Crane Lifting Height: Selection Tips and Insights for Choosing the Perfect Overhead Crane

Discover key factors for choosing the ideal overhead crane lifting height, ensuring optimal performance, safety, and efficiency.

What is Crane Lifting Height?

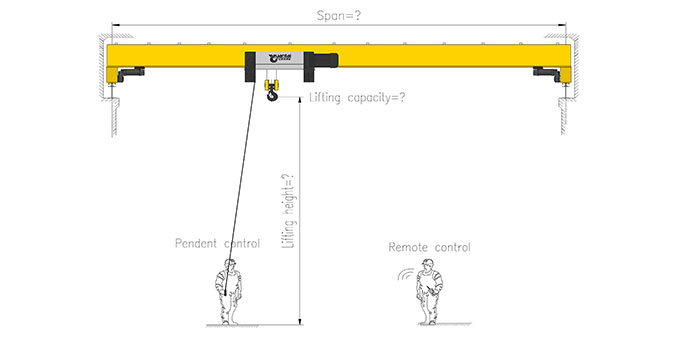

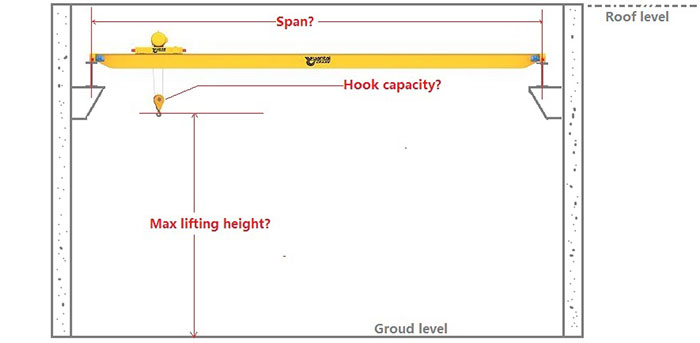

Crane lifting height is the vertical distance from the hook or lifting mechanism of an overhead crane to the floor. It determines how high the crane can lift a load, and it plays a significant role in ensuring the crane operates efficiently within your facility.

- Definition: Distance between hook and floor.

- Importance: Affects how high loads can be lifted and moved.

- Influence on operations: Directly impacts crane performance and safety.

The lifting height must be appropriate for the tasks at hand, considering load size, obstacles, and available headroom in the facility.

Why is Crane Lifting Height Important?

The lifting height is crucial in overhead crane applications for several reasons:

- Operational Efficiency: The right lifting height allows for smooth and efficient load handling.

- Safety: Adequate height clearance ensures there’s no interference with overhead structures, reducing the risk of accidents.

- Performance: Ensures the crane can lift loads as needed, without limitations or obstructions.

Without the proper lifting height, the crane might not be able to perform its intended functions, leading to operational delays and safety concerns.

Relevance of Lifting Height in Crane Selection

Choosing the right lifting height is a key factor in ensuring the crane’s performance, safety, and operational efficiency.

- Optimal Performance: A crane with the correct lifting height will handle loads efficiently and safely.

- Avoiding Obstacles: Ensures the crane clears any overhead structures in the facility, preventing collisions.

- Improved Efficiency: Proper lifting height allows for smooth material flow without interference.

Inaccurate selection of lifting height could lead to wasted space, slower operations, and potential safety hazards. Therefore, it's essential to consider lifting height early in the crane selection process to ensure it fits your operational needs and facility constraints.

Crane Lifting Height

What is Crane Lifting Height?

Crane lifting height refers to the vertical distance between the lowest point of the crane’s hook or lifting device and the floor of the facility. It determines how high the crane can lift materials, and it plays a critical role in the crane’s ability to perform its tasks efficiently.

- Lifting Height Definition: The distance between the hook and the floor, often determined by the height of the facility and the crane’s design.

- Why It Matters: Adequate lifting height is essential to move loads without interference from overhead structures, ensuring smooth operations, and preventing accidents or collisions.

Choosing the correct lifting height is important because it impacts the crane’s capacity to handle different types of loads, including bulky or oversized materials, and it ensures safe and efficient operation within the building’s limitations.

Factors Affecting Lifting Height

Building Height and Headroom:

Building height refers to the overall vertical space within the facility, while headroom is the clearance between the top of the crane and the ceiling or any overhead structures.

