Lumber & Timber Handling with Lumberyard Bridge Crane, Good Price

Overhead Bridge Crane Streamlining Lumber and Timber Handling

In lumberyards and sawmills, the efficient handling of lumber and timber is paramount. Every piece of wood processed, transported, and stored must be managed with precision to ensure smooth operations and maintain profitability. This blog delves into the pivotal role of bridge cranes in optimizing material handling processes within these crucial industrial settings.

Lumber and timber, the backbone of the construction and woodworking industries, come in various shapes, sizes, and weights. From sturdy beams to delicate boards, each piece serves a purpose in the construction of homes, furniture, and countless other structures. Handling these materials efficiently requires a deep understanding of their characteristics and the challenges they present.

In lumberyards and sawmills, time is money. Every delay, mishap, or inefficiency in material handling can result in costly setbacks. Efficient material handling is not just about moving wood from point A to point B; it's about maximizing productivity, minimizing waste, and ensuring the safety of workers. Smooth operations keep the supply chain flowing and customers satisfied.

Overhead Bridge Cranes Optimizing Operations in Sawmills

Enter the unsung hero of lumber and timber handling: the bridge crane. These versatile machines are the backbone of material handling in lumberyards, sawmills, and woodworking facilities worldwide. Mounted on rails spanning the length of the workspace, bridge cranes offer unparalleled mobility and lifting capabilities, making them indispensable for a range of tasks.

- Loading and Unloading Timber: Bridge cranes excel in loading and unloading timber from trucks, trains, or storage areas. With their adjustable lifting capacities, they can handle heavy loads with ease, reducing the strain on workers and minimizing the risk of accidents. This efficiency ensures a steady flow of raw materials into the facility, keeping production lines running smoothly.

- Sorting and Stacking Lumber: Sorting and stacking lumber is a delicate process that requires precision and organization. Bridge cranes, equipped with specialized attachments, can maneuver through stacks of lumber with ease, sorting them by size, grade, or type. This systematic approach not only streamlines inventory management but also minimizes the risk of damage to the wood, ensuring higher-quality end products.

- Transporting Lumber within the Facility: Once sorted and stacked, lumber needs to be transported to various processing stations within the facility. Bridge cranes, with their ability to traverse the entire workspace, offer unmatched flexibility in moving materials from one location to another. Whether it's feeding lumber into cutting machines or transferring finished products to storage areas, bridge cranes play a vital role in keeping operations running smoothly.

In conclusion, bridge cranes are the unsung heroes of lumber and timber handling, driving efficiency, productivity, and safety in lumberyards and sawmills around the world. By streamlining material handling processes, these versatile machines ensure the seamless flow of wood from forest to finished product, powering the industries that build our world.

Typical Loads in Lumber and Timber Handling

In the bustling world of lumber and timber handling, understanding the characteristics of typical loads is essential for smooth operations. From sturdy lumber to delicate wooden boards, each type of material presents its own set of challenges and considerations. This blog explores the common types of loads encountered in lumberyards and sawmills, along with their key characteristics.

Types of Lumber and Timber Handled

- Lumber: Lumber, also known as timber, refers to processed wood that has been sawn into beams, planks, or boards. It is a staple material in construction, used for framing, decking, and various other applications.

- Timber: Timber typically refers to unprocessed wood harvested from trees. It may come in the form of logs, poles, or rough-cut boards and is often used for structural purposes or further processing into lumber.

- Wooden Boards: Wooden boards encompass a wide range of products, including plywood, particleboard, and oriented strand board (OSB). These engineered wood products are manufactured by bonding together wood fibers or veneers and are used in various construction and woodworking projects.

Characteristics of the Loads

- Weight: The weight of lumber and timber loads can vary significantly depending on the type of wood and its dimensions. While some boards may be relatively lightweight, others, such as hardwood beams or large timber logs, can be quite heavy and require specialized equipment for handling.

