Single Girder Bridge Crane 10 Ton 20 Ton for Newsprint Mills

Single Girder Bridge Cranes for General Material Handling in Newsprint Mills

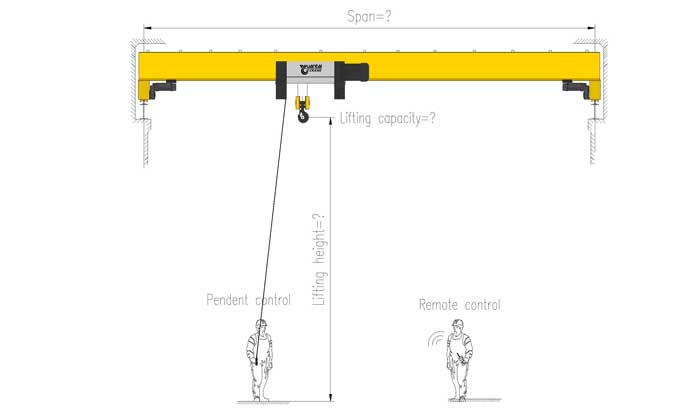

Single girder bridge cranes represent a cornerstone in industrial material handling, characterized by a singular beam spanning the width of the structure, supported by end trucks on each side. This design allows for efficient lifting and transportation of heavy loads within industrial settings. Comprising key components such as the bridge girder, hoist mechanism, end trucks, electrical systems, and controls, these cranes are meticulously engineered to meet diverse material handling needs.

In terms of classification, single girder bridge cranes exhibit versatility in both lifting mechanisms and operational modes. Variations in lifting mechanisms, including electric wire rope hoists or chain hoists, cater to specific load requirements and operational preferences. Furthermore, operational modes range from manual to semi-automated or fully automated systems, offering flexibility to align with varying levels of automation and user preferences.

The advantages offered by single girder bridge cranes are manifold, making them indispensable assets in industrial environments. Their cost-effectiveness stems from efficient design and construction, providing optimal performance without exorbitant expenses. Ease of installation further enhances their appeal, enabling swift deployment and integration into existing infrastructure. Additionally, their suitability for light to moderate lifting applications makes them versatile solutions across a wide range of industries, including manufacturing, warehousing, and logistics. Ultimately, the combination of these advantages positions single girder bridge cranes as indispensable tools for optimizing material handling processes and enhancing operational efficiency within industrial facilities.

1 ton to 20 ton single girder overhead crane for newsprint mills, custom bridge crane design for your needs.

Importance of Efficient Material Handling in Newsprint Mills

Efficient material handling holds paramount importance within newsprint mills, driven by several key factors that significantly impact operational effectiveness and overall success.

Firstly, newsprint mills operate under stringent production schedules with high throughput requirements. To meet these demands, streamlined material handling systems are imperative, ensuring uninterrupted workflow and timely delivery of products to meet market demands.

Moreover, newsprint mills handle a myriad of heavy loads, including newsprint rolls, pulp, chemicals, and packaging supplies. Efficient material handling systems, such as single girder bridge cranes, play a crucial role in safely and effectively managing these heavy loads, minimizing the risk of accidents, damage to materials, and disruptions to production processes.

Space optimization is another critical aspect addressed by efficient material handling solutions. Newsprint mills often operate within confined environments where space utilization is paramount. By employing compact and versatile equipment like single girder bridge cranes, mills can optimize floor space usage, allowing for efficient material storage and movement without compromising operational efficiency.

Worker safety is of utmost concern in newsprint mills, where manual handling of heavy loads poses significant risks of workplace accidents and injuries. Efficient material handling systems reduce reliance on manual labor, mitigating the potential for accidents and promoting a safer working environment for employees.

Furthermore, investing in efficient material handling yields substantial cost savings for newsprint mills. By minimizing downtime, reducing labor costs associated with manual handling, and prolonging the lifespan of equipment through proper maintenance, mills can realize significant cost efficiencies and improve overall profitability.

Lastly, compliance with safety standards and regulations is non-negotiable for newsprint mills. Adhering to regulatory requirements governing material handling practices ensures a safe working environment for employees and mitigates legal and financial risks associated with non-compliance.

