Modular KBK Cranes: Custom Solutions for Diverse Industries

Modular KBK cranes provide customizable, flexible solutions for various industries, optimizing space, efficiency, and mobility in dynamic production environments.

Overview of KBK Crane Systems:

Modular KBK crane systems are a type of overhead crane that stand out for their flexibility and adaptability in various industrial settings. Unlike traditional fixed cranes, KBK cranes are made up of modular components that can be easily assembled, adjusted, and expanded according to the specific needs of a business. These systems are designed to handle a wide range of lifting tasks, from light to heavy-duty operations, and can be tailored to fit almost any workspace layout.

At their core, KBK cranes consist of rails, trolleys, hoists, and other parts that can be customized and reconfigured as needed. The modular design means businesses can install a crane system that meets their current needs and upgrade it later without replacing the entire system. This makes KBK cranes ideal for industries that experience changing demands or require flexibility to adapt to different operational challenges.

These cranes are used in a variety of sectors, including manufacturing, automotive, electronics, and logistics, where versatility is key. They can be installed in spaces ranging from small workshops to large warehouses, offering businesses the ability to lift and transport materials with ease and precision.

Importance of Customization:

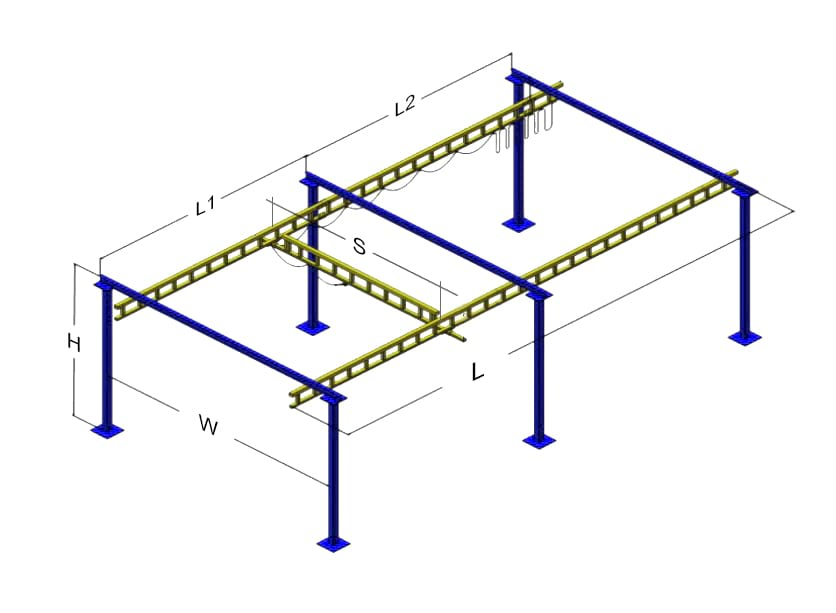

One of the standout features of modular KBK crane systems is their ability to be fully customized in terms of span, height, and load capacity. Each of these factors plays a crucial role in optimizing crane performance to match specific operational needs.

- Span Customization allows businesses to tailor the crane’s reach to the width of their workspace, whether it's a narrow aisle or a broad factory floor. By adjusting the span, the crane can cover a larger area or fit into tighter spaces without compromising its ability to lift loads effectively.

- Height Customization is essential for ensuring the crane can work in environments with varying ceiling heights. Whether you're operating in a high-bay warehouse or a facility with lower ceilings, the crane's lifting height can be adapted to meet the required specifications. This feature is particularly useful in industries with limited vertical space, allowing businesses to maximize storage and workspace usage.

- Load Capacity Customization is perhaps the most important aspect of KBK crane systems. Depending on the type of materials being lifted, from lightweight components to heavy machinery, the crane’s load capacity can be adjusted. This ensures that businesses have the right crane for the job, whether they are moving small parts in an electronics assembly line or lifting large engine components in an automotive manufacturing plant.

By offering these customization options, modular KBK cranes can meet the unique needs of any operation, improving efficiency, safety, and overall productivity. Customizing the crane ensures that it performs optimally in its specific environment, allowing businesses to streamline their operations and reduce downtime.

Basisc of Modular KBK Cranes

Definition and Key Components:

Modular KBK crane systems, also known as Kranbahn cranes, are a type of overhead crane that uses a modular approach to design and assembly. Unlike traditional single-piece cranes, KBK systems are made up of several interconnected components, allowing them to be customized, expanded, and reconfigured as needed. This modularity is what makes KBK cranes highly versatile and adaptable for a wide range of industries and applications.

The key components of a modular KBK crane system include:

- Rails: The rails form the foundation of the crane system, acting as the track along which the crane travels. These are usually made of high-strength steel and can be easily adjusted to fit the required span or layout of the facility. The rails can also be installed on either the ceiling or on the ground, depending on the specific needs of the space.