- Dimensions: Lumber and timber come in a variety of shapes and sizes, ranging from small boards to large beams or logs. The dimensions of the loads impact their handling requirements, including the type of equipment needed and the space required for storage and transportation.

- Variability in Load Sizes: One of the unique challenges in lumber and timber handling is the variability in load sizes. Not only do different types of wood come in various dimensions, but individual pieces within a batch may also vary in size and shape. This variability requires flexibility in handling equipment and careful planning to optimize space and minimize waste.

These characteristics is crucial for efficient material handling in lumberyards and sawmills. By carefully assessing the types of loads encountered and their specific requirements, operators can select the appropriate equipment and processes to streamline operations and maximize productivity.

In conclusion, the diverse range of lumber and timber loads encountered in lumberyards and sawmills requires careful consideration of their characteristics and handling requirements. By understanding the weight, dimensions, and variability of loads, operators can effectively manage material handling processes and ensure the smooth flow of wood from raw material to finished product.

Bridge Crane Applications in Lumber and Timber Handling

Bridge cranes stand tall as indispensable assets in the realm of lumber and timber handling, offering unmatched versatility and efficiency in a variety of settings. From bustling lumberyards to buzzing sawmills and woodworking facilities, these mighty machines play a pivotal role in streamlining operations and maximizing productivity. Let's delve into the typical applications of bridge cranes in these dynamic environments.

Primary Settings for Use

- Lumberyards: At lumberyards, where raw timber is processed and prepared for distribution, bridge cranes reign supreme. These facilities often handle large volumes of lumber and timber, requiring robust equipment to facilitate loading, unloading, and storage operations.

- Sawmills: Sawmills, the heart of timber processing, rely heavily on bridge cranes for seamless material handling. From receiving raw logs to sawing, sorting, and stacking lumber, these facilities leverage the mobility and lifting capabilities of bridge cranes to maintain a steady flow of materials throughout the production process.

- Woodworking Facilities: In woodworking facilities, where lumber is transformed into a myriad of finished products, bridge cranes play a crucial role in material transport and organization. Whether it's moving lumber to cutting machines, assembling components, or storing finished products, bridge cranes ensure efficient workflow and timely delivery.

Specific Operations

- Loading and Unloading Timber: Bridge cranes excel in the loading and unloading of timber from trucks, railcars, or storage areas. Their adjustable lifting capacities and precise maneuverability allow for swift and safe handling of heavy loads, minimizing downtime and maximizing throughput.

- Sorting and Stacking Lumber: Sorting and stacking lumber is a meticulous process that demands precision and organization. Bridge cranes, equipped with specialized attachments and advanced control systems, navigate through stacks of lumber with ease, sorting them by size, grade, or type. This systematic approach optimizes inventory management and minimizes the risk of damage to the wood.

- Transporting Lumber within the Facility: Once sorted and stacked, lumber must be transported to various processing stations within the facility. Bridge cranes, traversing the length and breadth of the workspace on elevated rails, offer unparalleled flexibility in material transport. Whether it's feeding lumber into cutting machines, transferring finished products to storage areas, or replenishing supply bins, bridge cranes ensure the seamless flow of materials throughout the facility.

In conclusion, bridge cranes are indispensable assets in the lumber and timber industry, serving as the backbone of material handling operations in lumberyards, sawmills, and woodworking facilities. From loading and unloading timber to sorting, stacking, and transporting lumber within the facility, these mighty machines enable efficient workflow, optimize space utilization, and ensure the timely delivery of high-quality products to customers.

1 Ton to 10 Ton Overhead Bridge Cranesfor Lumber and Timber Handling

In the bustling world of lumber and timber handling, the tonnage capacity of bridge cranes plays a crucial role in determining their effectiveness and suitability for various tasks. From lifting heavy timber logs to maneuvering delicate wooden boards, bridge cranes must be equipped to handle a wide range of loads with precision and efficiency. Let's explore the typical tonnage capacity of these versatile machines and the factors that influence their requirements.

