10-30 tons Explosion-Proof Crane for Sale Trinidad and Tobago

Refineries in Trinidad and Tobago, such as the Pointe-à-Pierre Refinery, use these cranes to handle volatile and hazardous materials safely. Explosion-proof features are crucial for compliance with safety regulations and to prevent accidents.

Explosion-Proof Cranes:

- Definition: Explosion-proof cranes are specialized lifting equipment designed to operate safely in hazardous environments where there is a risk of explosive atmospheres. These cranes are engineered to prevent sparks and overheating that could ignite flammable gases or dust.

- Importance: Ensuring safety in environments with volatile substances is critical. Explosion-proof cranes help to mitigate the risk of explosions, protect personnel, and safeguard valuable infrastructure and materials. They comply with stringent safety regulations to prevent accidents and ensure reliable operation in hazardous conditions.

Double Girder Configuration:

- Definition: Double girder cranes have two parallel main girders that support the crane’s hoist and trolley system. This design provides enhanced strength and stability, making them suitable for heavy-duty applications.

- Importance: The double girder design allows for greater load capacities, wider spans, and improved structural integrity. It also offers more flexibility in terms of hoist movement and load handling, which is crucial in complex refinery operations where precise and safe material handling is required.

Application in Refinery Operations

Handling Volatile Materials:

Refineries process and handle a variety of hazardous materials, including refined oil products, chemical tanks, and other potentially explosive substances. Explosion-proof double girder cranes are essential for safely moving these materials within the refinery.

Operational Efficiency:

These cranes improve operational efficiency by facilitating safe and precise handling of heavy loads, minimizing downtime, and ensuring smooth operations in high-risk environments. Their robust design is tailored to meet the demanding conditions of refinery operations.

Overview of Refineries in Trinidad and Tobago

Refining Industry:

Trinidad and Tobago is home to significant refining operations, with a focus on processing crude oil and producing various refined petroleum products. The country’s refineries are critical to its economy, supplying both domestic and international markets.

Specific Focus on Pointe-à-Pierre Refinery and Its Operational Needs

- Operational Characteristics:The Pointe-à-Pierre Refinery operates with a variety of complex and hazardous materials, requiring high safety standards for equipment. The refinery’s operations involve the handling of large quantities of refined products and chemicals, which makes explosion-proof cranes essential.

- Crane Requirements:The refinery’s operational needs include reliable and safe material handling systems that can manage heavy and potentially explosive loads. Double girder cranes with explosion-proof features are tailored to meet these requirements, providing the necessary strength and safety for the refinery’s demanding environment.

- Safety and Compliance:The refinery must adhere to rigorous safety regulations to prevent accidents and ensure compliance with local and international standards. Explosion-proof cranes play a crucial role in maintaining safety and operational efficiency within this high-risk environment.

This introduction provides a comprehensive overview of the role and importance of explosion-proof double girder cranes in refinery operations, with a specific focus on the context of Trinidad and Tobago and the Pointe-à-Pierre Refinery.

double girder overhead explosion proof bridge crane for sale

Explosion-Proof Crane Requirements

Regulatory Standards and Compliance

International and Local Safety Standards

ATEX (Atmosphères Explosibles):

- Overview: A set of European Union directives governing equipment used in explosive atmospheres. The ATEX directives classify equipment based on the level of protection they offer in hazardous environments.

- Application: For explosion-proof cranes, ATEX certification ensures that the equipment meets the safety requirements for operating in environments where explosive gases or dust may be present. Cranes must be designed and manufactured to prevent ignition sources from causing explosions.

IECEx (International Electrotechnical Commission Explosive Atmospheres):

- Overview: An international certification scheme for equipment used in explosive atmospheres. IECEx provides standards for electrical and mechanical equipment, ensuring safety and reliability in hazardous environments.

- Application: Cranes with IECEx certification are validated for safety and reliability in explosive atmospheres, ensuring they meet global standards for preventing ignition sources in hazardous conditions.

