Traditional & European Style Electric Explosion Proof Hoist

Explore key differences in safety, performance, and applications between Traditional and BNR explosion-proof hoists for hazardous environments.

Overview of Explosion-Proof Hoists

Explosion-proof hoists are special lifting equipment designed to operate in hazardous environments. These environments may have explosive gases or dust that can ignite under normal conditions. The hoists are built with extra safety measures to prevent any sparks or heat that could cause an explosion. Their main job is to lift heavy loads while keeping workers safe.

In industries like oil, gas, chemicals, and mining, these hoists are crucial. They ensure that workers can perform heavy lifting tasks without risking a dangerous explosion. The hoists are made to handle specific environmental conditions, making them reliable and safe for critical operations.

Types of Explosion-Proof Hoists

Explosion-proof hoists are categorized based on the type of hazardous environment they are designed for. There are two main types:

- Gas Explosion-Proof Hoists: These are made to prevent ignition in areas where explosive gases are present. They are sealed and designed to handle flammable air mixtures.

- Dust Explosion-Proof Hoists: These are built for environments with combustible dust, such as in chemical plants or grain mills. The design prevents any sparks from igniting the dust.

Both types play a key role in maintaining safety, but they are suited for different industrial environments.

Safety Standards Followed

Explosion-proof hoists must meet strict safety standards to ensure their reliability and safety. These standards are designed to guide the construction and testing of the hoists, so they meet specific safety levels. Some of the most important standards include:

- GB/T 3811-2008: This standard covers design rules for cranes, ensuring hoists are built to be safe and durable.

- GB/T 6067-2010: This standard outlines safety rules for lifting appliances, including hoists, to ensure they operate under safe conditions.

- GB/T 3836.1-2021: A general requirement for equipment used in explosive atmospheres. It sets out safety guidelines for all explosion-proof electrical equipment.

- GB/T 3836.2-2021: This standard focuses on protection by flameproof enclosures, ensuring hoists do not cause sparks or heat in dangerous environments.

- JB/T 10222-2011: This one specifically applies to explosion-proof hoists, defining their safety features and testing procedures.

Following these standards ensures that each hoist is built to perform safely in explosive environments.

Explosion-Proof Hoist Types

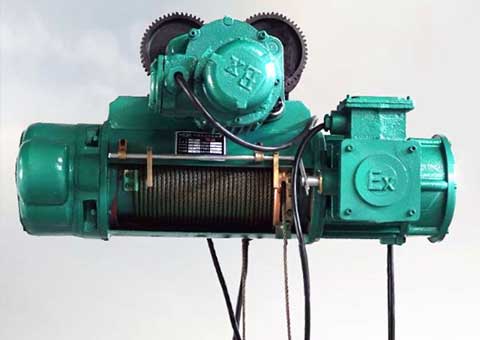

Traditional Explosion-Proof Electric Wire Rope Hoist

The traditional explosion-proof electric wire rope hoist is designed to work safely in environments with explosive gases. It starts with a standard wire rope hoist but is enhanced with explosion-proof features. These include specially designed motors and electrical components that can handle hazardous conditions.

Key features of the traditional hoist:

- Explosion-Proof Motor: Ensures no sparks or heat are produced in dangerous areas.

- Compact and Reliable: Built to be lightweight and easy to install.

- Versatile: Can be used in various types of cranes, including single girder suspension cranes and bridge cranes.

- Safety Features: Flameproof enclosures to prevent any ignition of explosive gases or vapors.

- Application Areas: Often used in military, nuclear, aerospace, and chemical industries, where the risk of explosion is high.

This type of hoist is generally more affordable and commonly used in a wide range of industries due to its reliable performance.

Explosion proof electric wire rope hoist

Main Specifications of Traditional Explosion-Proof Electric Wire Rope Hoist

| Capacity | t | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | 20 | 32 | 40 | 50 | |

| Hoisting height | m | 6, 9, 12 | 6, 9, 12, 18, 24, 30 | 9, 12, 18, 24, 30 | 9, 12, 18 | 6, 9, 12 | 9, 12, 18 | 10 | 15 | ||||

| Hoisting spee | m/min | 8, 0.8/8 | 7, 0.7/7 | 3.5, 3.5/0.35 | 3, 3/0.3 | 2.4, 2.4/0.24 | 3, 3/0.3 | ||||||

| Travelling speed | m/min | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| Electric current | 3P, 380V, 50Hz | ||||||||||||

| wire rope | Dia | mm | Φ5 | Φ7.7 | Φ11 | Φ13 | Φ15 | Φ15 | Φ20 | Φ15 | Φ26 | Φ26 | Φ26 |

| Specification | GB20119 | 6×9 | 6×19 | 6×37 | 6×37 | 6×37 | 6×37 | 6×37 | 6×37 | 6×37 | 6×37 | 6×37 | |

