Guide to Buying Customized Overhead Cranes in Bolivia

Guide to Buying Customized Overhead Cranes in Bolivia:

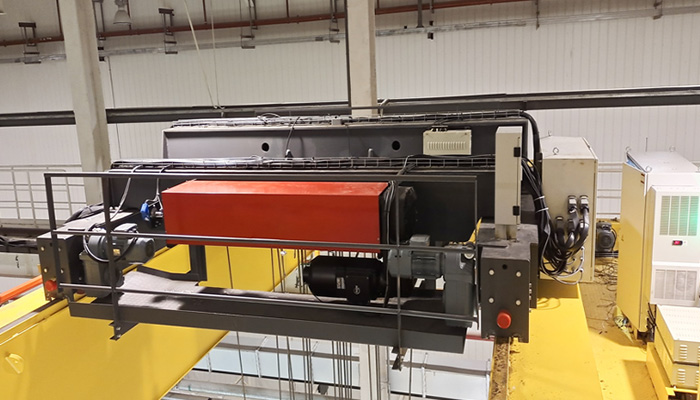

Investing in customized overhead cranes in Bolivia is a strategic move that can significantly enhance the efficiency of your operations. To ensure you make the right choice, it all begins with a thorough assessment of your industrial needs. Whether you operate in manufacturing, construction, mining, or other sectors, understanding your requirements is the cornerstone of a successful crane acquisition.

Identify the Specific Requirements of Your Industry

Each industry comes with its unique set of challenges and material handling demands. Before diving into the world of overhead cranes, take a close look at the intricacies of your industry. Are you involved in manufacturing intricate components, erecting large structures in construction, or facilitating mining operations deep within the earth? Understanding the nuances of your industry is the first step in selecting a crane that aligns with your operational goals.

Determine the Types of Materials to be Lifted

Not all cranes are created equal, and the materials you intend to lift play a crucial role in determining the crane specifications. Are you handling raw materials, finished products, or heavy machinery? The type, size, and weight of the materials influence the crane's design, lifting capacity, and overall functionality. A careful evaluation of your material handling needs ensures that the chosen crane is up to the task.

Assess the Weight and Frequency of Lifts

Efficient material handling is about precision and reliability. Evaluate the weight of the heaviest loads your crane will need to lift. This information is fundamental in selecting a crane with an appropriate lifting capacity, preventing overloading issues and ensuring safety. Additionally, consider the frequency of lifts – how often will the crane be in operation? This factor influences the crane's duty cycle and maintenance requirements.

By meticulously assessing your industrial needs, you set the stage for a tailored crane solution that seamlessly integrates into your workflow. The next steps in the guide will delve into workspace considerations, customization options, and the crucial aspect of regulatory compliance. Stay tuned to embark on a comprehensive journey towards acquiring the ideal overhead crane for your business in Bolivia.

Know Your Workspace Constraints:

In the pursuit of a customized overhead crane solution for your operations in Bolivia, understanding the constraints of your workspace is pivotal. The efficiency and effectiveness of your crane system are directly influenced by how well it integrates with the available space in your workshop or facility.

- Measure Available Space -Before selecting a crane, it's imperative to measure and assess the available space where the crane will operate. Consider the dimensions of your workshop or facility, taking into account any existing machinery, structures, or obstacles that might affect the crane's movement. Accurate measurements are the foundation for choosing a crane that optimally utilizes the available space.

- Consider Height and Layout -The height and layout of your workspace play a crucial role in determining the type of crane that best suits your needs. This is particularly relevant when choosing between single girder and double girder cranes:

Characteristics:

Have a single bridge girder supporting the hoist and trolley.

Generally lighter and more cost effective.

Ideal for low to medium duty applications.

Suitability:

Well suited for workshops with limited vertical space.

Optimal for tasks with lighter lifting requirements.

Characteristics:

Feature two bridge girders for increased stability and lifting capacity.

Suitable for heavy duty applications and larger spans.

Provide better hook height and greater lifting capabilities.

Suitability:

Ideal for workshops with ample vertical space.

Suited for tasks demanding higher lifting capacities.

Achieving the right balance between available space and crane functionality is key. Consider the workflow within your workshop and how the crane's movement aligns with the layout. A well thought out crane system enhances productivity without impeding other essential operations.

Evaluate Lifting Capacity:

Determining the lifting capacity of your overhead crane is a critical step in ensuring its performance aligns with your operational needs. This evaluation involves understanding the maximum weight your crane needs to lift and selecting a crane with a lifting capacity that not only meets but comfortably exceeds your heaviest load.