In essence, efficient material handling is a cornerstone of operational success in newsprint mills, driving productivity, safety, cost savings, and regulatory compliance. By investing in advanced material handling solutions and adhering to best practices, newsprint mills can optimize their operations and maintain a competitive edge in the industry.

Characteristics of Single Girder Bridge Cranes for Newsprint Mills

Loads Handling

Newsprint Rolls

Newsprint mills are characterized by the handling of large, heavy rolls of paper, vital for printing newspapers, magazines, and other publications. These rolls, often weighing several tons each, present unique challenges in terms of handling and transportation within the mill environment.

Single girder bridge cranes are specifically engineered to address the demands associated with newsprint roll handling. With robust lifting capacities and specialized lifting attachments, these cranes can safely and efficiently handle the bulky and heavy newsprint rolls encountered in newsprint mills. The design of single girder bridge cranes ensures optimal load distribution and stability, minimizing the risk of accidents and damage to both the rolls and surrounding equipment.

Moreover, single girder bridge cranes are equipped with features tailored to the precise requirements of newsprint roll handling. Adjustable lifting speeds allow operators to control the movement of the crane with precision, ensuring smooth and controlled handling of the rolls. Additionally, precise control mechanisms enable operators to position the rolls accurately, facilitating seamless integration into the production process.

One of the key considerations in newsprint roll handling is the prevention of damage during transportation and storage. Single girder bridge cranes incorporate features designed to safeguard the integrity of the rolls throughout the handling process. Gentle handling is achieved through careful control of lifting and movement speeds, minimizing the risk of tears, creases, or other forms of damage to the paper.

In summary, single girder bridge cranes are indispensable tools in newsprint mills, specifically tailored to meet the challenges associated with handling large, heavy newsprint rolls. With their robust design, specialized features, and precise control mechanisms, these cranes ensure safe, efficient, and damage-free handling of newsprint rolls, contributing to the overall productivity and success of newsprint mills.

General Materials

In addition to their primary role in handling newsprint rolls, single girder bridge cranes play a pivotal role in managing a diverse array of general materials within newsprint mills. These materials may include pulp, chemicals, packaging supplies, maintenance equipment, and other raw materials or consumables essential to the paper manufacturing process.

Single girder bridge cranes are equipped with versatile lifting attachments or hooks designed to accommodate the specific requirements of different types of materials. Whether it's the bulkiness of pulp bales, the hazardous nature of chemicals, or the varied shapes and sizes of packaging supplies, these cranes are engineered to provide a solution for safely and efficiently handling each type of material.

The versatility of single girder bridge cranes extends beyond their lifting attachments to encompass their ability to adapt to varying load characteristics and handling requirements. Load stability, weight distribution, and material characteristics are carefully considered to ensure safe and efficient handling operations. Factors such as center of gravity, friction, and potential hazards are taken into account during the planning and execution of material handling tasks.

Moreover, single girder bridge cranes are designed with the flexibility to handle materials in different sections of the newsprint mill, from the receiving area to the production line, and from storage facilities to maintenance zones. This versatility allows for seamless integration of material handling processes throughout the mill, optimizing workflow and minimizing disruptions to production.

In essence, single girder bridge cranes serve as versatile workhorses within newsprint mills, capable of efficiently managing a wide range of general materials essential to the paper manufacturing process. Their adaptability, combined with careful consideration of load characteristics and handling requirements, ensures safe, reliable, and efficient material handling operations across the mill environment.

Low headroom single girder overhead cranes save your workshop space

Application Areas

Single girder bridge cranes serve as indispensable tools across various sections of newsprint mills, playing crucial roles in facilitating material handling operations and supporting seamless workflow throughout the production process.

Raw Material Handling:

In the raw material handling phase, single girder bridge cranes are responsible for transporting essential materials such as pulp and chemicals from storage areas to processing units.

These cranes ensure efficient movement of raw materials, minimizing delays and disruptions in the production process.

By precisely positioning materials at the processing units, single girder bridge cranes contribute to the optimization of manufacturing operations, ensuring consistent material supply to meet production demands.

b. Production Line:

Within the production line, single girder bridge cranes play a pivotal role in loading and unloading materials onto production machines.

