Customizing Your Aluminum Gantry Crane: Tailoring Specifications to Meet Your Needs

Custom aluminum gantry cranes play a crucial role in modern industrial operations, offering tailored solutions that enhance efficiency and safety across various sectors. Whether in workshops, warehouses, or construction sites, these cranes are designed to meet specific lifting needs with precision and reliability.

Importance in Industrial Operations: In today's industrial landscape, the versatility and adaptability of custom aluminum gantry cranes are indispensable. They provide targeted solutions for lifting heavy machinery parts, loading goods, and handling materials in diverse environments. By customizing these cranes, businesses can optimize their operational workflows, minimize downtime, and improve overall productivity.

Process of Specifying and Acquiring Custom Cranes: Specifying and acquiring a custom aluminum gantry crane involves a detailed assessment of operational requirements. This includes defining the exact tasks the crane will perform, determining the maximum load capacity needed, and specifying the span and lifting height required to fit the workspace. Consideration of operational conditions, such as indoor or outdoor use and environmental factors like humidity and temperature, is crucial. By collaborating closely with crane manufacturers, businesses can ensure that the crane design meets all safety standards and operational needs effectively.

Custom aluminum gantry cranes are not just equipment; they are tailored solutions designed to meet specific challenges and enhance operational efficiency in industrial settings.

5 ton aluminum gantry crane customized for project in the Philippines

Understanding Your Requirements

To ensure the optimal performance and suitability of a custom aluminum gantry crane for your operations, it's essential to thoroughly assess your specific requirements. This involves evaluating operational needs and challenges to effectively tailor the crane to meet your exact lifting demands.

- Assessing Operational Needs and Challenges: Begin by identifying the precise tasks the gantry crane will undertake within your industrial environment. Whether it's lifting heavy machinery parts in a workshop, handling materials in a warehouse, or maneuvering construction materials on-site, understanding these operational challenges is crucial. Consider factors such as the frequency of use, the nature of the materials being lifted, and any spatial constraints or environmental conditions that may affect crane performance.

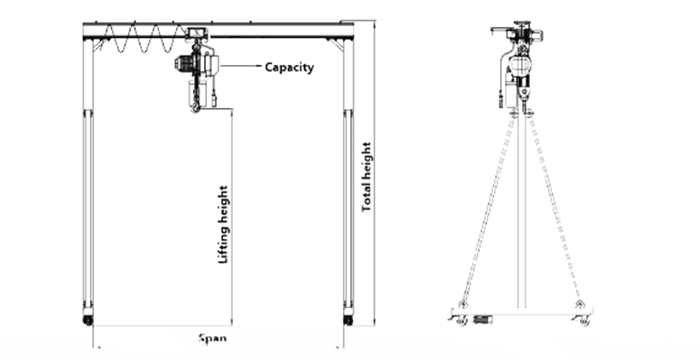

- Determining Load Capacities, Span Requirements, and Lift Heights: Define the maximum weight that the gantry crane will need to lift on a regular basis. This load capacity should account for the heaviest items in your operations to ensure safe and efficient lifting. Measure the span required between the crane's legs to fit comfortably within your workspace while providing adequate clearance for lifting operations. Additionally, specify the lift height needed to reach the required elevation for material handling tasks. Consider any overhead obstructions or height restrictions that may impact crane functionality.

By carefully assessing these operational needs and specifying the load capacities, span requirements, and lift heights accurately, you can ensure that the custom aluminum gantry crane is tailored to enhance productivity, safety, and operational efficiency in your specific industrial setting. This process forms the foundation for collaborating effectively with crane manufacturers to design and acquire a crane that meets all your operational requirements seamlessly.

Consulting with Crane Manufacturers

Choosing the right manufacturer for your custom aluminum gantry crane is crucial to ensuring it meets your operational needs effectively. Here’s how to navigate the process:

- Finding Reputable Manufacturers: Start by researching manufacturers known for their expertise in designing and producing custom aluminum gantry cranes. Look for companies with a proven track record in the industry and positive reviews from past clients. Manufacturers with extensive experience in handling similar projects are likely to offer reliable solutions tailored to your specific requirements.