| Track | GB706 | 16~28b | 20a~45c | 28a~63c | I30a~63c | I28a~63c | I30a~63c | I63c | I63c | ||||

| Min curvature radius | m | 1.5 | 1.5~3.2 | 1.5~3.5 | 1.5~3.7 | 2.0~4.0 | 3.0~7.5 | ||||||

| Working class | M3 | M3 | M3 | M3 | M3 | M3 | M3 | M3 | M3 | ||||

Design & Features

The traditional explosion-proof electric wire rope hoist is built based on a standard wire rope hoist but incorporates additional features to make it safe for use in explosive environments. The key to its design is the explosion-proof motor and electrical appliances, which are specially designed to prevent any risk of ignition in hazardous areas.

- Explosion-Proof Motor: The motor is designed to eliminate sparks or overheating, ensuring safe operation in explosive environments.

- Lightweight & Compact: Despite its explosion-proof features, the hoist is still lightweight and compact, making it easy to install and maneuver.

- Reliability: The hoist is highly reliable and durable, built to withstand tough working conditions.

- Explosion-Proof Measures: The hoist includes flameproof enclosures and other mechanical safety features to protect against ignition sources.

Applications

This hoist is versatile and can be used in various industries, particularly where explosive gases or vapors may be present. It’s suitable for:

- Military & Nuclear Industries: Essential in sensitive, high-risk environments where safety is crucial.

- Aviation & Aerospace: Used in workshops and factories where explosive atmospheres may exist.

- Machinery & Petroleum Industries: For heavy lifting in manufacturing plants and oil rigs.

- Chemical Industries: Ideal for environments with flammable gases and chemicals.

The traditional explosion-proof hoist can be used in various types of cranes, including:

- Explosion-Proof Cranes: Specifically designed for hazardous environments.

- Single Girder Suspension Cranes: Used for lighter-duty applications in explosion-proof settings.

- Bridge Cranes: Ideal for larger operations where lifting and movement of heavy materials is required.

European Explosion-Proof Electric Wire Rope Hoist

The European explosion-proof electric wire rope hoist is designed with more advanced features and higher safety standards. It follows strict European regulations and is built to operate in even more demanding environments, especially where both gas and dust hazards are present.

Key features of the European hoist:

- Enhanced Explosion-Proof Design: Meets higher safety standards, offering greater protection in highly explosive environments.

- Durability: Designed for long-term use in harsh conditions, offering increased resistance to wear and tear.

- Gas and Dust Protection: Suitable for areas where both flammable gases and combustible dust are present.

- Higher Precision: More advanced control systems for precise lifting and safe operation.

- Application Areas: Typically used in petrochemical, mining, and other heavy industries where the environment poses higher risk.

This hoist is built to meet the strictest European safety standards, making it ideal for industries that need extra protection and reliability in hazardous conditions.

Main Specificaitons of European Explosion-proof Electric Wire Rope Hoists

| Lifting capacity(t) | 3 | 5 | 10 | 16 | 20 | 30 | 50 |

| Lifting height(m) | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 | 6~12 | 6~12 |

| Lifting speed(m/min) | 0.8~5 | 0.8~5 | 0.66~4 | 0.66~4 | 0.66~4 | 0.4~2.7 | 0.4~2.7 |

| Traveling speed(m/min) | 2~6 | 2~16 | 2~16 | 2~16 | 2~16 | 2~16 | 2~16 |

| Work class | M5 | ||||||

| Explosion-proof grade | Exd II CT4/Ex tD A21 IP65 T130℃ | ||||||

Design & Features

The European explosion-proof electric wire rope hoist is engineered to meet the highest safety standards, offering enhanced protection in environments where both gas and dust explosions are a concern. It follows strict European regulations, ensuring that it operates safely and reliably even in the most hazardous settings.

- European Standard Explosion-Proof Design: Built according to European safety regulations, offering superior performance and safety in dangerous environments.

- Specialized Applications: Designed for use in industries where there is a high risk of explosions from gases or dust.

- Robust Construction: Made with durable materials that can withstand tough environments, this hoist offers long-term reliability and safety.

- Gas and Dust Explosion-Proof: Engineered to safely operate in both gas and dust hazardous areas, making it ideal for chemical plants, mining, and petrochemical industries.

Applications

The European explosion-proof hoist is built for industries where high safety standards and reliable operation are essential. Some of the key sectors that rely on this hoist include:

- Petrochemical Industry: Used in refineries, oil rigs, and gas facilities, where flammable gases are present.

- Mining Industry: Ideal for underground mining and other areas where explosive gases and dust are common.

- Chemical Plants: Designed to handle the challenges of chemical production facilities, where both flammable gases and combustible dust may be present.

Due to its advanced safety features, the European explosion-proof hoist is especially suited for high-risk, heavy-duty operations.