- Importance of Vertical Space: The available headroom in your facility directly affects how much lifting height you can have. If there’s limited vertical space, a lower lifting height might be necessary, potentially limiting the crane’s lifting capacity.

- Clearance Considerations: Ensuring enough clearance between the crane and the ceiling is critical to avoid collisions and maximize the crane’s reach.

Crane Design:

Different crane designs influence the lifting height due to their structural configurations. Common types include single girder and double girder cranes.

- Single Girder Cranes: These typically offer lifting heights from 6m to 20m. They are simpler and more cost-effective but have limitations in height compared to double girder cranes.

- Double Girder Cranes: These cranes provide higher lifting heights, often ranging from 12m to 50m, and are better suited for heavy-duty operations and larger facilities where greater height clearance is needed.

The crane’s design affects its ability to reach higher lifting heights and handle heavier loads, and it should be chosen based on your facility’s operational requirements.

Hoisting Mechanism:

The type and configuration of the hoisting mechanism play a vital role in determining the lifting height of a crane.

- Hoist Type: Different hoists (electric, manual, pneumatic) have various designs that impact their lifting range. Electric hoists, for example, typically offer more precise and higher lifting capabilities.

- Hoist Configuration: The way the hoist is configured on the crane (e.g., top-running, underhung) can influence the available lifting height. Top-running hoists generally offer more height clearance, while underhung hoists may be limited by the building’s ceiling height.

The hoisting mechanism determines how much load can be lifted to the desired height, so it’s essential to consider both the type and configuration when determining the crane's lifting capacity.

Types of Overhead Cranes and Their Lifting Heights

Single girder overhead crane lifting height

Single girder overhead crane lifting height

- Typical Lifting Heights: 6m to 20m

- Best Suited For: Smaller to medium-sized facilities and lighter loads

Single girder overhead cranes are equipped with one horizontal beam (the girder) that supports the hoist. This simpler design makes them more cost-effective and ideal for small to medium-sized facilities with moderate lifting needs. Lifting heights typically range from 6m to 20m, offering ample clearance for most lighter loads.

Key Considerations

- Cost-effective solution for light-duty applications

- Ideal for low to medium lifting heights

- Best suited for general material handling in smaller workshops, warehouses, and assembly lines

double girder overhead crane lifting height

double girder overhead crane lifting height

- Typical Lifting Heights: 12m to 50m

- Best Suited For: Heavy-duty operations in large facilities with higher lifting needs

Double girder overhead cranes use two horizontal beams, which provide enhanced lifting capacity and greater clearance. They are ideal for heavy-duty applications and larger facilities requiring higher lifting heights, typically ranging from 12m to 50m. These cranes are commonly used in steel mills, manufacturing plants, and large-scale industrial environments.

Key Considerations

- Higher lifting capacities and heights

- Suitable for heavy-duty operations and larger facilities

- Perfect for industries such as steel production, heavy machinery handling, and large-scale warehousing

- Typical Lifting Heights: 6m to 12m

- Best Suited For: Facilities with limited headroom or smaller spaces

Underhung cranes are mounted from the ceiling rather than running on rails, making them an ideal solution for facilities with limited vertical space. With typical lifting heights ranging from 6m to 12m, they are well-suited for environments where headroom is restricted, but material handling is still essential. These cranes are often used in workshops or maintenance areas with confined spaces.

Key Considerations

- Perfect for low-headroom or confined spaces

- Suitable for light to medium-duty tasks

- Commonly found in small factories, workshops, and maintenance bays

How Lifting Height Impacts Crane Selection

Impact on Facility Layout

- Facility Height and Layout: The height and layout of your facility directly impact the choice of crane lifting height. If your building has lower ceilings, a crane with a lower lifting height is necessary to fit within the space. On the other hand, taller buildings offer more flexibility, allowing cranes with greater lifting heights to be used.

- Headroom Requirements: Adequate headroom is essential to accommodate the crane's hoisting mechanism. In facilities with limited vertical space, ensuring sufficient headroom allows the crane to operate without obstruction.

- Optimal Crane Placement: Proper crane placement is crucial to avoid interference with other building features, such as overhead beams, lights, or HVAC systems. Ensuring proper clearance around the crane ensures it operates efficiently and safely.

