Overhead Cranes 5 to 10 Tons for Automobile Part Cylinder Handling

5 to 10 Tons Overhead Cranes for Automobile Parts – Cylinder Heads and Crankshafts

5-10 tons overhead cranes efficiently handle cylinder heads and crankshafts in automotive manufacturing, ensuring precise, safe, and productive operations.

In automotive manufacturing, the efficient handling of heavy and intricate components is crucial to maintaining production flow and ensuring quality. Overhead cranes play a vital role in this process by enabling the safe and precise movement of parts within the factory. These cranes are designed to handle a wide range of automotive components, but the 5 to 10-ton capacity range is particularly important for managing heavier and more complex items like cylinder heads and crankshafts.

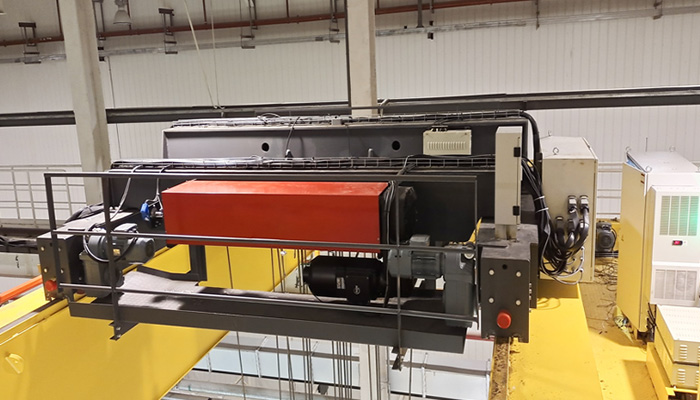

European style double girder overhead cranes for sale

Importance of Overhead Cranes in Automotive Manufacturing

Overhead cranes are indispensable in automotive manufacturing due to their ability to lift and transport large and heavy components with precision. These cranes provide a solution for moving parts through various stages of production, assembly, and maintenance. Their use helps prevent manual lifting injuries, reduces production downtime, and ensures that components are handled gently to avoid damage. The integration of overhead cranes into manufacturing processes supports higher efficiency and accuracy, which are essential for meeting production targets and maintaining quality standards.

Relevance of the 5 to 10-Ton Capacity Range

The 5 to 10-ton capacity range of overhead cranes is specifically designed to handle heavy automotive parts, including cylinder heads and crankshafts. Cylinder heads and crankshafts are critical engine components that are both heavy and complex. They require careful handling to avoid damage during production and assembly. Overhead cranes with this capacity range are equipped to manage these parts effectively, providing the strength and precision needed to handle their weight and ensure safe movement within the manufacturing facility.

By choosing overhead cranes with a 5 to 10-ton capacity, automotive manufacturers can optimize their production lines for efficiency and safety. These cranes are robust enough to support the weight of heavy components while offering the precision needed for accurate handling. This balance of power and precision makes them an ideal choice for handling cylinder heads and crankshafts, ensuring smooth operations and high-quality outcomes in automotive manufacturing.

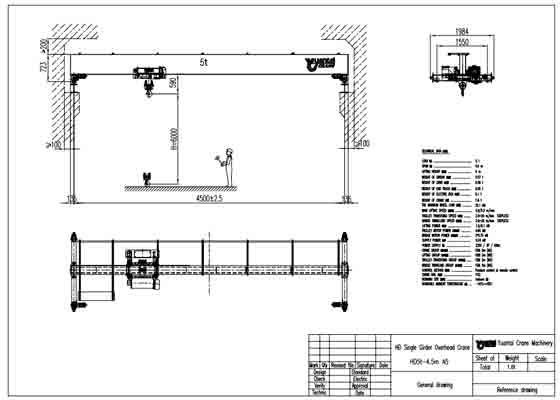

5 Ton Overhead Crane

Overview: A 5-ton overhead crane is designed to handle medium loads, making it suitable for various industrial applications where lighter to medium-heavy components need to be lifted and moved. This crane type is versatile and commonly used in smaller manufacturing facilities, warehouses, and workshops.

Key Features:

- Load Capacity: Up to 5 tons, ideal for handling lighter to medium-heavy loads.

- Design Variations: Available in both single girder and double girder configurations. Single girder cranes are typically used for lighter tasks and are more cost-effective, while double girder cranes offer enhanced stability and load handling capabilities.

- Hoist and Trolley Systems: Features hoists with sufficient capacity for 5-ton loads, along with trolleys that move along the crane's bridge. Includes options for manual, electric, or pneumatic hoists depending on the application.

- Applications: Commonly used in automotive parts manufacturing, small machinery handling, and general industrial tasks.

