How to Get Detailed Price on Bucket Grab for Cranes

How to Get Detailed Price on Bucket Grab for Cranes

Learn effective strategies to obtain detailed pricing on bucket grabs for cranes, ensuring informed purchasing decisions and optimal investment value.

The pricing of bucket grabs is crucial for businesses involved in construction, manufacturing, and material handling. Bucket grabs are essential tools for efficiently moving bulk materials like cement, aggregates, and other heavy loads. Knowing the cost helps organizations budget effectively, make informed purchasing decisions, and ensure they are getting value for their investment. An accurate understanding of pricing also enables companies to compare different products and suppliers, ensuring they select the best option for their specific needs.

The price of bucket grabs can vary widely based on several key factors. These include the type of bucket grab, which can range from clamshell to hydraulic designs, each suited for different applications and loads. The materials used in construction also play a significant role; high-quality, durable materials will typically cost more but offer better performance and longevity. Additionally, the size and capacity of the grab, customization options, and the reputation of the manufacturer can all affect pricing. Understanding these factors is essential for accurately assessing costs and making the right choice.

This guide aims to provide a clear and straightforward approach to obtaining detailed pricing information for bucket grabs used in cranes. It will cover the various types of bucket grabs available, the factors that influence their prices, and effective strategies for researching and requesting quotes from suppliers. By following this guide, readers will be better equipped to navigate the market, compare options, and ultimately make informed decisions that align with their operational needs and budget constraints.

Types of Bucket Grabs

Overview of Different Types of Bucket Grabs:

Bucket grabs come in several designs, each tailored for specific applications and material handling needs. Understanding the different types can help users select the most suitable option for their operations.

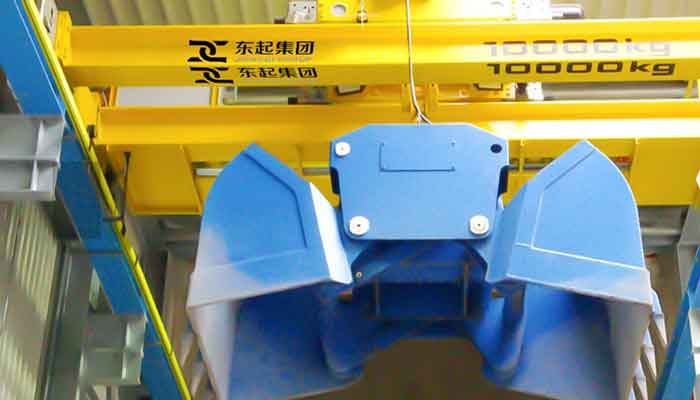

Clamshell grab bucket overhead cranes for sale

Clamshell Grabs: Clamshell grabs are one of the most common types used in construction and material handling. They consist of two hinged jaws that open and close like a clam, making them ideal for scooping up loose materials such as sand, gravel, and cement. Clamshell grabs are versatile and can be operated using hydraulic or mechanical systems. Their design allows for precise control when picking up materials from various angles, making them effective for both loading and unloading tasks.Orange Peel Grabs: Orange peel grabs feature multiple tines that resemble the segments of an orange. This design is particularly effective for handling bulk materials like scrap metal, rocks, and other irregularly shaped items. The tines can grip materials securely, allowing for efficient lifting and transport. Orange peel grabs are often used in recycling facilities and construction sites where heavy and bulky materials are common. Their robust construction ensures durability under challenging conditions.

Hydraulic Grabs: Hydraulic grabs utilize hydraulic cylinders to open and close the bucket, providing enhanced control and power. These grabs can be designed in various configurations, including clamshell and orange peel styles. Hydraulic grabs are known for their ability to handle heavy loads with ease, making them ideal for demanding applications in ports, shipyards, and heavy construction. The hydraulic mechanism allows for smooth operation and can be adjusted for different lifting capacities and material types.

Variations in Pricing Based on Type:

The pricing of bucket grabs varies significantly depending on their type and intended application.

- Clamshell Grabs: Generally, clamshell grabs are more affordable than specialized grabs, with prices ranging from moderate to higher-end based on size and material quality. Basic models may start at a lower price point, while larger or custom-designed grabs can be considerably more expensive.

- Orange Peel Grabs: These grabs tend to be priced higher than clamshells due to their specialized design and the materials used for construction. The complexity of the tines and their ability to handle heavy, irregular loads contribute to the increased cost. Prices can vary widely depending on the number of tines and the grab's capacity.