Determine the Maximum Weight to Lift

Begin by assessing the heaviest loads your crane will encounter in regular operations. Consider the materials, products, or machinery that require lifting within your industrial setting. Accurate information about the maximum weight ensures that the chosen crane can handle the full spectrum of tasks in your workshop.

Choose a Crane with Comfortable Excess Capacity

While selecting a crane with a lifting capacity matching your maximum load is essential, it's advisable to choose a crane with a comfortable excess capacity. This ensures several benefits:

- Safety and Reliability -Safety Margin: A crane with a safety margin above the maximum load provides a buffer for unforeseen circumstances, preventing overloading issues and ensuring safe operations.

- Operational Flexibility - Versatility: Having excess lifting capacity allows your crane to handle a variety of loads without pushing it to its limits. This is especially beneficial in dynamic industrial environments.

- Future Proofing - Adaptability: Considering potential growth and changes in your operations, a crane with excess capacity is more adaptable to future needs. It future proofs your investment.

While it's important to have a comfortable excess capacity, it's equally crucial to strike a balance with the associated costs. Evaluate your budget constraints and operational requirements to determine the optimal lifting capacity that meets both safety standards and financial considerations.

Types of Cranes Based on Lifting Capacity

Consider different types of overhead cranes based on lifting capacity, such as:

Light Duty Cranes

Characteristics:

Suitable for tasks with lower lifting requirements.

Cost effective and energy efficient.

Medium Duty Cranes

Characteristics:

Versatile for a wide range of applications.

Balances lifting capacity and operational efficiency.

Heavy Duty Cranes

Characteristics:

Designed for demanding tasks with substantial lifting requirements.

Provides high lifting capacities and durability.

Engage with crane manufacturers or suppliers for expert advice on selecting the right lifting capacity for your specific needs. Professional consultation ensures that your overhead crane not only meets current requirements but is also aligned with the future growth of your operations.

By carefully evaluating the lifting capacity of your overhead crane, you set the stage for a safe, reliable, and efficient material handling solution. The guide will continue to explore customization options, regulatory compliance, and specific crane types, offering practical insights for buyers in Bolivia.

Consider Crane Span and Reach:

In the quest for a customized overhead crane solution that seamlessly integrates into your Bolivian operations, evaluating crane span and reach is a crucial step. These parameters directly impact the crane's coverage area and its ability to efficiently handle materials within your workspace.

Evaluate the Span of Your Crane

The span of a crane refers to the distance between the runways or supporting structures. This measurement is vital in determining the coverage area of the crane within your facility. When assessing the span:

Single Span Cranes

Characteristics:

Suitable for workshops with a narrow layout.

Economical choice for limited space.

Double Span Cranes

Characteristics:

Feature two parallel runways for increased stability.

Ideal for wider workshops with larger coverage requirements.

Multi Span Cranes

Characteristics:

Employ multiple runways for extensive coverage.

Suitable for facilities with irregular layouts or multiple workstations.

Consider the Reach of Your Crane

The reach of a crane is the horizontal distance it can travel along the runway. This parameter is crucial for ensuring that the crane can efficiently access various points within your workspace. When considering reach:

Standard Reach

Characteristics:

Ideal for linear layouts where materials are positioned along a straight path.

Offers a straightforward and predictable material handling trajectory.

Articulating Reach

Characteristics:

Suitable for workshops with non linear layouts or irregularly positioned materials.

Provides flexibility in accessing materials from different angles.

Balancing Span and Reach

Achieving the right balance between crane span and reach is essential for optimizing material handling efficiency. Consider the layout of your workshop and the specific locations where materials need to be lifted and transported. A well designed crane system ensures that it can reach all critical points without compromising stability or operational safety.

- Customization for Specific Workstations -In situations where specific workstations have unique layout requirements, consider customized solutions that cater to the specific span and reach needed. Work closely with crane manufacturers to design a system that precisely aligns with your operational demands.

- Simulation and Planning -Utilize simulation tools and planning software to visualize the crane's movement within your workspace. This aids in fine tuning the span and reach parameters to achieve optimal coverage and efficiency.

By carefully considering crane span and reach, you lay the groundwork for a crane system that maximizes coverage and enhances material handling capabilities. The guide will continue to explore customization options, regulatory compliance, and specific types of overhead cranes, providing practical insights for buyers in Bolivia.

