Where to Find the Suitable 10 Ton Overhead Crane for Sale

Where to find the suitable 10 ton overhead crane for sale? Find the suitable 10 ton overhead crane for sale with this comprehensive guide, offering insights on selection, suppliers, and decision-making. Click!

Where to Find the Suitable 10 Ton Overhead Crane for Sale: A Comprehensive Guide

In the industry and construction, having the right equipment can make all the difference. One such crucial piece of machinery is the 10 ton overhead crane. Whether you're lifting heavy loads in a manufacturing plant or maneuvering materials on a construction site, a reliable overhead crane can streamline operations and enhance productivity.

However, not all overhead cranes are created equal. Finding the perfect fit for your specific needs requires careful consideration and research. That's where this guide comes in handy. We're here to navigate you through the process of finding the ideal 10 ton overhead crane for sale.

Before diving into the nitty-gritty details of crane shopping, let's take a moment to understand why finding the right one is so crucial. A 10 ton overhead crane isn't just another piece of equipment; it's a vital tool that directly impacts efficiency, safety, and overall workflow.

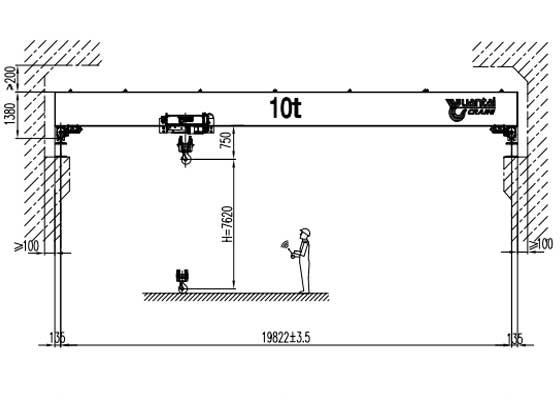

Single girder overhead crane 10 ton

Application of 10 Ton Overhead Crane

Industries that Commonly Require 10 ton Overhead Cranes

- Manufacturing: From automotive plants to steel mills, manufacturing facilities often deal with large and heavy materials that need to be moved efficiently. 10 ton overhead cranes play a vital role in handling these materials with precision and speed.

- Construction: In the construction industry, lifting and moving heavy components such as steel beams, concrete panels, and machinery is a daily occurrence. A reliable 10 ton overhead crane enables construction crews to perform these tasks safely and effectively.

- Warehousing and Logistics: Warehouses and distribution centers rely on overhead cranes to handle the storage and movement of bulky goods. Whether it's loading and unloading shipping containers or rearranging inventory within the facility, a 10 ton crane provides the necessary lifting capacity.

- Shipbuilding and Maritime: Building and repairing ships require the maneuvering of massive components and equipment. 10 ton overhead cranes are indispensable in shipyards for tasks such as lifting engines, hull sections, and ship modules.

- Mining and Extraction: The mining industry deals with exceptionally heavy loads, from extracting raw materials to transporting them for processing. 10 ton overhead cranes are essential for lifting and moving equipment and materials in mining operations.

Advantages of Using a 10 ton Overhead Crane

- High Load Capacity: The primary advantage of a 10 ton overhead crane is its ability to lift heavy loads with ease. This high load capacity makes it suitable for handling a wide range of materials and equipment.

- Versatility: Despite its robust lifting capabilities, a 10 ton overhead crane offers versatility in operation. With customizable features such as adjustable span and height, it can adapt to various work environments and tasks.

- Improved Efficiency: By automating the lifting and moving process, overhead cranes streamline operations and reduce manual labor. This efficiency boost translates to higher productivity and cost savings in the long run.

- Enhanced Safety: Safety is paramount in any industrial setting, and overhead cranes are designed with safety features such as overload protection and emergency stop mechanisms. A 10 ton crane ensures safe lifting and handling of heavy loads, minimizing the risk of accidents and injuries.

- Space Optimization: Unlike floor-mounted equipment, overhead cranes utilize vertical space, leaving the floor area clear for other operations. This space optimization is especially valuable in crowded work environments where space is at a premium.

