Calculating the Total Weight of a 5-Ton Overhead Crane for Workshop Design

Guide to determining the total weight of a 5-ton overhead crane, crucial for accurate workshop design and structural planning.

Overview of Overhead Cranes

Overhead cranes, particularly bridge cranes, play a pivotal role in various industrial and manufacturing settings by facilitating the movement of heavy loads. A 5-ton overhead crane, also known as a 5-ton bridge crane, is a commonly used type of crane that can handle loads up to 5 metric tons. These cranes are widely used in warehouses, manufacturing facilities, and workshops due to their ability to efficiently lift and transport heavy materials across a defined area.

The primary aim of this article is to provide a comprehensive guide on calculating the total weight of a 5-ton overhead crane, which is crucial for effective workshop design. Understanding the weight of the crane is essential for ensuring that the workshop's structure can support the crane's load and operate efficiently. This guide will delve into the key factors influencing crane weight, including design type, span length, lifting height, and working duty rating.

Key Factors Influencing Crane Weight

Crane Design Type

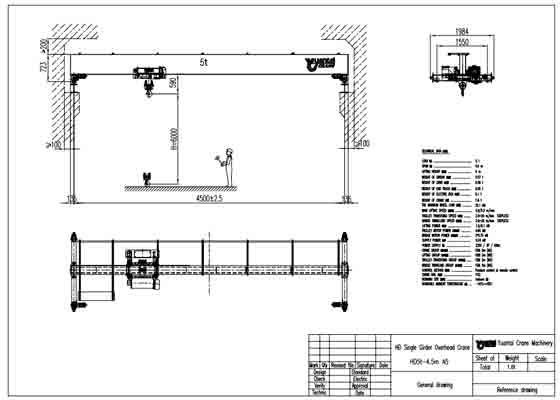

The design type of an overhead crane significantly impacts its weight. There are two primary designs for overhead cranes: single girder and double girder.

- Single Girder Design: This design features one main girder supporting the crane's hoist and trolley. Single girder cranes are generally lighter and more cost-effective compared to double girder cranes. They are suitable for applications where the span is not excessively large and the lifting height requirements are moderate.

- Double Girder Design: Double girder cranes have two parallel girders that provide additional support and strength. This design is typically used for heavier loads, larger spans, and higher lifting heights. Double girder cranes are more robust and offer greater lifting capacities and durability but are also heavier.

Span Length

Span length refers to the distance between the crane's support structures or runway beams. It plays a crucial role in determining the crane's overall weight.

- Effect on Weight: As the span length increases, the crane's weight generally increases due to the need for additional structural components to maintain stability and support the extended span. Longer spans require larger girders and more material, resulting in a heavier crane.

Lifting Height

Lifting height is the maximum distance the crane can lift a load. It is another important factor affecting the crane's weight.

- Relationship to Weight: Higher lifting heights necessitate longer hoists and more robust structural elements to ensure safe and effective lifting operations. This additional equipment and material contribute to the overall weight of the crane.

Working Duty Rating

Working duty ratings, such as A6, define the crane's operational intensity and frequency. These ratings impact the design and weight of the crane.

- Explanation of Duty Ratings: Duty ratings are classifications that specify how often and how heavily a crane will be used. For example, an A6 duty rating indicates a crane designed for high-frequency use with moderate loads.

- Impact on Weight: Cranes with higher duty ratings typically require more reinforced components and additional structural support to handle the increased workload. This reinforcement adds to the crane's overall weight.

Calculating Crane Weight Based on Design Type

Single girder cranes are generally lighter compared to double girder designs. The weight of a 5-ton single girder overhead crane varies based on span length and lifting height.

- Typical Weight Ranges: For a single girder crane, the weight can vary based on the span length and lifting height. For instance, a 5-ton single girder crane with a span of 5 meters and a lifting height of 6 meters may weigh approximately 2,200 kg. As the span length and lifting height increase, the weight also increases due to the need for more structural support.

Example Calculations:

- Span 5 meters, Lifting Height 6 meters: Weight = 2,200 kg

- Span 10.5 meters, Lifting Height 9 meters: Weight = 2,521 kg

- Span 15 meters, Lifting Height 12 meters: Weight = 3,200 kg

- Span 15 meters, Lifting Height 12 meters: Weight = 3,928 kg

Double Girder Design

Double girder cranes are heavier due to their additional structural components. The weight of a 5-ton double girder overhead crane is influenced by the span length, lifting height, and duty rating.

Typical Weight Ranges: Double girder cranes are designed for higher loads and larger spans, resulting in increased weight. For example, a 5-ton double girder crane with a span of 10.5 meters and a lifting height of 12 meters may weigh around 8,400 kg.

