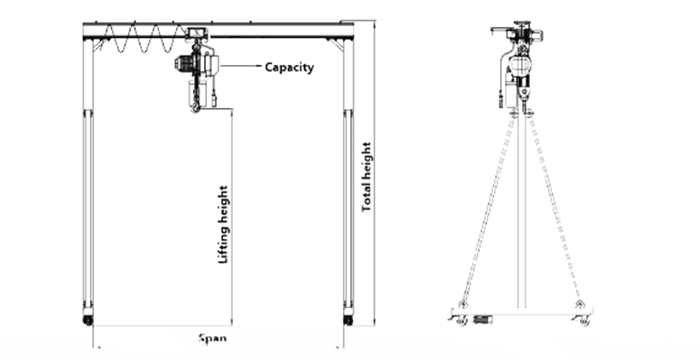

Aluminum Gantry Crane for Small Parts Assembly Workshops 0.5 to 3T

Aluminum Gantry Cranes: Precision Handling in Small Parts Assembly Workshops

In the field of manufacturing, where every second counts and accuracy reigns supreme, small parts assembly workshops stand as the nerve centers of precision. These workshops are where intricate components come together to form the intricate machinery that drives our modern world. From electronics to automotive industries, the meticulous handling of small parts is crucial to ensure seamless functionality and quality craftsmanship.

At the heart of this precision lies the indispensable role of aluminum gantry cranes. These towering structures, often overshadowed by the larger behemoths of the industrial world, play a pivotal role in optimizing efficiency and accuracy within small parts assembly workshops. As the backbone of handling operations, aluminum gantry cranes elevate the entire process, ensuring that each component finds its place with pinpoint accuracy.

Adjustable aluminum gantry cranes for light and small parts handling

Precision Handling in Small Parts Assembly Workshops

Precision handling in small parts assembly workshops is the art and science of delicately manipulating and positioning tiny components with utmost accuracy and care. It's not just about moving parts from one place to another; it's about ensuring that each component is placed exactly where it needs to be, with precision measured in microns. This level of precision is essential in small parts assembly because even the slightest deviation can result in malfunctioning products, compromised quality, and costly rework.

In these workshops, the significance of precision handling cannot be overstated. Small parts often form the building blocks of larger assemblies, and any errors at this stage can have cascading effects downstream. For example, in electronics manufacturing, a single misplaced resistor or solder joint can render an entire circuit board nonfunctional. Similarly, in automotive assembly, improperly aligned engine components can lead to catastrophic failures on the road.

However, achieving precision handling in small parts assembly is not without its challenges. The very nature of small components presents unique obstacles that must be overcome:

- Size and Fragility: Small parts are often tiny and delicate, making them susceptible to damage from even minor mishandling. Their small size also means that they can be difficult to grasp and manipulate accurately.

- Tolerance Requirements: Many small parts have tight tolerance requirements, meaning they must be positioned with extreme accuracy to meet specifications. Achieving such precision consistently can be a daunting task.

- Complexity and Variety: Small parts come in a myriad of shapes, sizes, and materials, each with its own handling requirements. This diversity adds complexity to the handling process, requiring adaptable solutions that can accommodate a wide range of components.

- Assembly Speed: In modern manufacturing environments, speed is of the essence. Small parts must be handled quickly and efficiently to keep up with production demands, without sacrificing accuracy or quality.

- Safety Concerns: Working with small parts often involves repetitive tasks that can lead to strain and fatigue for operators. Ensuring the safety and wellbeing of workers while maintaining precision is paramount.

Despite these challenges, precision handling in small parts assembly workshops is not only achievable but essential for ensuring the quality and reliability of the final products. By understanding the significance of precision handling and addressing the challenges headon, manufacturers can optimize their assembly processes and deliver superior products to their customers.

Aluminum Gantry Cranes: The Precision Solution

In the quest for precision handling in small parts assembly workshops, aluminum gantry cranes emerge as the unsung heroes. These versatile lifting solutions offer a perfect blend of strength, agility, and precision, making them the ideal choice for handling delicate components with unparalleled accuracy.