The industries that benefit from 10 ton overhead cranes and recognizing their advantages lays the foundation for informed decision-making when selecting the right crane for your specific needs. In the next section, we'll delve into key considerations to keep in mind during your crane search.

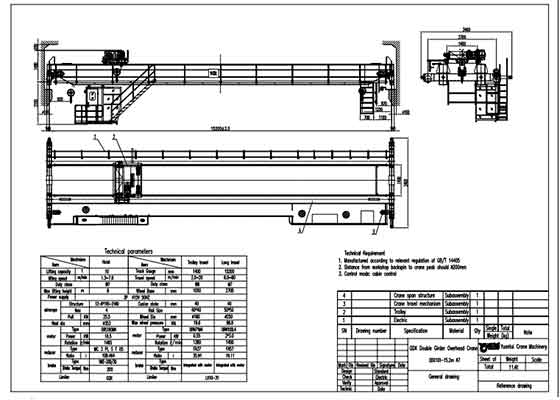

Double girder overhead crane 10 ton

Key Considerations When Searching for a 10 Ton Overhead Crane for Sale

As you embark on your quest to find the perfect 10 ton overhead crane, it's essential to consider several key factors to ensure that the crane meets your specific requirements. Let's explore these considerations in detail:

- Load Capacity :The load capacity of a crane is perhaps the most critical factor to consider. Ensure that the crane's capacity aligns with the heaviest loads you anticipate lifting. It's advisable to choose a crane with a slightly higher capacity than your maximum load to account for potential future needs and ensure safety.

- Span and Height :Consider the span and height requirements of your workspace when selecting an overhead crane. The span refers to the distance between the crane's runway rails, while the height refers to the vertical distance between the floor and the crane's lifting mechanism. Choose a crane with a span and height that accommodate your operational needs without compromising safety or efficiency.

- Duty Cycle :The duty cycle of a crane refers to the frequency and duration of its use. Determine the expected duty cycle of your operations to select a crane that can withstand the required workload. Cranes with higher duty cycles are designed for continuous or heavy-duty use and may be more suitable for demanding applications.

- Hoist Speed :The hoist speed of a crane influences the efficiency of lifting and moving operations. Consider the required speed for your specific tasks, balancing the need for productivity with safety considerations. Opt for a crane with adjustable hoist speeds to accommodate different load sizes and operational requirements.

- Safety Features :Safety should always be a top priority when selecting an overhead crane. Look for cranes equipped with essential safety features such as overload protection, emergency stop buttons, and collision avoidance systems. Additionally, consider investing in optional safety enhancements such as remote monitoring and anti-sway technology for added peace of mind.

- Maintenance Requirements :Regular maintenance is essential to ensure the continued performance and longevity of your overhead crane. Consider the maintenance requirements of different crane models, including inspection intervals, lubrication needs, and availability of spare parts. Choose a crane with straightforward maintenance procedures and reliable support from the manufacturer or supplier.

By carefully evaluating these key considerations, you can narrow down your options and choose a 10 ton overhead crane that meets your operational needs, safety requirements, and budget constraints. In the next section, we'll explore where to find reputable sellers and manufacturers offering quality overhead cranes for sale.

Evaluating Potential Sellers and Products

Now that you've identified your requirements and preferences for a 10 ton overhead crane, it's time to evaluate potential sellers and the products they offer. Here are three crucial factors to consider during this process:

Reputation and Experience of the Seller

Industry Reputation:

Conduct thorough research into the seller's reputation within the industry.

Look for reviews, testimonials, and feedback from previous customers to assess their credibility and reliability.

Pay attention to online forums, review platforms, and industry-specific websites where customers share their experiences with the seller.

Positive reviews and endorsements from reputable sources indicate a seller's commitment to customer satisfaction and quality service.

Experience:

Consider the seller's experience in the crane industry as a key factor in your evaluation.

A company with a long-standing presence in the industry is likely to have a wealth of experience and expertise.

Evaluate the seller's track record of successful projects and satisfied clients to gauge their proficiency in meeting customer needs.

Experience often translates into a deeper understanding of industry trends, regulations, and best practices, which can benefit you as a buyer.

