Selecting the Right Overhead Crane: Key Specifications for Your Facility Layout

Overhead cranes are essential tools in many industrial environments, serving as the backbone for material handling processes. These cranes are designed to lift and transport heavy loads across large areas, significantly enhancing efficiency and safety in various operations. From manufacturing plants to warehouses, overhead cranes can handle a wide range of materials, including raw components, finished products, and equipment, making them crucial for optimizing workflow and reducing manual labor.

The importance of selecting the right overhead crane for your facility cannot be overstated. A well-chosen crane can improve productivity, minimize downtime, and ensure safe handling of materials. Conversely, an ill-suited crane can lead to operational inefficiencies, increased maintenance costs, and safety hazards.

This article aims to guide readers through the process of selecting the right overhead crane based on their specific facility layout. By understanding the key specifications and considerations involved, facility managers and decision-makers can make informed choices that enhance their operations. Whether you're setting up a new facility or upgrading an existing one, this guide will provide valuable insights to help you choose the most suitable overhead crane for your needs.

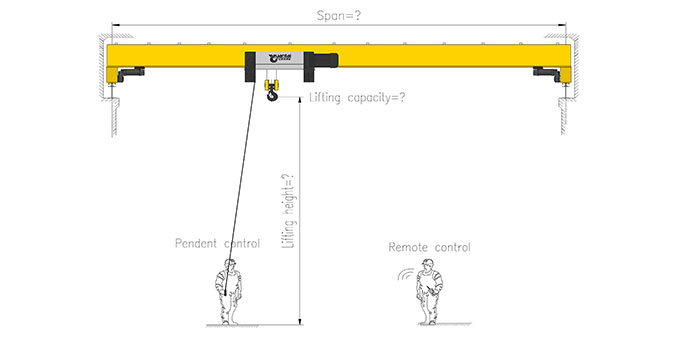

key specifications of single girder overhead crane needed to fit into your facility

Understanding Your Facility Layout

When selecting an overhead crane, understanding your facility layout is crucial. The layout directly influences the crane's performance and its ability to meet your operational needs. Here, we will explore the different types of facility layouts and the importance of evaluating existing infrastructure.

Types of Facility Layouts

- Open Floor Plan

An open floor plan is characterized by vast, unobstructed spaces that allow for flexible movement and operations. This layout is often seen in manufacturing plants, warehouses, and distribution centers. The advantages of an open floor plan include easy access for machinery, the ability to accommodate larger equipment, and the flexibility to rearrange workstations as needed. However, careful planning is required to ensure that the overhead crane can effectively navigate the space and efficiently lift and transport loads across the entire area. - Dedicated Workstations

Dedicated workstations are designed for specific tasks, often found in assembly lines or specialized manufacturing environments. Each workstation typically has its own equipment and tools, which can limit the movement of an overhead crane. In this layout, it's essential to choose a crane that can efficiently serve multiple workstations without obstructing workflows. Understanding the layout and spacing between workstations will help determine the crane's span and lifting capacity to ensure it meets operational demands. - Multi-Level Facilities

Multi-level facilities, such as warehouses or manufacturing plants with multiple floors, require careful consideration when selecting an overhead crane. In these setups, cranes may need to operate on different levels or lift loads to significant heights. This necessitates selecting cranes with suitable lifting heights, spans, and features that facilitate vertical movement. Additionally, the installation of tracks and other support structures must be accounted for to ensure the crane can effectively service all levels of the facility.

Importance of Evaluating Existing Infrastructure

Before selecting an overhead crane, it's vital to evaluate the existing infrastructure of your facility. This evaluation helps identify potential limitations and ensures the chosen crane integrates smoothly into your operational setup.

- Space Limitations

Understanding the available space is fundamental. This includes considering the height of the facility, the layout of columns and walls, and any obstructions that may hinder crane movement. Space limitations will influence the crane's span and lifting height, determining the type of crane that can be accommodated without compromising functionality. Conducting a thorough space analysis will help in selecting a crane that can operate effectively within the defined area. - Structural Support Considerations

The structural integrity of your facility is another critical factor to assess. Overhead cranes require adequate support to handle heavy loads safely. This involves examining the load-bearing capacity of the building's beams and columns, as well as the overall stability of the structure. If the existing infrastructure cannot support the selected crane, modifications may be necessary, which can add to installation costs and timelines. Consulting with structural engineers or crane manufacturers can provide insights into necessary adjustments to ensure safe and efficient crane operations.

By thoroughly understanding your facility layout and evaluating existing infrastructure, you can make informed decisions that will optimize the performance and safety of your overhead crane system.

