Single vs Double Girder Gantry Crane Parts: A Comprehensive Guide

Gantry cranes are used in a variety of industries to lift and move heavy loads. They are available in different configurations, including single and double girder models. Single girder gantry cranes have one main beam that supports the hoist trolley, while double girder gantry cranes have two main beams for added stability and lifting capacity. Understanding the parts of these cranes is essential for safe and efficient operation. This comprehensive guide provides an overview of the parts of both single and double girder gantry cranes, including the gantry frame, hoist trolley, crane running mechanism, electric control system, and more. Whether you are new to gantry cranes or looking to expand your knowledge, this guide will help you understand the components of these powerful machines.

A single girder gantry crane is a type of gantry crane that has a single girder/beam structure. It is composed of the main beam, support legs, cross beam, crane drive, controls, and hoist. Single girder gantry cranes use a variety of lifting hoists depending on the type of work and can use European hoists as well. The lifting mechanism is usually a wire rope hoist traveling on the single girder, and the crane travels on the rail track fixed on the ground/floor. Single-girder gantry crane beams are made by section steel or welded box girder or lattice girder gantry cranes.

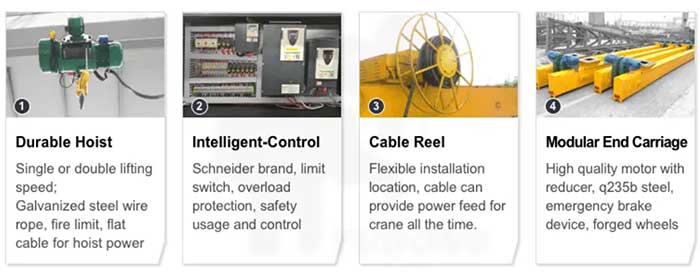

Customized parts and components availale to custom single girder gantry crane design and solution

Single Girder Gantry Crane Components and Parts

- Main beam: serves as the backbone of the crane and supports the weight of the hoist and trolley. It is usually made of steel.

- Support legs: provide stability to the crane and transfer the weight of the crane to the ground. They are usually made of steel.

- Cross beam: connects the two support legs and provides additional support to the main beam. It is usually made of steel.

- Crane drive: powers the movement of the crane along the rails. It is usually powered by an electric motor.

- Controls: allow operators to control the movement of the crane. They are usually located in a control cabin or on a pendant.

- Hoist: lifts and lowers loads. It is usually powered by an electric motor.

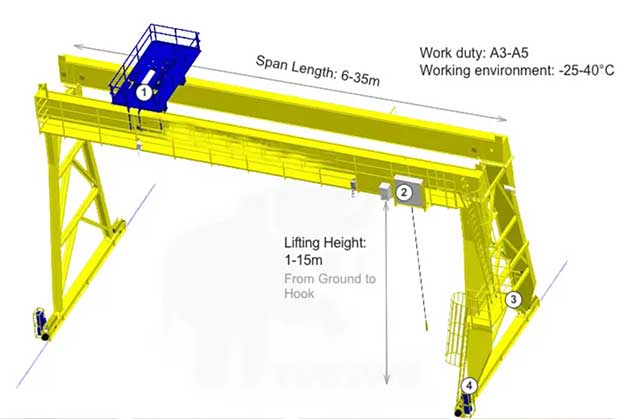

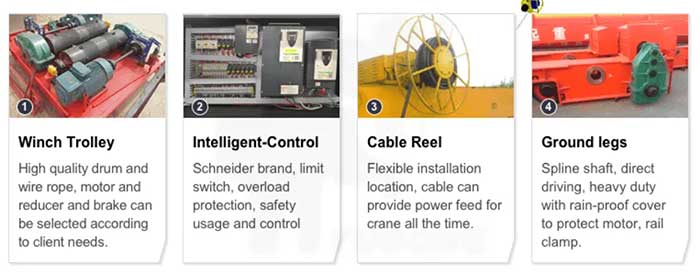

A double girder gantry crane is a type of bridge crane that has legs at both ends to support the bridge frame on the ground track. It consists of the gantry frame, hoist trolley, crane running mechanism, and electric control system. The crane has a double main beam/girder structure, with a winch hoist that runs on the girders for lifting operations. It travels on rail tracks to handle materials in different positions. Additionally, there may be outstretched cantilevers at the two ends of the main beam for a larger working range.

Customized double girder gantry crane with selection parts and components are available.

Double Girder Gantry Crane Components and Parts

- Two main beams: provide additional support to the hoist and trolley. They are usually made of steel.

