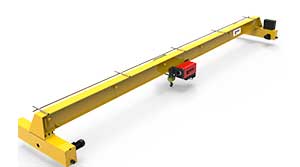

European Style &Traditional Style Overhead Crane Comparisions

Bridge crane comparisons of European overhead cranes & Traditional overhead cranes in terms of features, advantages, main parts, girder & hoists,etc.

European-style bridge cranes are designed and manufactured in accordance with FEM Europe standard. They are equipped with high-performance ABM or SEW brand engines, Schneider brand inverters and electrical components, variable speeds, box girder design, low headroom monorail hoist. The optimized design of European type bridge crane is light weight, small wheel pressure, short size, high headroom, multiple modes to meet all users’ various uses. They have excellent drive performance, frequency conversion speed regulation and stable operation. The end beams are divided into single beam crane end beams and double beam crane end beams.

Traditional overhead cranes differ from European-style overhead cranes in terms of design concepts. European-style overhead cranes have smaller dimensions and lighter dead weight compared to traditional cranes. The limiting distance is minimum from hook to wall and headroom is the lowest which makes cranes work closer to the front and lifting height higher that increases effective working space of workplace .

Single girder & double girder gantry crane with traiditional MH & MG gantry crane design and configurations.

Single girder & double girder gantry crane with traiditional MH & MG gantry crane design and configurations.Main Beam Comparisons of European style & Traditional style Bridge Crane

This article is mainly through the electric single girder crane of the two main girder structures for comparison to do some analysis and comments.

1. Finite element analysis comparison

To visually compare the structural advantages and disadvantages of the two main beams, two groups of main beam cross-sections with the same cross-sectional area are used for span-to-tension simulation. The equivalent comparison test only takes the structural characteristics of the main beam omitting the end beam part. The forces of equal size and opposite direction are directly applied to the main beam flange plate at the same location. The combined force on one side is set to 12 tons of load force for comparative testing. The finite element comparison test is as follows.

Comparison model setting

Two types of single girder bridge crane main girder section

The left side is the European main girder which is constructed into square or rectangle box girder and the right side is the conventional main girder with is constructed into u shaped box girder + I beam main girder.

Constraint and loading

In a tension test, the boundary load conditions of the main girder of the two cross-sections.

Equivalent force

Force clouds for two different types of cross-sectional main beams.

The European main beam has a more consistent stress distribution than the traditional main beam.

Stiffness comparison

Overall deformation of two types of cross-sectional beams.

The European main beam has slightly more distortion than the standard main beam.

Benefits and drawbacks of European main girders vs traditional main girders

European type electric single-girder crane main girder

Here are the main differences between the two types of electric single girder cranes:

- Due to the use of hoist wheels in the middle or lower, it improves the space utilization in the height direction and improves the problem of low lifting space of the main beam of traditional electric single girder crane.

- The structure of the hoist wheel spacing is enlarged to increase the wheel contact length, which effectively improves the stress concentration problem at the travel track and the horizontal oscillation of the electric hoist in the direction perpendicular to the main beam.

- The main load-bearing part of the structure is changed from the original I-beam to a thicker lower flange plate.

Traditional electric single girder bridge crane main girder

Here are the main differences between the two types of electric single girder bridge cranes:

- The main load-bearing part of the structure is different.

- The I-beam is firmly connected to the main beam by two full weld seams and several spacer connection welds in one structure.

- The main beam of this structure takes up more height space when used with conventional electric hoists.

- Due to the close spacing of hoist wheels on both sides of the track, the electric hoist easily swings in the horizontal plane perpendicular to the direction of the main beam.

Wrap it up,

- European-style electric hoist single girder crane main girder has higher material and welding requirements and even requires reliable frequency conversion technology protection.

- Traditional electric single girder crane main beam has rugged and thick design and is durable.

- The two cross-sectional electric single girder cranes need to be selected strictly according to the manufacturing conditions and use of the environment.

Lifting system compariosn of European style and Traditional type bridge crane

European style wire rope hoist

Model NRL (Low-Headroom Monorail Hoist)

Model NRL (Low-Headroom Monorail Hoist)Capacity: 3 ton, 5 ton, 10 ton. Customized European style low headroom cranet maximize your workshop space.

Model NRS (Standard-Headroom Monorail Hoist)

Capacity: 3 ton, 5 ton, 10 ton, 16 ton, 20 ton. Customized for your single girder cranes with European style.

Model NRT (Double-Rail Trolley or Crab)

Model NRT (Double-Rail Trolley or Crab)Capacity / SWL: 3 ton - 80 ton. Popular for double girder cranes, customized desgin available.

Model NRF (Foot-Mounted Hoist)

Capacity / SWL: 3 ton, 5 ton, 10 ton, 16 ton, 20 ton, 32 ton, 50 ton, 80 ton, etc. Contact to get your custom design.

- Due to the design, hoist motor, gear box and drum are arranged scientifically and compactly which enlarges the working space of crane and increases the lifting height.

- The integrated and compact design of hoisting motor, reducer, reel and limit switch saves space for user.

- Modular design increases the reliability of mechanism while reducing the time and cost for maintaining.

Cd/md wire rope hoists

CD&MD model electric wire rope hoist is a type of light-duty lifting equipment with features such as a compact structure, light weight, small volume, wide application, and simple operation.

CD&MD model electric wire rope hoist is a type of light-duty lifting equipment with features such as a compact structure, light weight, small volume, wide application, and simple operation. Electric wire rope hoist with capacity above 5 ton, such as 10 ton, 16 ton, with double travelling motors, which can customized with 2 speeds.

Electric wire rope hoist with capacity above 5 ton, such as 10 ton, 16 ton, with double travelling motors, which can customized with 2 speeds.  From CD/MD electric hoist, Low Headroom Wire Rope Electric Hoist is developed. The product's characteristics include a compact design, single- or double-speed lifting, higher hook approach, and stable operation.

From CD/MD electric hoist, Low Headroom Wire Rope Electric Hoist is developed. The product's characteristics include a compact design, single- or double-speed lifting, higher hook approach, and stable operation. Double girder wire rope hoist with capacity from 5 ton -63 ton which are widely used on double girder cranes.

Double girder wire rope hoist with capacity from 5 ton -63 ton which are widely used on double girder cranes. - Electric wire rope electric hoist with trolley has a compact structure, a small size, a rapid speed, low noise, is safe and dependable, has universal parts, strong interchangeability, a single heavy lifting capability, is easy to maintain, and saves manufacturing site space.

- Electric cable hoists with trolley can be fitted in various types of cranes (single beam cranes, cantilever cranes, gantry cranes, basic gantry frames) or hanging in the I-beam, straight or curve rail reciprocating lifting high loads.

- The inner drum is comprised of lightweight seamless steel tubing with an anti-rope reel cover. High intensity coil casing built of premium cast iron. The pressure plate and bolt are attached to the end of the steel wire rope to keep it from wrapping into the gearbox and engine and ensuring smooth lifting.

- The electric wire hoist with trolley's major component is the drum. It is linked to the traveling mechanism above by a balance beam, to the reducer and motor on both sides, and to the wire rope and hook below. Limited guide bar equipment was installed in front of the exterior cover.