Indoor Crane & Types of Indoor Overhead Crane Systems Overview

Indoor Crane & Types of Indoor Overhead Crane Systems Overview. Indoor crane & crane system overview for you to select right indoor crane type, overhead crane, gantry crane, jib crane or light small indoor crane. Check now!

Indoor crane and indoor crane system

What is an indoor crane?An indoor crane is a type of crane that is designed to be used indoors, typically within factories, warehouses, or other industrial settings. What is an indoor crane system? An indoor crane system is a type of material handling system used to lift and move heavy loads within a facility. It typically consists of several components that work together to enable safe and efficient material handling. Some of the key components included in an indoor crane system are:

- Crane: The crane is the main component of the system and is responsible for lifting and moving heavy loads. There are several types of cranes used in indoor applications, including overhead cranes, jib cranes, gantry cranes, bridge cranes, and monorail cranes.

- Runway: The runway is a track or rail system that supports the crane and allows it to move along the length of the facility. The runway can be mounted on the ceiling or on columns, depending on the type of crane being used.

- Hoist: The hoist is the mechanism that lifts and lowers the load. It is typically attached to the crane and can be powered by electricity or compressed air.

- Trolley: The trolley is a mechanism that allows the hoist to move horizontally along the length of the crane. It is typically attached to the hoist and can be powered by electricity or compressed air.

- Controls: The controls are used to operate the crane and hoist. They can be located on the crane itself or on a separate control panel. The controls typically include buttons or levers for moving the crane, hoist, and trolley.

- Safety features: Safety features such as overload protection, emergency stop buttons, and anti-collision systems are essential components of an indoor crane system. These features help prevent accidents and injuries in the workplace.

- Power supply: The power supply is an important component of an indoor crane system as it provides the electrical power needed to operate the crane, hoist, and controls. The power supply can vary depending on the specific requirements of the system.

In summary, an indoor crane system is a complex system of components that work together to enable safe and efficient material handling within a facility. The specific components included in the system can vary depending on the type of crane being used and the specific requirements of the application.

Indoor crane types, and how to select right type for your use?

There are several types of indoor cranes used for lifting and moving heavy loads within buildings or enclosed spaces. Some common types of indoor cranes include:

- Overhead cranes: These are the most commonly used indoor cranes, which are suspended from the ceiling and move along a track. They are used for lifting and moving heavy loads in manufacturing plants, warehouses, and other industrial settings.

- Gantry cranes: These cranes are similar to overhead cranes, but they are supported by a structure on the ground instead of being suspended from the ceiling. They are often used in shipyards, construction sites, and other outdoor settings, but can also be used indoors.

- Jib cranes: These cranes have a horizontal arm that extends from a vertical mast, allowing them to move loads in a circular or semi-circular motion. They are often used in smaller spaces or for more precise lifting and positioning.

- Wall-mounted cranes: These cranes are attached to a wall or vertical structure and can be used for lifting and moving loads in tight spaces or where floor space is limited.

- Stacker cranes: These cranes are used in automated warehouses and distribution centers to move and stack pallets or other materials. They are often guided by a computerized system and can operate without human intervention.

These are just a few examples of the different types of indoor cranes available. The type of crane you choose will depend on the specific needs of your application, including the weight and size of the loads you need to lift, the available space, and any safety requirements.

Indoor overhead crane

Indoor overhead cranes and bridge cranes are two types of cranes commonly used in industrial settings for material handling.

Indoor overhead cranes are a type of crane that is mounted on a runway system and can move along the length of a facility. They are typically used in manufacturing and production facilities to lift and move heavy loads. Bridge cranes are a type of overhead crane that consists of a horizontal beam that is supported by two legs and can move along the length of the facility.

The main types of indoor overhead cranes are:

- Single girder overhead crane: This type of crane has one main girder and is used for lighter loads and shorter spans.

- Double girder overhead crane: This type of crane has two main girders and is used for heavier loads and longer spans.

- Underslung overhead crane: This type of crane is mounted below the runway system and is used in facilities with low headroom.

- Top running overhead crane: This type of crane is mounted on top of the runway system and is used for heavier loads and longer spans.

Single girder overhead crane Crane capacity: Top running design up to 32 ton, underhung design 0.25 -20 ton.