- End carriages: connect the two main beams and provide support for the hoist trolley. They are usually made of steel.

- Cross travel rails: guide the hoist trolley along the length of the crane. They are usually made of steel.

- Crane drive: powers the movement of the crane along the rails. It is usually powered by an electric motor.

- Controls: allow operators to control the movement of the crane. They are usually located in a control cabin or on a pendant.

- Hoist trolley: lifts and lowers loads. It is usually powered by an electric motor.

Single vs Double Girder Gantry Cranes

|

Part |

Single Girder Gantry Crane |

Double Girder Gantry Crane |

|

Main beam |

1 |

2 |

|

Support legs |

2 |

2 |

|

Cross beam |

1 |

0 |

|

End carriages |

0 |

2 |

|

Cross travel rails |

0 |

2 |

|

Crane drive |

1 |

1 |

|

Controls |

1 |

1 |

|

Hoist trolley |

0 |

1 |

Here is the comparison table of the main parts of single girder and double girder gantry cranes with more details and descriptions:

|

Part |

Single Girder Gantry Crane |

Double Girder Gantry Crane |

|

Main beam |

The main beam serves as the backbone of the crane and supports the weight of the hoist and trolley. It is usually made of steel. |

Double girder gantry cranes have two main beams that provide additional support to the hoist and trolley. They are usually made of steel. |

|

Support legs |

Support legs provide stability to the crane and transfer the weight of the crane to the ground. They are usually made of steel. |

Double girder gantry cranes have two support legs that provide stability to the crane and transfer the weight of the crane to the ground. They are usually made of steel. |

|

Cross beam |

The cross beam connects the two support legs and provides additional support to the main beam. It is usually made of steel. |

Double girder gantry cranes do not have a cross beam. |

|

End carriages |

Single girder gantry cranes do not have end carriages. |

End carriages connect the two main beams and provide support for the hoist trolley. They are usually made of steel. |

|

Cross travel rails |

Single girder gantry cranes do not have cross travel rails. |

Cross travel rails guide the hoist trolley along the length of the crane. They are usually made of steel. |

|

Crane drive |

The crane drive powers the movement of the crane along the rails. It is usually powered by an electric motor. |

The crane drive powers the movement of the crane along the rails. It is usually powered by an electric motor. |

|

Controls |

Controls allow operators to control the movement of the crane. They are usually located in a control cabin or on a pendant. |

Controls allow operators to control the movement of the crane. They are usually located in a control cabin or on a pendant. |

|

Hoist trolley |

The hoist lifts and lowers loads. It is usually powered by an electric motor. |

The hoist trolley lifts and lowers loads. It is usually powered by an electric motor. |

Here is a comparison table of single girder and double girder gantry cranes:

|

Feature |

Single Girder Gantry Crane |

Double Girder Gantry Crane |

|

Load capacity |

Up to 20 tons |

Up to 200 tons |

|

Span length |

Up to 35 meters |

Up to 35 meters |

|

Lifting height |

Up to 30 meters |

Up to 30 meters |

|

Speed |

Up to 40 m/min |

Up to 40 m/min |

|

Hoist type |

Wire rope hoist or chain hoist |

Wire rope hoist or chain hoist trolley or winch |

|

Maintenance cost |

Low |

High |

|

Price |

Low |

High |

FAQ on main gatnry cranes components and parts

What are the main parts of gantry cranes?

The main parts of gantry cranes include the bridge, trolley, hoist, legs, and end trucks.

-Gantry Frame

The gantry frame is the primary supporting structure of the crane. It consists of two vertical legs, a horizontal beam, and a trolley that runs along the beam. The gantry frame is designed to provide stability to the crane during lifting operations.

What is the function of the bridge in a gantry crane?

The bridge in a gantry crane is the horizontal beam that spans the gap between the two legs of the crane. Its main function is to support the trolley and hoist, and to provide a stable platform for them to move along the length of the crane. The bridge also helps distribute the weight of the load being lifted evenly across the legs of the crane, ensuring that the crane remains stable and balanced during operation. Additionally, the bridge can be designed to accommodate different types of loads and lifting configurations, making it a versatile component of the gantry crane system.

What materials are typically used to construct the legs of a gantry crane?

The legs of a gantry crane are usually made of steel. Steel is a popular choice for construction due to its strength, durability, and ability to withstand heavy loads. The steel used in gantry crane legs is typically high-strength, low-alloy (HSLA) steel, which is specially designed to withstand the stresses and strains of crane operation. In addition to steel, other materials such as aluminum or composite materials can also be used for gantry crane legs, depending on the specific application and requirements.