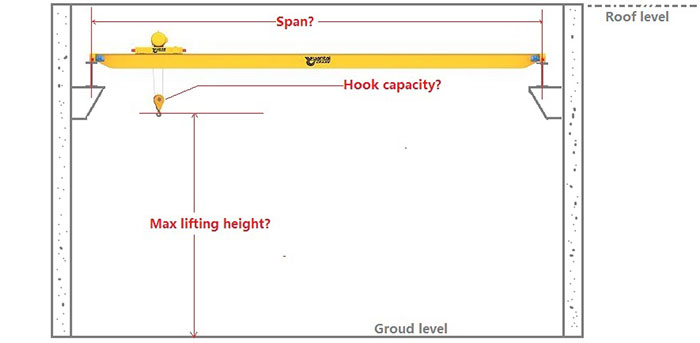

key specifications of double girder overhead crane needed to fit into your facility

Key Specifications to Consider

When selecting an overhead crane, there are several key specifications that must be carefully evaluated to ensure optimal performance and safety. Each of these specifications plays a critical role in the crane’s ability to meet your facility’s operational needs.

Lifting Capacity

- Determining the Maximum Load Requirements

The lifting capacity is perhaps the most crucial specification when selecting an overhead crane. It defines the maximum weight the crane can safely lift and move. To determine the appropriate capacity, assess the heaviest loads that will be handled in your facility. This includes not just the weight of the materials but also any additional factors, such as the weight of attachments (e.g., hooks, slings) and load stability. It is advisable to select a crane with a capacity that exceeds your maximum load requirements to account for potential variations in weight and to enhance safety margins. - Examples of Typical Loads in Various Industries

Different industries have varying typical loads. For instance, manufacturing plants may handle heavy machinery parts weighing several tons, while warehouses might deal with pallets of goods that can vary significantly in weight. In construction, overhead cranes may lift steel beams or concrete panels, which can also be quite heavy. Understanding the specific loads associated with your industry will help you select a crane with an appropriate lifting capacity.

Span Length

- Understanding the Distance Between Support Structures

The span length of an overhead crane refers to the distance between the two support structures (typically columns) that the crane travels across. This measurement is critical, as it affects the crane's ability to cover the necessary work area. When determining the span length, consider the layout of your facility, including any obstacles that might limit the distance. - Impact of Span on Crane Performance

The span length influences not only the operational efficiency but also the stability of the crane. A longer span may require additional engineering considerations to ensure that the crane remains stable while handling heavy loads. If your operations require a wide span, you may need to invest in a crane with a more robust design to maintain structural integrity and safety.

Lifting Height

- Assessing the Height Requirements Based on Facility Design

Lifting height is the maximum vertical distance a crane can lift a load. Assessing the height requirements involves understanding the ceiling height of your facility and the vertical space needed for safe operations. This includes accounting for any obstructions like lighting fixtures, HVAC systems, or overhead pipes that may limit how high the crane can lift. - Clearances Needed for Loads and Operators

In addition to the lifting height, it’s essential to consider the clearances required for both loads and operators. The clearance height ensures that loads can be lifted safely without risking contact with structures above. Additionally, operator safety is paramount; there should be sufficient space to maneuver loads without risking injury to personnel working nearby.

Operating Speed

- Speed Requirements Based on Workflow and Operations

The operating speed of an overhead crane impacts productivity. Depending on your operations, you may need a crane that can operate at varying speeds. For instance, in high-volume production environments, faster operating speeds can enhance efficiency, while in applications involving delicate materials, slower speeds may be necessary to ensure careful handling. - Adjusting for Load Handling and Safety

While speed is an important factor, it should not compromise safety. Cranes should be able to adjust their speed based on the load being handled, allowing for a balance between efficiency and safety. Incorporating variable speed drives can enhance the crane’s flexibility, enabling operators to adapt the speed to different operational conditions and ensuring safe load handling at all times.

By carefully considering these key specifications—lifting capacity, span length, lifting height, and operating speed—you can make an informed decision that aligns with your facility’s needs, enhancing efficiency and safety in your operations.

Other Key Considerations

In addition to the core specifications previously discussed, several other factors are crucial when selecting an overhead crane. These considerations ensure that the crane operates safely, efficiently, and effectively within your facility.

Power Supply and Control Systems

- Electrical Requirements and Compatibility

Understanding the electrical requirements of your chosen overhead crane is vital for seamless integration into your facility. Different cranes may require specific voltage levels, phase configurations, and power supply types (AC or DC). Ensure that your facility’s electrical infrastructure can support these requirements. Assessing compatibility will help prevent operational disruptions and ensure that the crane functions efficiently. - Control System Options: Manual vs. Automated

Overhead cranes can be equipped with various control systems, including manual and automated options. Manual control systems provide operators with hands-on operation, which can be beneficial for precise load handling in complex environments. Conversely, automated control systems enhance efficiency and reduce the risk of human error, allowing for programmed routines and remote operation. Consider the nature of your operations and the skills of your operators when choosing the most suitable control system for your crane.