Certifications and Accreditations:

Verify if the seller holds relevant certifications and accreditations from industry organizations.

Certifications such as ISO 9001 for quality management systems and specific accreditations related to crane manufacturing attest to the seller's commitment to quality and compliance with industry standards.

Check if the seller adheres to safety standards and regulatory requirements set by organizations like OSHA (Occupational Safety and Health Administration) or ANSI (American National Standards Institute).

Certifications and accreditations serve as tangible evidence of the seller's dedication to delivering high-quality products and services that meet or exceed industry benchmarks.

Quality of the Product

Manufacturer Reputation:

Research the reputation of the crane manufacturer to ensure credibility and reliability.

Look for information about the manufacturer's history, industry standing, and track record of delivering quality products.

Seek feedback from industry experts, customers, and online reviews to gauge the manufacturer's reputation for producing reliable and durable cranes.

A reputable manufacturer is more likely to adhere to strict quality standards and provide excellent after-sales support.

Product Specifications:

Carefully review the specifications of the crane models offered by the seller to ensure they align with your requirements.

Consider factors such as load capacity, span, height of lift, and any specialized features or configurations needed for your specific application.

Verify that the cranes meet relevant industry standards and safety regulations to ensure compliance and minimize risks during operation.

Ensure the seller provides detailed product information and documentation to facilitate informed decision-making.

Material and Construction:

Evaluate the materials and construction methods used in the manufacturing of the cranes to assess their quality and durability.

Look for cranes constructed with high-quality steel or other robust materials known for their strength and resistance to corrosion.

Assess the design and engineering of the cranes to ensure they are built to withstand heavy loads and harsh operating conditions.

Consider factors such as weld quality, structural reinforcement, and component reliability to determine the overall construction integrity of the cranes.

Choose cranes built with precision engineering and attention to detail to ensure reliable performance and longevity in demanding industrial environments.

Warranty and After-Sales Support

Warranty Coverage:

Inquire about the warranty coverage provided for the overhead cranes to understand the level of protection offered.

A comprehensive warranty demonstrates the seller's confidence in their products and provides assurance against defects or malfunctions.

Review the warranty terms and conditions, including coverage duration, scope of protection, and any exclusions or limitations.

Clarify the process for initiating warranty claims and obtaining repairs or replacements in case of issues with the crane.

Choose a seller that offers a robust warranty package to safeguard your investment and provide peace of mind.

After-Sales Service:

Assess the seller's after-sales support offerings to ensure ongoing maintenance and technical assistance are readily available.

Inquire about maintenance services, including scheduled inspections, preventive maintenance programs, and emergency repair services.

Verify the availability of technical support from qualified professionals to address any operational or troubleshooting issues that may arise.

Ensure the seller maintains an inventory of spare parts to facilitate prompt repairs and minimize downtime for your crane.

Evaluate the seller's responsiveness and accessibility for after-sales service requests to ensure timely resolution of any issues.

Customer Feedback:

Seek feedback from existing customers regarding their experience with the seller's after-sales service.

Positive testimonials and references from satisfied customers indicate a seller's commitment to providing excellent support and assistance.

Consider reaching out to industry peers or online communities to gather unbiased feedback on the seller's after-sales service reputation.

Pay attention to any recurring themes or patterns in customer feedback, such as responsiveness, professionalism, and effectiveness of support.

Use customer feedback as valuable insights to assess the seller's after-sales service capabilities and make an informed decision.

By carefully evaluating the reputation of sellers, the quality of their products, and the level of after-sales support they provide, you can make an informed decision when purchasing a 10 ton overhead crane. Remember to prioritize reliability, durability, and long-term value when selecting a seller and product.

Single girder overhead crane drawing helps to confirm your 10 overhead crane specifications

Comparing Options and Making the Right Choice

As you navigate through the plethora of options available for 10 ton overhead cranes, it's essential to compare them carefully and make a well-informed decision. Here's a step-by-step guide to help you through the process:

Creating a Shortlist of Potential Cranes

Review Specifications:

Refer back to your initial requirements and carefully review the specifications provided by each crane manufacturer.

