Choose Custom Explosion-Proof Hoists and Cranes for Your Needs

Flammable Liquid Management: Ensure safety & efficiency with the right explosion-proof equipment for handling flammable liquids in industrial settings.

Overview of Flammable Liquid Management

Importance of Safe Handling and Storage:Flammable liquids are commonly used in various industries, including oil and gas, chemical manufacturing, pharmaceuticals, and paint and coatings. These substances are vital for many processes but pose significant risks if not handled and stored properly. Safe handling and storage are crucial to prevent accidents, protect workers, and ensure smooth operations. Proper management includes using appropriate containers, maintaining safe storage conditions, and following established protocols for handling and disposal.

Risks Associated with Flammable Liquids in Industrial Settings:The risks associated with flammable liquids are severe and can lead to catastrophic consequences. These include fires, explosions, and toxic releases, which can cause injuries, fatalities, property damage, and environmental harm. Even small quantities of flammable liquids can ignite if exposed to a spark, heat source, or static electricity. Therefore, industries must implement stringent safety measures to mitigate these risks, including the use of explosion-proof equipment.

Need for Explosion-Proof Equipment

Explanation of Explosion-Proof Technology:Explosion-proof technology is designed to contain any ignition or explosion within the equipment, preventing it from spreading to the surrounding environment. This is achieved through robust construction, using materials that can withstand high pressures and temperatures. Explosion-proof hoists and cranes are built with sealed electrical components, non-sparking materials, and reinforced housings to ensure they can operate safely in hazardous environments where flammable liquids are present.

Regulatory Standards and Compliance Requirements:Industries handling flammable liquids must adhere to strict regulatory standards to ensure safety. Regulatory bodies such as OSHA (Occupational Safety and Health Administration), ATEX (Atmosphères Explosibles), NEC (National Electrical Code), and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) provide guidelines and requirements for explosion-proof equipment. Compliance with these standards is not only a legal obligation but also a critical step in protecting workers and preventing industrial accidents. Failure to comply can result in severe penalties, operational shutdowns, and increased risk of accidents. Thus, selecting the right explosion-proof hoists and cranes is essential for maintaining safety and regulatory compliance in industries that deal with flammable liquids.

Explosion-Proof Hoists and Cranes

Definition and Key Features

What Makes a Hoist or Crane Explosion-Proof?A hoist or crane is considered explosion-proof if it is designed to operate safely in hazardous environments where flammable gases, vapors, or dust are present. The main goal of explosion-proof equipment is to prevent any sparks or high temperatures from igniting these substances. This is achieved through specific design features and materials that contain potential ignition sources and withstand explosive conditions.

Components and Materials Used in Explosion-Proof Equipment

- Sealed Electrical Components: Electrical parts are enclosed in housings that prevent the escape of sparks or heat.

- Non-Sparking Materials: Components are often made from non-sparking materials such as bronze, brass, or stainless steel to reduce the risk of generating sparks.

- Reinforced Housings: The equipment is built with strong, thick casings to contain any internal explosions.

- Temperature Controls: Components are designed to operate at temperatures below the ignition points of surrounding flammable substances.

- Specialized Motors and Brakes: Motors and brakes are designed to minimize heat generation and are often equipped with additional safety features to prevent overheating.

Types of Explosion-Proof Hoists and Cranes

Explosion Proof Electric Chain Hoists

Electric chain hoists are used for lifting and moving heavy loads with precision. When designed to be explosion-proof, these hoists feature sealed electric motors and control systems to prevent any sparks from escaping. They are ideal for industries where precise load control is necessary, such as in the chemical and pharmaceutical sectors.

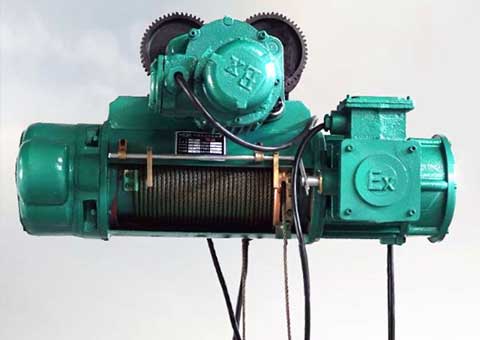

Explosion Proof Wire Rope Hoists

Wire rope hoists are used for lifting heavier loads over greater distances. Explosion-proof wire rope hoists are equipped with heavy-duty casings and sealed components to ensure safe operation in hazardous environments. These hoists are commonly used in oil and gas, mining, and chemical industries due to their robust design and high load capacity.