Customize Crane Controls:

Tailoring the controls of your overhead crane is a crucial aspect of ensuring smooth and efficient operations within your Bolivian industrial setting. The control system you choose plays a pivotal role in how well the crane integrates into your workflow. This section explores customization options for crane controls, accommodating diverse operational preferences.

Choose a Control System

Selecting the right control system is akin to providing your crane with its operational language. The choice depends on your operational requirements and preferences:

Pendant Control

Characteristics:

Wired control pendant connected directly to the crane.

Operator has direct control from the shop floor.

Ideal for applications requiring proximity and direct line of sight.

Radio Remote Control

Characteristics:

Wireless remote control for crane operations.

Offers flexibility and mobility to the operator.

Suitable for tasks where operators need to move around the workspace.

Cabin Operated Controls

Characteristics:

Operator controls the crane from an enclosed cabin attached to the crane.

Provides a clear view of the entire workspace.

Suitable for heavy duty applications or when precision is paramount.

Features to Consider

Beyond the choice of the control system, certain features enhance the overall functionality and precision of crane operations:

Variable Speed Controls

Advantages:

Enables precise movements, especially crucial in applications requiring delicate handling.

Enhances safety by allowing operators to control the speed based on the load and task.

Emergency Stop Systems

Advantages:

Ensures rapid halting of crane operations in emergency situations.

Enhances overall safety and minimizes the risk of accidents.

Automation and Programmability

Advantages:

Allows for the automation of repetitive tasks.

Programmable controls can streamline operations and reduce manual intervention.

Operator Training and Familiarization

Regardless of the chosen control system, investing in operator training is paramount. Ensure that your crane operators are well versed in the chosen control interface, safety protocols, and emergency procedures. Familiar operators contribute to the overall efficiency and safety of crane operations.

Consider how the chosen control system integrates with other systems within your facility. Seamless integration enhances overall workflow efficiency, providing a synchronized approach to material handling operations.

By customizing crane controls to suit your operational preferences and integrating features that enhance precision and safety, you lay the groundwork for a crane system that seamlessly aligns with your specific needs. The guide will continue to explore regulatory compliance, specific types of overhead cranes, and market dynamics in Bolivia.

Factor in Safety Features:

Safety is paramount in any industrial setting, and when it comes to overhead cranes in Bolivia, prioritizing safety features is non negotiable. This section emphasizes the importance of integrating robust safety features into your customized overhead crane system.

Prioritize Essential Safety Features

Overload Protection

Importance:

Prevents the crane from attempting to lift loads beyond its rated capacity.

Enhances equipment longevity and prevents catastrophic failures.

Emergency Stop Systems

Importance:

Allows for rapid cessation of crane operations in emergency situations.

Crucial for averting accidents and minimizing potential damages.

Limit Switches

Importance:

Sets predefined limits for crane movements, preventing collisions with structures or obstacles.

Ensures controlled and safe operations within the specified boundaries.

Consider Advanced Safety Technologies

Collision Avoidance Systems

Advantages:

Utilizes sensors and advanced technology to detect obstacles in the crane's path.

Automatically adjusts crane movements to prevent collisions, enhancing safety in dynamic environments.

Load Monitoring Systems

Advantages:

Monitors the load in real time during lifting operations.

Provides operators with accurate load information, preventing overload situations.

Proximity Sensors

Advantages:

Alerts operators to the presence of objects or personnel in close proximity to the crane.

Enhances situational awareness, reducing the risk of accidents.

Compliance with Industry Standards

Ensure that the chosen safety features align with industry standards and regulations in Bolivia. Adherence to established safety norms not only guarantees a secure working environment but also ensures legal compliance.

Operator Training on Safety Protocols -Invest in comprehensive training programs for crane operators, focusing on the proper utilization of safety features. Operators should be well versed in emergency procedures, understanding how to effectively use safety systems to avert potential risks.

Regular Maintenance and Inspections -Establish a routine maintenance schedule to inspect and test safety features regularly. Proactive maintenance ensures that safety systems remain in optimal working condition, providing ongoing protection for both personnel and equipment.

By prioritizing safety features in your customized overhead crane system, you create a secure work environment that aligns with international safety standards. The guide will continue to explore customization options, specific types of overhead cranes, and market dynamics in Bolivia.

Adapt to Industry Standards:

When customizing an overhead crane for your operations in Bolivia, aligning with industry standards and regulations is paramount. This section emphasizes the importance of ensuring that your customized crane complies with established norms, with a specific focus on safety and environmental standards.

Ensure Compliance with Safety Standards

National Safety Standards

Importance:

Familiarize yourself with safety standards set by relevant national authorities in Bolivia.