Local Regulations in Trinidad and Tobago

Trinidad and Tobago adheres to international safety standards, such as those set by the International Organization for Standardization (ISO) and the Occupational Safety and Health Administration (OSHA), while also implementing local regulations tailored to address specific environmental and operational conditions unique to the region. These regulations are designed to ensure the safe and efficient operation of equipment in the country's diverse industrial landscape, particularly in the oil and gas sector.

Application

Local regulations in Trinidad and Tobago include specific requirements for equipment used in hazardous environments, like those encountered in the oil and gas industry. Key regulatory aspects include:

- Explosion-Proof Requirements Cranes and other equipment used in environments with flammable gases or vapors must be explosion-proof. This involves adhering to standards such as ATEX (Atmosphères Explosibles) or IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres).

- Environmental Protection Standards Regulations may mandate the use of corrosion-resistant materials and coatings to protect equipment from the aggressive chemicals and high humidity prevalent in industrial settings.

- Operational Safety Protocols Equipment must comply with local safety protocols that ensure safe operation, maintenance, and emergency procedures. This includes regular inspections, maintenance schedules, and training for personnel.

- Compliance and Certification All equipment must be certified to meet both international and local standards. Compliance is verified through inspections and certifications issued by authorized bodies to ensure that equipment is safe and fit for use in specific environments.

- Documentation and Record-Keeping Facilities are required to maintain detailed records of equipment specifications, inspection reports, maintenance logs, and compliance certifications. This documentation is essential for audits and regulatory reviews.

Compliance with both international and local regulations is crucial for ensuring safety, efficiency, and legal operation within Trinidad and Tobago's oil and gas industry. Adhering to these standards not only protects personnel and equipment but also ensures the facility operates within the legal framework, avoiding penalties and enhancing operational reliability.

Specific Regulations for Trinidad and Tobago

Occupational Safety and Health Regulations

Trinidad and Tobago's Occupational Safety and Health (OSH) regulations govern safety standards in workplaces, including refineries and other hazardous environments. These regulations are designed to protect workers and ensure safe operational practices.

Application

Explosion-Proof Cranes Must comply with OSH regulations, ensuring they are safe to operate in environments with flammable gases or vapors. This compliance involves:

Adhering to standards such as ATEX or IECEx for explosion-proof equipment.

Regular inspections and maintenance to ensure ongoing compliance with safety standards.

Implementing safety protocols for the operation and maintenance of cranes in hazardous locations.

Training workers on the safe use and handling of explosion-proof equipment to prevent accidents and ensure a safe working environment.

Environmental and Industry Standards

Trinidad and Tobago has specific environmental and industry standards for the oil and gas sector, focusing on the safe handling of hazardous materials and maintaining operational safety. These standards are aimed at minimizing environmental impact and ensuring the safety of operations.

Application

Refinery Compliance Refineries must adhere to these standards, ensuring that all equipment, including explosion-proof cranes, meets necessary safety and performance criteria. This involves:

Using corrosion-resistant materials and coatings to protect equipment from aggressive chemicals and environmental conditions.

Ensuring that equipment is designed and maintained to handle hazardous materials safely.

Conducting regular audits and inspections to verify compliance with environmental and industry standards.

Maintaining detailed records of equipment specifications, inspection reports, and maintenance logs for regulatory reviews.

Implementing emergency response plans and safety protocols to handle potential accidents or spills involving hazardous materials.

Compliance with both OSH regulations and environmental and industry standards in Trinidad and Tobago is essential for the safe and efficient operation of equipment in the oil and gas industry. Ensuring that explosion-proof cranes and other equipment meet these regulations protects workers, minimizes environmental impact, and ensures legal operation within the country.