- Discussing Specific Requirements: Once you've identified potential manufacturers, initiate discussions to outline your specific needs and expectations. Provide detailed information about your operational environment, including the types of materials to be lifted, operational frequencies, and any unique challenges or constraints. Clearly communicate your desired load capacities, span requirements, and lift heights to ensure the crane is designed to perform optimally in your workspace.

- Customization Options: Explore customization options with the manufacturer to tailor the gantry crane precisely to your requirements. This may include adjusting the crane’s dimensions, choosing between manual or electric hoists, incorporating safety features such as overload protection systems, or integrating specialized controls for enhanced operational efficiency. Discuss how these customizations can address your operational challenges and improve overall productivity.

- Collaboration and Design Process: Engage in collaborative discussions throughout the design process to refine specifications and ensure alignment with your operational goals. Manufacturers may provide CAD drawings, simulations, or prototypes to visualize the crane’s configuration and functionality. This collaborative approach allows for feedback and adjustments, ensuring the final crane design meets all safety standards and operational requirements.

By consulting with experienced crane manufacturers and discussing specific requirements and customization options in detail, you can secure a custom aluminum gantry crane that enhances productivity, safety, and efficiency in your industrial operations. Effective communication and collaboration are key to achieving a tailored solution that meets your unique lifting needs seamlessly.

Key Specifications to Consider

When specifying a custom aluminum gantry crane, several key specifications must be carefully evaluated to ensure optimal performance and safety:

- Load Capacity: The load capacity is a critical specification that determines the maximum weight the crane can safely lift. Assess your operational needs to accurately determine the heaviest load that the crane will handle regularly. Consider potential future requirements to ensure the crane can accommodate growth and changing operational demands.

- Span: The span refers to the distance between the legs or supports of the gantry crane. Measure the span required based on the layout of your workspace and the positioning of the materials or equipment to be lifted. Optimal span configuration ensures stability and efficient load handling within your operational environment.

- Height: Specify the lift height needed for your operations, considering the vertical distance from the floor to the highest point the crane’s hook needs to reach. Measure the clearance required to lift materials safely and effectively without obstruction. Ensure the crane’s height adjustment capabilities align with your workspace constraints and operational tasks.

- Environmental Factors: Additionally, consider environmental factors such as indoor or outdoor use, temperature variations, humidity levels, and exposure to corrosive elements. These factors can influence the crane’s material selection, protective coatings, and maintenance requirements to ensure longevity and reliability in diverse operating conditions.

- Safety and Compliance: Ensure the gantry crane meets all relevant safety standards and regulatory requirements for your industry. This includes considerations for overload protection systems, emergency stop mechanisms, and operator safety features. Compliance with safety standards ensures safe operation and mitigates risks in the workplace.

By carefully evaluating these key specifications and consulting with experienced crane manufacturers, you can tailor a custom aluminum gantry crane that precisely meets your operational requirements. This proactive approach ensures efficient material handling, enhances workplace safety, and supports overall productivity in industrial settings.

Learn more on types of aluminum portable gantry cranes and specifications

Customization Options of Aluminum Portable Gantry Cranes

When customizing your aluminum portable gantry crane, several key options can be tailored to meet your specific operational requirements:

- Frame Design: Selecting the right frame design is crucial for optimizing load capacity and structural stability:

Single or Double Girder: Choose between single girder for lighter loads and more economical solutions, or double girder for heavier lifting capacities and increased stability.

A-frame or T-frame Designs: A-frame designs offer excellent stability and load-bearing capabilities, ideal for applications where space is limited or uneven terrain is a concern. T-frame designs provide enhanced load distribution and structural support, suitable for heavier-duty operations.

- Mobility Options: Choosing the mobility configuration that best suits your operational needs ensures flexibility and efficiency:

- Fixed Gantry: Ideal for dedicated lifting tasks in a permanent location, providing maximum stability and load capacity.

