Overhead Grab Bucket Cranes for Quartz Sand Handling in Glass Production Factory

Importance of Efficient Material Handling in Glass Manufacturing

In glass manufacturing, efficiently handling raw materials is crucial for maintaining smooth and productive operations. Key materials like quartz sand, soda ash, and limestone must be moved quickly and safely from storage to the production line. If this process is slow or inefficient, it can lead to delays, extra costs, and lower-quality products.

Efficient material handling helps:

- Save time and reduce labor costs.

- Minimize spillage and waste, ensuring better quality.

- Prevent contamination, which can affect the final product.

Choosing the right equipment to handle materials is essential. When done well, it improves the flow of operations, keeps production on track, and maintains high standards for finished glass products.

The Role of Overhead Grab Bucket Cranes in Improving Production Efficiency

Overhead grab bucket cranes are key to improving material handling efficiency in glass manufacturing. These cranes are designed to lift and transport bulk materials, like quartz sand, with precision and control. By operating overhead, they free up valuable floor space and reduce congestion in the plant.

Benefits of using overhead grab bucket cranes:

- Space-saving: They use vertical space, opening up more room on the production floor.

- Improved efficiency: These cranes speed up the process of moving materials, reducing delays.

- Reduced spillage: The grab bucket securely holds materials, minimizing waste.

- Enhanced safety: Modern cranes have safety features like overload protection and precise load control.

By using overhead grab bucket cranes, glass manufacturing plants can improve productivity, reduce costs, and keep production moving smoothly.

grab bucket overhead crane, customized design for your needs , contact us WhatsApp: + 86 151 3871 1597

Handling Quartz Sand and Other Raw Materials

Quartz sand is one of the most important materials in glass production. Its quality directly impacts the final product’s strength and clarity. Efficiently moving quartz sand is vital to prevent contamination and waste.

How overhead grab bucket cranes help:

- They lift and transport large volumes of quartz sand quickly and safely.

- The grab bucket ensures secure handling, preventing spillage.

- Cranes are versatile and can also handle other materials like soda ash and limestone.

Using grab bucket cranes to handle quartz sand and other raw materials ensures a steady flow of materials into the production process. This reduces downtime and helps maintain product quality. By improving material handling, overhead grab bucket cranes are essential for optimizing glass manufacturing operations.

Key Features of Overhead Grab Bucket Cranes

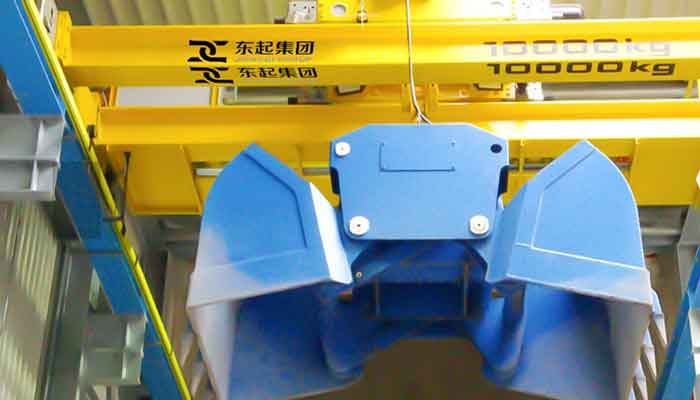

Description of Grab Bucket Design and Functionality

Overhead grab bucket cranes are designed to handle bulk materials like quartz sand with precision and efficiency. The grab bucket is suspended from the crane by ropes, chains, or cables, and is equipped with a mechanism that allows it to open and close. This design enables the crane to securely "grab" and lift materials from one location and transport them to another without spilling. The functionality of the grab bucket is crucial for minimizing material waste, ensuring safety, and improving operational efficiency. The crane’s design also allows for high lifting capacity, making it ideal for handling large volumes of materials, such as quartz sand, in manufacturing plants.

Types of Grabs: Clamshell Grab Bucket and Their Suitability for Quartz Sand

- Clamshell Grab Bucket: The clamshell grab bucket is the most commonly used type for handling materials like quartz sand. It features two jaws or halves that open and close like a clam shell. This design makes it easy to scoop and securely lift bulk materials, such as sand, gravel, and other fine materials. The bucket’s shape and mechanism are ideal for gripping loose, granular materials, preventing spillage and maintaining the integrity of the load.

- Suitability for Quartz Sand: The clamshell grab bucket is especially suited for handling quartz sand because it can effectively scoop large volumes of sand while minimizing loss. Quartz sand is often stored in loose, bulk form, and the clamshell design allows the crane to pick up and transport the material without spilling or wasting it, making the process more efficient in glass manufacturing plants.

Lifting Mechanisms: Electric Hoists vs. Manual Systems

- Electric Hoists: Most overhead grab bucket cranes are equipped with electric hoists. These hoists are powered by electricity and are known for their efficiency and ability to handle heavy loads with precision. Electric hoists can lift large quantities of quartz sand quickly and safely, making them ideal for high-volume glass manufacturing plants. They offer precise control over the crane’s movements, reducing the risk of spillage and improving safety during operation.