Safety Features

- Emergency Stop Mechanisms

Safety is paramount when operating overhead cranes. Emergency stop mechanisms are critical features that allow operators to quickly halt the crane's operation in case of an emergency. These mechanisms should be easily accessible and clearly marked, ensuring that operators can respond swiftly in critical situations. Regular testing and maintenance of these systems are essential to ensure their reliability. - Load Monitoring Systems

Load monitoring systems are important for preventing overloads and ensuring safe operation. These systems provide real-time feedback on the weight being lifted, alerting operators when approaching maximum load limits. This feature helps prevent accidents, protects both personnel and equipment, and ensures compliance with safety regulations. - Anti-Collision Technologies

In busy industrial environments, the risk of collisions between cranes, loads, and other equipment is significant. Anti-collision technologies, such as proximity sensors and laser detection systems, can help prevent accidents by alerting operators to potential collisions. Integrating these technologies enhances the overall safety of crane operations and minimizes the risk of damage to the facility or personnel.

Maintenance and Accessibility

- Routine Maintenance Considerations

Regular maintenance is vital for ensuring the longevity and safe operation of overhead cranes. Consider the maintenance requirements of the crane, including lubrication, inspection of mechanical components, and checking electrical systems. Develop a routine maintenance schedule that aligns with the crane's usage patterns to prevent breakdowns and prolong its operational life. Additionally, assess whether the manufacturer offers support and guidance for ongoing maintenance. - Accessibility for Inspections and Repairs

Accessibility is a critical factor in maintenance and inspection routines. Ensure that the crane is designed with easy access to all necessary components, such as motors, gears, and electrical systems. This facilitates routine inspections and repairs, minimizing downtime and ensuring that maintenance can be performed efficiently. If possible, choose cranes that have been designed with maintenance-friendly features, such as removable panels or raised platforms for easy access.

By considering these key factors—power supply and control systems, safety features, and maintenance and accessibility—you can ensure that your overhead crane operates effectively while prioritizing safety and minimizing potential disruptions in your facility.

Customization Options

When selecting an overhead crane, it's important to recognize that standard models may not always meet the specific needs of your facility. Customization options can enhance the crane’s performance and functionality, ensuring it aligns perfectly with your operational requirements.

Modifications for Unique Facility Needs

- Specialized Attachments (e.g., Grabs, Hooks)

Depending on the materials being handled, specialized attachments can greatly enhance the versatility and efficiency of your overhead crane. For example, if your operations involve lifting bulk materials, grab attachments can facilitate quick and efficient loading and unloading. Hooks designed for specific loads, such as those with safety latches or swivel capabilities, can improve safety and handling ease. Assessing the types of loads your facility regularly handles will help you identify which specialized attachments would provide the greatest benefit. - Adjustable Configurations Based on Workflows

Different operational workflows may require unique crane configurations. For instance, a facility that frequently changes its layout may benefit from a crane with adjustable spans or height capabilities, allowing it to adapt to various work environments. Custom configurations can also include features like multi-speed operation or varying lifting heights, catering to the specific tasks performed in your facility. Collaborating with a manufacturer to design an overhead crane that matches your workflows can significantly enhance efficiency and productivity.

Importance of Working with Manufacturers for Tailored Solutions

Engaging with manufacturers for tailored solutions is essential when seeking customization options. Manufacturers possess the expertise to understand the intricacies of overhead crane design and can provide insights into modifications that would best suit your needs. By working closely with them, you can discuss your specific operational challenges and requirements, leading to a more effective and efficient crane solution.

Additionally, collaborating with manufacturers allows for a more comprehensive approach to crane design. They can offer guidance on safety features, compatibility with existing infrastructure, and maintenance requirements. This partnership can result in a crane tailored to not only meet current demands but also adapt to future changes in your facility.

In conclusion, customization options for overhead cranes can significantly improve their effectiveness in your operations. By considering specialized attachments and adjustable configurations and engaging with manufacturers for tailored solutions, you can ensure your crane meets the unique needs of your facility, enhances productivity, and maintains safety standards.

Conclusion

Selecting the right specifications for overhead cranes is a critical step in optimizing operations within your facility. The effectiveness of your crane directly impacts productivity, safety, and overall workflow efficiency. By thoroughly evaluating key specifications such as lifting capacity, span length, lifting height, operating speed, power supply, safety features, and maintenance considerations, you can ensure that your chosen crane is well-suited to your specific needs.

It’s essential to recognize that each facility has unique requirements, and what works for one may not be appropriate for another. Therefore, taking the time to assess your facility's layout, operational demands, and potential challenges is crucial before making a decision. A well-informed choice will lead to enhanced performance and a safer working environment.

If you are in the process of selecting an overhead crane or considering upgrades to your current equipment, we encourage you to contact industry experts or manufacturers. They can provide personalized assessments and recommendations tailored to your facility's specific needs. By seeking professional guidance, you can ensure that your investment in an overhead crane meets all operational demands while maximizing safety and efficiency. Don't hesitate to reach out and explore the best options available for your unique circumstances.