- Adjustable Gantry: Offers flexibility in span width adjustments, accommodating various load sizes and configurations within the same workspace.

- Portable Gantry: Designed for easy transportation and setup across different work areas, facilitating versatile lifting operations where mobility is essential.

These customization options allow you to tailor your aluminum portable gantry crane to match specific lifting requirements, operational environments, and logistical demands. Consult with experienced crane manufacturers to explore these options further and ensure your crane solution meets all technical specifications and safety standards relevant to your industry.

Material and Construction

Choosing aluminum for your gantry crane construction offers several significant advantages that enhance both performance and longevity:

Importance of Aluminum in Gantry Crane Construction: Aluminum is a preferred material for gantry crane construction due to its exceptional properties that cater to various industrial needs:

Benefits of Aluminum:

- Lightweight: Aluminum gantry cranes are significantly lighter than steel counterparts, facilitating easier transportation, installation, and mobility within workspaces. This characteristic is particularly beneficial in applications requiring frequent repositioning or use in environments with weight limitations.

- Corrosion-Resistant: Aluminum exhibits excellent resistance to corrosion, making it suitable for both indoor and outdoor applications. This property ensures longevity and reduces maintenance costs over the crane's operational lifespan, particularly in humid or corrosive environments such as coastal areas or chemical plants.

- Durable: Despite its lightweight nature, aluminum is robust and durable, capable of withstanding heavy loads and harsh working conditions. This durability translates to reliable performance and operational safety, crucial in demanding industrial settings where crane reliability is paramount.

By leveraging these properties, aluminum gantry cranes offer enhanced operational efficiency, reduced maintenance requirements, and extended service life, making them a practical choice for various lifting applications across industries.

Safety and Compliance

When selecting and operating aluminum gantry cranes, prioritizing safety and compliance is paramount to ensure a secure working environment and regulatory adherence:

Ensuring Compliance with Local and International Safety Standards: Before procurement, verify that the gantry crane meets relevant safety standards set forth by local regulatory authorities and international bodies such as ANSI (American National Standards Institute) or ISO (International Organization for Standardization). Compliance ensures the crane is designed, manufactured, and operated in accordance with recognized safety protocols, mitigating risks and liabilities.

Incorporating Essential Safety Features: To enhance operational safety, aluminum gantry cranes should incorporate essential safety features tailored to specific industrial applications:

- Overload Protection: Integrating overload detection systems prevents the crane from lifting loads exceeding its rated capacity, safeguarding against structural damage and accidents due to overloading.

- Emergency Stop Buttons: Strategically placed emergency stop buttons allow operators to halt crane operations immediately in case of emergencies or unsafe conditions, minimizing risks to personnel and equipment.

- Safety Audits and Inspections: Regular safety audits and inspections ensure ongoing compliance with safety standards and identify potential hazards or maintenance needs. Periodic checks and maintenance routines help maintain optimal crane performance and reliability over time.

By prioritizing safety features and compliance with regulatory standards, aluminum gantry cranes can effectively mitigate risks, enhance workplace safety, and support efficient operations in diverse industrial environments.

Cost Considerations

When investing in custom aluminum gantry cranes, understanding the various cost factors involved is crucial for budgeting and decision-making:

Factors Influencing the Cost of Custom Aluminum Gantry Cranes:

- Customization Complexity: The level of customization required, such as specific frame designs (single or double girder, A-frame, T-frame), specialized controls (manual, semi-automated, fully automated), and additional features (hoist options, mobility configurations), significantly impacts the overall cost. More complex customizations often entail higher engineering and manufacturing expenses.

- Load Capacity and Span: The crane's load capacity, which determines the maximum weight it can safely lift, and the span (distance between legs or supports) required for your operational needs directly influence costs. Higher load capacities and wider spans typically require heavier-duty materials and structural reinforcements, contributing to increased costs.

