10 Ton Single Girder Gantry Crane for Power Station Zimbabwe

10 ton gantry crane for sale Zimbabwe - Single girder gantry crane 10 ton for power station, custom electric wire rope hoist gantry crane & goliath crane.

What is Single Girder Gantry Crane?

The Electric Single Girder Gantry Crane stands out as a widely employed lifting apparatus, finding extensive utility across diverse sectors, including manufacturing, railways, highways, construction, power generation, shipyards, and ports. This motorized Single Girder Gantry Crane typically pairs with electric wire rope hoists or electric chain hoists, making it ideal for handling heavy loads. Its deployment not only enhances workshop productivity but also ensures operational safety. In catering to diverse lifting requirements and work settings, Yuantai Crane offers a range of electric Single Girder Gantry Cranes for sale, encompassing options like the single girder variant, double girder model, semi-gantry crane, truss-style design, and portable solution. 10 ton sigle girder gantry crane for sale Zambia

10 ton sigle girder gantry crane for sale Zambia

Overview of 10 ton gantry crane for Zambia

In response to the burgeoning demand for dependable and efficient equipment to support construction and maintenance efforts in Zimbabwe's expanding power sector, there is a growing imperative for robust lifting solutions capable of effortlessly handling substantial loads while enhancing operational efficacy. Recently, Yuantai Crane stepped up to the plate by providing a 10-ton single girder gantry crane to a power station in Zimbabwe. This offering serves as an economical and steadfast material handling answer for outdoor projects.

Customer Background:

Our esteemed client hails from a prominent power station situated in Zimbabwe, steadfastly committed to fulfilling the energy requirements of the region. With a keen focus on optimizing power generation and minimizing downtime, they oversee an array of heavy machinery and equipment. However, their existing lifting equipment was found wanting in terms of both efficiency and load-bearing capacity.

Customer Requirements:

Recognizing the critical need to upgrade their lifting apparatus, our client sought a professional solution that would seamlessly deliver reliable lifting operations. They articulated their requirements with precision, stipulating the necessity for a 10-ton single girder gantry crane capable of precisely managing diverse loads, ensuring a secure working environment for their personnel, and mitigating operational hindrances.

Our Single Girder Gantry Crane Design Solutions:

Cognizant of our customers' imperative need for dependable lifting solutions, our team of experts conducted a meticulous analysis of the requirements, culminating in tailor-made design solutions. Our proposal centered around a 10-ton single girder gantry crane equipped with a wire rope hoist, boasting an 8-meter span and a 2.7-meter lifting height. This bespoke design was meticulously crafted to align with the distinctive operational demands of the power station, ensuring efficiency and safety in equal measure.

The Single Girder Electric Wire Rope Hoist Gantry Crane comes equipped with its own power supply, exemplifying a sustainable and eco-conscious solution that aligns seamlessly with the customer's dedication to environmental stewardship. These Electric Single Girder Gantry Cranes not only eliminate the need for excessive physical exertion within power stations but also effectively mitigate worker fatigue while significantly enhancing overall work efficiency.

Benefits and Features of the Single Girder Electric Wire Rope Hoist Gantry Crane:

- Efficiency Enhancement: This crane optimizes workflow by swiftly and precisely handling heavy loads, reducing downtime and boosting overall productivity.

- Environmental Responsibility: It operates with its dedicated power supply, aligning perfectly with green initiatives and reducing the carbon footprint.

- Worker Well-being: By eliminating strenuous manual labor, it enhances safety and reduces worker fatigue, promoting a healthier and more productive workforce.

- Customizable Design: Tailored to your specific needs, it can be configured with various lifting capacities, spans, and lifting heights, ensuring versatility for diverse applications.

- Precise Control: The crane offers precise load control, ensuring safe and accurate placement of materials, even in tight or complex spaces.

- Durability and Reliability: Constructed with robust materials and precision engineering, it delivers long-lasting, dependable performance, minimizing maintenance requirements.

- Space Optimization: The single girder design maximizes available workspace while providing ample clearance for efficient material handling.

- Remote Operation: It can be operated remotely, allowing for safe control from a distance, further enhancing worker safety.

- Adaptability: Suitable for various industries and applications, including manufacturing, construction, power generation, and more, making it a versatile choice.

- Cost-Efficiency: Its efficient operation and reduced maintenance needs translate into long-term cost savings.

- Safety Features: Equipped with safety mechanisms such as overload protection and emergency stop controls, ensuring a secure working environment.

- Compliance: Complies with industry standards and regulations, guaranteeing safe and reliable operation.

Incorporating these benefits and features, the Single Girder Electric Wire Rope Hoist Gantry Crane represents a smart and sustainable choice for businesses seeking to enhance their lifting operations while prioritizing safety and efficiency.