- Hoists: The hoist is the lifting mechanism of the crane, responsible for raising and lowering the load. Hoists come in various configurations, from electric to manual, and are chosen based on the required lifting capacity and operational efficiency. The hoist is mounted on the trolley, which allows it to move along the crane rails.

- Trolleys: The trolley is a moveable platform that carries the hoist and allows it to travel along the length of the crane rails. Trolleys can be powered (electric or motorized) or manually operated, depending on the system's design and the workload requirements. Trolleys can be equipped with additional safety features, such as anti-sway systems, to ensure stable load handling.

- End Carriages: These components provide support for the entire crane system. End carriages are positioned at both ends of the crane rails and are equipped with wheels that allow the crane to move horizontally along the rails. The end carriages provide stability and are crucial for ensuring smooth operation.

- Control Systems: KBK cranes can be equipped with various control systems, ranging from simple manual controls to sophisticated wireless or pendant controls. These control systems allow operators to precisely move the crane and lift loads, ensuring efficient and safe operation.

Each of these components can be selected and configured to meet the specific needs of an operation, from load capacity and travel speed to crane span and height. The modular design of KBK cranes allows each of these elements to be easily added, replaced, or reconfigured as business needs change over time.

KBK crane system for sale , cusomized design 500kg, 1 ton, 2 ton

How Modular Design Works:

The modular nature of KBK crane systems means that they are not fixed in their configuration. Instead, they can be customized and adapted in several ways, making them an ideal choice for businesses with varying demands or those operating in dynamic environments.

- Customizable Components: The modular design allows businesses to choose and change individual components to meet their exact needs. For instance, the span of the crane can be adjusted by adding or removing rail sections to fit the width of the workspace. Similarly, the height of the crane can be altered by adjusting the elevation of the rails or hoist.

- Expandable Systems: One of the greatest advantages of KBK cranes is their ability to expand. As businesses grow or change their operations, the crane system can be expanded to handle new requirements. Additional rail sections can be added to extend the span, new hoists can be incorporated to increase lifting capacity, or new trolleys can be added to improve load handling.

- Adaptable for Different Environments: Modular KBK crane systems can be adapted to a variety of environments. They can be used in tight spaces, such as small workshops or warehouses, by configuring the crane to fit within limited dimensions. Alternatively, they can be adapted for large-scale operations by extending their reach and load capacity. This adaptability allows KBK cranes to function effectively in industries ranging from automotive manufacturing to electronics assembly and even aerospace.

- Easy Upgrades and Modifications: As industries evolve and technological advancements emerge, businesses may find that their existing crane systems need upgrades to improve performance or integrate with new technologies. The modular design of KBK cranes makes it easy to upgrade components without having to replace the entire system. This ensures that businesses can keep their crane systems up-to-date and aligned with their changing operational needs.

In essence, the modular design of KBK cranes allows businesses to invest in a system that can evolve with them. It ensures long-term flexibility, scalability, and cost-effectiveness, as the crane system can be easily adapted and expanded based on new challenges or opportunities. Whether a company needs to reconfigure its crane system to accommodate a new production line or simply needs to upgrade to a more powerful hoist, the modular nature of KBK cranes makes these changes straightforward and efficient.

Customization Options: Span, Height, and Load Capacity

Span Customization:

Customizing the span of a KBK crane ensures that the crane fits perfectly within a given space, accommodating various floor plans and operational needs. The span refers to the distance between the crane’s support rails, and it can be adjusted to meet the specific dimensions of the workspace.

Adjusting Span Length: The span can be modified by adding or removing rail sections, allowing the crane to cover the necessary areas of the facility. This flexibility is especially valuable for businesses that may have changing layouts or different space requirements over time.

Benefits for Various Floor Plans:

- Adaptability: A customizable span allows KBK cranes to be used in industries with diverse space requirements, such as automotive, electronics, and small-scale manufacturing.

- Space Optimization: The ability to adjust the span ensures that the crane doesn't occupy unnecessary space while still effectively covering the required operational areas.

- Efficient Material Handling: In environments like narrow aisles or wide-open production floors, adjustable span lengths ensure efficient material handling without congestion.

Height Customization:

Height customization is essential for ensuring that a KBK crane can handle loads effectively, regardless of the available ceiling height or the nature of the task. Adjusting the lifting height allows the crane to accommodate different load types and work in environments with various spatial constraints.

Importance of Height Flexibility: Height can be customized based on the vertical clearance of a facility. This ensures safe and efficient lifting operations, whether in a tall warehouse or a confined space.

Examples of Height Customization:

- Tall Warehouses and Factories: In facilities with high ceilings or multiple levels, the crane can be configured to lift loads across vertical levels, maximizing available height.