- Material and Construction Quality: The choice of materials, particularly high-quality aluminum alloys known for their lightweight, corrosion-resistant, and durable properties, affects both initial purchase costs and long-term maintenance expenses. Opting for superior construction materials ensures longevity and reliability but may entail higher upfront investments.

- Installation Requirements: Consideration of installation complexities, such as site preparation, crane assembly, and integration with existing infrastructure, impacts overall project costs. Factors like accessibility to installation sites and any necessary modifications to support structures can affect budgeting considerations.

- Ongoing Maintenance and Service: Budgeting for ongoing maintenance, inspections, and servicing is essential for ensuring optimal crane performance and longevity. Regular maintenance helps prevent downtime, ensures safety compliance, and prolongs the operational lifespan of the crane, thereby reducing long-term costs associated with repairs and replacements.

Budgeting for Initial Purchase, Installation, and Ongoing Maintenance:

- Initial Purchase: Allocate funds for the initial purchase of the custom aluminum gantry crane, factoring in the chosen specifications, customization options, and delivery costs. Request detailed quotations from reputable manufacturers that outline all included features and potential additional expenses.

- Installation Costs: Plan for installation expenses, including site preparation, crane assembly, and any necessary modifications to infrastructure. Consider hiring certified professionals or leveraging manufacturer-provided installation services to ensure safe and efficient crane setup.

- Ongoing Maintenance: Establish a budget for routine maintenance, inspections, and servicing to uphold crane performance and safety standards. Budgeting for spare parts, lubricants, and emergency repairs helps minimize operational disruptions and unforeseen expenses over the crane's lifespan.

By carefully evaluating these cost considerations and budgeting effectively for initial purchase, installation, and ongoing maintenance, businesses can make informed decisions regarding the acquisition of custom aluminum gantry cranes. Prioritizing quality, safety, and long-term operational efficiency ensures a worthwhile investment in enhancing material handling capabilities within industrial operations.

Installation and Maintenance

Planning for Installation Logistics and Site Preparation:

- Site Assessment: Conduct a thorough assessment of the installation site to identify any potential challenges or requirements. Ensure that the site has adequate space, proper surface conditions, and necessary support structures to accommodate the gantry crane.

- Preparation and Permits: Prepare the site by clearing obstacles, leveling the ground, and reinforcing any weak areas. Obtain any necessary permits or approvals from local authorities to comply with regulations and safety standards.

- Coordination with Manufacturers: Collaborate closely with the crane manufacturer to understand the specific installation requirements and procedures. Ensure that all components, tools, and equipment needed for assembly are available on-site.

- Professional Installation: Hire certified professionals or utilize the manufacturer’s installation services to ensure proper assembly and integration of the crane. Proper installation is crucial for the crane’s performance, safety, and longevity.

Establishing a Maintenance Schedule to Ensure Longevity and Reliability:

- Routine Inspections: Implement a regular inspection schedule to check for any signs of wear, damage, or malfunctions. Inspections should include checking the structural integrity, moving parts, electrical systems, and safety features of the crane.

- Preventive Maintenance: Perform preventive maintenance tasks such as lubricating moving parts, tightening bolts, and replacing worn components. Preventive maintenance helps prevent breakdowns and extends the crane’s operational life.

- Training for Operators: Provide comprehensive training for crane operators on proper usage, safety protocols, and routine maintenance tasks. Well-trained operators can identify potential issues early and ensure safe crane operation.

- Record Keeping: Maintain detailed records of all inspections, maintenance activities, and repairs. Keeping a maintenance log helps track the crane’s condition over time and ensures compliance with safety regulations.

- Manufacturer Support: Utilize support services offered by the crane manufacturer, such as technical assistance, spare parts supply, and regular maintenance checks. Manufacturer support ensures that the crane remains in optimal working condition.

By carefully planning for installation and establishing a robust maintenance schedule, businesses can ensure the longevity, reliability, and safe operation of their custom aluminum gantry cranes. Proper installation and regular maintenance not only enhance the crane’s performance but also contribute to a safer and more efficient working environment.