By seamlessly integrating with production machinery, these cranes facilitate continuous manufacturing processes, ensuring uninterrupted production flow.

Their precise control mechanisms enable accurate positioning of materials, optimizing production efficiency and minimizing waste.

Finished Product Handling:

After the completion of the manufacturing process, single girder bridge cranes are utilized for handling finished newsprint rolls.

These cranes are responsible for moving finished products to storage areas or loading docks for shipment, ensuring timely delivery to customers.

Their ability to handle heavy loads with precision ensures the safe and efficient movement of finished products, minimizing the risk of damage and ensuring product quality.

Maintenance and Storage:

In maintenance and storage areas, single girder bridge cranes play a crucial role in supporting maintenance activities and managing inventory.

They assist in lifting equipment and spare parts to maintenance areas, facilitating timely repairs and preventive maintenance.

Additionally, single girder bridge cranes provide storage support for inventory, optimizing space utilization and ensuring efficient organization of materials.

In essence, single girder bridge cranes are versatile assets that find application across various sections of newsprint mills, contributing to improved productivity, efficiency, and safety throughout the production process. Their ability to handle diverse material handling tasks with precision and reliability makes them indispensable components in the operations of newsprint mills.

Tonnage Ranges

Single girder bridge cranes designed for newsprint mills typically exhibit lifting capacities within the range of 10 to 20 tons, strategically tailored to meet the demands of paper manufacturing operations, which often involve handling heavy loads.

This tonnage range is carefully selected to ensure optimal performance and efficiency in material handling tasks within newsprint mills. It strikes a balance between lifting capacity, maneuverability, and cost-effectiveness, making it ideal for addressing the diverse needs encountered in the production process.

By offering lifting capacities ranging from 10 to 20 tons, these cranes are well-equipped to handle the substantial weight of newsprint rolls and other materials commonly utilized in newsprint mills. Their robust design and construction ensure reliable performance, even when tasked with lifting heavy loads.

Moreover, cranes within this tonnage range are versatile enough to accommodate various loads encountered across different sections of the newsprint mill. Whether it's transporting raw materials in the processing area, loading finished products onto storage racks, or assisting in maintenance tasks, these cranes provide a comprehensive material handling solution.

The versatility of single girder bridge cranes within the 10 to 20-ton lifting capacity range extends beyond their ability to handle different types of loads. They also offer flexibility in terms of installation and configuration, allowing for seamless integration into existing mill infrastructure while optimizing space utilization and workflow efficiency.

In summary, single girder bridge cranes with lifting capacities ranging from 10 to 20 tons serve as reliable and efficient solutions for material handling within newsprint mills. Their ability to handle heavy loads with precision, versatility, and cost-effectiveness makes them indispensable assets in optimizing production processes and ensuring operational success in the paper manufacturing industry.

Benefits of Single Girder Bridge Cranes in Newsprint Mills

Increased Efficiency in Material Handling

- Streamlined Workflow: Single girder bridge cranes facilitate the smooth flow of materials within newsprint mills, reducing bottlenecks and optimizing production processes.

- Quick Load Handling: The efficient lifting and maneuvering capabilities of these cranes enable rapid loading and unloading of newsprint rolls and other materials, minimizing waiting times and enhancing overall efficiency.

- Precise Positioning: Advanced control systems allow for precise positioning of loads, ensuring accurate placement of materials onto production machinery or storage racks, thereby improving overall productivity.

Reduction in Downtime

- Quick Maintenance Access: Single girder bridge cranes provide easy access for maintenance personnel to inspect and service equipment, reducing downtime associated with maintenance activities.

- Minimized Equipment Failures: Proper handling and transportation of materials using cranes help prevent damage to machinery and equipment, reducing the frequency of breakdowns and unplanned downtime.

- Efficient Troubleshooting: In the event of equipment malfunction or material blockages, the versatility of single girder bridge cranes allows for swift intervention and troubleshooting, minimizing production interruptions.

Enhanced Safety Measures

- Accident Prevention: Single girder bridge cranes are equipped with safety features such as overload protection, emergency stop buttons, and collision avoidance systems to minimize the risk of accidents and injuries in the workplace.