- Confined Spaces or Low-Ceiling Areas: For operations in spaces with limited vertical clearance, the crane can be set to a lower height, ensuring it works within the available headroom while still providing reliable lifting capabilities.

Load Capacity Customization:

KBK modular crane systems are highly customizable when it comes to load capacity, offering a range of 250kg to 2000kg. This makes them ideal for operations that need to handle light to medium-duty lifting tasks, such as small components, parts, and tools.

Adapting Load Capacities for Specific Tasks: The load capacity can be tailored to suit the weight of the materials being lifted, ensuring that the crane is not overburdened. This customization helps improve efficiency and safety.

Examples of Load Capacity Applications:

- Light-Duty Applications (250kg to 1000kg): In industries like automotive and electronics, where small components or tools need to be lifted, a capacity range of 250kg to 1000kg is ideal. For example, lifting automotive parts, such as alternators, or delicate electronics components requires a precise and light crane system.

- Medium-Duty Applications (1000kg to 2000kg): In general manufacturing or medium-scale operations, a load capacity of 1000kg to 2000kg is suitable for handling heavier items, such as subassemblies or small machinery parts. This range ensures that the crane can lift moderately heavy items with stability and safety.

The customization of load capacities within the 250kg to 2000kg range ensures that businesses can select the most suitable crane for their specific lifting needs without investing in excessive capacity. This provides an optimal balance of performance and cost-efficiency.

Benefits Across Key Industries

Automotive Industry:

Modular KBK cranes are invaluable in the automotive industry, where they handle a variety of lifting tasks along vehicle assembly lines. These cranes are highly flexible, allowing for the efficient handling of engine components, vehicle frames, and other heavy parts, making them an essential part of the production process.

Flexibility for Lifting Engine Components and Frames: Automotive assembly lines require cranes that can handle a wide range of parts, from lightweight components like battery packs and alternators to heavier items like engine blocks and vehicle frames. Modular KBK cranes can be customized to handle both small, delicate parts and large, heavy components by adjusting their load capacity and span.

Case Studies in Automotive Plants:

- Case Study 1: In an automotive manufacturing facility, a modular KBK crane with a span of 10 meters and a load capacity of 1000kg is used to move engine components from one assembly station to another. This system allows for smooth transitions between tasks while maintaining high efficiency.

- Case Study 2: A KBK crane in a vehicle assembly plant is designed with a wider span (15 meters) and a higher load capacity (2000kg) to lift heavy vehicle frames. The system's modular design allows for quick adaptation to changes in production demands, ensuring continuous operation.

Electronics and Semiconductor Industry:

In the electronics and semiconductor industry, precision and care are paramount when handling delicate components. Modular KBK cranes are well-suited for environments where sensitive parts, such as circuit boards, microchips, and semiconductor wafers, need to be moved without damage.

- Handling Delicate Components with Precision: KBK cranes in this sector are designed to lift lightweight, fragile components with great accuracy, preventing any risk of damage during transportation. Their fine control and smooth movement capabilities are ideal for tasks that require high precision, such as transferring items from one workstation to another in an electronics assembly line.

- Advantages in Controlled Environments like Clean Rooms: Modular KBK cranes can be used in clean rooms and other controlled environments where contamination control is critical. Their ability to be fitted with special features, like cleanroom-compatible materials or non-contaminating components, ensures that they can operate without introducing dust or debris into sensitive environments. This makes them essential for industries where cleanliness is non-negotiable, such as semiconductor manufacturing or precision electronics.

General Manufacturing and Warehousing:

In general manufacturing and warehousing, modular KBK cranes provide flexible material handling solutions for a wide range of tasks, from moving raw materials to handling finished goods.

Applications in Diverse Manufacturing Sectors: KBK cranes are ideal for diverse manufacturing tasks, including the movement of raw materials, semi-finished goods, and completed assemblies. Whether it's handling metal sheets in a factory or moving packaged products in a warehouse, these cranes offer reliable performance across various sectors.

Examples of Efficient Material Handling:

Logistics and Distribution Centers:

Modular KBK cranes are highly effective in logistics and distribution centers, where flexibility, speed, and space efficiency are crucial for handling a high volume of goods.

By offering versatile, customizable solutions, KBK cranes improve efficiency and productivity across these key industries, from automotive production lines to logistics hubs, making them an indispensable tool for a wide variety of operations.

Applications in Confined Spaces

Space Efficiency in Small and Tight Environments:

Modular KBK cranes are designed with space efficiency in mind, making them ideal for small and tight environments where space is limited. Their compact modular design allows them to be adapted to various confined spaces, such as workshops, narrow aisles, or multi-story facilities, ensuring they can still operate effectively without causing congestion or obstructing other operations.