Explosion Proof Overhead Cranes

Overhead cranes, also known as bridge cranes, consist of parallel runways with a traveling bridge spanning the gap. Explosion-proof overhead cranes are designed with sealed electrical components and robust construction to prevent ignition of flammable substances. They are widely used in large-scale industrial facilities where heavy materials need to be moved across vast areas, such as in refineries and chemical plants.

Explosion Proof Jib Cranes

Jib cranes have a horizontal arm (jib) that supports a movable hoist and are ideal for lifting loads in smaller, localized areas. Explosion-proof jib cranes are designed with non-sparking materials and sealed components, making them suitable for use in confined spaces where flammable liquids or gases are present. These cranes are often used in workshops and manufacturing facilities.

Explosion Proof Gantry Cranes

Gantry cranes are similar to overhead cranes but are supported by legs that move on wheels or along a track. Explosion-proof gantry cranes are equipped with reinforced structures and sealed electrical systems to ensure safe operation in hazardous environments. They are versatile and can be used both indoors and outdoors, making them suitable for a variety of industrial applications, including shipyards and outdoor storage areas.

Industry-Specific Applications

Oil and Gas Industry

Typical Flammable Liquids Handled:In the oil and gas industry, various flammable liquids are commonly handled, including crude oil, gasoline, diesel fuel, kerosene, and other hydrocarbons. These substances are highly volatile and can easily ignite if not managed properly.

Recommended Explosion-Proof Hoists and Cranes

For the oil and gas industry, explosion-proof electric chain hoists, wire rope hoists, and overhead cranes are highly recommended. These hoists and cranes are designed to handle heavy loads and operate safely in environments where flammable gases and liquids are present. For outdoor applications, explosion-proof gantry cranes are also suitable due to their mobility and robust construction.

Case Studies and Examples

- Example 1: A major oil refinery implemented explosion-proof overhead cranes to handle large containers of crude oil. The cranes' robust design and sealed components ensured safe operation in the highly volatile environment, reducing the risk of fires and explosions.

- Example 2: A natural gas processing plant utilized explosion-proof wire rope hoists to manage the transfer of heavy equipment. The non-sparking materials and temperature controls of the hoists provided a safe working environment for the plant's operations.

Chemical Manufacturing

Handling Volatile Substances Safely:Chemical manufacturing involves the handling of various volatile substances, such as solvents, acids, and gases. These materials can be highly reactive and pose significant risks if not managed with care.

Equipment Selection Criteria

When selecting explosion-proof hoists and cranes for chemical manufacturing, consider the following criteria:

- Load capacity requirements

- Compatibility with corrosive and reactive chemicals

- Durability and ease of maintenance

- Compliance with industry standards and regulations

Case Studies and Examples

- Example 1: A chemical plant handling flammable solvents installed explosion-proof jib cranes for localized lifting tasks. The cranes' sealed electrical components and non-sparking materials ensured safe operation in confined spaces.

- Example 2: An industrial chemical manufacturer used explosion-proof gantry cranes to transport large containers of hazardous chemicals. The cranes' reinforced housings and temperature controls prevented any ignition of flammable vapors.

Pharmaceutical Industry

The pharmaceutical industry often uses flammable solvents and other materials in drug production and research. These substances must be handled with extreme caution to prevent any risk of explosion or fire.

Specialized Hoists and Cranes for Cleanroom Environments

Pharmaceutical facilities require specialized explosion-proof hoists and cranes that meet stringent cleanliness standards. These include electric chain hoists and wire rope hoists with smooth, easy-to-clean surfaces and sealed components to prevent contamination.

Case Studies and Examples

- Example 1: A pharmaceutical company installed explosion-proof electric chain hoists in their cleanroom facility. The hoists' non-sparking materials and sealed motors ensured safe handling of flammable solvents without compromising the cleanroom environment.

- Example 2: A research lab used explosion-proof wire rope hoists to manage large equipment and hazardous materials. The hoists' robust design and compliance with cleanroom standards provided a safe and efficient working environment.

Paint and Coating Industry

Managing Flammable Paints and Solvents:The paint and coating industry deals with flammable paints, varnishes, and solvents that pose significant fire and explosion hazards. Proper handling and storage are essential to maintain a safe working environment.