- Ergonomic Design: These cranes are designed with ergonomics in mind, reducing strain on operators and minimizing the risk of musculoskeletal injuries associated with manual material handling tasks.

- Operator Training: Proper training programs ensure that crane operators are equipped with the knowledge and skills to operate the equipment safely, further enhancing workplace safety within newsprint mills.

Flexibility in Operations

- Adaptability to Changing Requirements: Single girder bridge cranes can be customized with various lifting attachments and accessories to accommodate different types of loads and operational needs within newsprint mills.

- Scalability: As production demands evolve, single girder bridge cranes offer the flexibility to scale up or down in capacity and functionality, providing a cost-effective solution for changing business requirements.

- Integration with Automation: These cranes can be integrated with automation systems and digital technologies to enhance operational efficiency and adaptability, ensuring seamless integration with future advancements in material handling technology.

Components of Single Girder Bridge Cranes

Girder Structure

- Main Beam: The primary horizontal beam that spans the width of the crane runway, providing support for the hoist mechanism and load.

- End Carriages: Structural components located at each end of the girder, housing wheels or tracks for smooth movement along the crane runway.

- Box Girder Design: Many single girder bridge cranes feature a box girder design, which offers increased strength and rigidity, allowing for efficient load handling.

Hoisting Mechanism

- Hoist: The lifting component of the crane, consisting of a motorized mechanism with hooks, chains, or wire ropes for lifting and lowering loads.

- Trolley: The mechanism that moves horizontally along the length of the girder, supporting the hoist and allowing for precise positioning of loads.

- Lifting Speed Control: Variable speed controls enable operators to adjust the lifting speed based on load requirements, ensuring safe and efficient material handling.

End Trucks

- Wheels or Tracks: End trucks are equipped with wheels or tracks that travel along the crane runway, allowing for smooth and controlled movement of the crane.

- Motorized Drive: End trucks may be equipped with motorized drives for powered movement along the crane runway, offering precise control and maneuverability.

- Bearing Systems: High-quality bearing systems ensure smooth and quiet operation of the end trucks, reducing wear and extending the lifespan of the crane components.

Electrical Systems

- Power Supply: Single girder bridge cranes typically require electrical power for operation, supplied through overhead lines or festoon systems.

- Control Panels: Electrical control panels house the crane's control system, including motor starters, relays, and safety devices, allowing for centralized control of crane movements.

- Safety Features: Electrical systems include safety features such as limit switches, overload protection, and emergency stop buttons to ensure safe operation and protect against equipment damage.

Controls and Automation Features

- Pendant Control: Hand-held pendant controls allow operators to maneuver the crane and control lifting and traversing movements from a safe distance.

- Radio Remote Control: Some cranes feature radio remote control systems, enabling operators to control crane movements wirelessly, providing greater flexibility and safety.

- Automation Integration: Advanced single girder bridge cranes may feature automation integration capabilities, allowing for seamless integration with other manufacturing processes and systems, enhancing overall productivity and efficiency.

Considerations for Installation and Maintenance

Structural Requirements

Ensuring the structural integrity of the crane system is essential for safe and efficient operation within newsprint mills. Several key considerations must be addressed to meet structural requirements:

Crane Runway:

The crane runway serves as the foundation for the crane's movement along the designated path within the mill. It is crucial to ensure that the runway is constructed to support the weight and movement of the single girder bridge crane.

Structural engineers meticulously design the crane runway to withstand the dynamic loads imposed by the crane during operation, including the weight of the crane itself, the lifted load, and the forces generated during movement.

Factors such as material selection, beam sizing, and reinforcement are carefully considered to optimize the strength and stability of the crane runway.

Building Specifications:

Prior to crane installation, it is imperative to verify that the building structure meets the necessary requirements for accommodating the crane system. This includes assessing overhead clearance, floor load capacity, and structural support capabilities.

Adequate overhead clearance ensures sufficient space for the crane to maneuver without encountering obstructions or interfering with existing structures within the mill. Clearance requirements may vary depending on the crane's lifting height and configuration.

Floor load capacity refers to the maximum weight that the building floor can support without risk of structural failure. Structural engineers conduct load calculations to determine if the floor can withstand the additional weight imposed by the crane and its operating loads.