Shortlist crane models that meet your criteria for load capacity, span, height, and essential safety features.

Ensure that the selected cranes align with the specific needs and constraints of your project or application.

Compare Features:

Conduct a detailed comparison of the features and capabilities offered by each crane on your shortlist.

Consider factors such as hoist speed, lifting height, duty cycle, and any additional options or accessories available.

Evaluate how each crane's features contribute to its overall performance, efficiency, and suitability for your intended use.

Evaluate Compatibility:

Assess the compatibility of each shortlisted crane with your existing infrastructure, facility layout, and operational requirements.

Consider factors such as crane size, mounting configuration, and power supply compatibility to ensure seamless integration into your workflow.

Evaluate any potential modifications or adaptations that may be required to accommodate the selected cranes within your facility.

Verify that the selected cranes meet relevant safety standards and regulatory requirements for your industry or application.

Conducting a Cost-Benefit Analysis

Assess Total Cost:

Calculate the total cost of ownership for each crane by considering various expenses, including:

Purchase Price: Determine the initial cost of acquiring each crane model.

Installation Costs: Estimate expenses associated with crane installation, such as labor, equipment, and site preparation.

Maintenance Expenses: Anticipate ongoing maintenance costs, including routine inspections, repairs, and spare parts.

Potential Downtime Costs: Factor in the financial impact of downtime on productivity, revenue loss, and operational disruptions.

Summarize these costs to gain a comprehensive understanding of the financial investment required for each crane option.

Evaluate Benefits:

Identify and quantify the benefits offered by each crane to assess their value proposition:

Increased Productivity: Evaluate how each crane's features and capabilities contribute to productivity gains, such as faster lifting speeds or enhanced maneuverability.

Improved Safety: Consider safety features and risk mitigation measures incorporated into each crane design to minimize accidents, injuries, and associated costs.

Longevity and Reliability: Assess the expected lifespan and durability of each crane model to determine its long-term value in terms of reduced replacement and downtime costs.

Translate qualitative benefits into measurable metrics whenever possible to facilitate comparison and decision-making.

Calculate ROI:

Conduct a cost-benefit analysis to determine the return on investment (ROI) for each crane option:

Compare the total cost of ownership against the quantified benefits to calculate the net financial impact of each crane.

Divide the net benefits by the total cost of ownership and express the result as a percentage to determine the ROI.

Analyze the ROI of each crane option to identify the most cost-effective solution that maximizes financial returns relative to the investment made.

Consider the payback period—the time required for the cumulative benefits to offset the initial investment—as an additional factor in evaluating ROI.

By conducting a thorough cost-benefit analysis, you can make an informed decision that optimizes both financial considerations and operational outcomes when selecting an overhead crane for your specific needs.

Seeking Input from Industry Experts

Consult Peers:

Reach out to industry colleagues or peers who have firsthand experience with overhead cranes.

Solicit their feedback and recommendations based on their knowledge and expertise in crane selection, installation, and operation.

Engage in open discussions to gain insights into their experiences with different crane models, suppliers, and service providers.

Leverage their expertise to identify potential challenges, best practices, and valuable considerations when evaluating crane options.

Engage with Suppliers:

Directly engage with potential suppliers and manufacturers to gain insights into their product offerings and capabilities.

Schedule meetings or site visits to discuss your specific requirements and assess how each supplier can address your needs.

Ask detailed questions about crane specifications, customization options, lead times, and after-sales support services.

Request references or case studies showcasing successful crane installations and customer satisfaction to validate the supplier's track record.

Hire Consultants:

Consider hiring consultants or experts specializing in crane technology and industrial equipment.

Consultants can provide independent assessments and recommendations based on their in-depth knowledge and experience.

Seek consultants with a proven track record of assisting clients in selecting, implementing, and optimizing overhead crane solutions.

Collaborate with consultants to conduct thorough evaluations, technical analyses, and feasibility studies to inform your decision-making process.

Benefit from their impartial perspective, industry insights, and strategic guidance to identify the most suitable crane options aligned with your business objectives.