Explosion-Proof Features

Design and Construction for Hazardous Environments

Explosion-Proof Enclosures

Explosion-proof enclosures are critical safety components designed to prevent the ignition of explosive gases or dust within a crane’s electrical and mechanical systems. These enclosures are engineered to contain and isolate potential ignition sources, ensuring that any internal explosions do not result in external ignition, thus maintaining the safety of the surrounding environment.

Key Features:

- Containment: Built to withstand internal explosions and prevent flames or sparks from escaping.

- Robust Construction: Made from durable materials such as cast aluminum, stainless steel, or heavy-duty alloys to ensure integrity under extreme conditions.

- Sealing and Insulation: Equipped with advanced sealing mechanisms to prevent the ingress of flammable gases, dust, or moisture.

- Temperature Control: Designed to manage and dissipate heat effectively, preventing overheating of internal components.

Application

In hazardous environments, such as oil and gas refineries, it is essential to house all electrical components within explosion-proof enclosures to mitigate the risk of ignition. This includes:

- Motors: Enclosed to prevent sparks or heat from igniting explosive atmospheres.

- Control Panels: Protected to ensure safe operation and prevent electrical faults from causing explosions.

- Wiring: Insulated and enclosed to prevent electrical arcing and sparking.

- Lighting Systems: Sealed within explosion-proof fixtures to provide safe illumination without risk of igniting gases or dust.

Implementation Steps:

- Assessment: Evaluate the specific hazardous environment to determine the level of explosion-proof protection required.

- Selection: Choose appropriate enclosures based on the classification of explosive materials present (e.g., gas, vapor, dust).

- Installation: Ensure proper installation by certified professionals to maintain the integrity of the explosion-proof design.

- Maintenance: Conduct regular inspections and maintenance to ensure enclosures remain sealed and functional, preventing any potential ignition sources from developing over time.

Explosion-proof enclosures are essential for the safe operation of cranes in hazardous environments, particularly in the oil and gas industry. By housing all electrical components in these protective enclosures, facilities can significantly reduce the risk of ignition and ensure compliance with stringent safety regulations.

Material and Construction

The construction of cranes for use in harsh and explosive environments, such as those found in the oil and gas industry, demands the use of specialized materials. These materials must be both corrosion-resistant and fire-resistant to ensure the crane's durability and safety. The selection of materials is based on their ability to withstand the specific environmental stresses they will encounter, including exposure to aggressive chemicals, high temperatures, and potential fire hazards.

Key Characteristics:

- Corrosion Resistance: Materials must resist chemical reactions that cause degradation when exposed to corrosive substances like sulfur and other by-products.

- Fire Resistance: Materials should be able to endure high temperatures and not contribute to the spread of fire.

- Durability: High strength-to-weight ratio to ensure longevity and maintain performance under heavy loads and continuous operation.

Application

Crane Components:

Girders:

- Material: Typically made from high-strength, corrosion-resistant steel, such as stainless steel or weathering steel.

- Coatings: Often coated with epoxy or other protective layers to enhance corrosion resistance and durability.

Hoists:

- Material: Constructed from corrosion-resistant metals and alloys, such as aluminum or specially treated steel.

- Sealing: Enclosed in explosion-proof housings to protect internal components from environmental exposure and ignition sources.

Trolleys:

- Material: Made from durable, corrosion-resistant steel or composite materials.

- Design: Designed to operate smoothly and efficiently, even under harsh conditions, with sealed bearings and protected mechanisms.

Benefits:

- Increased Lifespan: Use of high-quality, corrosion-resistant materials reduces wear and tear, extending the operational life of the crane.

- Enhanced Safety: Fire-resistant materials and explosion-proof designs prevent accidents in hazardous environments, protecting both equipment and personnel.

- Reduced Maintenance: Durable materials decrease the frequency and cost of maintenance, ensuring reliable performance and operational efficiency.

Implementation Steps:

- Material Selection: Choose materials based on the specific environmental conditions and stress factors present in the operational environment.

- Protective Coatings: Apply suitable coatings to further enhance the resistance of materials to corrosion and high temperatures.