Benefits:

- Cost-Effective: Generally less expensive to purchase and maintain compared to higher capacity cranes.

- Space Efficiency: Suitable for facilities with limited space, as single girder models have a smaller footprint.

- Versatility: Adaptable to various tasks including assembly, maintenance, and light-duty lifting.

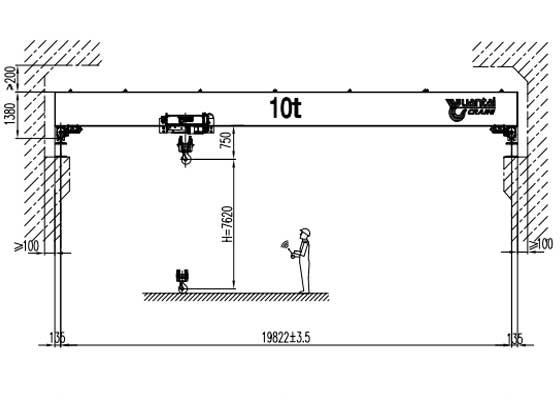

10 Ton Overhead Crane

Overview: A 10-ton overhead crane is designed for heavier lifting tasks, offering greater capacity compared to 5-ton models. It is commonly used in industries that require lifting and moving heavier components, such as automotive manufacturing, construction, and heavy equipment maintenance.

Key Features:

- Load Capacity: Up to 10 tons, accommodating heavier and larger components.

- Design Variations: Available in both single girder and double girder designs. Single girder cranes are cost-effective and suitable for lighter tasks, while double girder cranes offer greater load capacity and stability.

- Hoist and Trolley Systems: Equipped with more powerful hoists and trolleys to handle the increased load. Features include variable speed controls, load limit switches, and smooth start/stop mechanisms for precise operation.

- Applications: Ideal for handling medium to heavy automotive parts, large machinery components, and in manufacturing environments requiring robust lifting solutions.

Benefits:

- Increased Capacity: Suitable for handling heavier loads than a 5-ton crane, making it appropriate for more demanding tasks.

- Improved Stability: Double girder configurations enhance stability and reduce load sway, providing more precise control during lifting operations.

- Enhanced Efficiency: Streamlines heavy lifting tasks, improving overall operational productivity and reducing manual labor.

In summary, the 5-ton and 10-ton overhead cranes cater to different lifting needs based on load capacity and application requirements. The 5-ton crane is ideal for lighter tasks and smaller facilities, while the 10-ton crane is suited for heavier lifting and more demanding industrial applications.

Precision Control Systems

Importance of Precision

In the automotive manufacturing industry, precision in handling components like cylinder heads and crankshafts is crucial. These parts are not only heavy but also intricate, requiring exact placement and movement to avoid damage. Precision control systems in overhead cranes ensure that these components are lifted, moved, and positioned with utmost accuracy. This reduces the risk of accidental impacts or misalignment, which can lead to defects or costly delays in production.

The role of precision in handling complex automotive components extends beyond just avoiding damage. It also ensures smooth operations within the manufacturing line. Accurate handling contributes to a streamlined workflow, where parts are efficiently moved between stages of production without unnecessary interruptions. This helps maintain a steady pace in manufacturing and improves overall productivity.

Control Technologies

Modern overhead cranes are equipped with advanced control systems that significantly enhance their accuracy and reliability. Two key technologies used in these systems are:

- Variable Frequency Drives (VFDs): VFDs control the speed of the crane's motors by adjusting the frequency of the electrical power supplied to them. This allows for smooth acceleration and deceleration, which is essential when handling heavy and delicate components. VFDs help in fine-tuning the crane’s movements, making it easier to position parts with precision and reducing the risk of sudden jolts or jerks that could damage the components.

- Programmable Logic Controllers (PLCs): PLCs are specialized computers used to control the crane’s operations. They manage the crane’s movements based on programmed instructions, ensuring that each action is carried out accurately and consistently. PLCs can be programmed to execute complex sequences, allowing for precise control of lifting, lowering, and traversing operations. This programmability also enables operators to set specific handling parameters, further enhancing the crane's ability to manage delicate and heavy parts effectively.

By integrating these control technologies, overhead cranes offer enhanced precision and reliability. They ensure that automotive components are handled with the exactitude needed to maintain quality and efficiency in the manufacturing process. These advanced systems contribute to smoother operations, minimizing the risk of errors and optimizing overall productivity in automotive manufacturing facilities.