- Manual Systems: In some smaller or more cost-conscious operations, manual lifting systems may be used. These systems rely on human power to operate the crane, which makes them slower and less efficient than electric hoists. While manual systems may be sufficient for light-duty tasks, they are not ideal for handling large or heavy loads like quartz sand, as they require more effort and time.

Durability and Reliability in Harsh Environments

Overhead grab bucket cranes are designed to perform reliably in tough, industrial environments. In glass manufacturing, raw materials like quartz sand are often abrasive, and the plant environment can be dusty or moist, requiring cranes that are built to last and function smoothly under challenging conditions.

- Corrosion Resistance: To withstand harsh conditions, overhead grab bucket cranes are often made from high-quality, corrosion-resistant materials. This ensures that the crane’s components, especially the bucket and hoist system, maintain their strength and functionality over time, even when exposed to dust or moisture.

- Heavy-Duty Construction: These cranes are built to handle the demanding nature of bulk material handling. The crane’s frame, hoisting system, and grab bucket are all designed for durability, reducing the risk of damage and ensuring long-lasting performance.

- Reliability for Continuous Use: Glass manufacturing plants typically operate with high production demands, meaning cranes need to perform reliably for long hours. Overhead grab bucket cranes are designed for continuous operation, offering long-term reliability even in the toughest environments. This ensures that production remains uninterrupted and materials like quartz sand are consistently handled without delays.

Overall, the combination of durable materials, efficient lifting mechanisms, and the suitability of clamshell grab buckets makes overhead grab bucket cranes an essential tool for handling quartz sand in glass manufacturing plants.

Typical Capacities for Glass Manufacturing Plants

5 Ton Grab Bucket Cranes: Ideal for Smaller Production Plants

5-ton grab bucket cranes are commonly used in smaller glass manufacturing plants that handle moderate quantities of quartz sand and other raw materials. These cranes offer a balance between lifting capacity and operational efficiency, making them ideal for facilities with lower production volumes.

- Efficiency in Moving Smaller Loads of Quartz Sand: The 5-ton capacity is well-suited for lifting and moving smaller amounts of quartz sand, which is often stored in manageable bulk quantities. These cranes allow for precise handling and reduce the risk of spillage, ensuring that the plant operates smoothly and efficiently.

- Space-Saving Design: Smaller plants often have limited floor space, and the 5-ton grab bucket crane is designed to make the most of vertical space, reducing the footprint of the crane while maintaining strong performance. This is particularly beneficial in plants with tighter layouts or lower production demands.

While 5-ton cranes are best suited for smaller production volumes, they still provide high reliability and can operate in harsh environments, making them a practical choice for smaller glass manufacturing facilities.

10 Ton Grab Bucket Cranes: Suitable for Medium to Large-Sized Glass Plants

For medium to large-sized glass manufacturing plants, 10-ton grab bucket cranes provide a higher lifting capacity to handle increased production demands. These cranes are designed to lift and transport larger volumes of quartz sand, making them a better fit for operations that require more intensive material handling.

- Handling Larger Volumes of Quartz Sand: The 10-ton capacity allows for more efficient movement of large quantities of raw materials, ensuring that production can keep pace with higher demands. Whether for transferring quartz sand from storage to production lines or for transporting bulk materials across the plant, these cranes significantly improve throughput.

- Increased Lifting Power for Heavy-Duty Applications: With a higher lifting capacity, the 10-ton grab bucket crane can handle heavier or denser materials, such as higher-density quartz sand or other raw materials used in glass manufacturing. This makes them ideal for plants that need to manage a diverse range of materials with varying weight and volume requirements.

By providing increased lifting power and higher efficiency, 10-ton grab bucket cranes are essential for medium and large plants that rely on large-scale material handling for continuous production. They help maintain smooth operations, reduce downtime, and ensure optimal productivity in handling quartz sand and other materials.

Overall, both 5-ton and 10-ton grab bucket cranes are vital for glass manufacturing plants, with each offering specific benefits based on the size and requirements of the facility.

Benefits of Overhead Grab Bucket Cranes in Quartz Sand Handling

Precision Handling of Bulk Materials with Minimal Spillage

One of the key advantages of overhead grab bucket cranes is their ability to handle bulk materials, such as quartz sand, with high precision. The grab bucket’s design ensures that materials are securely held and transported without spilling.

- Controlled Handling: The crane’s lifting mechanism and bucket design allow for smooth and controlled movements, reducing the chances of quartz sand spilling during the lifting and transportation processes.

- Efficient Loading and Unloading: The precise control over the bucket’s opening and closing functions ensures that the right amount of material is scooped and placed without unnecessary loss, which helps optimize material usage and costs.

Enhanced Operational Efficiency and Reduced Downtime

Overhead grab bucket cranes significantly improve operational efficiency in glass manufacturing plants. These cranes can quickly and reliably move large volumes of quartz sand, ensuring that production lines stay active without delays.