Aluminum gantry cranes are lightweight yet robust lifting structures designed to navigate the tight confines of small parts assembly workshops. Unlike their heavier steel counterparts, aluminum gantry cranes offer several distinct advantages that make them wellsuited for precision handling tasks. Their lightweight construction not only makes them easy to maneuver and position but also reduces the risk of damage to delicate workshop floors. Additionally, aluminum gantry cranes are corrosionresistant, making them suitable for use in environments where exposure to moisture or chemicals is a concern.

At the heart of the aluminum gantry crane's precision lies its advanced control systems and ergonomic design features. These cranes are equipped with precisionengineered components that enable operators to manipulate loads with pinpoint accuracy. Variable speed controls, finetuned joystick movements, and responsive braking systems allow for smooth and precise handling of even the smallest components. Furthermore, the modular design of aluminum gantry cranes allows for easy customization and integration of specialized lifting attachments, further enhancing their versatility and precision.

In essence, aluminum gantry cranes act as the precision solution for small parts assembly workshops, offering unmatched control, agility, and reliability in handling delicate components. With their ability to facilitate precise movement and positioning, these cranes empower manufacturers to achieve the highest levels of accuracy and efficiency in their assembly processes.

Applications in Small Parts Assembly Workshops

Aluminum gantry cranes stand as indispensable tools in small parts assembly workshops, revolutionizing the handling of delicate components and driving efficiency to new heights. Through their versatility, agility, and precision, these cranes excel in a myriad of tasks within the assembly process, offering manufacturers a reliable solution for achieving increased productivity and accuracy.

Examples of Specific Tasks:

- Component Assembly: Aluminum gantry cranes are utilized to transport small parts to assembly stations, where they are delicately positioned and integrated into larger assemblies. Whether it's fitting electronic components onto circuit boards or assembling intricate mechanical parts, these cranes ensure precise placement and alignment.

- Material Handling: From bins of small parts to delicate machinery components, aluminum gantry cranes provide a reliable means of lifting and transporting materials throughout the workshop. Their lightweight yet robust construction allows for easy maneuverability in tight spaces, making them ideal for navigating cluttered work areas.

- Quality Control Inspections: Aluminum gantry cranes play a crucial role in quality control processes, facilitating the movement of components to inspection stations where they undergo rigorous testing and verification. Their precision movement capabilities ensure that components are presented accurately for inspection, helping to identify defects and deviations from specifications.

Case Studies:

- Electronics Manufacturing: A leading electronics manufacturer implemented aluminum gantry cranes in its small parts assembly workshop to streamline the handling of delicate circuit board components. By utilizing the cranes for precise placement and alignment, the manufacturer achieved a 20% increase in assembly speed and a significant reduction in rework due to misaligned components.

- Precision Engineering: In a precision engineering workshop, aluminum gantry cranes were deployed to handle intricate mechanical components used in the assembly of highprecision machinery. The cranes' precise movement capabilities allowed for seamless integration of components, resulting in a 15% improvement in assembly accuracy and a reduction in assembly time by 30%.

- Medical Device Manufacturing: A medical device manufacturer incorporated aluminum gantry cranes into its small parts assembly process to handle delicate components used in the production of surgical instruments. The cranes' agility and precision proved instrumental in achieving a 25% reduction in assembly errors and a notable increase in overall productivity.

In each of these case studies, aluminum gantry cranes proved to be invaluable assets in small parts assembly workshops, driving improvements in productivity, accuracy, and quality. By facilitating precise handling of components and streamlining assembly processes, these cranes empower manufacturers to meet the demands of modern production environments effectively.

Advantages of Precision Handling with Aluminum Gantry Cranes

Precision handling is the cornerstone of efficient and accurate small parts assembly, and aluminum gantry cranes emerge as the quintessential solution for achieving superior results. By offering unparalleled control, versatility, and reliability, these cranes provide manufacturers with a multitude of advantages over alternative handling methods.

Benefits of Using Aluminum Gantry Cranes:

- Precision and Accuracy: Aluminum gantry cranes enable operators to precisely position components with micrometerlevel accuracy, ensuring that each part is placed exactly where it needs to be. This precision minimizes the risk of errors and rework, leading to higherquality finished products.

- Versatility: Aluminum gantry cranes are highly adaptable to a wide range of handling tasks, from lifting delicate electronic components to transporting heavy machinery parts. Their modular design allows for easy customization with various lifting attachments, making them suitable for diverse applications within small parts assembly workshops.