Managing Clearance

- Crane and Load Clearance: Ensure that the crane’s hook has enough clearance from the ceiling to move freely. This prevents the crane or the load from making contact with building structures like beams or walls, which could cause damage or malfunction.

- Vertical Space Efficiency: Maximizing available vertical space is key to improving operational efficiency. A crane with the right lifting height makes full use of your facility's height, enhancing storage capacity and material handling without wasting valuable overhead space.

Operational Efficiency

- Maximizing Vertical Space: Selecting the correct lifting height ensures the optimal use of vertical space. For example, taller buildings benefit from cranes with higher lifting heights, enabling them to handle larger or taller loads. This maximizes storage and handling capabilities, allowing for more efficient use of the facility’s total available space.

- Improved Material Flow: By choosing a crane with the appropriate lifting height, you can streamline material flow. The crane’s ability to lift materials to the necessary height ensures smoother handling and reduces unnecessary lifting or moving of loads.

- Handling Larger Loads: A crane with a higher lifting height can handle larger or bulkier loads that require additional clearance. This improves the efficiency of operations, as you’re able to handle more types of materials without needing separate lifting solutions for different load sizes.

Preventing Interference with Overhead Installations

- Avoiding Obstructions: Choosing the right lifting height helps ensure that the crane doesn't interfere with existing overhead installations, like lighting, ducts, or pipes. A crane with the right lifting height avoids collisions, which could damage equipment or reduce operational efficiency.

- Maximizing Space Efficiency: Correct crane height selection helps ensure that all aspects of your facility layout work together. The crane’s lifting height should complement the overhead infrastructure, optimizing space and minimizing the potential for operational disruptions.

Safety Considerations

- Adequate Clearance to Prevent Interference: Safety is paramount when selecting a crane with the appropriate lifting height. Ensuring enough clearance prevents the crane or its load from coming into contact with overhead structures, such as beams or other machinery, minimizing the risk of damage or accidents.

- Clearance Above Load Path: It’s crucial to make sure that the crane's hook and load have sufficient clearance above their path, especially when moving loads along the crane's span. This ensures that the crane can operate safely without interference from overhead objects.

- Safety Zones: Designate safety zones around the crane’s operation area to prevent accidents. These zones keep personnel and other equipment clear of the crane’s operating space, reducing the risk of injury or damage.

Enhancing Operational Safety

- Preventing Load Interference: Selecting the correct lifting height helps to minimize load interference. Cranes with the right height prevent the load from swinging into structures or other equipment, which could damage both the load and the infrastructure.

- Structural Integrity: Choosing a crane with the appropriate height also helps maintain the integrity of the building structure. When a crane operates with the right clearance, it reduces stress on the building and minimizes the risk of damage to overhead systems or other infrastructure.

Factors to Consider When Choosing the Right Lifting Height

- Facility Size and Headroom Availability: Start by assessing the ceiling height and available vertical space within your facility. Make sure that the crane’s lifting height can be accommodated within the facility's layout, leaving enough room for safe operation and movement.

- Material Handling Needs: Lifting height needs can vary depending on the size, type, and shape of the material being handled. Heavier or larger loads may require a crane with a higher lifting height to ensure that the load can be lifted and moved safely within the space.

- Types of Operations: Different operations have different lifting height requirements. For example, light-duty operations may only need a lower lifting height, while heavy-duty operations or those involving oversized materials will need a crane capable of handling greater heights.

- Industry-Specific Requirements: Certain industries, such as automotive manufacturing, aerospace, or steel production, may require specialized cranes with specific lifting height capabilities. For example, aerospace facilities may need higher lifting heights for large components, while manufacturing plants may require mid-range heights for general material handling.

By carefully evaluating these factors, you can ensure that your crane’s lifting height aligns with the needs of your facility and operational requirements, optimizing both safety and efficiency.

Lifting Height and Span: The Relationship and Its Effect on Crane Selection

How Span and Lifting Height Interact

- Balance Between Span and Height: The span (the distance between crane supports) and lifting height are closely related when selecting a crane. A larger span generally demands a more substantial crane structure, which could require a higher lifting height to maintain efficient load handling across the facility. Striking a balance between these two elements ensures that the crane can perform effectively without compromising stability or operational capacity.