Foundation:

Proper preparation and construction of the foundation are essential to securely anchor the crane runway and support structures, ensuring stability and safety during crane operation.

Foundation design considerations include soil conditions, load distribution, and reinforcement requirements. Engineers conduct soil tests to assess the soil's bearing capacity and determine the appropriate foundation design.

The foundation must be constructed to withstand the dynamic loads and vibrations generated by the crane during operation, minimizing the risk of settlement or foundation failure.

Additionally, proper drainage measures should be implemented to prevent water accumulation and soil erosion, which can compromise the integrity of the foundation over time.

In summary, addressing structural requirements is crucial for the successful installation and operation of single girder bridge cranes within newsprint mills. By ensuring the structural integrity of the crane system, mills can optimize safety, efficiency, and reliability in material handling operations, ultimately contributing to overall productivity and operational success.

Safety Regulations Compliance

Compliance with safety regulations is paramount to ensure the safe installation and operation of overhead cranes, including single girder bridge cranes, within newsprint mills. Attention to safety regulations involves several critical aspects:

Local Regulations:

It is essential to adhere to applicable safety regulations and standards governing the installation and operation of overhead cranes within the specific region or jurisdiction where the newsprint mill is located.

Local authorities may have specific requirements and regulations related to crane installation, operation, inspection, and maintenance to ensure the safety of workers and compliance with local laws.

Industry Standards:

Compliance with industry-specific safety standards and guidelines is crucial for the safe operation of overhead cranes in newsprint mills. These standards are established to promote safety, prevent accidents, and mitigate risks associated with crane operations.

Organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) set forth comprehensive standards for crane safety, covering various aspects including design, installation, operation, and maintenance.

Newsprint mills must ensure that their crane systems comply with relevant OSHA and ANSI standards, as well as any industry-specific standards applicable to the paper manufacturing sector.

Safety Features:

Installing necessary safety features is essential to prevent accidents and ensure the safe operation of single girder bridge cranes within newsprint mills.

Common safety features include limit switches, which prevent the crane from traveling beyond predetermined limits, and overload protection devices, which prevent the crane from lifting loads beyond its rated capacity.

Emergency stop buttons provide a quick means to halt crane operation in case of emergency or hazardous situations, while fencing and barriers help prevent unauthorized access to crane operating areas, reducing the risk of accidents.

In summary, compliance with safety regulations and standards is crucial to ensure the safe installation and operation of single girder bridge cranes within newsprint mills. By adhering to local regulations, industry standards, and implementing necessary safety features, newsprint mills can create a safe working environment for their employees and mitigate risks associated with crane operations.

Routine Maintenance Procedures

To ensure the reliable and safe operation of single girder bridge cranes within newsprint mills, rigorous routine maintenance procedures must be established and followed. These procedures encompass several critical components:

Inspection Schedule:

Establishing a regular inspection schedule is crucial to assess the condition of crane components systematically. This includes examining structural elements, electrical systems, mechanical parts, and safety features.

Inspections should be conducted by qualified personnel trained to identify signs of wear, damage, or malfunction that could compromise crane performance or safety.

Inspection schedules may vary based on factors such as crane usage, environmental conditions, and regulatory requirements, but they typically include daily, weekly, monthly, and annual inspections.

Lubrication:

Implementing a comprehensive lubrication regimen is essential to maintain the smooth operation of moving parts within the crane system.

Lubricants are applied to critical components such as bearings, gears, and joints to reduce friction and wear, extending the lifespan of crane components and ensuring optimal performance.

Lubrication schedules should be established based on manufacturer recommendations and industry best practices, with attention to the type and quantity of lubricants used for each application.

Preventive Maintenance:

Performing routine preventive maintenance tasks is vital to prevent unexpected breakdowns and ensure the continuous operation of single girder bridge cranes.

Preventive maintenance tasks may include bolt tightening, alignment checks, lubrication, inspection of electrical connections, and calibration of safety devices.

Regular maintenance helps identify potential issues before they escalate into major problems, minimizing downtime and costly repairs.

Documentation:

Maintaining comprehensive records of maintenance activities is essential for tracking the condition of the crane, documenting maintenance history, and ensuring compliance with regulatory requirements.