- Hydraulic Grabs: Hydraulic grabs are typically the most expensive option due to their advanced technology and capabilities. The hydraulic system adds to the cost, but it also provides significant benefits in terms of power and precision. Buyers should expect to pay a premium for hydraulic grabs, especially those designed for heavy-duty applications.

Overall, when considering the price of bucket grabs, it's important to evaluate the specific needs of your operation, the type of materials being handled, and the long-term value each type offers.

Steel scrap handling overhead cranes

Factors Influencing the Price of Bucket Grabs

Material and Construction Quality:

The materials used in the construction of bucket grabs play a significant role in determining their price and performance.

- Types of Materials Used (e.g., Steel, Alloys): Bucket grabs are typically made from various grades of steel, including carbon steel and alloy steel. Higher-grade materials often come with increased costs but provide better strength and resilience. Alloy steels, which may include elements like chromium or nickel, offer enhanced properties such as corrosion resistance and toughness, making them suitable for heavy-duty applications. The choice of material directly impacts the grab's ability to withstand harsh working conditions and heavy loads.

- Durability and Wear Resistance: Durability is a critical factor in the pricing of bucket grabs. Grabs designed for frequent use in demanding environments, such as construction sites or ports, require robust construction to resist wear and tear. Features like hardfacing, which involves applying a wear-resistant layer to high-impact areas, can increase the longevity of the grab but also add to the overall cost. Buyers should consider the expected lifespan and maintenance needs when evaluating price versus durability.

Size and Capacity:

The size and load capacity of a bucket grab significantly influence its price.

- Load Capacity Considerations: Bucket grabs come in various load capacities, typically ranging from a few hundred kilograms to several tons. Grabs with higher load capacities are generally more expensive due to the additional materials and engineering required to ensure safety and performance. It's essential to choose a grab that matches the specific load requirements of your operation, as selecting an undersized grab can lead to safety risks and operational inefficiencies.

- Dimensions and Design Specifications: The overall dimensions and design specifications of a bucket grab also affect its pricing. Larger grabs that can handle more substantial volumes or larger materials tend to cost more. Additionally, specialized designs that enhance efficiency or adaptability may involve higher manufacturing costs. Buyers should assess their operational needs to determine the appropriate size and design for their applications.

Customization Options:

Customization can enhance the functionality of bucket grabs but may also lead to increased pricing.

- Special Features (e.g., Dust Control, Hydraulic Systems): Many manufacturers offer customization options that include special features such as dust control systems, which help manage airborne particles during material handling. Hydraulic systems can also be integrated for improved control and efficiency. These enhancements typically add to the base price of the grab, but they can provide significant operational benefits, especially in environments where dust suppression or precision handling is crucial.

- Tailored Designs for Specific Applications: Some projects may require bucket grabs tailored for specific tasks, such as handling particular materials or fitting unique machinery. Custom designs can address these needs but often come at a premium. When considering customization, it's important to evaluate whether the added cost will result in improved efficiency or productivity in your operations.

Manufacturer Reputation:

The reputation of the manufacturer can significantly impact the pricing of bucket grabs.

- Brand Reliability and History: Established manufacturers with a history of producing high-quality equipment often charge higher prices due to their reputation and reliability. Buyers may be willing to pay a premium for products from reputable brands, as these companies typically have a track record of durability and performance. Researching manufacturers and their history can provide insights into the quality and reliability of their products.

- Warranty and Support Services: A strong warranty and support services can justify higher prices. Manufacturers that offer comprehensive warranties demonstrate confidence in their products, and robust customer support can be invaluable for addressing any issues that arise post-purchase. When evaluating price, consider the level of after-sales support and warranty coverage, as these factors can affect the overall value of the investment.

Researching Prices

Online Marketplaces

Online marketplaces are valuable resources for researching the prices of bucket grabs, offering a wide range of options and competitive pricing.

Websites to Check (e.g., Alibaba, ThomasNet)

Popular online platforms like Alibaba and ThomasNet provide extensive listings of bucket grabs from various manufacturers and suppliers. Alibaba is particularly useful for finding international suppliers and comparing prices across a vast array of products. ThomasNet focuses on North American manufacturers, offering detailed information about industrial products, including specifications and pricing. In addition to these sites, other platforms such as eBay, Made-in-China, and Global Sources can also be explored for additional options and pricing information.

