or negotiation opportunities, ensures a well-rounded evaluation process. These decisions significantly impact operational efficiency, safety, and the company's financial bottom line.

The significance of cost management and optimization in overhead crane operations cannot be overstated. Employing strategies such as efficient utilization, operator training, upgrading existing cranes, and closely monitoring total cost of ownership allows businesses to streamline operations, minimize expenses, and maximize productivity.

In conclusion, mastering the understanding of overhead crane costs requires a comprehensive approach that encompasses initial acquisition considerations, ongoing operational efficiencies, and long-term cost management strategies. By prioritizing informed decision-making and embracing cost-effective practices, businesses can leverage overhead cranes as indispensable assets contributing to operational excellence and sustainable growth.