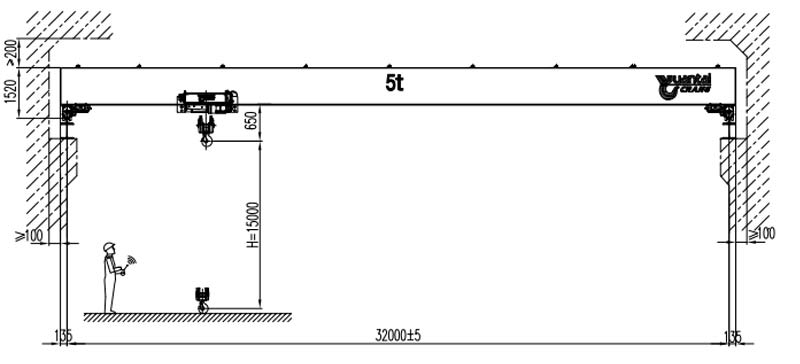

5 ton overhead crane , HD series for Your reference

Range of Capacities

- Minimum Capacity: 1 Ton: Bridge cranes with a minimum capacity of 1 ton are commonly used for handling lighter loads, such as smaller timber bundles or wooden boards. These cranes offer flexibility and precision for tasks that require careful handling, such as sorting and stacking lumber.

- Maximum Capacity: 10 Tons: At the other end of the spectrum, bridge cranes with a maximum capacity of 10 tons are capable of lifting heavier loads, such as large timber logs or bundled lumber. These cranes are essential for heavy-duty applications in sawmills and lumberyards, where robust lifting capabilities are required to maintain productivity.

Factors Influencing Capacity Requirements

- Type of Lumber or Timber: Different types of lumber and timber vary widely in weight and density, influencing the tonnage capacity required for handling. Heavy hardwood logs, for example, may necessitate a crane with higher lifting capacity compared to lighter softwood boards.

- Volume of Material Handled: The volume of material processed or stored in a facility directly impacts the tonnage capacity needed in bridge cranes. High-volume operations with large quantities of lumber or timber may require cranes with higher lifting capacities to maintain throughput and efficiency.

- Operational Demands: The specific tasks and operational demands within a facility also influence tonnage capacity requirements. Cranes used for loading and unloading heavy timber logs from trucks or railcars, for instance, must be equipped to handle substantial loads safely and efficiently.

These factors is essential for selecting the appropriate bridge crane with the right tonnage capacity for the job. By assessing the type of lumber or timber handled, the volume of material processed, and the operational demands of the facility, operators can ensure that their bridge cranes are optimized for performance and productivity.

In conclusion, the tonnage capacity of bridge cranes is a critical consideration in lumber and timber handling operations, impacting their ability to lift and maneuver loads of varying weights and sizes. By understanding the range of capacities available and the factors influencing their requirements, operators can select the right crane for the job, ensuring safe and efficient material handling in lumberyards, sawmills, and woodworking facilities.

Optimizing Lumber and Timber Handling Operations with Overhead Bridge Cranes

Efficient material handling is the cornerstone of success in lumberyards, sawmills, and woodworking facilities. Bridge cranes play a vital role in streamlining these operations, but their effectiveness hinges on several key focus areas for optimization. Let's explore how to maximize the potential of bridge cranes in lumber and timber handling through targeted improvements in safety, organization, and inventory management.

Safe Movement of Lumber Stacks and Timber Bundles

- Safety Protocols and Procedures: Establishing comprehensive safety protocols is paramount to ensuring the well-being of workers and the integrity of the operation. This includes clearly defined procedures for load handling, signaling, and emergency response to minimize the risk of accidents.

- Training for Crane Operators: Proper training and certification of crane operators are essential for safe and efficient material handling. Operators should be well-versed in crane operation techniques, load limits, and safety procedures to mitigate risks and optimize performance.

