Pulp Mill Overhead Cranes & Gantry Cranes, 40 Ton Cranes For You

Pulp Mill Overhead Cranes & Gantry Cranes, 40 Ton Cranes For You. Pulp Mill Overhead Cranes & Gantry Cranes for Optimizing Material Flow in Pulp Processing for handling log and timber bundles, processed pulp bales. Custom Double Girder Cranes.

Overview of Pulp Mill

Pulp is a crucial raw material for paper manufacturing, and the process of preparing pulp usually involves the conversion of wood, waste paper, or other fiber sources into fine fibers. Here are some key features and functions of pulp mills:

- Raw Material Handling: The primary task of a pulp mill is to handle raw materials, which may include wood, waste paper, cardboard, and more. The raw materials are brought into the factory and transformed into pulp through processes like pulping and cooking.

- Cooking and Bleaching: Raw materials enter the cooking process, where wood fibers are separated and bleached to produce white pulp.

- Washing and Impurity Removal: The pulp goes through a washing process to remove bleaching agents and other impurities, ensuring the quality of the final paper.

- Dehydration and Drying: The pulp is dehydrated and subjected to a drying process to form the precursor of paper.

- Papermaking Operations: The pulp is sent to paper machines where, through a series of operations, it ultimately becomes finished paper.

- Wastewater Treatment: Since the pulp production process generates wastewater, pulp mills typically include wastewater treatment facilities to meet environmental standards.

In pulp mills, various equipment and machinery are used for different stages of production, including conveyors, reactors, filtration equipment, drying machines, etc. Additionally, heavy machinery such as cranes and hoists is often required to handle large quantities of raw materials and semi-finished products.

It's important to note that the scale and technological level of pulp mills may vary depending on the type of factory and its geographical location.

Overhead Cranes for Pulp Mill Material Handling

In pulp mills, overhead cranes are widely used across various production stages to handle raw materials, intermediate products, and finished goods. Here are some key applications of overhead cranes in pulp mills:

- Raw Material Handling: Overhead cranes are employed to handle the incoming raw materials, such as wood, waste paper, cardboard, etc. They are used for unloading, transporting, and stacking raw materials, ensuring their efficient entry into the production line.

- . Pulp Production Stages: Throughout the different stages of pulp production, overhead cranes are used to feed raw materials into processing equipment such as grinders, cooking vessels, and washers. This aids in the smooth preparation of pulp.

- Intermediate Product Handling: Overhead cranes play a crucial role in intermediate stages like dewatering and drying. They can be utilized to move dewatered pulp and semi-finished products within drying machines.

- Paper Machine Operations: During paper machine operations, overhead cranes are essential for lifting and positioning pulp rolls, ensuring their proper treatment throughout the operation.

- Maintenance and Equipment Replacement: Overhead cranes are also used for maintenance tasks, including replacing equipment components, repairing machinery, and conducting regular inspections to ensure the smooth functioning of all equipment.

- Waste Handling: Overhead cranes can be employed in waste handling processes, ensuring compliance with environmental standards by efficiently managing waste and wastewater.

These applications highlight the versatility of overhead cranes in pulp mills, from raw material processing to final product preparation. Different types of overhead cranes, such as bridge cranes, gantry cranes, and hoists, may be used at different stages depending on the factory's requirements and equipment configuration.

Pulp Mill Operations: Optimizing Material Flow in Pulp Processing

Pulp mill operations stand at the heart of the paper manufacturing process, where raw materials undergo intricate processes to produce the pulp essential for crafting various paper products. In this segment, we delve into the critical aspects of optimizing material flow within pulp processing, emphasizing the role of efficient material handling solutions.

Pulp milling is a complex series of processes aimed at extracting fibers from raw materials such as logs and timber. These processes involve chipping, cooking, and refining to produce the pulp, a foundational material for subsequent paper manufacturing stages.

Efficient material flow is the lifeblood of pulp mill operations. From the moment raw logs enter the mill to the processing of pulp bales, the seamless movement of materials plays a pivotal role in maintaining operational efficiency. The optimization of material flow not only enhances productivity but also contributes to cost-effectiveness and the overall quality of the final paper products.