Suitable Explosion-Proof Lifting Solutions

Explosion-proof jib cranes and electric chain hoists are ideal for the paint and coating industry. These cranes and hoists are designed to handle the specific requirements of managing flammable substances safely.

Case Studies and Examples

- Example 1: A paint manufacturing plant implemented explosion-proof jib cranes to handle large containers of flammable paint. The cranes' non-sparking materials and sealed components ensured safe operation and minimized the risk of ignition.

- Example 2: A coating facility used explosion-proof electric chain hoists to lift and move heavy drums of solvents. The hoists' robust construction and temperature controls provided a safe solution for managing flammable materials.

Key Considerations for Selecting Explosion-Proof Equipment

Capacity and Load Requirements

Determining the Appropriate Load Capacity

Selecting the right explosion-proof hoist or crane begins with determining the appropriate load capacity. This involves:

- Assessing Maximum Loads: Identify the heaviest load that will be lifted. Consider future needs as well to ensure the equipment can handle potential increases in load requirements.

- Calculating Duty Cycle: Understand the frequency and duration of lifting operations. Heavy-duty cycles require more robust equipment.

- Considering Safety Margins: Incorporate a safety factor to account for unexpected overloads, ensuring the equipment operates safely under all conditions.

Matching Equipment Specifications to Operational Needs

Once the load capacity is determined, match the equipment specifications to the specific operational needs:

- Type of Lifting: Determine whether the operations require precise positioning (which may favor electric chain hoists) or moving heavy loads over long distances (which may favor wire rope hoists or overhead cranes).

- Operational Environment: Choose equipment that fits the spatial constraints and workflow of the facility. For instance, jib cranes are ideal for localized lifting, while gantry cranes provide flexibility in larger, open areas.

- Special Requirements: Consider any additional requirements such as cleanroom standards in the pharmaceutical industry or corrosion resistance in chemical manufacturing.

Environmental Conditions

Assessing the Work Environment for Explosive Hazards

The next step is to thoroughly assess the work environment for potential explosive hazards:

- Identify Hazardous Zones: Determine the classification of different areas based on the presence and concentration of flammable substances. This may include areas designated as Zone 1 or Zone 2 under ATEX regulations or Class I, Division 1 or 2 under NEC.

- Evaluate Potential Ignition Sources: Identify sources of ignition, such as electrical equipment, static electricity, and high temperatures, and ensure these are adequately controlled.

Selecting Equipment Based on Temperature, Humidity, and Other Factors

Environmental conditions greatly influence the selection of explosion-proof equipment:

- Temperature Ranges: Choose equipment that can operate safely within the temperature ranges of the environment. This includes both ambient temperature and potential hot spots.

- Humidity and Corrosive Atmospheres: In environments with high humidity or corrosive substances, select equipment with corrosion-resistant materials and sealed components to prevent degradation and maintain safety.

- Dust and Particulates: In industries where dust is a concern, such as grain handling or woodworking, ensure the equipment is rated for dust ignition-proof performance.

Maintenance and Inspection

Regular Maintenance Protocols for Explosion-Proof Equipment

Maintaining explosion-proof equipment is crucial for ensuring ongoing safety and compliance:

- Scheduled Maintenance: Follow a regular maintenance schedule based on the manufacturer’s recommendations. This typically includes lubrication, inspection of seals and housings, and testing of safety mechanisms.

- Trained Personnel: Ensure maintenance tasks are performed by trained personnel familiar with the specific requirements of explosion-proof equipment.

Importance of Routine Inspections and Certifications

Routine inspections and certifications are essential for maintaining the integrity of explosion-proof equipment:

- Periodic Inspections: Conduct periodic inspections to check for wear and tear, corrosion, and any damage that could compromise safety. This includes visual inspections and functional tests.

- Certifications and Documentation: Keep detailed records of all maintenance and inspections. Ensure the equipment maintains current certifications as required by regulatory bodies such as ATEX, NEC, or IECEx.

- Compliance Audits: Periodically audit compliance with safety standards and regulatory requirements. This helps identify any gaps and ensures ongoing adherence to best practices.

By carefully considering capacity and load requirements, environmental conditions, and maintenance protocols, industries can select the right explosion-proof hoists and cranes to ensure safe and efficient operations in hazardous environments.