- Efficiency: With their rapid deployment and precise movement capabilities, aluminum gantry cranes significantly improve workflow efficiency in small parts assembly. Operators can quickly move components between workstations, reducing downtime and increasing overall productivity.

- Safety: Aluminum gantry cranes are designed with safety in mind, featuring builtin safety features such as overload protection and emergency stop mechanisms. Their lightweight construction also minimizes the risk of accidents or injuries associated with heavier lifting equipment.

- Space Saving: Unlike traditional overhead cranes or forklifts, aluminum gantry cranes are freestanding structures that require minimal floor space. This compact footprint makes them ideal for use in small parts assembly workshops where space is at a premium.

Comparison with Alternative Handling Methods and Their Limitations:

- Manual Handling: While manual handling may suffice for lighter loads, it lacks the precision and efficiency required for small parts assembly. Manual handling also poses a higher risk of ergonomic injuries and fatigue among workers.

- Forklifts: Forklifts are suitable for lifting heavier loads but lack the precision and agility of aluminum gantry cranes. Their larger size and slower maneuverability make them less suitable for navigating tight spaces and handling delicate components.

- Overhead Cranes: Overhead cranes offer similar lifting capabilities to aluminum gantry cranes but require extensive installation and infrastructure modifications. Additionally, overhead cranes are limited in their flexibility and adaptability compared to the modular design of aluminum gantry cranes.

- Conveyor Systems: Conveyor systems are effective for transporting components between workstations but lack the versatility and precision of aluminum gantry cranes. They also require continuous motion, which may not be suitable for all assembly processes.

In conclusion, the advantages of precision handling with aluminum gantry cranes are clear: unparalleled precision, versatility, efficiency, safety, and spacesaving design. When compared to alternative handling methods, aluminum gantry cranes emerge as the superior solution for small parts assembly, providing manufacturers with the tools they need to achieve optimal results in today's fastpaced manufacturing environments.

Safety Considerations

Ensuring the safety of workers and protecting valuable equipment is paramount in any industrial setting, and small parts assembly workshops are no exception. When utilizing aluminum gantry cranes for precision handling, it is essential to adhere to rigorous safety measures and protocols to mitigate the risk of accidents or injuries.

Overview of Safety Measures and Protocols:

- Load Capacity Awareness: Operators must be aware of the maximum load capacity of the aluminum gantry crane and ensure that loads do not exceed this limit. Overloading the crane can lead to structural damage and compromise safety.

- PreUse Inspection: Prior to each use, operators should conduct a thorough inspection of the aluminum gantry crane to check for any signs of damage or wear. This includes examining the structure, wheels, hoisting mechanisms, and control systems for any abnormalities.

- Clear Communication: Effective communication between operators and other personnel is essential to ensure safe crane operation. Clear signals should be established for lifting, lowering, and moving loads, and operators should always be aware of their surroundings to avoid collisions or entanglements.

- Proper Lifting Techniques: Operators should be trained in proper lifting techniques to minimize the risk of strain or injury. This includes maintaining a stable stance, using appropriate hand signals, and avoiding sudden movements that could destabilize the load.

- Emergency Procedures: In the event of an emergency or malfunction, operators should be familiar with the appropriate emergency procedures and know how to safely stop the crane and secure the load. This may include activating emergency stop buttons or lowering the load to the ground.

- Fall Protection: When working at height, operators should use appropriate fall protection equipment such as harnesses and lanyards to prevent falls. Guardrails or safety nets should also be installed around elevated work areas to provide additional protection.

Importance of Proper Training and Maintenance:

- Operator Training: All personnel tasked with operating aluminum gantry cranes should undergo comprehensive training on safe operation practices, including proper use of controls, load handling techniques, and emergency procedures. Regular refresher training should also be provided to ensure that operators remain proficient in their skills.

- Maintenance Inspections: Regular maintenance inspections are essential to ensure the continued safe operation of aluminum gantry cranes. This includes lubricating moving parts, inspecting electrical components, and checking for signs of wear or damage. Any issues should be promptly addressed to prevent equipment failure.

- Documentation and Records: Keeping detailed records of training, maintenance activities, and inspections is crucial for ensuring compliance with safety regulations and standards. This documentation serves as a valuable reference for identifying potential hazards and implementing corrective actions.