Ensure that your customized crane meets or exceeds these standards for safe operations.

Importance:

Consider adherence to international standards, such as those outlined by the International Organization for Standardization (ISO).

ISO standards provide a global benchmark for quality, safety, and efficiency.

Environmental Standards and Sustainability

Environmental Impact Assessment

Importance:

Evaluate the environmental impact of crane operations in your facility.

Ensure that your customized crane minimizes environmental footprint.

Energy Efficiency

Importance:

Opt for energy efficient features to reduce overall energy consumption.

Align with global efforts towards sustainability and environmental responsibility.

Regular Audits and Inspections

Internal Audits

Importance:

Conduct regular internal audits to assess compliance with safety and environmental standards.

Identify areas for improvement and corrective actions.

Third Party Inspections

Importance:

Engage third party inspection services to provide unbiased assessments of your crane system.

External validation enhances confidence in your compliance efforts.

Legal Compliance

Work with Legal Experts

Importance:

Consult with legal experts in Bolivia to ensure that your customized crane complies with all relevant laws and regulations.

Address any potential legal implications.

Documentation and Certifications

Importance:

Maintain thorough documentation of your crane's design, features, and safety measures.

Obtain certifications and approvals from relevant authorities.

Continuous Improvement

Feedback Mechanisms

Importance:

Establish mechanisms for collecting feedback from operators, maintenance teams, and safety personnel.

Use feedback to continuously improve safety and environmental aspects of crane operations.

By adapting your customized overhead crane to industry standards and regulations in Bolivia, you not only ensure legal compliance but also contribute to a safer and environmentally responsible workplace. The guide will continue to explore specific types of overhead cranes, market dynamics, and additional considerations for buyers in Bolivia.

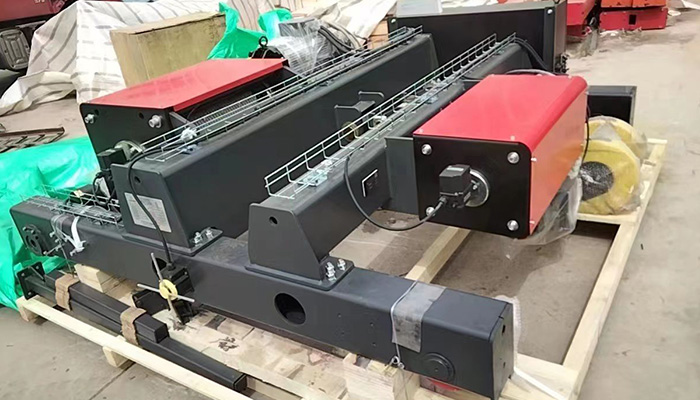

Select Suitable Hoist Mechanism:

The choice of hoist mechanism is a critical decision when customizing an overhead crane for your operations in Bolivia. This section explores key considerations in selecting a suitable hoist mechanism, focusing on options such as wire rope hoists and chain hoists, along with features like dual speed hoisting.

Characteristics

Durability:

Wire rope hoists are known for their durability and resistance to wear and tear.

Suitable for applications involving heavy loads and high frequency use.

Versatility:

Well suited for lifting applications requiring precision and smooth movement.

Ideal for tasks where load sway control is crucial.

Applications

Heavy Industries:

Commonly used in heavy industries such as manufacturing, construction, and mining.

Suitable for lifting and transporting substantial loads.

Characteristics

Simplicity:

Chain hoists are simpler in design and operation.

Provide reliable and straightforward lifting capabilities.

Cost Effective:

Often a cost effective solution for light to medium duty lifting requirements.

Suited for applications with lower frequency and less demanding conditions.

Applications

Light to Medium Industries:

Widely used in industries where the lifting requirements are not excessively heavy.

Suitable for tasks with moderate loads and less frequent use.

Consider Load Requirements

Weight Capacity

Matching Capacity:

Choose a hoist mechanism that matches the weight capacity requirements of your specific application.

Ensure that the hoist can comfortably handle the heaviest loads in your operations.

Dual Speed Hoisting

Advantages:

Opt for dual speed hoisting mechanisms for enhanced efficiency.

Allows for both high speed movement in unloaded conditions and slow, precise positioning when carrying a load.

Application Specific Features

Specialized Attachments

Customization:

Explore options for specialized attachments based on your unique lifting requirements.

Attachments can enhance the versatility of the hoist mechanism.

Environmental Considerations

Corrosion Resistance:

Assess environmental conditions in your facility.

Choose hoist mechanisms with corrosion resistant features for longevity.