Comparing Prices Across Different Platforms

When using online marketplaces, it's crucial to compare prices across different platforms to get a comprehensive view of the market. Prices can vary significantly based on the supplier, location, and any additional features offered. Take note of shipping costs, as these can impact the total price. Additionally, read customer reviews and ratings to assess the reliability of the supplier and the quality of their products. This comparison process helps ensure that you find the best deal while also considering the reputation of the seller.

Manufacturer Websites

Manufacturer websites are another essential resource for obtaining accurate pricing information.

- Direct Inquiries for Quotes:Many manufacturers provide the option to request quotes directly through their websites. This approach allows you to specify your requirements, such as size, capacity, and any customization needs. By reaching out directly, you can often receive tailored pricing that reflects your specific situation. It's also an opportunity to ask about bulk purchasing discounts, which can lead to significant savings if you need multiple units.

- Accessing Product Catalogs and Pricing Guides:Most manufacturers will have product catalogs available on their websites, showcasing their range of bucket grabs along with specifications and pricing information. These catalogs can provide insights into the different models available, their features, and the associated costs. Some manufacturers may also offer downloadable pricing guides or brochures that detail their products and services, making it easier to compare options and make informed decisions.

Industry Trade Shows and Expos

Attending industry trade shows and expos can provide valuable insights and opportunities for researching bucket grab prices.

Networking with Manufacturers. Trade shows are excellent venues for networking with manufacturers and suppliers. Engaging directly with company representatives allows you to ask questions, discuss specific needs, and gain insights into new products and technologies. Often, manufacturers showcase their latest innovations, which can help you stay updated on industry trends and pricing.

Gathering Information on New Products and Pricing

At trade shows, you can gather brochures, catalogs, and promotional materials that detail new products and pricing structures. Many exhibitors offer special pricing or discounts for orders placed during the event, providing an additional incentive to explore options on-site. Additionally, attending seminars or workshops at these events can further enhance your understanding of the market and assist in making informed purchasing decisions.

By utilizing these research methods, you can effectively gather detailed pricing information on bucket grabs, ensuring you make an informed choice that aligns with your operational needs and budget.

Requesting Quotes

Preparing a Request for Quote (RFQ):

Creating an effective Request for Quote (RFQ) is a crucial step in obtaining accurate pricing and ensuring that suppliers understand your specific needs.

Essential Information to Include (Specifications, Quantities):

When drafting an RFQ, it's important to include all relevant details to ensure suppliers can provide accurate quotes. Key information to include consists of:

- Specifications: Clearly outline the type of bucket grab you need (e.g., clamshell, orange peel, hydraulic), along with specific dimensions, load capacity, and any necessary features or customizations.

- Quantities: Specify how many units you are looking to purchase. If you anticipate needing additional units in the future, mentioning this can also help suppliers provide bulk pricing options.

- Delivery Requirements: Include details about your desired delivery timeline and location, as this can affect pricing and availability.

- Budget Constraints: If you have a budget range in mind, sharing this information may help suppliers tailor their quotes to meet your financial requirements.

Importance of Clarity and Detail:

Providing clear and detailed information in your RFQ is essential for receiving accurate responses. Ambiguities or vague descriptions can lead to misunderstandings and result in quotes that do not meet your needs. A well-structured RFQ helps suppliers understand your requirements from the outset, reducing the likelihood of back-and-forth communication and speeding up the quoting process. It also reflects professionalism, which can encourage suppliers to take your request seriously.

Contacting Multiple Suppliers:

Reaching out to several suppliers is a strategic approach that can enhance your chances of finding the best deal.

Benefits of Obtaining Multiple Quotes: Obtaining quotes from multiple suppliers allows you to compare pricing, features, and service levels. This competitive approach can lead to better pricing and terms, as suppliers may adjust their offers based on what others are providing. Additionally, you can evaluate the range of products available and identify which suppliers offer the best value for your specific needs. This practice also helps you avoid over-reliance on a single supplier, which can be risky if issues arise with availability or support.

Evaluating Responses for Best Value: Once you receive quotes, it's important to carefully evaluate each response.

Consider not only the price but also the following factors:

- Quality and Specifications: Ensure that the products quoted meet your specifications and quality standards.