Hoist Trolley

The hoist trolley is the component that carries the load. It is attached to the gantry frame and moves along the beam. The hoist trolley can be fitted with various lifting tools such as hooks, magnets, or grabs, depending on the type of load being lifted.

How does the trolley move along the bridge of a gantry crane?

The trolley of a gantry crane moves along the bridge by means of a hoist mechanism. The hoist mechanism consists of a motor, a gearbox, and a drum which is used to wind the hoist rope. The hoist rope is attached to the trolley, and as the drum rotates, the trolley moves along the bridge. The operator controls the movement of the trolley by using a pendant control or a radio remote control. The trolley can move along the bridge in both directions, allowing it to position the load anywhere within the crane's working area.

Ground beam of gantry cranes

The ground beam of a gantry crane is a large, horizontal beam that runs along the ground and is anchored to concrete footings. It supports the weight of the crane and its load, providing stability and support for the crane’s legs and bridge frame. The ground beam also helps to distribute the weight of the crane and its load evenly across the ground, reducing the risk of damage or instability. It is an essential part of the gantry crane’s overall structure and must be constructed to withstand the weight and movement of the gantry crane. Regular inspection of the ground beam is necessary to ensure safe and efficient operation.

Gantry crane wheels

Gantry crane wheels are typically either single or double rim. Single rim flanged track wheels are common, mainly used in gantry cranes under 5 tonnes. You’ll also see them on double beam bridge gantry cranes. A double rim is chiefly found on heavier gantry cranes, double beam bridge gantry cranes, and mechanisms for crane operation

How to select a gantry crane wheel for your application?

- Selecting the right gantry crane wheel for your crane involves several factors, including:

- Load capacity: Choose wheels that can support the maximum weight of your crane and its load.

- Wheel diameter: Select wheels with a diameter that is appropriate for the rail size and the surface conditions of your operating area.

- Wheel material: Choose wheels made of durable materials that can withstand the wear and tear of regular use. Common materials include steel, cast iron, and polyurethane.

- Wheel type: Consider the type of wheel needed for your specific application. Options include single flange, double flange, and flat tread wheels.

- Operating conditions: Take into account the operating environment, such as temperature, humidity, and exposure to chemicals or corrosive materials.

- Maintenance requirements: Consider the maintenance requirements of the wheels and select ones that are easy to maintain and replace.

It is recommended to consult with a qualified engineer or crane manufacturer to ensure that you select the right gantry crane wheel for your specific application and operating conditions.

Crane rail

The crane rail of gantry cranes is a rail track that runs along the ground and supports the movement of the gantry crane. The crane travels along the rail to different positions for material handling. The rail is usually made of steel and is designed to withstand the weight and movement of the crane. The rail is an essential component of the gantry crane system, and it must be installed and maintained correctly to ensure safe and efficient operation.

How to construct gantry crane rail ?

To construct a gantry crane rail, the ground surface must be prepared and the required length and width of the rail determined. Rail supports or beams should be installed at regular intervals, and the rail sections connected using bolts or welding. Rail stops or bumpers should be installed at each end of the rail to prevent the gantry crane from running off. The rail must be tested for proper alignment and stability, and regularly inspected and maintained for safe and efficient operation. It is recommended to consult with a qualified engineer or contractor to ensure that the gantry crane rail is constructed correctly and meets all safety requirements.

Electrical System

The electrical system of a full gantry crane consists of various components such as motors, cables, and control panels. The motors provide power to the crane’s movement, and the cables transmit the power from the electrical source to the crane’s motors. The control panel allows the operator to control the crane.

How to supply power to gantry cranes ?

Here are the three main power supply methods for gantry cranes and their features:

- Overhead slide line: uses a slide line material made of steel-aluminum/copper alloy.

- Ground conductor line: uses rigid construction bars or cable festoon systems.

- Ground cable reel: uses a reel with conductor cable wrapped around it.

The selection of the power supply method depends on several factors such as crane capacity, speed, travel distance, environmental conditions, and maintenance requirements.

Controls and Safety Features

The controls and safety features of a full gantry crane are crucial components that ensure the safe operation of the crane. The operator can control the crane’s movement using a control panel that is fitted with buttons and switches. The safety features include limit switches that prevent the crane from overloading or moving beyond its operational limits.

What are the safety parts and components of gantry cranes ?

Gantry cranes have several safety features that ensure the safety of the crane during operation. These features include overload protection devices, travel limit switches, emergency stop buttons, and anti-collision systems. They protect the operator, the equipment, and the surrounding environment from potential risks .