Workshop Overhead Crane:Maximize Hook Coverage for Your Workshop

How to Make the Most of an Overhead Crane's Hook Coverage for Your Workshop?

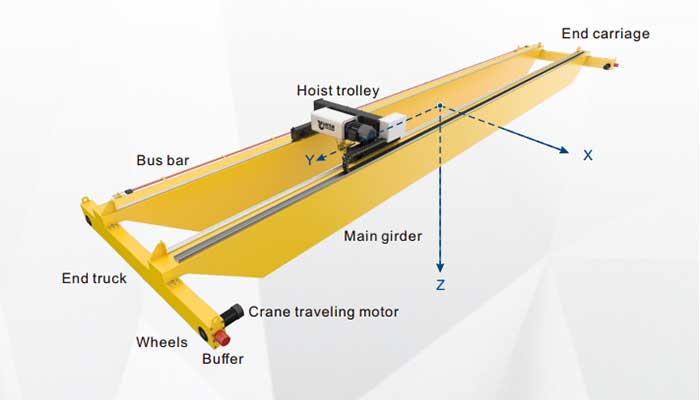

Hook coverage of overhead crane or working span regulates a the travelling crane hook’s ability to reach multifarious areas of your workshops or factory. It covers all prime motions of the hook in X, Y, and Z dimensions (from the floor’s coverage area to the coverage area of the uppermost height of the hook).

The hook coverage of an electric overhead crane is determined by how closely it can travel to the runway and bridge ends. A good hook coverage will boost output and profitability as well as the effectiveness and profitability of your workshop and facility unit. You should be well-versed in hook coverage if you intend to buy a workshop overhead crane from a reputable maker of EOT cranes.

The optimizing workshop hook coverage, you can maximize the overhead travelling crane’s efficiency and flexibility.

What is Hook Coverage of Bridge travelling crane ?

The region or covering area that your workshop crane's hook can access is known as hook coverage or operating span. From the coverage area of the workshop floor to the coverage area of the hook's highest point, it encompasses all three motions of the hook in the x, y, and z dimensions. How closely a travelling crane's hook can move to the end of the runway and bridge has an effect on hook coverage.

The benifits or impact of your movable overhead crane can have on the work area and facility operations increases with the size of its hook coverage. The effectiveness and profitability of your facility are maximized by good connection coverage, which also positions your workshop and company for future growth in both profitability and productivity. Greater hook coverage will give your workshop the flexibility it needs to adjust to shifting conditions or growing workloads as operations grow or change.

Common Mistakes: How to Right-Size an Overhead Crane for Your Workshop

When it comes to hook coverage, failing to plan far enough in advance is a common error. Although upgrading an existing workshop crane to increase hook coverage is feasible, it is not advised because it can be a time-consuming and costly investment. The replacement of significant components and occasionally the rearrangement of electronics required to modify an existing overhead crane to increase hook coverage can cause operations to be delayed. When it comes to ensuring that your workshop production area has excellent hook coverage, plan prior to account for changes in workflow or an increase in production.

A thorough understanding of your building space is requrired to your workshop and facility which , includes obstructions on the walls, ceiling, and floor, in order to plan for optimum workshop bridge crane hook coverage. Your crane's hook coverage region will never be as large as its overall span or runway length. To minimize change orders and increase the profitability of your output, explain the layout of your workshop and facility and make sure your overhead crane builder is asking the right questions.

Second, prepare your next project or product in advance for possible growth or changes. Aim for the best hook coverage you can with your workshop crane because you might need more coverage than you anticipate sooner than you had anticipated.

How to determine hook coverage

You can determine hook coverage in various ways including, side Approach, end Approach, crane span, Runway beam size, runway support structure , and Runway length and distance between runway supports, etc.

The side Approach

This side approach can be used to determine the crane's usable lateral working span. However, this length is not usually symmetrical. Both a short and a long half are included with the hoist trolley. You can decide the short and long sides when installing a bridge crane to make sure the side approach span is sufficient.

The end Approach

The end approach will defines the centerline coverage of the hook, including end-to-end movement. The end approach, as opposed to the side approach, is symmetrical. The total bridge crane span could be longer than the working span depending on the length of the runway. A zero-clearance end stop can offer roughly one foot of lateral or centerline coverage when you need more hook security. You should have a thorough understanding of the working area when determining the hook coverage of your workshop overhead crane. The working span of the hook may be constrained by the work area's walls, items, and floor-to-ceiling height. Before the job is finished, you should think about any modifications and improvements. If your project is successful, maximizing the working period might be a costly endeavor and could reduce your daily output.

Calculating the necessary workshop crane size to optimize coverage

It is essential to take the correct measurements to maximize the hook coverage of your overhead crane. Runway beam size is among the crucial metrics.

Crane runway beam size

The runway beam size must be measured from the bottom to the summit of the beam. This measurement can be used to estimate the overall height.

Runway rail size

The overhead crane's wheel capacity is influenced by the width of the runway rail. The height and breadth of the runway rail are critical dimensions for your workshop overhead crane. Because these two provide the longest lifespan and maintain the tracks' alignment.

Crane span

The distance between runways is known as the bridge crane span. This typically spans the bay's breadth. If you want to obtain enough material to make the girders and provide accurate drawings, precise measurements are a requirement.

Crane runway length and distance between runway column supports

The dimensions for the runway support and length are parallel. The crane's weight should be supported by the supports in proportion to the runway's length.

All in all, before buying an overhead crane for your workshop. You should have a thorough understanding of your building space, including obstructions on the walls, ceiling, and floor, in order to plan for optimum hook coverage. Your workshop overhead crane's hook coverage region will never be as large as its overall span or runway length. To decrease the likelihood of change orders and increase the profitability of your production, you should ask your overhead crane builder the correct queries.

Always set up your workhsop crane to provide the greatest hook coverage, as you may require more coverage than you anticipated.

Which lifting crane provide the greatest hook coverage for your workshop?

The profitability of your working area and how efficiently your crane uses each inch will be determined by the workshop crane's individual components, even though the size of your overhead crane will ultimately have the largest impact on hook coverage. Take into account these optimized crane parts and designs to achieve the highest lifting heights and hook-to-wall measurements.

Double-girder low headroom overhead crane

Advanced crane design with European style low headroom enables the double girder overhead crane to provide the maximized hook coverage. European Standard double girder overhead crane & eot Crane with FEM standard Hoist Crane Trolley can be used to handle objcets with capacity from 5 ton to 80 ton.

Low headroom double girder ovehread crane for better hook coverage

For the best clearance, go with a double-girder crane construction. By allowing for even higher hook heights than single-girder cranes, double-girder crane designs maximize your vertical hook reach. The low headroom crane offered can be used for loads handling with capacities up to 80 tons . Your top dimensions are reduced by its small trolley design while the vertical hook coverage is increased.

Every component, from the hoist choice to the bridge drives and girders, is designed to work together in Yuantai Cranes' crane packages to achieve the maximum working span and floor coverage.Are you prepared for better hook coverage on your upcoming project?For immediate advice, please feel free to contact our crane specialist and check what we can do for your applications.