Engage with crane manufacturers or suppliers for expert advice on selecting the most suitable hoist mechanism for your specific needs. Consider factors such as the nature of your industry, frequency of use, and load capacities.

By carefully selecting a suitable hoist mechanism, you ensure that your customized overhead crane is optimized for efficiency, durability, and safety in the Bolivian industrial landscape. The guide will continue to explore market dynamics, additional considerations for buyers, and conclude with practical insights for acquiring the ideal overhead crane.

Explore Specialized Attachments:

Part : Explore Specialized Attachments

When customizing an overhead crane for operations in Bolivia, delving into the realm of specialized lifting attachments can profoundly impact the versatility and efficiency of the crane system. This section underscores the strategic importance of clear communication with the crane manufacturer regarding operational needs and explores various specialized attachments, including customized hooks, magnets, and more.

Communicate Operational Needs

- Task Specific Requirements -In the collaborative process with the crane manufacturer, articulate your operational requirements with precision. Provide insights into specific tasks or challenges unique to your industry that may necessitate the incorporation of specialized attachments.

- Industry Specific Considerations -Opt for a crane manufacturer with in depth expertise in your industry. A manufacturer familiar with the intricacies of your sector is better equipped to tailor solutions that seamlessly integrate with your operational dynamics.

Customized Hooks

- Purpose Driven Design -Engage in a tailored design process for hooks, ensuring they align with the intricacies of your lifting needs. Consider factors such as load shape, size, and weight distribution to create hooks that optimize efficiency and safety.

- Safety Features -Incorporate safety features into customized hooks to prevent load slippage and enhance overall operational safety. These safety mechanisms should align with industry standards to ensure compliance and reliability.

Magnetic Attachments

- Magnetic Lifters -Explore the application of magnetic lifters for tasks involving ferrous materials. Magnetic attachments offer an efficient solution for lifting and transporting metal loads, contributing to streamlined material handling processes.

- Adjustable Magnetic Strength -Opt for magnetic attachments with adjustable strength settings. This feature provides precise control over the gripping force, allowing for flexibility based on the specific requirements of different loads.

Grabs and Clamps

- Grabs for Bulk Materials -Consider the use of grabs for efficient handling of bulk materials. Grabs are particularly suited for applications involving loose or granular materials, providing a secure and controlled lifting solution.

- Clamps for Sheet Materials -Explore the application of clamps for secure handling of sheet materials. Clamps offer precision in lifting and placing flat or sheet like loads, making them ideal for industries with such material requirements.

- Rotating Hooks -In scenarios where rotational capabilities are essential, explore the integration of rotating hooks into the crane system. These attachments facilitate precise positioning of loads during lifting and transporting operations. Telescopic Spreaders -Consider the use of telescopic spreaders for tasks that require extended reach. These attachments enhance the crane's flexibility by allowing it to handle loads at varying distances, catering to diverse operational needs.

Collaborative Design Process

- Engage in Design Discussions -Adopt a collaborative approach during the design phase, engaging in comprehensive discussions with the crane manufacturer. This ensures that the design of specialized attachments aligns seamlessly with your operational requirements and challenges.

- Prototype Testing -As part of the validation process, consider prototype testing for specialized attachments. Testing allows for the evaluation of performance and functionality, ensuring that the attachments meet or exceed expectations before full implementation.

By exploring and integrating a spectrum of specialized attachments into your customized overhead crane, you not only address specific operational challenges but also elevate the crane system to a level of adaptability that enhances overall efficiency. The guide will conclude with insights into market dynamics, additional considerations for buyers in Bolivia, and practical tips for acquiring the ideal overhead crane.

Work with Reputable Suppliers:

In the pursuit of a customized overhead crane for your operations in Bolivia, the choice of a supplier or manufacturer plays a pivotal role. This section underscores the critical importance of partnering with reputable and experienced entities in the industry, offering practical insights into the selection process.

Importance of Supplier Selection

Reliability and Experience

Proven Track Record:

Opt for suppliers with a demonstrable track record of reliability and experience in the field.

A well established supplier is more likely to deliver on promises and provide quality solutions.

Customization Expertise

Industry Specific Knowledge:

Seek suppliers with a deep understanding of your industry's nuances.

Customization expertise tailored to your sector ensures a crane system finely tuned to your operational needs.

Importance of Supplier Selection

Reliability and Experience

Proven Track Record:

Opt for suppliers with a demonstrable track record of reliability and experience in the field.

A well established supplier is more likely to deliver on promises and provide quality solutions.