Explosion-proof hoists for the environment

Explosion-proof hoists are suitable for use in explosive gas environments Zone 1 and Zone 2 or combustible dust environments Zone 21 and Zone 22.

| Temperature Group | Maximum permissible surface temperature ℃ | |

| TA or TB | T1 | 450 |

| T2 | 300 | |

| T3 | 200 | |

| T4 | 135 | |

| T5 | 100 | |

| T6 | 85 | |

Class II explosion-proof hoist explosion-proof level and the corresponding temperature group applicable explosive gases are listed below:

| Explosion-proof grade | Temperature Group | |||||

| T1 | T2 | T3 | T4 | T5 | T6 | |

| IIA | Ethane, propane, styrene, benzene, xylene, carbon monoxide, acetone, acetic acid, methyl acetate, ammonia, pyridine | Ethanol, butane, propylene, ethyl acetate, methylene chloride, vinyl chloride, chloroethanol, thiophene, cyclopentane, dimethylamine | Pentane, hexane, ethylcyclopentane, turpentine, naphtha, petroleum (including military gasoline), fuel oil, chlorobutane, tetrahydrothiophene | Acetaldehyde, trimethylamine | Ethyl nitrite | |

| IIB | Propyne, acrylonitrile, hydrogen cyanide, coke oven gas | Ethylene, ethylene oxide, methyl acrylate, furans | Dimethyl ether, acrolein, tetrahydrofuran, hydrogen sulfide | Dibutyl ether, diethyl ether, ethyl methyl ether, tetrafluoroethylene | ||

| IIC | Hydrogen, water gas | Ethyne C2H2 | Carbon disulfide | Ethyl nitrate | ||

Dust class explosion-proof hoist each anti-dust structure form and the corresponding temperature groups of combustible dust to adapt to the following table:

| Dust explosion-proof form | Temperature Group | |

| TA、T1 or TB、T1 | TA、T2 or TB、T2 | |

| A or B | Magnesium, red phosphorus, calcium carbide, soap powder, green fuel, phenol dyes, polyethylene, polypropylene, polyurethane, polyvinyl chloride, hard rubber, natural resins, rosin, wheat flour, corn starch, granulated sugar powder, cotton fiber, synthetic staple fiber, anthracite powder, charcoal powder, coal coke powder | Sifted Rice Flour, Cocoa Flour, Malt Flour, Flax Meal Flour, Coconut Flour, Peat Flour, Lignite Flour, Bituminous Coal Flour, Coal Flour for Coke, Lignite Coke Flour |

Comparison of Key Features

Explosion-Proof Measures

Flameproof Enclosures:

- General Design): The traditional hoistis built with basic flameproof enclosures to protect against explosive gases in standard industrial environments. It ensures safety through robust housing and sealing mechanisms that prevent sparks or heat from igniting the surroundings.

- European Standard): The BNR hoist takes flameproof enclosures a step further. Built to meet European standards, it offers enhanced protection, particularly in environments where both explosive gases and combustible dust are present. The design is more advanced, ensuring safer operation in more demanding conditions.

Temperature Control and Environmental Adaptability

- Traditional Electric Hoists: Designed to handle a wide range of temperatures, typically from -20°C to +40°C. This makes it suitable for most standard industrial environments.

- European Style Electric Hoists: These hoists are engineered for more specialized environments, with better performance in extreme conditions. They can operate in a broader temperature range and are more adaptable to varying environmental factors like humidity, altitude, and temperature extremes, thanks to their robust European design.

Performance

Hoisting Speed:

- Traditional Electric Hoists: Available in single-speed or double-speed configurations, the hoisting speed is generally slower, with speeds typically ranging from 2.4m/min to 8m/min depending on capacity and configuration. This is suitable for general applications.

- European Style Electric Hoists: The BNR hoist may offer more refined hoisting speeds, especially at higher capacities or in specialized applications. It can support more precise speed control, allowing for higher safety and efficiency in environments where precise lifting is crucial.

Capacity Range:

- Both Models: Both the Traditional and European hoists have a similar capacity range from 0.5t to 50t, making them versatile for a variety of lifting tasks.

- European Style Electric Hoists: While the capacity range is similar, the BNR model may provide higher precision in extreme environments, offering more control and stability in hazardous conditions like mining, chemical plants, or petrochemical industries.

Applications

- Traditional Electric Hoists: These hoists are versatile and widely used across multiple industrial sectors. They are suitable for applications in military, aerospace, machinery, petroleum, and chemical industries, where explosion risks are present but less extreme.

- European Style Electric Hoists: The European hoists are more specialized, focusing on high-risk environments that require the highest levels of safety and reliability. They are ideal for industries like petrochemical, mining, and chemical plants, where the presence of both explosive gases and dust requires a more robust and specialized design.

Customization Options

Both Models: Both Traditional and European style hoists offer customization options to meet specific operational needs.