Applications in Automotive Manufacturing

Handling Cylinder Heads

Handling cylinder heads presents several challenges due to their weight, size, and complexity. These engine components are typically heavy and have intricate shapes, making them difficult to maneuver manually or with basic lifting equipment. Overhead cranes with a 5 to 10-ton capacity are ideally suited for these tasks due to their ability to lift heavy loads while providing precise control.

Challenges and Requirements:

- Weight and Size: Cylinder heads are often bulky and weigh several hundred kilograms. Cranes must be able to handle these weights without compromising stability or precision.

- Complex Shape: The irregular shape of cylinder heads requires careful handling to prevent damage to delicate surfaces and internal passages.

- Precision Handling: Accurate positioning is crucial during the assembly and maintenance phases to ensure that cylinder heads align correctly with other engine components.

Examples of Crane Use:

- Assembly Lines: On automotive assembly lines, overhead cranes are used to lift cylinder heads from storage or machining stations and position them accurately onto engine blocks. This ensures smooth integration into the engine assembly process.

- Maintenance Facilities: In maintenance and repair shops, cranes facilitate the removal and replacement of cylinder heads during engine overhauls. The precision of the crane's control systems ensures that cylinder heads are handled gently, preventing damage to both the component and the engine.

Handling Crankshafts

Crankshafts are another critical component in automotive engines that require careful handling due to their weight and length. Effective handling of crankshafts involves considerations related to their size, shape, and the precision needed to ensure proper assembly.

Special Considerations:

- Length and Weight: Crankshafts are long and heavy, necessitating cranes that can support their full length and weight without bending or flexing.

- Balancing: Proper balance is essential when lifting and positioning crankshafts to avoid deformation or damage.

- Alignment: Accurate alignment is crucial when positioning crankshafts in engine blocks to ensure smooth operation and prevent mechanical issues.

Case Studies or Examples:

- Crankshaft Manufacturing: In crankshaft manufacturing facilities, overhead cranes are used to transport finished crankshafts from machining stations to storage or packaging areas. The cranes' precision control systems allow for careful handling and placement, preserving the quality of the finished product.

- Engine Assembly: During engine assembly, cranes are employed to position crankshafts within engine blocks. The cranes must ensure that crankshafts are aligned correctly to avoid misalignment and ensure proper engine function. In some cases, automated systems integrated with the crane's control technology provide additional accuracy and efficiency.

By addressing the specific challenges associated with handling cylinder heads and crankshafts, overhead cranes equipped with advanced precision control systems enhance the efficiency and safety of automotive manufacturing processes. Their ability to manage heavy and complex components effectively ensures high-quality production and assembly outcomes.

Safety Features

Built-in Safety Mechanisms

Safety is a paramount concern when operating overhead cranes, especially when handling heavy and complex components like cylinder heads and crankshafts. Modern cranes are equipped with a range of built-in safety features designed to protect both the operators and the equipment.

Overview of Safety Features:

- Load Limiters: Load limiters are devices that prevent the crane from lifting loads that exceed its rated capacity. They monitor the weight being lifted and provide an alert or automatically halt operations if the load approaches or exceeds safe limits. This feature helps prevent overloading, which could lead to equipment failure or accidents.

- Emergency Stops: Emergency stop buttons are strategically placed on the crane and its control panel. These buttons allow operators to quickly shut down the crane in case of an emergency, stopping all movements to prevent accidents or damage. The presence of accessible and reliable emergency stops is crucial for immediate response during critical situations.

- Safety Brakes: Safety brakes are designed to hold the load securely in place when the crane is not in operation. These brakes engage automatically if there is a sudden loss of power or other operational issues. They ensure that the load remains stable and does not accidentally shift or fall, which is essential for preventing accidents.

Importance of Safety Features: These safety mechanisms are critical in preventing accidents, reducing the risk of injury, and ensuring the reliable operation of the crane. By incorporating these features, manufacturers can safeguard their workers and maintain a safe working environment. Regular maintenance and proper use of these safety systems are essential for their effectiveness and reliability.

Maintenance and Inspections

To ensure the continued safety and performance of overhead cranes, regular maintenance and inspections are necessary. Proper upkeep helps identify potential issues before they become serious problems, thereby reducing the risk of accidents and extending the life of the equipment.

Regular Maintenance Practices:

- Routine Checks: Conduct regular checks of the crane’s mechanical and electrical systems, including hoists, trolleys, and control panels. This helps ensure that all components are functioning correctly and that any wear and tear are addressed promptly.

- Lubrication: Ensure that all moving parts are properly lubricated to minimize friction and wear. Regular lubrication helps prevent mechanical failures and ensures smooth operation.

- Calibration: Periodically calibrate control systems and load limiters to ensure they are accurate and functioning within their specified parameters.

