Gantry Crane Safety: Gantry Crane Design & Safety Devices

Gantry crane with electric hoist designed and manufactured by Yuantai Cranes are widely used for all kinds of working circumstance with different protection schemes.

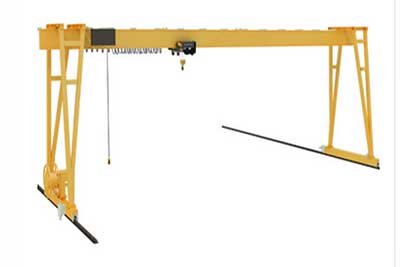

Main types of gantry cranes designs with various safety devices

Truss girder gantry crane for sale

Truss girder gantry crane for saleSafety devices in general forgantry craneare as below:

a. Electrical safety device

- General power switch earth leakage protection device

- Crane travelling emergency stop button

- Crane travelling warning light

- Lifting travel limit(max), crane travel limit and trolley travel limit

- Lifting load limiter

- Anemoclinograph

- Lifting trolley travel locking device

- Crane stop rail clamping device

b. Electrical system protection device

- Lightning arrester

- Overload, overcurrent, short-circuit protection, monitoring indicator and interlocking device

- Overvoltage, undervoltage protection; mechanical and electric interlock mechanism (avoid misoperation)

Gantry crane are equipped with the inclined staircase, handrail, walking platform and other safety auxiliary facilities to ensure convenient construction and personnel safety.

Gantry Crane Design to Ensure Safety in Different Working Surroundings

Featured gantry crane designs to ensure safety in different surround environments The following are gantry crane protection schemes:

- If the environment is humid, the gantry cranes may be designed with a warm-up device.There are unique criteria for gantry crane humidity during operation. In general, humidity levels should be less than 85%.

- If the electric hoist type gantry crane is used outside, the rain cover will needed.

- If the gantry crane used in doors with hazardous environments, such as explosive or dusty application, the explosion proof parts and components will be used.

- As for salty or underwater loads handling, such as a grab gantry crane for sand grabbing, the water proof and anti-corrosion features may be added.

- A gantry crane safety equipment with an electric hoist is essential when working in chilly conditions. It is recommended that the gantry crane use a heated device and an enclosed driver's cab. In terms of anti-skip and anti-freeze methods, we recommend that ice and snow be removed as soon as possible, and that all parts of the gantry crane be cold-proof.

- In hot weather, the drivers' cab of a gantry crane should be equipped with a cooling device and an electric fan mounted on the engine. If the gantry crane becomes too hot, the current should be turned off to ensure the safety of the gantry crane operators. 7.If gantry cranes are working in dust, the gantry crane will be installed a driver’s cabin.

Lists of crane safety devices

Overload Limiter

The comprehensive error of the overload limiter should not be greater than 5%, and the lifting times and lifting weight can be recorded. (2) When the load reaches 90% of the rated lifting capacity, it should be able to send out an alarm signal; when it is 100-110% of the rated lifting capacity, it should automatically cut off the lifting control power supply of the hanging object through interlock control. (3) The overload limiter shall not be adjusted or canceled without authorization, daily spot inspection and maintenance shall be in place, and regular calibration shall be carried out.

Torque Limiter

(1) The moment limiter is used for variable-amplitude operating lifting equipment such as truck cranes, crawler cranes, and tower cranes. (2) The comprehensive error of the torque limiter should not be greater than 10%. (3) After the hoisting machinery is equipped with a moment limiter, it should be adjusted or calibrated according to its performance and accuracy. When the load moment reaches the rated lifting moment, it can automatically cut off the power source for lifting or luffing, and issue a prohibition sex alarm signal.

Ascending and Descending Limit Position Limiter

Ascent limit

The limit position limiter must ensure that when the spreader is lifted to the limit position, the power source for lifting will be automatically cut off. For the hydraulic lifting mechanism, a prohibitive alarm signal should be given, and a deceleration limit should be set. There are many heavy hammer types, and the electric hoist triggers the limit switch for the operation of the rope guide. (2) Lowering limit: Under the working condition that the spreader may be lower than the lower limit position, it should be ensured that when the spreader is lowered to the limit position, the power source for lowering can be automatically cut off to ensure that the wire rope is wound on the drum. The number of turns specified by the design (generally at least 3 turns).

Operating Limit Position Protection (Limit, Collision Avoidance Device)

Limit switch:

It also known as the operating limit position limiter, it should ensure that when the mechanism is at the limit position of its movement, it will automatically cut off the forward power source and stop the movement, and the deceleration limit should be set before the stop limit action. (2) Collision avoidance device: When there are two or more cranes operating in the same span, each crane should be equipped with a collision avoidance device. At present, infrared and laser ranging are widely used. In terms of performance, laser is better than infrared.

Buffers, Rail End Stops

The operating mechanism of the crane running on the track, and the operating mechanism of the heavy lifting and trolley should be equipped with buffers. The buffers can be mounted on a crane or on a rail end stop. The stop device at the end of the track should be firm and reliable to prevent the crane from derailing. (2) The buffer has the good performance of absorbing the energy of the moving mechanism and reducing the impact, and mainly includes hydraulic type, polyurethane or rubber material, and spring type.

Track Sweeping Device

When the material may accumulate on the track and become an obstacle to the operation, the crane and trolley running on the track should be equipped with a track cleaning device under the platform frame (or end beam) and the trolley frame. The gap between the bottom surface of the rail plate and the top surface of the track is generally 5mm~10mm.

Anti-wind and Anti-skid Device

- There are three main types of anti-wind and anti-skid devices for cranes such as port machinery and outdoor gantry cranes, namely rail clamps (wheels), anchor devices and iron shoes. Tall outdoor cranes should also be equipped with anemometers and wind speed alarm devices, which should be able to send out an alarm signal when the wind force is greater than the set value of the wind speed calculated in the working state.

- Crane users should formulate management standards for the use and maintenance of anti-wind and anti-skid devices. Before the arrival of typhoon seasons, inspections and repairs should be concentrated, and deficiencies should be replenished in time; annual anti-typhoon drills should include the operation of wind-proof devices and equipment.

Interlock Protection

Interlocking protection devices shall be provided for the doors of bridge cranes and gantry cranes, the hatch doors for boarding bridge frames from the driver's cab, and the doors for boarding trolleys.

- When the door is opened, the operating mechanism of the crane cannot be started. the

- When the driver's cab is located in the moving part, an interlock protection device should be installed at the passageway entering the driver's cab. When the door of the passageway is opened, the operating mechanism of the crane cannot be started.

Other Safety Protection Devices

- Skew adjustment and display device: It should be ensured that for large-span gantry cranes and loading and unloading bridges, when the outriggers at both ends are deflected due to different forward speeds, the deflection situation can be indicated to the driver to make the deflection get adjusted.

- Spirit level: It should have good performance for checking the inclination of the crane with outriggers.

- The exposed moving parts on the crane that may hurt people, such as open gears, transmission wheels, chains, pulleys, etc., should be equipped with protective covers/bars.

- In terms of electrical protection: the crane should be equipped with electrical protection devices such as short circuit and overcurrent (overload) protection, overvoltage and loss of voltage protection, zero position protection, and power supply failure phase protection. The hoisting mechanism of the crane adopts thyristor stator voltage regulation, eddy current braking, dynamic braking, thyristor power supply, and DC unit power supply, and an overspeed protection device must be installed. In addition, cranes with a rated lifting capacity greater than 20t and used to lift molten metal should also be equipped with overspeed protection devices.