Main parts and components productions of 10 ton single girder gantry goliath cranes

10 ton gantrty crane main girder for sale Zambia

10 ton gantrty crane main girder for sale Zambia  gantry crane equipted with 10 ton single girder wire rope hoist

gantry crane equipted with 10 ton single girder wire rope hoist  cable roll of gantry crane 10 ton for Zambia

cable roll of gantry crane 10 ton for Zambia

Types of goliath cranes for Sale in Zimbabwe:

The electric goliath crane for sale in Zimbabwe comes in multiple configurations and sizes to suit your individual applications. Yuantai Crane are also capable of providing customized electric goliath cranes for your particular needs.

Main types of goliath cranes and gantry cranes

Gantry cranes and Goliath cranes come in various types and configurations to suit different lifting and material handling needs. Here are some common types of gantry cranes and Goliath cranes:

- Single Girder Gantry Crane: This type of crane features a single horizontal beam (girder) supported by legs on both sides. It's a cost-effective solution for light to moderate lifting capacities and is commonly used in workshops, warehouses, and manufacturing facilities.

- Double Girder Gantry Crane: In contrast to the single girder crane, the double girder gantry crane has two horizontal beams (girders) running parallel to each other. It offers higher lifting capacities and is suitable for heavy-duty applications in industries like steel production and shipyards.

- Box Girder Gantry Crane: This type of gantry crane features a box-shaped girder, which offers greater strength and stability, making it ideal for heavy loads and outdoor applications, such as container handling at ports.

- Rubber-Tired Gantry Crane (RTG): RTGs are mobile gantry cranes commonly used in container terminals. They are mounted on rubber tires, allowing for easy movement around the terminal to handle containers stacked in rows.

- Rail-Mounted Gantry Crane (RMG): RMGs are typically used in container yards and are mounted on rails. They can handle containers stacked in rows with high precision and efficiency.

- Semi-Gantry Crane: Semi-gantry cranes have one end supported by a building structure or wall, while the other end is supported by legs. They are suitable for applications where only partial coverage is needed, such as loading docks.

Light and portable gantry cranes

Portable gantry cranes come in several main types, each designed for specific lifting needs and environments. These types of portable gantry cranes include:

- Adjustable Height Portable Gantry Crane: These gantry cranes feature telescoping or adjustable-height legs, allowing you to raise or lower the crane to the desired working height. This flexibility is useful for accommodating various load sizes and work environments.

- Aluminum Portable Gantry Crane: Constructed from lightweight aluminum, these cranes are easy to move and ideal for applications where corrosion resistance is essential, such as in cleanroom environments or outdoor settings.

- Steel Portable Gantry Crane: Steel gantry cranes are robust and durable, suitable for heavy-duty lifting tasks. They can handle heavier loads compared to aluminum gantry cranes and are commonly used in manufacturing, workshops, and construction sites.

Adjustable Span Portable Gantry Crane: These gantry cranes feature an adjustable span, allowing you to extend or retract the horizontal beam as needed. This versatility is beneficial for accommodating different workspaces and load sizes. - Folding Portable Gantry Crane: Folding gantry cranes are designed to fold or collapse for easy storage and transportation. They are commonly used in settings where space is limited or when the crane needs to be moved frequently.

When looking for portable gantry cranes and Goliath cranes for sale, you can find various options and configurations based on your specific lifting requirements and the nature of your operations. It's essential to consider factors such as lifting capacity, span, height, mobility, and environmental conditions to choose the most suitable type of crane for your needs.

How to get Single Girder Gantry Crane price?

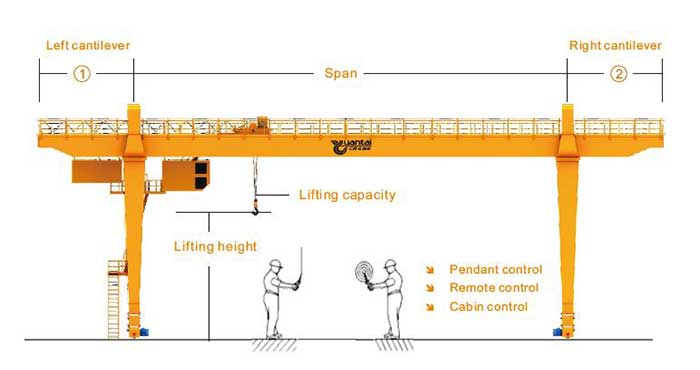

To buy a suitable Single Girder Gantry Crane, please help to confirm the Single Girder Gantry Crane specifications with the Single Girder Gantry Crane manufacturer first, to get a specific Single Girder Gantry Crane solution efficiently and accurately:

- Types of Single Girder Gantry Crane: Full gantry or semi-gantry? Single girder or double girder gantry? Truss gantry girder design or box girder design? Fixed or Movable Gantry Crane?

- Lifting capacity: _tons?

- Span: distance between the railway center _meters?

- Cantilevers: Single cantilever or Double cantilevers? Or without cantilevers?

- Lifting height: height of lifting from the ground to the lift center (Hook) _meters?

- Application or Working Conditions?

- Control methods: Remote control / Cabin control /Panel control?

- Power supply: _V/_Hz/3 Phase?