- Maintenance and Inspection of Equipment: Regular maintenance and inspection of bridge cranes are critical for identifying and addressing potential safety hazards. Routine checks of mechanical components, electrical systems, and structural integrity ensure that the equipment remains in optimal condition for safe operation.

Organized Material Handling Operations

- Efficient Workflow Design: Designing a streamlined workflow is key to maximizing productivity and minimizing downtime. By mapping out the sequence of material handling tasks and optimizing the layout of work areas, operators can minimize unnecessary movements and ensure a smooth flow of materials from intake to output.

- Minimizing Handling Time: Every second counts in material handling operations, so minimizing handling time is crucial for maintaining efficiency. This involves optimizing crane movements, reducing wait times, and implementing automated processes wherever possible to accelerate throughput.

- Preventing Damage to Lumber and Timber: Protecting the integrity of lumber and timber is essential for preserving quality and minimizing waste. Implementing measures such as cushioned attachments, careful stacking techniques, and monitoring systems can help prevent damage during handling and storage.

Inventory Management

- Real-time Tracking of Materials: Real-time tracking systems enable operators to monitor the movement and location of materials throughout the facility. By leveraging RFID tags, barcodes, or GPS technology, they can maintain accurate inventory records and quickly locate specific items as needed.

- Integration with Inventory Systems: Integrating bridge crane operations with inventory management systems enhances efficiency and accuracy. This seamless integration allows for automatic updates of inventory records, real-time stock monitoring, and optimized material replenishment strategies.

- Streamlining Stock Control: Implementing lean inventory practices and just-in-time delivery strategies can help minimize excess stock and storage costs. By synchronizing material flow with production schedules and customer demand, operators can optimize stock levels and reduce waste.

By focusing on these key areas for optimization, operators can harness the full potential of bridge cranes in lumber and timber handling operations. Through a combination of safety enhancements, workflow improvements, and advanced inventory management techniques, they can maximize efficiency, minimize costs, and ensure the smooth flow of materials from intake to output.

Advantages of Lumberyard Overhead Bridge Cranes

Bridge cranes stand tall as indispensable assets in the world of lumber and timber handling, offering a myriad of benefits that drive efficiency, safety, and profitability. Let's explore the advantages of using bridge cranes in lumberyard operations and how they contribute to a more streamlined and productive workflow.

- Increased Efficiency and Productivity : Bridge cranes are the workhorses of lumberyards, capable of lifting heavy loads with precision and speed. By automating material handling tasks and reducing reliance on manual labor, bridge cranes significantly increase operational efficiency and productivity. Tasks that once took hours can now be completed in minutes, allowing for faster turnaround times and increased output.

- Enhanced Safety for Workers : Safety is paramount in any industrial setting, and bridge cranes play a crucial role in ensuring the well-being of workers. By minimizing manual lifting and reducing the risk of accidents associated with heavy loads, bridge cranes enhance workplace safety and mitigate the potential for injuries. Advanced safety features such as overload protection and collision avoidance systems further safeguard workers and equipment from harm.

- Reduction in Material Damage : Handling lumber and timber requires finesse and precision to prevent damage and maintain product quality. Bridge cranes excel in this regard, offering smooth and controlled movements that minimize the risk of material damage during handling. By reducing the likelihood of dents, scratches, and breakage, bridge cranes help preserve the integrity of lumber and timber, minimizing waste and maximizing profitability.

- Improved Inventory Accuracy and Management : Accurate inventory management is essential for maintaining efficient operations and meeting customer demands. Bridge cranes, equipped with advanced tracking and monitoring systems, provide real-time visibility into material movements and stock levels. This enhanced inventory accuracy allows operators to optimize stock control, minimize stockouts, and ensure timely replenishment, improving overall inventory management efficiency.

