Goliath Gantry Crane Safety All You Want to Know

Goliath Gantry Cranes are an essential piece of equipment in various industries, including construction, mining, and shipbuilding. They provide a cost-effective solution for heavy lifting and moving of materials and equipment. However, their size and weight can also pose a significant safety risk to workers and the surrounding environment if not used correctly. In this article, we will discuss the key features and best practices for safe usage of Goliath Gantry Cranes.

Double Girder Gantry Crane for Safe Material Handling

Gantry Crane Safety Regulations & RequirementsGoliath Gantry Cranes are subject to various regulations and requirements to ensure their safe operation. The Occupational Safety and Health Administration (OSHA) in the United States, for example, has set specific standards for the safe use of cranes and derricks in construction operations. These standards cover the design, inspection, and operation of cranes, as well as the qualifications of crane operators.

In addition to OSHA regulations, other industry-specific standards may apply, depending on the type of Goliath Gantry Crane and the industry in which it is used. It is essential to understand and comply with all applicable safety regulations and requirements to ensure the safe operation of the crane and protect workers and the environment.

Goliath Gantry Cranes are designed with safety in mind, incorporating various safety features to prevent accidents and protect workers and equipment. Some of these safety features include:

Safety and Protection DevicesProtection devices are installed on Goliath Gantry Cranes to prevent accidents and protect workers. These devices can include limit switches, overload protection systems, and emergency brakes. Limit switches are designed to limit the crane's travel to prevent it from hitting objects or structures, while overload protection systems prevent the crane from lifting loads beyond its capacity. Emergency brakes are designed to stop the crane's motion in case of an emergency.

Goliath Gantry Cranes also include safety devices to protect workers from hazards. These devices can include rail sweeps, warning lights, and alarms. Rail sweeps are designed to remove debris and other hazards from the crane's path, while warning lights and alarms alert workers to the crane's movement and potential hazards.

|

Protection system |

||

|

Overload limiter |

Under overload condition, cut off the power of the crane, the screen can show the weight of lifting items. |

|

|

Rotary Limit switch |

For hoist travelling mechanism, protect the crane before it crashes the object. |

|

|

Lifting limiter |

For lifting protection, prevent the hook from knocking the hoist |

|

|

Buffer |

Ployurethane material. Used for anti-collision |

|

|

Other protection |

Phase-break protection, no-voltage protection, over-current protection |

|

Outdoor Gantry Crane Safety

Outdoor gantry cranes operate under different conditions than indoor models and must be designed to handle numerous environmental factors safely. For instance, the cranes must withstand wind and snow loads and must not topple over or fall due to such factors. Proper anchoring ensures the crane's stability when being utilized under such climatic conditions, while safety systems, such as emergency cut-off switches, help prevent accidents.

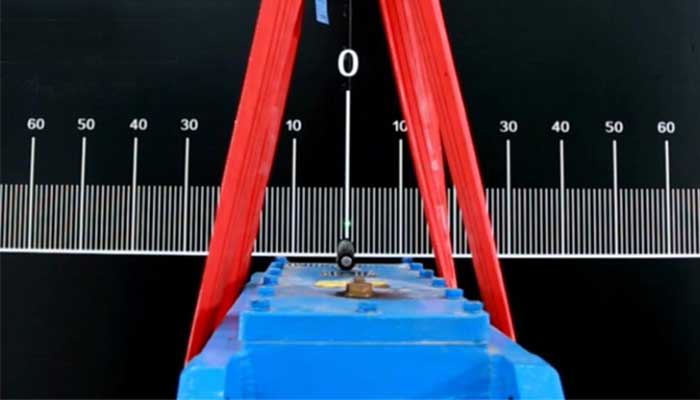

Outdoor gantry crane safety devices to ensure loading handling operations -antiwind devices

Operation Controls

Operator controls on Goliath Gantry Cranes are designed to ensure safe operation. These controls include emergency stop buttons, which allow operators to quickly stop the crane's movement in case of an emergency, as well as limit switches and load indicators to ensure that the crane is not overloaded or operated beyond its capacity.

Goliath Gantry Crane Operation Safety

Goliath Gantry Crane operation safety is critical to prevent accidents and protect workers and equipment. Some best practices for safe crane operation include:

Proper TrainingOperators must receive proper training before operating a Goliath Gantry Crane. The training should cover crane operation, safety procedures, and emergency response. Operators should also receive ongoing training to stay up-to-date with new safety regulations and best practices.

Pre-Operational ChecksBefore operating a Goliath Gantry Crane, operators must perform pre-operational checks to ensure that the crane is in good working condition. These checks should include inspecting the crane's components, such as the hoist, wire ropes, brakes, and limit switches, and testing the crane's controls and safety devices.

Load CapacityGoliath Gantry Cranes have a specific load capacity that should not be exceeded. Operators must ensure that they know the crane's load capacity and do not lift loads beyond this limit.

Gantry Crane Operation Training to Ensure SafetyProper training is critical to ensuring safe Goliath Gantry Crane operation. Operators must receive comprehensive training on the crane's operation, safety procedures, and emergency response. The training should cover topics such as crane setup, load handling, and proper use of safety devices.

Training should also cover the different types of Goliath Gantry Cranes and their specific safety features and requirements. Operators should receive ongoing training to stay up-to-date with new safety regulations and best practices.

Crane Inspection & Maintenance to Prevent Risks

Regular inspection and maintenance of Goliath Gantry Cranes are essential to prevent risks and ensure safe operation. Inspection and maintenance should include checking the crane's components, such as the hoist, wire ropes, brakes, and limit switches, as well as testing the crane's controls and safety devices.

Maintenance should also include lubrication of moving parts, replacement of worn parts, and repair of damaged components. Inspections and maintenance should be performed by qualified technicians and recorded in a maintenance log.

Main Reasons to Cause Gantry Crane Accidents

Goliath Gantry Crane accidents can occur for various reasons, including operator error, equipment failure, and environmental factors. Some common causes of Goliath Gantry Crane accidents include:

OverloadingOverloading is a common cause of Goliath Gantry Crane accidents. Operators must ensure that they do not lift loads beyond the crane's capacity to prevent accidents.

Improper Use of Safety DevicesSome Goliath Gantry Crane accidents occur due to the improper use of safety devices. Operators must receive proper training on the use of safety devices and ensure that they are in good working condition before operating the crane.

Lack of MaintenanceLack of maintenance can also cause Goliath Gantry Crane accidents. Regular inspection and maintenance are essential to ensure safe operation and prevent accidents.

All in All, goliath gantry cranes are essential equipment in various industries, but their safe operation requires proper training, regular inspection and maintenance, and compliance with safety regulations and requirements. By incorporating safety features and best practices, operators can ensure safe Goliath Gantry Crane operation and prevent accidents that can cause injury, damage to equipment, and loss of productivity.