Single girder overhead crane Crane capacity: Top running design up to 32 ton, underhung design 0.25 -20 ton. Double girder trolley / winch overhead crane Crane capacity: 5 ton -550 ton

Double girder trolley / winch overhead crane Crane capacity: 5 ton -550 ton European standard fem underhung overhead crane 500 kg -10 ton

European standard fem underhung overhead crane 500 kg -10 ton Hoist, winch & trolley overhead crane for sale Crane Lifting system : Electric hoist 0.25 - 80 ton, winch trolley hoist up to 550 ton

Hoist, winch & trolley overhead crane for sale Crane Lifting system : Electric hoist 0.25 - 80 ton, winch trolley hoist up to 550 tonIndoor overhead cranes are used in a variety of applications, including manufacturing, production, and construction. They offer several advantages, including:

- High lifting capacity: Indoor overhead cranes can lift heavy loads with ease, making material handling more efficient.

- Precise positioning: Indoor overhead cranes can be controlled with precision, allowing for accurate positioning of loads.

- Efficient material handling: Indoor overhead cranes can move loads quickly and efficiently, reducing the time and effort required for material handling.

- Bridge cranes are also used in manufacturing and production facilities to lift and move heavy loads. They offer several advantages, including:

- High lifting capacity: Bridge cranes can lift heavy loads with ease, making material handling more efficient.

- Flexible movement: Bridge cranes can move along the length of the facility, allowing for flexible movement and positioning of loads.

- Efficient material handling: Bridge cranes can move loads quickly and efficiently, reducing the time and effort required for material handling.

In summary, indoor overhead cranes and bridge cranes are important types of cranes used in industrial settings for material handling. They offer several advantages, including high lifting capacity, precise positioning, flexible movement, and efficient material handling. The specific type of crane used will depend on the specific requirements of the application.

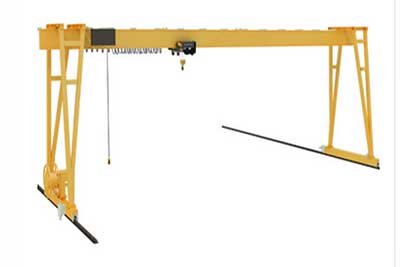

Indoor gantry cranes

Indoor gantry cranes and goliath cranes are two types of cranes commonly used in industrial settings for material handling.

Indoor gantry cranes are a type of crane that is supported by a gantry system and can move along the length of a facility. They are typically used in manufacturing and production facilities to lift and move heavy loads. Goliath cranes are a type of gantry crane that is typically used in outdoor applications, but can also be used indoors for specific applications.

The main types of indoor gantry cranes are:

- Single girder gantry crane/ goliath crane : This type of crane has one main girder and is used for lighter loads and shorter spans.

- Double girder gantry crane/ goliath crane : This type of crane has two main girders and is used for heavier loads and longer spans.

- Portable gantry crane: This type of crane is designed to be easily moved and can be used in multiple locations within a facility.

Truss girder gantry crane for sale

Truss girder gantry crane for saleIndoor gantry cranes are used in a variety of applications, including manufacturing, production, and construction. They offer several advantages, including:

- High lifting capacity: Indoor gantry cranes can lift heavy loads with ease, making material handling more efficient.

- Flexible movement: Indoor gantry cranes can move along the length of the facility, allowing for flexible movement and positioning of loads.

- Efficient material handling: Indoor gantry cranes can move loads quickly and efficiently, reducing the time and effort required for material handling.

- Goliath cranes are typically used in outdoor applications, but can also be used indoors for specific applications. They offer several advantages, including:

- High lifting capacity: Goliath cranes can lift heavy loads with ease, making material handling more efficient.

- Flexible movement: Goliath cranes can move along the length of the facility, allowing for flexible movement and positioning of loads.

- Efficient material handling: Goliath cranes can move loads quickly and efficiently, reducing the time and effort required for material handling.

In summary, indoor gantry cranes and goliath cranes are important types of cranes used in industrial settings for material handling. They offer several advantages, including high lifting capacity, flexible movement, and efficient material handling. The specific type of crane chosen will depend on the specific requirements of the application.