By seeking input from industry experts, including peers, suppliers, and consultants, you can leverage their knowledge and experience to make well-informed decisions when selecting an overhead crane solution. Their insights can help you navigate complexities, mitigate risks, and ultimately choose the crane option that best meets your needs and objectives.

Double girder overhead bridge crane drawing to confirm your required 10 ton overhead crane parameters

Making the Final Decision

Weigh Pros and Cons:

Review and analyze the findings from your comprehensive research and evaluation process.

Consider the pros and cons of each crane option in relation to your specific needs, requirements, and objectives.

Evaluate factors such as technical specifications, performance capabilities, supplier reputation, and after-sales support.

Prioritize criteria that are most critical to your operations, such as safety, reliability, efficiency, and cost-effectiveness.

Seek input from key stakeholders within your organization to ensure alignment and consensus on the final decision.

Consider Long-Term Implications:

Factor in the long-term implications and consequences of your decision beyond immediate considerations.

Anticipate future maintenance requirements, scalability, and potential expansion or changes in operational needs.

Evaluate each crane option's suitability for long-term use, including its adaptability to evolving industry trends and technological advancements.

Assess the total cost of ownership over the crane's lifespan, considering both upfront investment and ongoing operational expenses.

Strive to choose a crane option that not only meets your current needs but also offers flexibility and resilience to support future growth and development.

Trust Your Instincts:

Trust your instincts and intuition as you make the final decision.

Consider your gut feelings and personal convictions regarding each crane option, taking into account your overall comfort level and confidence in the selection.

Reflect on the insights gained from your research, evaluations, and consultations with industry experts.

Listen to your intuition and choose the crane option that resonates most strongly with your instincts and aligns closely with your vision for success.

Remember that while data-driven analysis and logical reasoning are important, intuition can often provide valuable guidance and clarity in complex decision-making processes.

By carefully weighing the pros and cons, considering long-term implications, and trusting your instincts, you can make a confident and well-informed final decision when selecting the ideal overhead crane solution for your business or project.

Conclusion

As we conclude our guide on finding the right 10 ton overhead crane for your needs, let's recap the key points discussed and emphasize the importance of thorough research and evaluation in the purchasing process.

Throughout this guide, we've explored various aspects of purchasing a 10 ton overhead crane, including:

The need for a 10 ton overhead crane in industries such as manufacturing, construction, warehousing, shipbuilding, and mining.

Recognizing the advantages of using a 10 ton overhead crane, such as high load capacity, versatility, efficiency, safety, and space optimization.

Key considerations when searching for a 10 ton overhead crane, including load capacity, span and height, duty cycle, hoist speed, safety features, and maintenance requirements.

Evaluating potential sellers and products based on reputation, experience, product quality, warranty, after-sales support, and customer feedback.

Comparing options and making the right choice by creating a shortlist of potential cranes, conducting a cost-benefit analysis, seeking input from industry experts, and making the final decision.

Purchasing a 10 ton overhead crane is a significant investment that can impact the efficiency, safety, and productivity of your operations. Therefore, it's crucial to conduct thorough research and evaluation before making a decision. By taking the time to understand your requirements, compare options, and consider factors such as quality, reliability, and after-sales support, you can make an informed choice that aligns with your specific needs and budget.

Final Recommendations for Finding the Right Crane

In conclusion, here are some final recommendations for finding the right 10 ton overhead crane for your specific needs:

Start by clearly defining your requirements and priorities for the crane, including load capacity, operational environment, and budget constraints.

Research reputable sellers and manufacturers, and carefully evaluate their products based on factors such as quality, features, and after-sales support.

Create a shortlist of potential crane options and conduct a thorough cost-benefit analysis to determine the best fit for your business or project.

Seek input from industry experts, colleagues, and peers to gain valuable insights and recommendations.

Trust your instincts and make the final decision based on a combination of objective analysis and subjective considerations.

By following these recommendations and leveraging the insights provided in this guide, you can confidently navigate the process of purchasing a 10 ton overhead crane and ensure that you find the right solution to meet your lifting and handling needs.

If you have any need of 10 ton hoists and cranes, please feel free to contact us by leaving a message down below.