- Quality Assurance: Implement rigorous testing and quality control measures to ensure all materials and components meet the required safety and performance standards.

- Regular Maintenance: Establish a maintenance schedule to inspect and maintain the integrity of the materials and coatings, ensuring long-term durability and safety.

The use of corrosion-resistant and fire-resistant materials in the construction of single girder cranes is essential for their safe and durable operation in the oil and gas industry. By carefully selecting and treating these materials, facilities can ensure their cranes withstand harsh environmental conditions, maintain high performance, and provide long-term reliability and safety

Flameproof Joints and Connections

Flameproof joints and connections are critical design features in cranes used in hazardous environments. These components are engineered to prevent flames or sparks from escaping through joints and connections, which could otherwise ignite flammable gases or dust present in the environment. Ensuring that these joints and connections are flameproof is essential for maintaining the overall safety of the crane and preventing it from becoming a source of ignition.

Key Features:

- Flame Containment: Joints and connections are designed to contain any internal flames or sparks, preventing them from igniting external flammable substances.

- Sealing Mechanisms: Advanced sealing techniques are used to ensure airtight and flame-tight connections.

- Durability: Built to withstand high pressures and temperatures, maintaining integrity under harsh conditions.

Application

Crane Components:

Joints:

- Design: Constructed with tight tolerances to ensure no gaps through which flames or sparks could escape.

- Materials: Made from flame-resistant materials that can endure high temperatures without degrading.

- Testing: Subjected to rigorous testing to ensure they meet flameproof standards and can contain any internal ignition sources.

Connections:

- Electrical Connections: Enclosed in flameproof housings to prevent electrical sparks from escaping.

- Mechanical Connections: Designed to maintain tight seals, even under mechanical stress, to prevent any escape of flames.

- Seals: Utilized to ensure that all connections are airtight and flame-tight, using materials that resist both flames and corrosive substances.

Seals:

- Material: Constructed from high-temperature-resistant materials that do not degrade over time.

- Installation: Proper installation is crucial to ensure the effectiveness of the seals in containing potential ignition sources.

Benefits:

- Increased Safety: Prevents the crane from becoming a source of ignition in hazardous environments, protecting both equipment and personnel.

- Compliance: Meets stringent safety regulations and standards for operation in explosive atmospheres, such as ATEX or IECEx.

- Reliability: Ensures the crane operates safely and effectively even under extreme conditions, minimizing the risk of accidents.

Implementation Steps:

- Design and Engineering: Incorporate flameproof joints and connections into the crane design, ensuring all components are aligned with safety standards.

- Material Selection: Use materials that are both flame-resistant and durable, capable of withstanding high temperatures and pressures.

- Quality Control: Implement thorough testing and quality assurance processes to verify the integrity and effectiveness of flameproof joints and connections.

- Maintenance: Regularly inspect and maintain these components to ensure they continue to function correctly and provide the necessary protection.

Flameproof joints and connections are essential for ensuring the safety of cranes operating in hazardous environments, particularly in the oil and gas industry. By preventing flames or sparks from escaping, these design features protect against the risk of ignition, ensuring safe operation and compliance with safety regulations. Proper design, material selection, and maintenance of these components are crucial for maintaining the safety and reliability of the crane.

Certification and Testing Processes

Certification Process

Overview: The certification process involves verifying that the crane meets all relevant safety standards and regulations specific to hazardous environments. This includes a comprehensive assessment of the crane's design, construction, and performance to ensure it can operate safely in explosive conditions.

Application:

- Accreditation: The crane must be certified by accredited bodies such as ATEX (Atmosphères Explosibles) or IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres).

- Design Assessment: Evaluates the crane’s design features to ensure they include necessary explosion-proof components, such as flameproof enclosures and corrosion-resistant materials.

- Construction Verification: Inspects the construction process to confirm that materials and assembly techniques meet stringent safety standards.