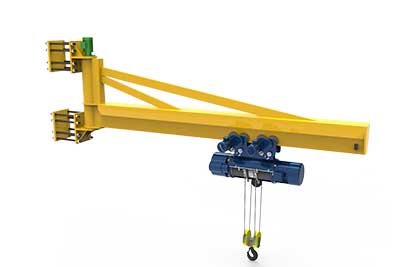

Indoor jib cranes

Indoor jib cranes or cantilever cranes are a type of crane that is typically used in industrial settings for material handling. They consist of a horizontal beam, called a jib, that is mounted on a vertical mast or wall and can rotate around its axis. Jib cranes are commonly used in manufacturing and production facilities to lift and move heavy loads.

The main types of indoor jib cranes are:

- Wall-mounted jib crane: This type of crane is mounted on a wall and can rotate 180 degrees.

- Mast-mounted jib crane: This type of crane is mounted on a vertical mast and can rotate 360 degrees.

- Articulating jib crane: This type of crane has a flexible arm that can be adjusted to reach around obstacles.

Pillar jib cranes for sale , free standing floor mounted electric jib crane, with customized rotating designs

Pillar jib cranes for sale , free standing floor mounted electric jib crane, with customized rotating designs Wall jib cranes for sale including the wall mounted jib crane and wall travelling jib cranes

Wall jib cranes for sale including the wall mounted jib crane and wall travelling jib cranes Portable jib crane for sale , customized roller jib crane for 1 ton 2 ton loads handling

Portable jib crane for sale , customized roller jib crane for 1 ton 2 ton loads handling Electric hoist for sale , including electric wire rope hoist and electric chain hoist,

Electric hoist for sale , including electric wire rope hoist and electric chain hoist,Indoor jib cranes are used in a variety of applications, including manufacturing, production, and construction. They offer several advantages, including:

- High lifting capacity: Indoor jib cranes can lift heavy loads with ease, making material handling more efficient.

- Flexible movement: Indoor jib cranes can rotate around their axis, allowing for flexible movement and positioning of loads.

- Efficient material handling: Indoor jib cranes can move loads quickly and efficiently, reducing the time and effort required for material handling.

- Space-saving design: Jib cranes have a compact design that takes up less space than other types of cranes, making them ideal for facilities with limited space.

In summary, indoor jib cranes or cantilever cranes are an important type of crane used in industrial settings for material handling. They offer several advantages, including high lifting capacity, flexible movement, efficient material handling, and a space-saving design.

Small indoor cranes for light loads handling for your facility

- Portable gantry cranes: These cranes are designed to be easily moved and can be used in multiple locations within a facility. They consist of a horizontal beam that is supported by two legs and can move along the length of the facility. Portable gantry cranes are typically used for lighter loads and shorter spans.

- Portable jib cranes: These cranes are similar to indoor jib cranes but are designed to be easily moved and can be used in multiple locations within a facility. They consist of a horizontal beam, called a jib, that is mounted on a vertical mast or wall and can rotate around its axis. Portable jib cranes are typically used for lighter loads and shorter spans.

- KBK cranes: These cranes are a type of modular crane system that consists of standardized components that can be easily assembled to create a custom crane system. KBK cranes are typically used for lighter loads and shorter spans.

- Workstation cranes: These cranes are a type of overhead crane that is designed for use in specific work areas, such as assembly lines or workstations. They consist of a horizontal beam that is supported by two legs and can move along the length of the work area. Workstation cranes are typically used for lighter loads and shorter spans. They offer several advantages, including:

- Monorail cranes: These cranes consist of a single rail that is mounted on the ceiling and can move along the length of the facility.

- Articulating jib cranes: These cranes have a flexible arm that can be adjusted to reach around obstacles.

- Light crane systems: These are lightweight crane systems that are designed for use in smaller facilities or work areas.

Choosing the Right Indoor Crane for Your Needs

When choosing an indoor crane, it is important to consider several factors to ensure that the crane meets your specific needs. One of the most important factors is the lifting capacity of the crane. You need to choose a crane that can lift the heaviest load you will need to move in your facility. The span of the crane is also important to consider as it determines how far the crane can reach.

Another important factor is the lifting height of the crane. You need to choose a crane that can lift loads to the required height in your facility. The working level of the crane is also important to consider as it determines the type of environment in which the crane can operate safely and efficiently.