Customization Expertise

Industry Specific Knowledge:

Seek suppliers with a deep understanding of your industry's nuances.

Customization expertise tailored to your sector ensures a crane system finely tuned to your operational needs.

Supplier's Customization Capabilities

Design Flexibility

Tailoring Solutions:

Assess the supplier's capability to tailor crane solutions to specific requirements.

Design flexibility is crucial for creating a crane system that aligns seamlessly with your operational demands.

Engineering Expertise

Technical Competence:

Evaluate the supplier's engineering expertise in the customization of overhead cranes.

Technical competence ensures the development of reliable and high performance crane systems.

After Sales Support and Maintenance

Service Commitments

After Sales Services:

Inquire about the supplier's after sales support and maintenance services.

A commitment to ongoing support ensures the longevity and optimal performance of your crane system.

Spare Parts Availability

Parts Inventory:

Check the availability of spare parts for the supplied crane systems.

A readily accessible inventory minimizes downtime during maintenance or repairs.

Transparent Communication

Open Dialogue

Communication Practices:

Prioritize suppliers with transparent and open communication practices.

Clear communication fosters a collaborative partnership throughout the customization process.

Project Timelines

Timeline Adherence:

Discuss and establish realistic project timelines with the supplier.

Adherence to timelines is a critical aspect of successful project execution.

Contractual Agreements

Clarity in Contracts

Detailed Agreements:

Ensure that contractual agreements are detailed and clear.

Clarity in contracts minimizes misunderstandings and ensures that both parties are aligned on expectations.

Warranty Provisions

Warranty Terms:

Examine warranty provisions for the supplied crane systems.

A robust warranty reflects the supplier's confidence in the quality and durability of their products.

By working with reputable and experienced suppliers in Bolivia, you pave the way for a successful collaboration that results in a customized overhead crane system meeting the highest standards of quality and performance. The guide will conclude with practical insights for buyers, summarizing key considerations and offering guidance on the acquisition of the ideal overhead crane.

Request Site Assessment and Consultation:

In the final stages of acquiring a customized overhead crane for your operations in Bolivia, the significance of a site assessment and consultation with the crane supplier cannot be overstated. This section emphasizes the practical steps of inviting suppliers for on site evaluations and seeking professional advice for the optimal crane design tailored to your unique requirements.

Importance of Site Assessment

Facility Understanding

On Site Dynamics:

Invite the crane supplier for a site assessment to gain a comprehensive understanding of your facility's dynamics.

This on site exploration allows for firsthand insights into spatial constraints, workflow intricacies, and potential challenges.

Customization Precision

Tailoring Solutions:

The site assessment enables the supplier to tailor crane solutions with precision.

Customization aligned with the specific characteristics of your facility ensures optimal performance.

Professional Consultation

Industry Specific Insights

Operational Nuances:

Engage in professional consultation with the supplier to gain insights into industry specific operational nuances.

Leverage the supplier's expertise to refine the crane design for enhanced efficiency.

Cost Efficient Solutions

Budget Considerations:

Seek advice on cost efficient solutions that meet your operational needs without compromising quality.

Professional consultation aids in finding a balance between functionality and budget constraints.

Tailored Crane Design

Spatial Considerations

Optimal Utilization:

The supplier's on site assessment informs the design process, ensuring optimal utilization of available space.

Crane designs are tailored to fit seamlessly into your facility layout.

Workflow Integration

Workflow Alignment:

Design considerations are aligned with your workflow requirements.

The crane system becomes an integral part of your operational processes, enhancing overall efficiency.

Safety and Compliance

Safety Recommendations

Risk Mitigation:

Receive safety recommendations based on the site assessment.

The supplier provides insights into potential safety hazards and proposes risk mitigation measures.

Regulatory Compliance

Adherence to Standards:

Ensure that the proposed crane design adheres to relevant industry standards and regulations.

Regulatory compliance is integral to a safe and legally sound operational environment.

Transparent Communication

Project Expectations

Clear Communication:

Use the consultation to communicate your project expectations clearly.

Align on deliverables, timelines, and any specific requirements crucial for project success.

Design Adjustments

Iterative Process:

Acknowledge that the design process may require adjustments based on consultation outcomes.

An iterative approach ensures that the final crane design precisely meets your operational needs.

Documentation and Agreements

Comprehensive Documentation

Project Outlines:

Ensure that the site assessment and consultation outcomes are comprehensively documented.

Project outlines, specifications, and agreements provide a clear foundation for moving forward.