- Impact of Span on Height: A wider span might necessitate additional clearance for the crane’s hoisting mechanisms or other components, especially when considering the clearance between the load and the ceiling. This can affect both the crane's design and the required lifting height. To maintain efficiency, a wider span may require additional height or clearance to support the crane’s load range and maneuverability.

- Impact of Height on Span: Cranes with higher lifting heights may need a wider span to provide stability and allow the crane to handle loads efficiently. Increasing the lifting height can place more stress on the crane structure, and a wider span helps to distribute this weight and maintain balance, preventing tipping or instability during operation.

Facility Space Planning

- Crane Span and Lifting Height Adjustments: As the span of a crane increases, adjustments to the lifting height may also be necessary to ensure that the crane can operate effectively over the extended area. For instance, a crane with a large span and high lifting height may need additional support structures to maintain safety and prevent mechanical failures.

- Facility Design Modifications: Increasing the span and height of a crane often requires modifications to the facility’s design. These adjustments could involve changing ceiling heights, reinforcing overhead installations (like beams, lighting, or ducts), and ensuring that the layout can accommodate the crane’s wider and taller frame. This ensures the crane can operate safely and without interference from existing building structures.

- Structural Considerations: With wider spans and higher cranes, the facility’s structural integrity becomes more crucial. Support structures, such as walls, columns, and roof beams, may need reinforcement to accommodate the crane’s larger dimensions and the additional load it will bear during operation.

- Maximizing Facility Layout: Efficient planning of both span and height can help optimize the layout of the facility, ensuring that the crane’s operational area does not cause disruptions or inefficiencies. Proper coordination of vertical and horizontal space will maximize material handling capabilities and reduce the risk of operational bottlenecks.

Lifting Height vs. Lifting Capacity

- Crane Lifting Height and Capacity Relationship: There is a direct relationship between the crane’s lifting height and its lifting capacity. Generally, as the lifting height increases, the lifting capacity of the crane may decrease. This is due to the increased structural demands placed on the crane to handle higher lifts, which can result in reduced stability or require lighter loads to maintain the crane’s structural integrity.

- Heavy-Duty Applications: For cranes used in heavy-duty applications, the lifting height and capacity trade-off becomes even more critical. Cranes designed to lift heavy loads at high elevations must be reinforced with stronger support systems, making it more challenging to balance both height and capacity. These cranes may require specialized designs to maintain lifting performance at higher heights without compromising safety.

- Compromise Between Height and Capacity: In some cases, achieving a higher lifting height may necessitate reducing the crane’s lifting capacity. This is an important factor to consider when selecting the right crane for your operation. It’s essential to assess whether the required lifting height justifies any reduction in capacity, or whether alternative solutions should be explored.

Crane Control Options and Lifting Height

- Manual vs. Electric Controls: The type of crane control system chosen—manual or electric—can be influenced by the crane’s lifting height. Electric controls are often preferred for cranes with high lifting heights due to their precision, ease of use, and ability to handle the added complexity of lifting heavy or awkward loads at greater elevations.

- Electric Control Systems: For cranes with high lifting heights, electric control systems provide more power, better precision, and enhanced safety features. These systems are ideal for maintaining smooth, efficient operation in complex environments, especially when heavy loads are involved. Electric controls ensure that the crane operates precisely even under challenging conditions, such as high-lift maneuvers or dynamic loading situations.

- Manual Controls for Lower Heights: Manual controls might suffice for cranes operating at lower heights, where lifting complexity and load requirements are less demanding. However, manual operation may become less practical and less safe as the lifting height increases, particularly in more complex or high-risk environments.

Remote Control vs. Cabin Operation

- Remote Control Systems: For cranes operating at high lifting heights, remote control systems offer significant advantages in terms of operator safety and efficiency. By allowing the operator to control the crane from a distance, these systems reduce the risk of injury from swinging loads, collisions with overhead structures, or equipment malfunctions. Remote control enhances visibility and allows operators to stay clear of the crane’s hazardous operating zone.

- Advantages of Remote Control: The primary benefits of remote control systems include improved operator safety, better visibility, and greater precision when maneuvering loads at higher elevations. These systems are especially useful in high-risk environments, such as construction sites or large-scale industrial facilities, where keeping operators out of the danger zone is essential.