Benefits of Using Explosion-Proof Hoists and Cranes

Enhanced Safety

- Reducing the Risk of Explosions and Fires:Explosion-proof hoists and cranes are designed to prevent sparks and high temperatures that could ignite flammable substances. This reduces the risk of explosions and fires, which are significant hazards in industries handling volatile materials. The use of non-sparking materials, sealed electrical components, and robust construction ensures that any potential ignition sources are contained, thus maintaining a safe working environment.

- Protecting Workers and Assets:The primary goal of explosion-proof equipment is to safeguard workers from the dangers of explosions and fires. By minimizing these risks, companies can prevent injuries, fatalities, and health hazards. Additionally, protecting assets such as machinery, facilities, and inventory from damage caused by fires or explosions is critical. This protection extends to preventing costly downtime and ensuring business continuity.

Regulatory Compliance

- Meeting Industry Standards and Legal Requirements:Explosion-proof hoists and cranes are designed to meet stringent industry standards and legal requirements set by regulatory bodies such as OSHA, ATEX, NEC, and IECEx. These standards dictate the design, construction, and operation of equipment used in hazardous environments. By using explosion-proof equipment, companies ensure they are in compliance with these regulations, which is crucial for legal and safety reasons.

- Avoiding Fines and Shutdowns:Non-compliance with safety regulations can result in hefty fines, legal penalties, and even operational shutdowns. Using explosion-proof hoists and cranes helps companies avoid these consequences by adhering to safety standards and regulatory requirements. This not only protects the company financially but also maintains its reputation and operational integrity.

Operational Efficiency

- Improving Handling and Lifting Processes:Explosion-proof hoists and cranes are engineered for high performance and reliability. They improve handling and lifting processes by providing precise control and robust lifting capabilities. This efficiency is particularly important in industries where accurate and safe movement of materials is critical, such as in chemical manufacturing or oil and gas extraction.

- Reducing Downtime and Increasing Productivity:Reliable explosion-proof equipment minimizes the risk of accidents and mechanical failures, leading to reduced downtime. Consistent and safe operations enhance overall productivity by ensuring that materials are handled smoothly and efficiently. This, in turn, increases output and profitability, as the company can maintain steady production rates without interruptions caused by safety incidents or equipment malfunctions.

By incorporating explosion-proof hoists and cranes into their operations, industries can significantly enhance safety, ensure regulatory compliance, and boost operational efficiency. This investment in specialized equipment not only protects workers and assets but also contributes to the overall success and sustainability of the business.

Conclusion

The handling and storage of flammable liquids in industrial settings present significant risks of fires and explosions. The use of explosion-proof hoists and cranes is crucial in mitigating these risks by containing potential ignition sources. These specialized equipment pieces are essential for ensuring the safe and efficient operation of industries that deal with volatile substances.

Industries such as oil and gas, chemical manufacturing, pharmaceuticals, and paint and coating have specific needs when it comes to managing flammable liquids. Explosion-proof hoists and cranes provide enhanced safety by reducing the risk of accidents, protecting workers, and safeguarding assets. They ensure regulatory compliance, helping companies meet stringent standards and avoid fines. Additionally, they improve operational efficiency by streamlining handling and lifting processes, reducing downtime, and increasing productivity.

Final Recommendations

Best Practices for Selecting and Using Explosion-Proof Hoists and Cranes

- Assess Capacity and Load Requirements: Determine the appropriate load capacity and match equipment specifications to operational needs to ensure the right fit for your facility.

- Evaluate Environmental Conditions: Assess the work environment for explosive hazards and select equipment based on temperature, humidity, and other relevant factors.

- Implement Regular Maintenance and Inspection Protocols: Follow scheduled maintenance and routine inspections to ensure the equipment remains in optimal condition and compliant with safety standards.

- Train Personnel: Ensure that staff handling and maintaining the equipment are adequately trained in safety protocols and operational procedures.

Encouragement to Prioritize Safety and Compliance in Industrial Operations

Prioritizing safety and compliance is not only a legal obligation but also a moral one. Investing in explosion-proof hoists and cranes demonstrates a commitment to protecting workers and maintaining a safe workplace. By adhering to best practices and regulatory requirements, companies can avoid costly accidents, enhance productivity, and sustain long-term success. Ensuring that the selection and use of explosion-proof equipment are carefully considered and implemented is a vital step in achieving these goals.