Mutual Agreement

Alignment on Terms:

Achieve mutual agreement on project terms, including design specifications, costs, and timelines.

A transparent agreement minimizes the risk of misunderstandings during project execution.

By requesting a site assessment and engaging in professional consultation with the crane supplier, you set the stage for a collaborative and informed customization process. The guide concludes with practical insights for buyers, summarizing key considerations and providing guidance for the successful acquisition of an ideal overhead crane.

Get Detailed Quotations of Crane for Sale In Bolivia

As you progress towards finalizing the acquisition of a customized overhead crane for your operations in Bolivia, obtaining detailed quotations becomes a critical step. This section outlines the essential elements to request in a quotation, emphasizing comprehensive coverage of the customized crane, including design, manufacturing, installation, and ongoing support.

Elements of a Comprehensive Quotation

Design Phase

Inclusive Design Costs:

Request a breakdown of costs associated with the design phase.

Ensure that all design related expenses are transparently outlined in the quotation.

Manufacturing

Detailed Manufacturing Costs:

Gain insight into the manufacturing costs of the customized crane.

Understand the specifics of the materials, labor, and processes involved in the manufacturing phase.

Installation

Transparent Installation Expenses:

Clarify the costs associated with the installation of the overhead crane.

Ensure that expenses related to on site setup, testing, and commissioning are clearly detailed.

Ongoing Support

After Sales Service Costs:

Request information on the costs of ongoing support and maintenance.

Understand the expenses tied to regular inspections, repairs, and any other post installation services.

Warranty Terms

Warranty Duration

Clear Warranty Period:

Clearly stipulate the duration of the warranty period for the customized crane.

A transparent understanding of warranty timelines provides clarity on the scope of coverage.

Coverage Details

Comprehensive Warranty Coverage:

Seek detailed information on the components covered under warranty.

Understand the extent of coverage for parts, labor, and potential contingencies.

After Sales Service Offerings

Service Packages

Available Service Packages:

Inquire about available after sales service packages.

Explore options tailored to your operational needs, encompassing regular maintenance, emergency repairs, and other support services.

Response Time Commitments

Timely Support Commitments:

Clarify the supplier's commitments regarding response times for after sales service requests.

Understand how quickly support will be mobilized in case of emergencies or unexpected issues.

Clarifications on Quotation

Detailed Breakdown

Comprehensive Itemization:

Ensure that the quotation provides a detailed breakdown of all costs.

Itemization facilitates a clear understanding of the financial aspects of the project.

Scope of Work

Explicit Scope Definition:

Seek clarification on the scope of work covered by the quotation.

Explicitly define what is included and what may be considered additional or supplementary.

Negotiation and Agreement

Open Communication

Transparent Negotiations:

Engage in open communication regarding the quotation.

If there are areas of negotiation, clearly express your considerations and expectations.

Final Agreement

Mutual Consent:

Ensure that all parties involved reach a final agreement.

A well defined and agreed upon quotation sets the foundation for a successful partnership.

By requesting detailed quotations that encompass all aspects of the customized crane, including design, manufacturing, installation, and ongoing support, you establish a clear understanding of the financial commitment and scope of services. The guide concludes with practical insights for buyers, summarizing key considerations and providing guidance for the successful acquisition of an ideal overhead crane.

Review Customer Testimonials:

As you approach the final stages of your journey to acquire a customized overhead crane for operations in Bolivia, reviewing customer testimonials becomes a crucial step. This section highlights the significance of researching supplier reputation through customer reviews and testimonials, along with the value of considering referrals from businesses in Bolivia that have successfully implemented customized crane solutions.

Researching Customer Testimonials

Online Platforms

Explore Diverse Sources:

Utilize online platforms to access a variety of customer testimonials.

Websites, forums, and social media can offer insights into the experiences of other businesses with the crane supplier.

Genuine Feedback

Verify Authenticity:

Seek genuine and unbiased feedback from customers.

Authentic testimonials provide a realistic perspective on the supplier's performance and the quality of their customized crane solutions.

Importance of Customer Testimonials

Track Record Evaluation

Supplier Performance:

Evaluate the supplier's track record through customer testimonials.

Positive testimonials indicate a history of successful projects and satisfied clients.

Red Flags Identification

Potential Concerns:

Use testimonials to identify any potential red flags.

Consistent negative feedback may indicate issues that could impact your own experience with the crane supplier.

Referrals from Businesses in Bolivia

Industry Networks

Leverage Industry Connections:

Tap into industry networks to seek referrals from businesses in Bolivia.

Recommendations from within the local business community provide valuable insights.