In conclusion, the benefits of using lumberyard bridge cranes are manifold, ranging from increased efficiency and productivity to enhanced safety, reduced material damage, and improved inventory accuracy and management. By harnessing the power of bridge cranes in lumber and timber handling operations, businesses can optimize their workflow, minimize costs, and stay ahead of the competition in today's fast-paced industrial landscape. overhead crane system low headroom design

overhead crane system low headroom design

Bridge Crane Success Stories: Transforming Lumber and Timber Handling

Real-world examples offer invaluable insights into the transformative impact of bridge cranes on lumber and timber handling operations. Let's explore case studies and examples that illustrate the success and benefits realized by implementing bridge cranes in lumberyards, sawmills, and woodworking facilities.

Successful Implementation in a Lumberyard

Case Study: Johnson Lumber Co.

Overview: Johnson Lumber Co., a leading lumber supplier, faced challenges with manual material handling, leading to inefficiencies and safety concerns. Seeking a solution, they invested in a state-of-the-art bridge crane system to streamline operations.

Benefits Realized:

- Increased Efficiency: With the bridge crane system in place, Johnson Lumber Co. experienced a significant boost in efficiency, reducing material handling times by 30%.

- Enhanced Safety: By minimizing manual lifting and reducing the risk of accidents, the bridge crane system improved workplace safety and morale among employees.

- Reduced Material Damage: The precise movements of the bridge crane minimized material damage during handling, resulting in fewer defects and waste.

- Improved Inventory Management: Real-time tracking capabilities allowed for better inventory control, optimizing stock levels and reducing stockouts.

Case Study: TimberTech Sawmill

Overview: TimberTech Sawmill, a large-scale timber processing facility, faced challenges with manual loading and unloading of heavy logs, leading to bottlenecks and inefficiencies. They turned to bridge cranes to streamline their operations.

Benefits Realized:

- Increased Throughput: Bridge cranes enabled TimberTech Sawmill to significantly increase throughput, reducing loading and unloading times by 50%.

- Enhanced Safety: By automating material handling tasks, the risk of accidents and injuries associated with manual lifting was greatly reduced.

- Cost Savings: The improved efficiency and reduced labor requirements resulted in substantial cost savings for TimberTech Sawmill, enhancing their competitive edge in the market.

- Optimized Space Utilization: Bridge cranes allowed TimberTech Sawmill to optimize space utilization within their facility, maximizing storage capacity and workflow efficiency.

Comparison of Different Facilities Using Overhead Bridge Cranes

Overview: A comparative analysis was conducted to assess the impact of bridge crane utilization in different lumber and timber handling facilities.

Findings:

- Lumberyards: Facilities equipped with bridge cranes demonstrated higher throughput, lower material damage rates, and improved safety compared to those relying on manual handling methods.

- Sawmills: Sawmills leveraging bridge cranes experienced increased productivity, reduced labor costs, and improved inventory accuracy, leading to enhanced overall efficiency.

- Woodworking Facilities: Woodworking facilities with bridge cranes reported faster turnaround times, reduced lead times, and improved customer satisfaction due to timely deliveries.

These case studies and comparisons underscore the significant benefits of implementing bridge cranes in lumber and timber handling operations. From increased efficiency and productivity to enhanced safety and cost savings, bridge cranes continue to revolutionize the way materials are handled and processed in the industry, driving success and innovation across the board. Top running overhead crane system

Top running overhead crane system

Navigating Challenges in Implementing Overhead Bridge Cranesfor Lumber and Timber Handling

While bridge cranes offer a multitude of benefits in lumber and timber handling, their implementation is not without challenges. Understanding and addressing these challenges are crucial for ensuring the success and sustainability of bridge crane systems in industrial settings. Let's explore the key challenges and considerations associated with implementing bridge cranes for lumber and timber handling.

Initial Investment and Costs

Challenge: The initial investment required for installing bridge crane systems can be significant, posing a financial barrier for some businesses. Factors such as crane capacity, span length, and customization options can impact upfront costs.