By prioritizing safety measures and protocols, and investing in proper training and maintenance practices, small parts assembly workshops can ensure the safe and efficient operation of aluminum gantry cranes, protecting both personnel and equipment from harm.

Case Studies

Aluminum gantry cranes have been instrumental in revolutionizing small parts assembly workshops, driving improvements in efficiency, productivity, and precision. Let's delve into two realworld examples where the implementation of aluminum gantry cranes has yielded tangible benefits:

Case Study 1: Electronics Manufacturing Facility

Background:

A leading electronics manufacturing facility was facing challenges in handling small components for circuit board assembly. The delicate nature of these components required precision handling to avoid damage and ensure accurate placement.

Solution:

The facility implemented aluminum gantry cranes equipped with specialized lifting attachments designed for handling small electronic components. These cranes were integrated into the assembly process, providing operators with precise control over the placement and alignment of components.

Results:

Increased Productivity: With the introduction of aluminum gantry cranes, the facility experienced a 30% increase in assembly speed. Operators could efficiently transport components between workstations, minimizing downtime and optimizing workflow.

Improved Accuracy: The precision movement capabilities of the cranes ensured that components were placed with micrometerlevel accuracy, reducing the incidence of misalignments and assembly errors.

Enhanced Safety: By eliminating the need for manual handling of delicate components, the risk of damage and ergonomic injuries among workers was significantly reduced. The cranes' builtin safety features further enhanced operator safety.

Case Study 2: Automotive Manufacturing Plant

Background:

An automotive manufacturing plant was struggling to meet production targets due to inefficiencies in handling small engine components. Manual lifting methods were timeconsuming and prone to errors, resulting in delays and quality issues.

Solution:

The plant implemented a fleet of aluminum gantry cranes strategically positioned throughout the assembly line. These cranes were equipped with specialized lifting attachments tailored to the unique shapes and sizes of engine components.

Results:

Streamlined Workflow: With the integration of aluminum gantry cranes, the assembly line saw a 25% reduction in cycle times. Operators could swiftly move components between workstations, optimizing the flow of production.

Enhanced Precision: The cranes' precise movement and positioning capabilities ensured that engine components were assembled with unparalleled accuracy. This led to a significant decrease in rework and scrap rates.

Cost Savings: By improving efficiency and reducing waste, the automotive plant realized substantial cost savings. The investment in aluminum gantry cranes quickly paid for itself through increased productivity and reduced production costs.

In both case studies, the implementation of aluminum gantry cranes transformed small parts assembly processes, driving improvements in efficiency, precision, and overall operational performance. These realworld examples highlight the tangible benefits that aluminum gantry cranes can bring to small parts assembly workshops, positioning them as indispensable tools for modern manufacturing environments.

Conclusion

In the dynamic world of manufacturing, where precision and efficiency are paramount, small parts assembly workshops stand as crucibles of innovation and precision. Throughout this exploration, we've delved into the intricate dance of precision handling and the pivotal role played by aluminum gantry cranes in elevating efficiency and accuracy to new heights.

Summary of Key Points:

Precision handling is essential in small parts assembly workshops to ensure accurate placement and alignment of components, minimizing errors and optimizing quality.

Aluminum gantry cranes offer unparalleled precision, versatility, and efficiency, making them the ideal solution for handling delicate components in tight spaces.

Through realworld examples and case studies, we've seen how the implementation of aluminum gantry cranes has led to tangible improvements in productivity, accuracy, and safety in small parts assembly workshops.

Get your custom aluminum

Crucial Role of Aluminum Gantry Cranes:

Aluminum gantry cranes serve as the backbone of precision handling in small parts assembly workshops, providing operators with the tools they need to navigate the complexities of modern manufacturing. With their precise movement capabilities and ergonomic design features, these cranes empower manufacturers to achieve the highest levels of efficiency and accuracy, driving success in today's competitive market.

Closing Remarks:

As technology continues to evolve and manufacturing processes become increasingly sophisticated, the potential for continued improvements in precision handling practices is boundless. Aluminum gantry cranes will continue to play a pivotal role in shaping the future of small parts assembly, enabling manufacturers to push the boundaries of innovation and deliver superior products to customers worldwide.

In conclusion, precision handling in small parts assembly workshops is not just a necessity—it's an art form. And with aluminum gantry cranes leading the way, the future of precision handling has never looked brighter.