Case Studies in Confined Spaces:

Maximizing Space Utilization and Reducing Operational Bottlenecks: By optimizing available space, KBK cranes reduce operational bottlenecks and improve workflow. In narrow aisles or areas with limited space, their compact design ensures that materials can be moved without disrupting other activities. This flexibility allows manufacturers and logistics companies to improve throughput by utilizing every inch of available space, increasing overall efficiency.

Flexible Solutions for Low Ceiling Heights:

KBK cranes can also be customized to work in facilities with low ceiling heights, providing a valuable solution for businesses that face vertical space limitations. By adjusting the height of the crane system, these cranes maintain their ability to perform effective lifting tasks despite restricted headroom.

Examples of KBK Crane Systems for Low Ceilings:

Efficient Lifting Despite Limited Vertical Space: KBK cranes are designed to maximize lifting capabilities even in environments with low ceilings. By customizing the lifting height, these cranes can be used in confined spaces without reducing performance. This flexibility is crucial for operations where lifting needs remain the same, but ceiling height is a limiting factor. Businesses can still achieve high-efficiency material handling without the need for costly infrastructure changes or relocation.

In facilities where space and ceiling height are limited, modular KBK cranes provide an ideal solution for overcoming these constraints. By offering customizable spans and lifting heights, these cranes allow businesses to optimize their operations in confined spaces without sacrificing performance or safety.

1 ton kbk modular crane system with low headroom hoist design for sale Marlta

Key Advantages of Modular KBK Cranes

Flexibility and Adaptability:

One of the standout features of modular KBK cranes is their flexibility and adaptability to ever-changing operational needs. As businesses evolve, so do their production environments, requiring systems that can quickly adapt to new workflows, layout changes, and fluctuating production demands. KBK cranes can be easily reconfigured, expanded, or upgraded to meet these new challenges, making them an ideal solution for industries with dynamic operations.

Cost-Effectiveness:

Modular KBK cranes offer cost-effective solutions for businesses by lowering both initial investment costs and ongoing maintenance expenses. The system’s modular nature allows companies to pay only for the components they need initially, with the option to scale up as their operations grow.

Ease of Installation and Maintenance:

The installation and maintenance processes for modular KBK cranes are straightforward and simple, allowing businesses to minimize downtime during both setup and service. The crane’s modular nature means that components are easy to transport, assemble, and maintain, reducing both installation time and long-term maintenance effort.

Enhanced Safety:

KBK cranes are not only designed for operational efficiency, but also with a strong focus on workplace safety. By reducing the need for manual lifting and improving load handling precision, these cranes contribute significantly to creating a safer work environment.

In industries where safety is a priority, KBK cranes are a highly effective tool for protecting employees while enhancing productivity. Their customizable design and robust safety features make them an excellent choice for businesses looking to improve both operational efficiency and workplace safety.

FAQs

How can I determine the right span and load capacity for my operation?

Choosing the right span and load capacity for your modular KBK crane depends on several factors, including the size of your workspace, the types of materials you handle, and the specific lifting requirements of your operations.

Working with an experienced crane supplier can help you assess your operational requirements and recommend the ideal span and load capacity to optimize your workflow and ensure safety.

What industries benefit the most from modular KBK cranes?

Modular KBK cranes are versatile and can be used across a wide variety of industries. The following sectors typically benefit the most from their flexibility and customization options:

Due to their adaptability, modular KBK cranes can be tailored to meet the needs of any industry, making them a highly effective solution for a broad range of material handling tasks.

Can KBK cranes be integrated with existing systems?

Yes, KBK cranes are highly adaptable and can be seamlessly integrated with existing systems. Since they are modular, they can be customized to work with the infrastructure already in place in your facility. Whether you're looking to add a crane system to a new production line or retrofit an existing setup, KBK cranes can be adjusted to meet the requirements of your current operations.

Consulting with a crane expert can help you design an integration plan that ensures smooth compatibility with your existing equipment and operational workflows.

Modular KBK crane systems offer significant benefits that make them an essential tool for businesses across various industries. Their flexibility in design, cost-effectiveness, and ease of installation make them an ideal solution for both small-scale operations and large industrial facilities. Whether it's adapting to changes in production layouts, reducing manual labor, or providing safe and efficient lifting solutions, KBK cranes are tailored to meet the evolving needs of industries such as automotive, electronics, manufacturing, and logistics. The ability to customize span, height, and load capacity ensures that these cranes can handle a wide range of operational challenges, while their modular design allows for easy upgrades and expansions as business demands grow.

For businesses looking to enhance productivity, improve safety, and optimize their material handling processes, modular KBK cranes provide the ultimate solution. Consider investing in a modular KBK system tailored to your specific needs, and explore how custom solutions can streamline your workflow, reduce operational costs, and boost overall efficiency. Reach out to a KBK crane expert today to discuss how these versatile systems can help you meet your unique operational challenges.