Documentation should include inspection reports, maintenance logs, service records, and any relevant documentation provided by manufacturers or service providers.

Records should be organized, easily accessible, and kept up-to-date to facilitate maintenance planning, troubleshooting, and regulatory inspections.

In summary, implementing rigorous routine maintenance procedures is essential to ensure the safe and reliable operation of single girder bridge cranes within newsprint mills. By establishing inspection schedules, implementing lubrication regimens, performing preventive maintenance tasks, and maintaining comprehensive documentation, mills can optimize crane performance, minimize downtime, and mitigate risks associated with crane operation.

Training for Operators and Maintenance Personnel

Ensuring the competency of operators and maintenance personnel is critical for the safe and efficient operation of single girder bridge cranes within newsprint mills. This involves comprehensive training programs and ongoing education initiatives:

Operator Training:

Provide thorough training programs for crane operators to equip them with the necessary knowledge and skills to operate the equipment safely and effectively.

Training should cover various aspects of crane operation, including control operation, load handling techniques, safety protocols, and emergency procedures.

Hands-on training sessions and simulations can help operators gain practical experience in operating the crane under different conditions and scenarios.

Certification:

Ensure that crane operators receive proper certification and licensing from relevant regulatory authorities or certifying organizations.

Certification programs typically involve written examinations, practical assessments, and demonstration of proficiency in crane operation and safety protocols.

Valid certification not only demonstrates the operator's competence but also ensures legal compliance and adherence to safety standards.

Maintenance Training:

Train maintenance personnel on proper maintenance procedures, troubleshooting techniques, and equipment-specific protocols to effectively maintain and repair the crane as needed.

Maintenance training programs should cover topics such as lubrication, inspection, preventive maintenance tasks, and troubleshooting common issues.

Hands-on training sessions and equipment demonstrations can provide maintenance personnel with practical experience in maintaining and servicing the crane.

Continuous Education:

Encourage ongoing education and training for both operators and maintenance personnel to stay updated on new technologies, best practices, and safety standards in the field of overhead crane operation and maintenance.

Continuous education initiatives may include seminars, workshops, online courses, and participation in industry conferences and trade shows.

Staying informed about advancements in crane technology, regulatory changes, and industry trends ensures that operators and maintenance personnel are equipped with the latest knowledge and skills to perform their roles effectively.

In summary, investing in comprehensive training programs and continuous education initiatives for operators and maintenance personnel is essential for ensuring the safe and efficient operation of single girder bridge cranes within newsprint mills. By prioritizing training and education, mills can enhance safety, optimize crane performance, and mitigate risks associated with crane operation and maintenance.

Custom Bridge Cranes for Your Needs

Single girder bridge cranes stand as indispensable assets within newsprint mills, facilitating the efficient handling of both newsprint rolls and general materials. Their adaptability is paramount, boasting tonnage ranges typically from 10 to 20 tons, thus adequately addressing the hefty loads characteristic of paper manufacturing operations. Across various sections of newsprint mills, from raw material handling to maintenance and storage, these cranes find versatile applications, ensuring seamless material flow throughout the production process.

In emphasizing the significance of single girder bridge cranes in newsprint mills, their pivotal role in enhancing workflow, operational efficiency, and safety cannot be overstated. By optimizing material handling processes, these cranes substantially contribute to heightened productivity, decreased downtime, and tangible cost savings within the mill's operations.

Moreover, the adherence to stringent safety regulations and the implementation of meticulous maintenance procedures are paramount. By upholding safety standards and ensuring proper maintenance, single girder bridge cranes not only safeguard the well-being of workers but also prolong the lifespan of equipment, fostering a secure working environment conducive to long-term operational success.

In summation, single girder bridge cranes are indispensable pillars within newsprint mills, playing a vital role in fostering efficiency, safety, and productivity. Their continued presence and optimization in line with evolving industry standards and technological advancements will undoubtedly shape the trajectory of material handling in the newsprint industry for years to come.

In conclusion, single girder bridge cranes are indispensable tools in newsprint mills, offering efficient and reliable material handling solutions that contribute to the overall success and competitiveness of the industry. With ongoing technological innovations, these cranes will continue to play a vital role in shaping the future of material handling in the newsprint industry.