- Performance Evaluation: Tests the crane’s operational performance in simulated hazardous conditions to verify its safety and reliability.

Testing Procedures

Detailed testing procedures are conducted to simulate hazardous conditions and ensure the crane's performance and safety. These tests include evaluating electrical safety, structural integrity, and resistance to explosive atmospheres.

Application:

- Electrical Safety Tests: Ensure that all electrical components and wiring are safe and will not ignite explosive gases or dust.

- Structural Integrity Tests: Confirm that the crane can withstand environmental stresses such as high temperatures, corrosive substances, and mechanical loads.

- Explosive Atmosphere Resistance: The crane is exposed to controlled explosive conditions to verify that it can operate safely without causing ignition.

- Thermal Testing: Evaluates the crane’s ability to manage and dissipate heat to prevent overheating in explosive environments.

Documentation and Reporting

Comprehensive documentation is required to verify the crane's compliance with safety standards. This includes detailed test reports, certification documents, and safety assessments, which serve as proof of compliance.

Application:

- Test Reports: Detailed reports documenting the results of all tests conducted, including methodologies and outcomes.

- Certification Documents: Official certificates from accredited bodies verifying that the crane meets all relevant safety standards and regulations.

- Safety Assessments: Thorough evaluations of the crane’s safety features and performance, highlighting its suitability for operation in hazardous environments.

- Maintenance Records: Documentation of all maintenance activities performed on the crane to ensure ongoing compliance and safety.

- Compliance Documentation: Records demonstrating adherence to both international standards (e.g., ATEX, IECEx) and local regulations specific to Trinidad and Tobago.

Conclusion

This section outlines the key requirements for explosion-proof cranes in refineries, focusing on compliance with safety standards, Trinidad and Tobago regulations, and essential explosion-proof features. Certification and rigorous testing ensure these cranes operate reliably in harsh conditions.

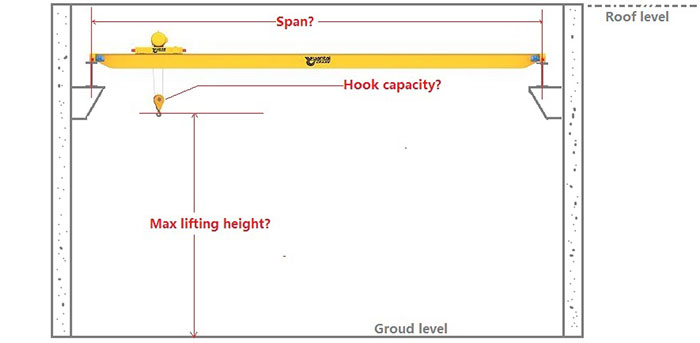

Main specifications required to custom your overhead bridge cranes

Technical Specifications

Capacity and Span

- Capacity :Crane capacities of 10 to 30 tons are ideal for handling heavy materials in refineries, ensuring safe and efficient load movement. Factors include load distribution and specific operational needs.

- Span :Span defines the crane’s reach and must cover critical refinery areas while allowing necessary clearances for safe operation.

Material and Coating

- Materials:Corrosion-resistant materials like stainless steel and epoxy coatings enhance durability and performance in harsh refinery environments.

- Design Considerations:Sealed components prevent corrosion, reducing maintenance needs and extending crane lifespan.

Span Considerations

- Span :The span must cover essential refinery areas, with design tailored to facility layout and clearance requirements for effective operation.

Load Handling

- Types of Loads:Cranes handle various loads, including refined oil products and chemical tanks, each requiring specific handling features.

- Capacity and Safety:Ensure the crane’s capacity meets operational needs with safety features like overload protection and regular maintenance.

Materials and Construction

- Materials:Use corrosion-resistant materials to withstand environmental factors, ensuring crane durability in refineries.

- Environmental Impact:Protective coatings and regular maintenance are necessary to manage high humidity, extreme temperatures, and salt exposure.