- Supplier Reputation: Research the suppliers' reliability and customer feedback to gauge their performance history.

- Delivery Times: Compare the proposed delivery schedules to ensure they align with your project timelines.

- Warranty and Support: Assess the warranty terms and after-sales support offered by each supplier, as these can significantly impact the long-term value of your purchase.

By thoroughly preparing your RFQ and contacting multiple suppliers, you can enhance your chances of securing a favorable deal on bucket grabs that meet your operational requirements and budget constraints.

Additional Considerations

Shipping and Handling Costs: When purchasing bucket grabs, it's essential to consider the logistics involved in getting the product from the supplier to your location.

Logistics and Associated Fees: Shipping and handling costs can significantly affect the overall price of your bucket grab. Factors to consider include:

- Shipping Method: Different shipping options (air freight, sea freight, ground transport) come with varying costs and delivery times. While air freight is faster, it is often more expensive than sea freight.

- Distance and Location: The distance between the supplier and your location will impact shipping fees. Additionally, remote or hard-to-access locations may incur extra charges.

- Customs and Duties: For international purchases, be aware of any customs duties, import taxes, or tariffs that may apply. These fees can add to the total cost and should be factored into your budget.

- Handling Fees: Some suppliers may charge handling fees for packaging and preparing the item for shipment. Understanding these costs upfront can help you avoid surprises when the final invoice arrives.

Installation and Maintenance Costs: Beyond the initial purchase price, consider the costs associated with installing and maintaining the bucket grab.

Evaluating Long-Term Costs Beyond Initial Purchase:

- Installation Costs: Depending on the complexity of the grab and your existing equipment, installation may require professional assistance, which can add to the overall expense. Ensure to inquire about any installation services offered by the supplier or whether you will need to hire a third-party contractor.

- Maintenance Costs: Regular maintenance is crucial for ensuring the longevity and performance of your bucket grab. Consider the costs of replacement parts, routine servicing, and any specialized maintenance required for hydraulic systems or other complex features. Understanding the maintenance schedule and associated costs can help you plan for future expenses effectively.

Total Cost of Ownership (TCO): Calculating the Total Cost of Ownership (TCO) provides a comprehensive view of the long-term financial commitment involved in purchasing a bucket grab.

Calculating Long-Term Investment Versus Upfront Price:

TCO encompasses all costs associated with owning and operating the bucket grab over its useful life, including:

- Initial Purchase Price: The upfront cost of the grab itself.

- Shipping and Handling: As discussed, include all logistics-related fees.

- Installation Costs: Any expenses incurred for setting up the equipment.

- Maintenance and Repair: Estimate ongoing maintenance costs, including parts and labor over the expected lifespan of the grab.

- Operational Costs: Consider energy consumption (if applicable) and any other operational expenses associated with using the grab.

By evaluating TCO, you can make informed decisions that go beyond just the initial purchase price, ensuring that you choose a bucket grab that aligns with your budget and operational needs over the long term. Understanding these additional considerations will help you navigate the purchasing process more effectively and make a sound investment in your equipment.

Conclusion

In summary, obtaining detailed pricing for bucket grabs involves several strategic steps. Start by researching prices through online marketplaces and manufacturer websites, ensuring you gather comprehensive information about specifications, quantities, and potential shipping costs. Preparing a well-structured Request for Quote (RFQ) is essential for clarity and accuracy, while contacting multiple suppliers allows you to compare offers and evaluate the best value. Additionally, considering shipping and handling costs, installation and maintenance expenses, and calculating the Total Cost of Ownership (TCO) will provide a holistic view of your investment.

Thorough research is crucial in navigating the complexities of purchasing equipment like bucket grabs. By exploring various sources, comparing quotes, and understanding the full scope of costs involved, you can make more informed decisions that align with your operational needs and budget constraints. Don't hesitate to leverage industry resources, engage with suppliers, and seek insights from industry peers to enhance your understanding of the market.

Finally, making informed purchasing decisions is about balancing initial costs with long-term value. By taking the time to evaluate all aspects of your investment—from pricing and supplier reputation to ongoing maintenance and total ownership costs—you position yourself for success. A well-informed choice not only ensures that you acquire a quality product but also contributes to the efficiency and effectiveness of your operations in the long run. With careful consideration and diligent research, you can confidently select the right bucket grab that meets your needs and supports your business objectives.