Case Studies and Examples

Custom Aluminum Gantry Crane Applications:

Manufacturing Facility in Cebu:

Challenge: A large manufacturing plant needed a versatile lifting solution for handling machinery parts and conducting maintenance within confined spaces.

Solution: A custom aluminum gantry crane with adjustable height and span was installed, allowing workers to lift and move heavy components with ease.

Outcome: The crane's portability and lightweight design significantly improved workflow efficiency, reduced downtime during maintenance, and enhanced overall productivity.

Warehouse in Manila:

Challenge: A logistics company required an efficient way to load and unload goods from trucks and manage inventory within their warehouse.

Solution: An aluminum gantry crane with a high load capacity and adjustable features was implemented, facilitating quick assembly and disassembly for various lifting tasks.

Outcome: The crane streamlined loading and unloading processes, optimized space utilization, and supported effective inventory management, leading to faster turnaround times and improved logistics operations.

Construction Site in Davao:

Challenge: A construction project needed a reliable crane to lift and position heavy building materials, such as steel beams and precast concrete panels, on uneven terrain.

Solution: A portable aluminum gantry crane with a sturdy, adjustable frame was deployed, providing the flexibility to adapt to different site conditions.

Outcome: The crane's adaptability and ease of mobility enhanced construction efficiency, reduced labor costs, and ensured precise positioning of materials, contributing to timely project completion.

Success Stories and Lessons Learned from Implementation:

Shipyard in Subic Bay:

Success Story: A shipyard utilized a custom aluminum gantry crane to support shipbuilding and repair activities. The crane's corrosion-resistant properties and robust construction allowed it to withstand harsh marine environments.

Lessons Learned: Regular maintenance and timely inspections were crucial to maintaining the crane's performance in challenging conditions. The importance of operator training and adherence to safety protocols was also emphasized to ensure safe and efficient operations.

Agricultural Operation in Negros Occidental:

Success Story: A farming operation implemented an aluminum gantry crane to handle livestock feed and agricultural equipment. The crane's lightweight nature and maneuverability proved beneficial for operating within barns and outdoor facilities.

Lessons Learned: Customizing the crane to suit specific agricultural needs, such as adjustable height for different tasks, enhanced its utility. The farm also highlighted the value of preventive maintenance to avoid unexpected downtime during peak seasons.

Event Setup in Quezon City:

Success Story: An event management company used an aluminum gantry crane for setting up temporary stages and lighting rigs. The crane's quick assembly and portability ensured minimal disruption to event schedules.

Lessons Learned: Flexibility in height and width adjustments was essential for adapting to various venue layouts. The ability to rapidly deploy and dismantle the crane was a key factor in optimizing event logistics and reducing setup time.

These case studies and examples demonstrate the practical applications and benefits of custom aluminum gantry cranes in diverse industries. By understanding the challenges faced and solutions implemented, businesses can gain insights into how these cranes can be tailored to meet their specific operational needs, leading to improved efficiency, productivity, and safety.

Conclusion

Acquiring a custom aluminum gantry crane involves careful consideration of various factors to ensure it meets your specific operational needs. Key considerations include assessing your operational requirements, consulting with experienced manufacturers, determining essential specifications such as load capacity, span, and height, and exploring customization options for frame design and mobility.

Thorough planning and consultation with experts are crucial in this process. By understanding the unique challenges and opportunities within your industry, you can select a gantry crane that enhances productivity, ensures safety, and offers long-term reliability. Custom aluminum gantry cranes provide a versatile and cost-effective lifting solution for diverse industrial applications, making them a valuable investment for businesses looking to optimize their operations.

For businesses in the Philippines and beyond, partnering with reputable crane manufacturers can provide the expertise and support needed to design and implement the ideal lifting solution. Whether for manufacturing, logistics, construction, or any other industry, a well-specified and customized aluminum gantry crane can significantly impact operational efficiency and success.