Considerations:

- ROI Analysis: Conducting a thorough cost-benefit analysis can help businesses evaluate the long-term return on investment of bridge crane systems, considering factors such as increased productivity, labor savings, and reduced material damage.

- Financing Options: Exploring financing options, such as leasing or equipment financing, can help businesses manage upfront costs and spread expenses over time.

Space and Infrastructure Requirements

Challenge: Bridge crane systems require adequate space and infrastructure to operate effectively, including sufficient ceiling height, structural support, and runway beam installation.

Considerations:

- Facility Assessment: Conducting a comprehensive assessment of facility layout and infrastructure is essential for determining the feasibility of installing bridge crane systems.

- Space Optimization: Optimizing space utilization through efficient layout design and material flow planning can help maximize the benefits of bridge crane systems within existing facility constraints.

Training and Skill Development for Operators

Challenge: Operating bridge cranes requires specialized skills and training to ensure safe and efficient handling of materials. Lack of proper training can lead to accidents, equipment damage, and productivity losses.

Considerations:

- Operator Training Programs: Implementing structured training programs for crane operators, covering equipment operation, safety protocols, and emergency procedures, is essential for ensuring competency and compliance.

- Continuous Education: Providing ongoing education and skill development opportunities for operators helps them stay updated on industry best practices, equipment advancements, and safety regulations.

Ongoing Maintenance and Upkeep

Challenge: Bridge crane systems require regular maintenance and upkeep to ensure optimal performance and longevity. Neglecting maintenance can lead to equipment malfunction, downtime, and costly repairs.

Considerations:

- Scheduled Maintenance Plans: Developing and implementing scheduled maintenance plans, including inspections, lubrication, and component replacement, helps prevent breakdowns and prolongs the lifespan of bridge crane systems.

- Proactive Monitoring: Implementing proactive monitoring systems, such as predictive maintenance technologies and condition monitoring, enables early detection of potential issues and allows for timely intervention to prevent major breakdowns.

By addressing these challenges and considerations proactively, businesses can successfully implement and leverage bridge crane systems for lumber and timber handling, unlocking their full potential to drive efficiency, safety, and profitability in industrial operations.

Harnessing the Future of Lumber and Timber Handling with Overhead Bridge Cranes

As we conclude our exploration of the pivotal role of bridge cranes in lumber and timber handling, it's clear that these mighty machines are revolutionizing industrial operations in lumberyards, sawmills, and woodworking facilities. Let's summarize our key points, glimpse into future trends, and reflect on the enduring importance of bridge cranes in shaping the future of the industry.

Summary of Key Points

Throughout this journey, we've uncovered the following key points:

- Bridge cranes play a vital role in optimizing material handling operations in lumberyards, sawmills, and woodworking facilities.

- They excel in loading and unloading timber, sorting and stacking lumber, and transporting materials within the facility.

- The tonnage capacity of bridge cranes varies, with capacities ranging from 1 ton to 10 tons, depending on the specific requirements of the operation.

- Focus areas for optimization include safe movement of materials, organized material handling operations, and efficient inventory management.

- The benefits of using bridge cranes are manifold, including increased efficiency, enhanced safety, reduced material damage, and improved inventory accuracy.

- Despite challenges such as initial investment costs, space requirements, training needs, and maintenance demands, the implementation of bridge cranes offers significant advantages for businesses.

In closing, bridge cranes stand as indispensable assets in the lumber and timber industry, driving efficiency, safety, and profitability. From loading heavy timber logs to delicately maneuvering wooden boards, these versatile machines enable seamless material handling operations that power the construction, woodworking, and manufacturing sectors. As we embrace the future of lumber and timber handling, let us continue to harness the potential of bridge cranes to build a sustainable and prosperous industry for generations to come.

If you have any need, please feel free to contact us. Contact us today to check what we can do to save your overhead bridge crane cost.