Loads Handling

In the intricate world of pulp mill operations, the handling of raw materials like logs and timber is a critical aspect that significantly influences the overall efficiency of the process. Let's delve into the challenges and requirements associated with the handling of these essential materials.

Log and Timber Bundles

Challenges in Handling Raw Materials

Variable Sizes and Shapes:

Logs and timber bundles come in diverse shapes and sizes, posing a challenge in creating a universal handling approach.

Efficient crane systems must be adaptable to accommodate the variability in these materials.

Preservation of Material Integrity:

Ensuring the integrity of logs and timber during handling is paramount to prevent damage or deformities.

Crane systems need to incorporate features that securely grip and lift these materials without causing harm.

Optimizing Workflow:

Pulp mill operations demand a seamless workflow, necessitating the swift and precise movement of raw materials.

Crane systems must be designed to optimize the flow of logs and timber bundles within the processing area.

Requirements for Efficient and Secure Handling

Customized Attachments:

Crane designs should incorporate customized attachments such as log grapples or specialized clamps.

These attachments ensure a secure grip on logs and timber bundles, minimizing the risk of slippage during lifting and transport.

Adaptable Configurations:

The crane systems must feature adaptable configurations to handle varying sizes and weights of logs and timber bundles.

This adaptability ensures that the crane remains versatile in accommodating the diversity of raw materials.

Integrated Safety Measures:

Safety is paramount in handling raw materials, and cranes should integrate safety features such as anti-sway technology and emergency braking systems.

These measures enhance the precision and security of material handling, reducing the likelihood of accidents.

Efficient handling of logs and timber bundles sets the foundation for a streamlined pulp milling process. The next section will explore another crucial aspect of pulp mill operations – the processing of pulp bales.

Processed Pulp Bales

The journey of material handling in pulp mill operations continues with a focus on the characteristics and challenges associated with processed pulp bales. These compressed bundles play a pivotal role in the paper production process, making their effective handling a crucial element in optimizing material flow.

Characteristics of Processed Pulp Bales

- Compactness and Density: Processed pulp bales are characterized by their high compactness and density, resulting from the compression of pulp fibers during processing.

Their condensed form allows for efficient storage and transportation within the mill. - Uniform Shape and Size: Pulp mills often produce processed bales with uniform shapes and sizes for standardized handling.

This uniformity aids in creating efficient workflows and ensures consistent processing in subsequent stages. - Critical Intermediate Product: Processed pulp bales serve as a critical intermediate product between raw materials and the paper production phase.

Their successful handling impacts the quality and efficiency of the entire paper manufacturing process.

Challenges in Handling Compressed Pulp Bales

- Weight Distribution: The compression process may result in uneven weight distribution within the bales. Crane systems must account for this variability to ensure stable lifting and transportation.

- Minimizing Handling Impact: Compressed pulp bales are more susceptible to damage from excessive impact during handling. Crane designs should incorporate features that minimize impact and ensure gentle, controlled movements.

- Swift and Accurate Placement: Efficient handling of compressed pulp bales requires swift and accurate placement. Crane systems should facilitate precise positioning to optimize downstream processes.

Cranes for Pulp Mill Operations

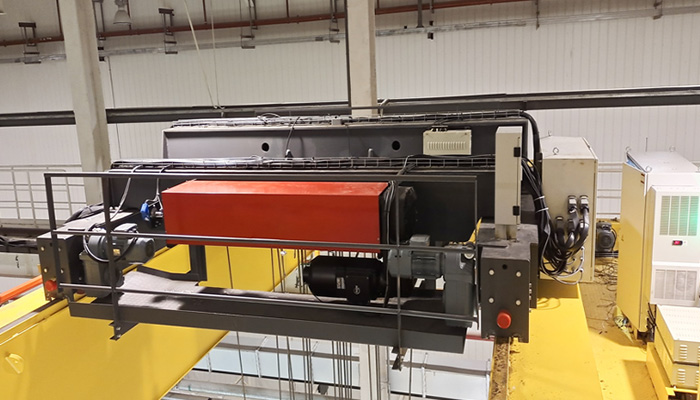

Double Girder Bridge Cranes with Clamps

In the intricate landscape of pulp mill operations, the choice of overhead cranes plays a pivotal role in ensuring the seamless handling of raw materials like logs, timber, and processed pulp bales. One design that stands out for its efficiency and versatility in this environment is the Double Girder Bridge Crane equipped with specialized clamps.