- Speed Control: Both hoists can be fitted with speed control systems, allowing for either single-speed or adjustable-speed operation depending on the work environment.

- Remote Control: Remote control options are available for both models, allowing operators to control the hoist from a safe distance. This is especially useful in hazardous environments.

- Frequency Conversion: Both hoists can be designed with frequency conversion options for smoother and more efficient speed regulation, improving precision in lifting tasks.

- Non-Standard Designs: Both models can be customized for non-standard applications. Whether for extreme temperatures, specialized lifting needs, or other specific requirements, both the Traditional and European hoists offer non-standard designs to meet unique customer demands.

Comparison of Key Features

| Feature | Traditional Explosion Proof Hoist | European Style Explosion Proof Hoist |

|---|---|---|

| Explosion-Proof Measures | Flameproof enclosures for basic explosive gas protection in standard environments. | Enhanced flameproof enclosures, meeting European standards for both gas and dust explosion-proof environments. |

| Temperature Control & Adaptability | Operates in temperatures from -20°C to +40°C, suitable for standard industrial environments. | Greater adaptability to extreme conditions, designed for broader temperature ranges and more demanding environments. |

| Hoisting Speed | Single-speed or double-speed options, with speeds ranging from 2.4m/min to 8m/min, depending on capacity. | Provides more precise hoisting speeds, ideal for high-precision lifting, particularly in hazardous environments. |

| Capacity Range | 0.5t to 50t, suitable for general lifting tasks. | 0.5t to 50t, but offers higher precision in extreme conditions and specialized applications. |

| Applications | Versatile use across military, aerospace, machinery, petroleum, and chemical industries. | Primarily used in petrochemical, mining, and chemical plants, where high levels of safety are required. |

| Customization Options | - Speed control options - Remote control - Frequency conversion available - Non-standard designs for specific needs | - Speed control options - Remote control - Frequency conversion available - Non-standard designs for specialized needs |

Standards & Certifications

Compliant Standards

Both the Traditional and BNR explosion-proof electric wire rope hoists are designed, manufactured, and tested in strict accordance with national and international safety standards to ensure they meet the highest safety and performance requirements.

- GB/T 3811-2008: Design rules for cranes, ensuring hoists are designed with safety and reliability in mind.

- GB/T 6067-2010: Safety rules for lifting appliances, covering essential safety features and operational standards.

- GB/T 3836.1-2021: General requirements for equipment used in explosive atmospheres, ensuring the hoists meet the necessary explosion-proof standards.

- GB/T 3836.2-2021: Equipment protection by flameproof enclosures, confirming the protection of electrical components in hazardous environments.

- JB/T 10222-2011: Explosion-proof hoist standards, specifying the design and testing of hoists for hazardous areas.

These standards ensure both hoists operate safely, effectively, and in compliance with regulations across a wide range of industries.

Explosion-Proof Certification

Both the Traditional and European hoists undergo rigorous testing by the National Center for Supervision and Inspection of Explosion-Proof Electrical Product Quality. The certification process includes the following steps:

- Safety Tests: Comprehensive tests are conducted to ensure the hoists meet the necessary explosion-proof requirements for both gas and dust environments.

- Conformity Certification: After passing these tests, the hoists are issued a certificate of conformity, verifying that they comply with all applicable national and international standards for explosion-proof equipment.

This certification provides assurance that the hoists can be safely used in environments with explosive gases, vapors, or dust, significantly reducing the risk of accidents.

Conclusion

Choosing the right hoist depends on the specific industry and environmental conditions:

- Traditional Explosion Proof Electric Hoist Best suited for industries where explosion risks are present but not extreme. Ideal for general industrial applications like machinery, aerospace, petroleum, and chemical sectors. It is a versatile option, offering reliability and safety for a broad range of applications.

- European Style Explosion Proof Electric Hoist Highly recommended for industries with higher explosion risks, such as petrochemical, mining, and chemical plants. The BNR hoist offers advanced safety features, making it the preferred choice for hazardous environments requiring the highest standards of safety and reliability.

Summary of Safety and Performance Considerations

When deciding between the Traditional and European hoists, key considerations include:

- Explosion-Proof Measures: Both hoists offer robust flameproof enclosures, but the BNR has enhanced protection for both gas and dust hazardous environments.

- Temperature & Environmental Adaptability: The BNR hoist is more suited for extreme conditions, while the traditional hoistis designed for general industrial settings.

- Customization & Speed Control: Both models provide speed control and remote options, with the BNR offering more precision for specialized applications.

- Industry Needs: For general industrial use, the traditional hoistis a versatile choice. However, for high-risk industries with stringent safety requirements, the BNR hoist is the better option, offering advanced protection and adaptability.

Ultimately, selecting the right hoist depends on the specific operational needs and safety standards required for your industry.