Recommended Inspection Schedules and Procedures:

- Daily Inspections: Operators should perform daily visual inspections before use, checking for obvious signs of damage or malfunction. This includes inspecting hooks, cables, and safety features.

- Monthly Inspections: Conduct more detailed inspections monthly, focusing on mechanical components, control systems, and safety devices. This includes checking for any signs of wear or potential issues that could affect performance.

- Annual Inspections: An in-depth annual inspection by a certified technician is essential. This comprehensive review should include all aspects of the crane’s operation, including structural integrity, electrical systems, and safety mechanisms.

Implementing these maintenance and inspection practices ensures that overhead cranes remain in optimal working condition, enhancing safety and performance in automotive manufacturing environments. By prioritizing regular upkeep, manufacturers can reduce downtime, prevent accidents, and maintain high standards of operational efficiency.

Benefits of 5 to 10 Ton Cranes for Automotive Parts

Enhanced Efficiency

Streamlined Manufacturing Processes: Overhead cranes with a 5 to 10-ton capacity are designed to handle heavy and complex automotive components with precision. Their ability to lift and move cylinder heads and crankshafts smoothly contributes to more streamlined manufacturing processes. By automating the movement of these parts, cranes reduce the need for manual handling, which can be time-consuming and prone to errors. This automation ensures that components are delivered to the correct location within the production line quickly and accurately, thereby minimizing delays and disruptions.

Impact on Production Speed and Operational Efficiency: The integration of 5 to 10-ton cranes into manufacturing operations significantly enhances production speed. These cranes can lift and position heavy components with ease, which speeds up the assembly and maintenance processes. Faster handling of parts translates into shorter production cycles and higher output rates. Additionally, the precision control systems in these cranes reduce the likelihood of errors and rework, further improving operational efficiency. Overall, the use of these cranes leads to a more efficient production environment, allowing manufacturers to meet demanding production schedules and maintain high-quality standards.

Cost-Effectiveness

Long-Term Financial Benefits: Investing in high-quality overhead cranes with a 5 to 10-ton capacity offers substantial long-term financial benefits. Although the initial investment may be significant, the durability and reliability of these cranes lead to reduced maintenance and repair costs over time. High-quality cranes are designed to withstand the rigors of heavy-duty use, which means they are less likely to experience frequent breakdowns or require costly repairs. This durability translates into lower total cost of ownership and provides a solid return on investment.

Return on Investment through Reduced Downtime and Improved Handling Accuracy: One of the key financial advantages of using these cranes is the reduction in downtime. By ensuring efficient and accurate handling of heavy components, overhead cranes minimize the likelihood of production interruptions due to equipment failures or handling errors. Improved handling accuracy also leads to fewer damaged parts, reducing the costs associated with rework and scrap. The combination of decreased downtime and enhanced accuracy contributes to a more productive and cost-effective manufacturing operation. Manufacturers can achieve a higher return on investment through increased productivity, lower operational costs, and improved product quality.

In summary, the adoption of 5 to 10-ton overhead cranes in automotive manufacturing provides significant benefits in terms of efficiency and cost-effectiveness. By enhancing production speed and accuracy, these cranes streamline manufacturing processes and contribute to a more profitable operation.

Conclusion

Recap of Key Points:

Overhead cranes with a 5 to 10-ton capacity are essential tools in the automotive manufacturing industry, specifically for handling heavy and complex components like cylinder heads and crankshafts. These cranes are equipped with advanced precision control systems that enhance accuracy and reliability, making them well-suited for managing the demands of modern automotive production lines. The design and construction of these cranes ensure they can handle the weight and intricacy of automotive parts, while built-in safety mechanisms protect both the equipment and the operators.

Summary of Advantages:

The use of 5 to 10-ton overhead cranes brings several significant advantages to automotive manufacturing:

- Enhanced Efficiency: By automating the movement of heavy components, these cranes streamline manufacturing processes, reduce manual handling, and accelerate production speed. Their precision control systems contribute to smooth operations and high productivity.

- Cost-Effectiveness: Investing in high-quality cranes reduces long-term maintenance costs and improves handling accuracy. This leads to decreased downtime, fewer damaged parts, and a higher return on investment through increased operational efficiency.

The integration of 5 to 10-ton overhead cranes into automotive manufacturing processes plays a crucial role in enhancing productivity, safety, and overall operational efficiency. Their ability to handle complex and heavy components with precision not only ensures smooth production flows but also helps maintain high standards of quality and safety. By leveraging these cranes, manufacturers can achieve more effective production lines, reduce costs, and ultimately improve their competitive edge in the automotive industry.