Example Calculations:

- Span 10.5 meters, Duty Rating A6: Weight = 8,400 kg

- Span 15 meters, Duty Rating A6: Weight = 9,620 kg

- Span 15 meters, Duty Rating A6: Weight = 11,190 kg

- Span 19.5 meters, Duty Rating A6: Weight = 13,063 kg

Influence of Span Length on Crane Weight

Definition of Span Length

Span length is the distance between the crane’s support beams. It is a critical factor in determining the crane’s weight because it affects the amount of structural support needed.

Weight Changes with Varying Spans

As the span length increases, the crane's weight increases due to the need for more robust materials and structural components.

Detailed Analysis:

- Span 5 meters: Generally lighter, requiring less material.

- Span 10.5 meters: Increased weight due to longer beams and additional supports.

- Span 15 meters: Heavier due to larger structural components.

- Span 15 meters and above: Significantly heavier as the span requires substantial reinforcement.

Case Studies

- Manufacturing Facility: A facility used a 5-ton overhead crane with varying spans to improve efficiency. The crane's weight increased proportionally with the span length, impacting both material and installation costs.

- Warehouse Example: In a warehouse setting, a longer span required additional structural support, resulting in higher crane weight and associated costs.

Lifting Height and Its Impact on Crane Weight

Definition of Lifting Height

Lifting height refers to the maximum vertical distance the crane can lift a load. It influences the crane's weight by affecting the length and strength of the hoisting mechanism.

Weight Adjustments with Different Heights

Increasing the lifting height requires longer hoists and additional structural components, which adds to the crane’s weight.

Detailed Analysis:

- Lifting Height 6 meters: Lower weight, simpler design.

- Lifting Height 9 meters: Moderate weight increase due to longer hoisting mechanism.

- Lifting Height 12 meters: Significant weight increase as more robust components are needed.

Case Studies

- Manufacturing Facility Upgrade: Upgrading to a crane with a higher lifting height required additional structural supports and reinforced components, impacting the overall weight.

- Construction Site Example: In a construction setting, a higher lifting height necessitated heavier cranes to ensure safe and efficient lifting operations.

Working Duty Rating and Its Effect on Crane Weight

Duty Ratings

Duty ratings classify the crane's operational intensity and frequency. Common ratings include A6, which indicates high-frequency use with moderate loads.

Impact of Duty Ratings on Crane Design

Cranes with higher duty ratings require more robust components to handle frequent and intense usage, leading to increased weight.

- Explanation of Duty Ratings:

- A6 Rating: Designed for high-frequency operations, requiring reinforced structures and additional safety features.

Example Calculations

5-Ton Crane with Duty Rating A6:

- Span 10.5 meters: Weight = 8,400 kg

- Span 15 meters: Weight = 9,620 kg

- Span 15 meters: Weight = 11,190 kg

Case Studies

- Automotive Assembly Line: A crane with an A6 duty rating was used for high-frequency operations, requiring substantial reinforcement and resulting in increased weight.

- Heavy Industry Example: In heavy industry applications, higher duty ratings led to significant weight increases due to enhanced structural components.

Practical Considerations for Workshop Design

Structural Design Requirements

The weight of the overhead crane directly influences the workshop’s structural design. Ensuring the workshop can support the crane’s weight is crucial for safe and effective operation.

- Reinforced Structures: Workshops may require additional reinforcement to support heavier cranes. This includes strengthening the foundation and support beams.

- Foundation Requirements: A robust foundation is essential to distribute the crane's weight evenly and prevent structural damage.

Cost Implications

The weight of the crane affects both material and installation costs.

- Increased Material Costs: Heavier cranes require more materials for construction, raising overall costs.

- Installation Costs: Installing a heavier crane involves more complex procedures and equipment, increasing installation costs.

Budget Considerations

- Crane Purchase and Installation: Budgeting for crane weight includes both the cost of the crane and any additional structural modifications required.

Conclusion

The total weight of a 5-ton overhead crane is crucial for effective workshop design. Key factors include crane design type, span length, lifting height, and working duty rating. Accurate weight calculations ensure that the workshop’s structure can support the crane and operate efficiently.

Proper weight calculations are essential to avoid structural issues and ensure safe crane operation. Consulting with engineers for accurate assessments and design considerations is highly recommended to prevent potential risks and ensure optimal performance.

Important Note

Disclaimer

The weights and costs provided in this article are based on general estimates and cost-effective production in China. Actual crane weight and costs should be calculated based on specific parameters, application environments, and production factors. The data presented here is for reference only and should not be used as the sole basis for construction or design decisions. For accurate calculations and to avoid any risks, please consult with our engineers before making any decisions.

This comprehensive article provides a detailed guide on calculating the total weight of a 5-ton overhead crane, covering key factors, practical considerations, and real-world examples to assist in effective workshop design and planning.