- Cabin Operation for High-Lift Cranes: For extremely high-lift cranes or those working in complex environments (e.g., offshore platforms, steel mills), cabin operation may be required. High-lift cranes require operators to have a clear, comprehensive view of their surroundings to safely manage the crane’s operations, preventing accidents and ensuring efficient handling of heavy loads.

- When Cabin Operation is Necessary: Crane cabins are essential when high lifting heights demand more precise control, especially in areas with limited visibility or hazardous conditions. Cabin operators can manage complex movements and ensure safety, particularly in environments where heavy, bulky loads are being lifted over long distances.

- Comfort and Safety: Cabin operation provides a controlled, safe environment for operators working with high-lift cranes, especially when managing heavy or awkwardly positioned loads. The cabin serves as a protective space, reducing the risks posed by high-altitude operations and enhancing operator focus and comfort during prolonged shifts.

Maintenance Considerations for High Lifting Height Cranes

- Impact on Maintenance Needs: Cranes with high lifting heights experience increased wear and tear due to the greater distance the hoist must travel. This increased travel distance, combined with the added load handling at greater heights, results in greater mechanical strain, especially on components like the hoisting mechanism, lifting gears, and cables.

- Increased Maintenance Demands for High Lifting Cranes: Cranes operating at higher lifting heights require more frequent maintenance to prevent failures. Regular inspections of critical components such as cables, hoists, and pulleys are necessary to detect and address any issues before they lead to costly repairs or downtime.

- Maintenance Techniques: Higher lifting height cranes may require specialized maintenance procedures, including advanced diagnostic tools, specialized lubricants, and more rigorous inspection protocols. For example, hoists and load-bearing components may need additional checks to ensure that they remain in optimal condition, preventing breakdowns.

- Durability and Wear: Hoisting mechanisms on high-lift cranes bear more strain, especially when handling heavy loads, leading to accelerated wear and tear. To mitigate this, cranes should be constructed from durable materials that can withstand the additional stresses imposed by higher lifts. Steel frames, corrosion-resistant components, and reinforced hoisting mechanisms can help extend the crane’s lifespan and minimize maintenance costs.

- Best Practices for Choosing the Right Crane Lifting Height: Conducting a thorough site evaluation is crucial for determining the appropriate lifting height. Consider the facility's headroom and clearance, assess the space for the crane’s span, and ensure that structural support is adequate. Working with structural engineers and crane manufacturers will ensure that the crane’s height and span are optimized for both current and future operational needs. Additionally, considering long-term maintenance and durability factors will help ensure the crane’s performance over its lifespan.

By carefully evaluating these factors and consulting with experts, you can select the ideal crane that balances lifting height, span, capacity, and operational efficiency, ensuring a safe, productive, and cost-effective solution for your facility.

Conclusion

Choosing the right crane lifting height is essential for maximizing operational efficiency and ensuring safety. It influences crane performance, facility space utilization, and smooth material flow. Proper lifting height also plays a crucial role in preventing crane loads or components from hitting overhead structures. By understanding the relationship between lifting height, crane span, and lifting capacity, you can make smarter decisions that benefit both your facility's layout and your operational needs.

Final Tips for Selecting the Right Crane

- Thorough Site Evaluation: Before making a decision, evaluate your facility’s headroom and clearance. This will help you understand how much vertical space is available for crane installation.

- Collaborate with Experts: Work closely with engineers and crane manufacturers. They can help tailor the crane’s lifting height to meet your specific needs and constraints, ensuring better performance and safety.

- Plan for the Future: Think ahead about potential growth. Select a crane lifting height that accommodates future expansion or changes in production requirements. This foresight can save you from unnecessary costs and upgrades down the road.

Actionable Next Steps

- Assess Your Needs: Start by evaluating the lifting height requirements of your facility based on current and future tasks.

- Seek Professional Advice: Reach out to crane manufacturers or consult with engineers to discuss your specific lifting height and operational needs. Getting expert advice will ensure the best crane selection for your facility.

- Act Now: Take the next step towards improving your facility’s crane system. A carefully chosen crane lifting height will optimize your operations and enhance safety.