The power supply and operating speed of the crane are also important considerations when choosing an indoor crane. You need to ensure that the power supply in your facility can support the crane's electrical requirements. Additionally, you need to choose a crane with an operating speed that will allow you to move loads efficiently.

Benefits of indoor crane for material handling

Using an indoor crane in a facility or warehouse can provide several benefits. Here are some of them:

- Improved efficiency: With an indoor crane, you can move heavy loads quickly and easily, reducing the time and effort required to complete tasks. This can help improve productivity and efficiency in your operations.

- Increased safety: Indoor cranes are designed to lift and move heavy loads safely, reducing the risk of accidents or injuries. They are also equipped with safety features such as limit switches and overload protection to ensure safe operation.

- Versatility: Indoor cranes can be used for a variety of tasks, including lifting and moving materials, equipment, and machinery. They can also be customized to fit the specific needs of your facility.

- Cost-effective: Investing in an indoor crane can be cost-effective in the long run, as it can help reduce labor costs and increase productivity. It can also help prevent damage to equipment or materials, which can result in costly repairs or replacements.

Overall, using an indoor crane can help improve efficiency, safety, versatility, and cost-effectiveness in your facility or warehouse.

Safety Considerations for Indoor Cranes:

Proper safety measures are essential when using indoor cranes to prevent accidents and injuries. One of the most important safety considerations is ensuring that crane operators are properly trained and certified to operate the crane safely. Operators should be familiar with all safety features and equipment on the crane, including overload protection, emergency stop buttons, and anti-collision systems.

It is also important to ensure that all safety features and equipment are in place and functioning properly before using the crane. Regular safety inspections should be conducted to identify any potential safety hazards or maintenance needs.

Operation procedures of an indoor crane

Operating an indoor crane involves several steps. Here are some general guidelines:

- Familiarize yourself with the crane: Before operating the crane, read through the operator's manual and become familiar with the crane's controls, safety features, and load capacity.

- Inspect the crane: Check the crane's condition to ensure that it is in good working order. Look for any signs of damage or wear and tear that could compromise its safety.

- Plan the lift: Determine the weight of the load to be lifted and ensure that it is within the crane's capacity. Plan the route of the lift, taking into account any obstacles or hazards.

- Position the crane: Position the crane so that it is stable and level. Use outriggers or stabilizers if necessary to ensure that the crane is secure.

- Attach the load: Use appropriate rigging equipment to attach the load to the crane's hook. Ensure that the load is balanced and secure.

- Operate the crane: Use the crane's controls to lift and move the load to its destination. Follow safe lifting practices, such as keeping the load within sight at all times and avoiding sudden movements.

- Lower the load: Lower the load carefully and smoothly, following safe lifting practices. Ensure that the load is placed in its intended location safely.

Remember, operating an indoor crane can be dangerous if not done properly. Always follow safe lifting practices and take appropriate safety precautions to ensure a successful lift.

Safe operation of indoor crane

When using an indoor crane, it is important to follow proper safety measures to prevent accidents and injuries. Here are some safety tips to keep in mind:

- Only qualified and trained operators should operate the crane.

- Inspect the crane before use to ensure that it is in good working condition.

- Make sure that the load being lifted does not exceed the crane's weight capacity.

- Keep the area around the crane clear of people and obstacles.

- Use proper rigging techniques to secure the load.

- Never leave a load suspended in the air when the crane is not in use.

- Be aware of any potential hazards in the surrounding area, such as power lines or other equipment.

- Follow all manufacturer instructions and safety guidelines.

By following these safety measures, you can help ensure that the use of an indoor crane is safe and efficient.

Maintenance and Inspection of Indoor Cranes:

Regular maintenance and inspection is essential to ensure safe and efficient operation of indoor cranes. Maintenance tasks should include lubrication, cleaning, and replacing worn parts as needed. Inspection procedures should also be followed to identify any potential safety hazards or maintenance needs.

In conclusion, indoor cranes are essential equipment in various industries for safe and efficient material handling. Choosing the right crane for your needs, ensuring proper safety measures are in place, and maintaining the crane for optimal performance are all important considerations when using indoor cranes. It is essential to prioritize safety when using indoor cranes to prevent accidents and injuries in the workplace.