Design Features of Double Girder Bridge Cranes

- Robust Structure: The double girder design provides enhanced stability and strength, allowing the crane to handle heavy loads with precision.

Robust structural components ensure longevity and durability, even in the demanding conditions of pulp mill operations. - Dual Girders for Increased Capacity: The utilization of dual girders significantly increases the load-bearing capacity of the crane. This feature is particularly crucial in pulp mills where the handling of substantial loads, such as logs and compressed pulp bales, is a routine requirement.

- Customizable Clamp Attachments: The crane is equipped with specialized clamp attachments designed to securely grip different types of materials, including logs, timber, and processed pulp bales. Customizability allows for the adaptation of clamps based on the specific characteristics and dimensions of the materials being handled.

- Precise Control and Maneuverability: Advanced control systems provide operators with precise control over the crane's movements. Maneuverability is a key feature, enabling the crane to navigate through the pulp processing area with accuracy and efficiency.

Advantages of Using Clamps in Material Handling

- Secure Material Grip: Clamps offer a secure and reliable grip on raw materials, ensuring stability during lifting and transport. This is particularly crucial when dealing with compressed pulp bales, where maintaining the integrity of the bundles is essential.

- Versatility in Material Handling: The adaptability of clamp attachments allows the crane to handle a variety of materials, from irregularly shaped logs to uniform processed pulp bales.

This versatility enhances the crane's utility across different stages of the pulp milling process. - Reduced Handling Time: The efficient gripping and release mechanism of clamps contribute to reduced handling times. Swift and controlled movements enhance overall workflow efficiency within the pulp mill.

European style standard double girder overhead crane with capacity from 5 ton to 80 ton

Application in Material Flow Optimization

Facilitating Material Flow within the Pulp Processing Area

The integration of Double Girder Bridge Cranes with Clamps in pulp mill operations goes beyond mere material handling; it becomes a catalyst for optimizing material flow within the intricate pulp processing area. Let's delve into how these cranes contribute to a seamless and efficient workflow.

Unloading Raw Materials

Efficient Log and Timber Unloading:

Upon arrival at the mill, raw materials like logs and timber bundles need to be swiftly and safely unloaded.

Double Girder Bridge Cranes with Clamps excel in this task, providing a secure grip for unloading materials from trucks or storage areas.

Stacking and Storage

Organized Stacking of Processed Pulp Bales:

After processing, compressed pulp bales must be systematically stacked for storage or further processing.

The precise control and adaptability of clamp attachments enable the crane to stack bales with minimal handling impact, ensuring the integrity of the compressed material.

Transporting Materials

Swift and Controlled Material Transport:

The crane's maneuverability, coupled with the secure grip of clamps, facilitates the efficient transport of materials within the processing area.

Materials can be transported to various stages of the pulp milling process with precision, reducing downtime and enhancing overall productivity.

Precision Handling in Pulp Mill Operations

Tailored Applications for Different Materials:

The customizability of clamp attachments allows for tailored applications, ensuring that the crane is optimized for handling different materials, each with its unique characteristics.

Whether it's logs, timber, or processed pulp bales, the crane adapts to the specific requirements of each material type.

Streamlining Workflow

Contributing to Overall Workflow Efficiency:

By seamlessly integrating into various stages of pulp processing, Double Girder Bridge Cranes with Clamps contribute to the overall efficiency of the workflow.

Reduced handling times, precise material placement, and secure grips collectively enhance the operational effectiveness of the pulp mill.