Direct Communication

Engage in Direct Conversations:

Reach out to businesses that have implemented customized crane solutions.

Direct communication allows you to gather detailed information about their experiences.

Key Considerations in Referrals

Project Similarity

Relevance to Your Project:

Consider referrals from businesses with projects similar to yours.

Similarities in operational needs and project scope enhance the relevance of the feedback.

Performance Evaluation

Effectiveness of the Solution:

Evaluate the performance of the implemented crane solution in real world scenarios.

Feedback on how well the crane meets operational requirements is invaluable.

Balanced Perspective

Weighing Positive and Negative Feedback

Holistic Assessment:

Maintain a balanced perspective by considering both positive and negative feedback.

A holistic assessment provides a comprehensive view of the supplier's capabilities.

Open Dialogue

Communication with Referring Businesses:

Engage in open dialogue with businesses that provide referrals.

Seek detailed insights into their collaboration with the crane supplier.

Decision Informing Insights

Confidence in Supplier Selection

Informed Decision Making:

Use customer testimonials and referrals to make an informed decision.

Confidence in your supplier selection is bolstered by the positive experiences of others.

Aligning with Local Business Practices

Cultural Alignment:

Referrals from businesses in Bolivia offer insights into how well the supplier aligns with local business practices.

Cultural alignment can contribute to a smoother collaboration.

By reviewing customer testimonials and considering referrals from businesses in Bolivia, you gain valuable insights into the supplier's reputation and the real world performance of their customized crane solutions. The guide concludes with practical insights for buyers, summarizing key considerations and providing guidance for the successful acquisition of an ideal overhead crane.

Plan for Training and Maintenance:

As you approach the finalization of your customized overhead crane acquisition in Bolivia, meticulous planning for training and maintenance is essential. This section underscores the importance of engaging in discussions with the supplier regarding training programs for operators and maintenance staff. Additionally, it emphasizes the establishment of a preventive maintenance plan to guarantee the longevity and optimal performance of the crane system.

Operator Training Programs

Comprehensive Operator Training

In Depth Training Modules:

Discuss and establish comprehensive training programs for crane operators.

Training modules should cover operational procedures, safety protocols, and emergency response measures.

Hands On Practical Training

Practical Simulation Exercises:

Integrate hands on practical training sessions for operators.

Practical exercises enhance operator proficiency and confidence in handling the customized crane.

Maintenance Staff Training

Technical Maintenance Training

Technical Proficiency Building:

Plan training sessions for maintenance staff focusing on technical aspects.

Training should cover routine inspections, troubleshooting, and minor repairs.

Emergency Response Training

Quick Response Protocols:

Incorporate emergency response training for maintenance staff.

Equip them with the skills to address unforeseen issues promptly and efficiently.

Preventive Maintenance Plan

Periodic Inspection Schedules

Routine Checklists:

Collaborate with the supplier to establish periodic inspection schedules.

Routine checklists should cover crucial components, ensuring early detection of potential issues.

Lubrication and Wear Checks

Proactive Lubrication:

Define a proactive lubrication plan as part of preventive maintenance.

Regular wear checks should be conducted to assess the condition of moving parts.

Supplier's Support in Training

Training Materials

Comprehensive Training Materials:

Confirm the availability of comprehensive training materials from the supplier.

Materials should serve as a reference for ongoing learning and skill retention.

Continuous Learning Opportunities

Post Training Support:

Inquire about post training support from the supplier.

Continuous learning opportunities ensure that operators and maintenance staff stay updated on best practices.

Collaborative Maintenance Planning

Shared Maintenance Responsibilities

Clear Responsibilities:

Clearly define responsibilities for maintenance tasks.

Collaboration between your maintenance team and the supplier ensures a coordinated approach to upkeep.

Reporting Protocols

Efficient Issue Reporting:

Establish efficient protocols for reporting issues.

A streamlined reporting system facilitates quick supplier response in case of major concerns.

Long Term Performance Assurance

Warranty Backed Maintenance

Extended Warranty Options:

Explore extended warranty options for maintenance services.

An extended warranty period adds an additional layer of performance assurance.

Performance Guarantees

Supplier's Performance Commitment:

Seek assurances from the supplier regarding the crane's long term performance.

Supplier commitment contributes to your confidence in the reliability of the customized crane.

By proactively planning for training and maintenance, you lay the groundwork for a smooth and efficient operation of the customized overhead crane. The guide concludes with practical insights for buyers, summarizing key considerations and providing guidance for the successful acquisition of an ideal crane system.