- Faster Material Transport: The ability to handle large quantities of materials at once means less time spent on material transfer and more time spent on actual production.

- Reduced Downtime: With fewer delays in handling and loading, the overall downtime in the plant is minimized. This leads to higher throughput and improved productivity, helping plants meet their production targets.

By streamlining material handling, overhead grab bucket cranes contribute directly to the overall efficiency and profitability of glass manufacturing plants.

Maximizing Storage Space by Using the Overhead System

Using an overhead crane system allows plants to maximize their available floor space. Because these cranes operate above ground, they free up valuable floor space that would otherwise be used for traditional material handling methods.

- Efficient Use of Vertical Space: Overhead cranes make it possible to store quartz sand and other raw materials in bulk without taking up valuable floor space. This is especially beneficial in facilities with limited space or those that need to accommodate large quantities of materials.

- Better Layout Flexibility: With overhead cranes handling the transportation of materials, plants have more flexibility in organizing their layout, allowing for more efficient workflows and smoother transitions between different stages of production.

This maximization of storage space enables glass manufacturing plants to optimize their operations and create more room for other critical processes.

Safety Features: Anti-Sway, Overload Protection, and Dust Control

Safety is a top priority when handling bulk materials, and overhead grab bucket cranes come equipped with several safety features that help ensure smooth and safe operation.

- Anti-Sway Mechanism: This feature helps reduce the swinging motion of the crane while moving materials, which can be especially important when handling bulk materials like quartz sand. The anti-sway system helps maintain stability and control during transportation, reducing the risk of accidents or material spillage.

- Overload Protection: Overload protection is a crucial safety feature that prevents the crane from lifting more than its rated capacity. This helps avoid accidents, damage to the crane, and excessive wear on the crane’s components, ensuring long-term reliability and safe operation.

- Dust Control: In glass manufacturing, materials like quartz sand can generate dust during handling. Overhead grab bucket cranes can be equipped with dust control features, such as enclosed buckets or dust suppression systems, to reduce the amount of airborne particles. This not only improves the working environment but also reduces health risks associated with inhaling dust over time.

Together, these safety features ensure that overhead grab bucket cranes provide safe, reliable, and efficient handling of quartz sand in glass manufacturing plants.

Customization Options for Grab Bucket Cranes

Tailoring Crane Design for Specific Plant Layouts and Workflows

One of the key benefits of overhead grab bucket cranes is their ability to be customized to fit specific plant layouts and workflows. Each glass manufacturing plant has unique spatial constraints and operational needs, and a one-size-fits-all crane may not always be the most efficient solution.

- Optimized Layout Integration: Customization ensures that the crane fits seamlessly within the existing infrastructure. This may include adjusting the crane’s reach, height, or track layout to accommodate narrow aisles, low ceilings, or specific material storage areas.

- Workflow Efficiency: Custom crane designs can be tailored to match the plant’s production process, ensuring that the crane handles quartz sand and other materials in a way that minimizes disruptions. This might involve modifying the crane’s speed, range, or controls to suit specific workflows and improve operational efficiency.

Tailoring the crane to the plant’s layout helps to streamline material handling processes, reduce bottlenecks, and improve overall productivity.

Custom Bucket Designs for Different Grades of Quartz Sand

Quartz sand comes in various grades and sizes, and using the right grab bucket design is crucial for efficient handling.

- Bucket Shape and Size Adjustments: Custom bucket designs can be created to handle different grades of quartz sand, from fine powders to coarser grains. For example, buckets can be modified with smaller openings or reinforced sides for finer grades of sand, which require extra care to avoid spillage.

- Specialized Clamshell Designs: Custom clamshell grabs can be tailored to handle specific properties of the quartz sand, such as moisture content or particle size. This ensures that the crane can efficiently scoop and transport materials without damaging or losing any of the sand.

Custom bucket designs help maintain the integrity of the material and prevent wastage, ensuring a smoother operation for plants that deal with various types of quartz sand.

Specialized Features: Anti-Corrosion Coatings for Harsh Environments

Glass manufacturing plants are often subject to harsh environments, especially those that handle raw materials like quartz sand. To ensure the longevity and reliability of the crane, specialized features such as anti-corrosion coatings are often applied.

- Anti-Corrosion Coatings: Since quartz sand and other materials can be abrasive or contain chemicals that accelerate corrosion, it is essential to protect crane components from wear and rust. Anti-corrosion coatings are applied to key parts of the crane, such as the bucket, hoist, and tracks, ensuring the crane performs reliably over time.

- Harsh Environment Durability: These coatings can withstand the harsh conditions of glass manufacturing plants, including high moisture levels, dust exposure, and exposure to chemicals. This makes the crane more durable, reducing the need for frequent repairs and prolonging its operational lifespan.

By adding these specialized features, cranes are better equipped to handle the demanding environment of glass manufacturing plants, ensuring that they operate smoothly even in challenging conditions.