Low Headroom Double Hook Overhead Crane

Tonnage Ranges

40 Tons and Above

Handling the substantial loads involved in pulp mill operations requires overhead cranes with robust load capacities. In this segment, we delve into the specific tonnage requirements, emphasizing the significance of cranes capable of handling 40 tons and above. Let's explore the scenarios where these high load capacities are not only beneficial but essential in optimizing pulp processing.

Diverse Raw Material Sizes

Varied Weight Distribution in Logs and Timber:

Logs and timber, essential raw materials in pulp milling, exhibit diverse weight distributions.

Cranes with a load capacity of 40 tons and above are equipped to handle the variability in weight, ensuring secure and stable lifting.

Compressed Pulp Bale Considerations

Addressing Weight Challenges in Processed Pulp Bales:

Processed pulp bales, while compressed for efficiency, can still pose challenges due to their condensed nature and potential uneven weight distribution.

Cranes with high load capacities are well-suited to address these challenges, providing stability during lifting and transport.

Simultaneous Handling of Multiple Materials

Efficient Handling of Multiple Materials:

Pulp mills often require the simultaneous handling of logs, timber bundles, and compressed pulp bales.

Cranes with load capacities of 40 tons and above offer the versatility needed to manage multiple materials concurrently, streamlining operations.

Optimizing Workflow in Large-Scale Mills

Large-Scale Pulp Processing Operations:

In large-scale pulp mills with high production volumes, the demand for efficient material handling is paramount.

Cranes with higher load capacities contribute to the optimization of workflow by accommodating the substantial quantities of raw and processed materials.

Heavy-Duty Applications

Handling Heavy-Duty Components and Equipment:

Beyond raw materials, the crane's load capacity extends to handling heavy-duty components and equipment within the pulp mill.

This includes transporting machinery, tools, and other essential elements required for maintenance and operational tasks.

In conclusion, the requirement for cranes with load capacities of 40 tons and above in pulp mill operations is rooted in the diverse and heavy-duty nature of the materials and processes involved. These cranes play a pivotal role in ensuring the efficiency, safety, and productivity of the entire pulp milling workflow.

Conclusion

Material Flow Optimization in Pulp Mill Operations

In this comprehensive exploration of pulp mill operations, we've delved into the intricate world of material handling, focusing on the efficient flow of logs, timber bundles, and processed pulp bales. The key takeaways include:

- Challenges in Handling Raw Materials: Logs and timber present challenges in varied shapes and sizes, requiring customized crane solutions for secure and efficient handling.

Processed pulp bales, with their compactness and uniformity, demand precise and gentle handling to maintain material integrity. - The Role of Double Girder Bridge Cranes with Clamps: These cranes, equipped with robust features and adaptable clamp attachments, emerged as efficient solutions for pulp mill operations. Their dual girders, customizable clamp attachments, and precise control contribute to optimized material flow.

- Applications in Material Flow Optimization: The cranes facilitate the unloading of raw materials, organized stacking of processed pulp bales, and swift transportation within the pulp processing area. Customizability allows tailored applications for different materials, contributing to overall workflow efficiency.

The significance of selecting the right crane design cannot be overstated. Tailored crane solutions, such as Double Girder Bridge Cranes with Clamps, ensure that the specific requirements of handling logs, timber, and compressed pulp bales are met with precision. This tailored approach not only enhances efficiency but also contributes to the longevity of equipment and the overall safety of operations.

As we conclude, it's essential to look forward to the future of crane technology in pulp mills. Advancements in automation, artificial intelligence, and robotics hold the promise of further streamlining material handling processes. These technological innovations aim to bring about increased efficiency, predictive maintenance, and a reduction in downtime, contributing to the continuous evolution of pulp mill operations.

In the dynamic landscape of pulp mill operations, the journey towards material flow optimization is ongoing. By embracing tailored crane solutions and staying attuned to technological advancements, pulp mills can navigate challenges and usher in a future marked by efficiency, sustainability, and innovation.