Gantry Crane Designs for Specialized Industrial Environments

Gantry Crane Designs for Specialized Industrial Environments

Gantry Crane Designs for Specialized Industrial Environments optimize efficiency and safety in aerospace, automotive, construction sectors.Get your design!

Gantry cranes are essential tools in industrial settings, designed to lift and move heavy loads horizontally within a confined area. Unlike traditional overhead cranes, gantry cranes are supported by legs that run on fixed rails or wheels, providing mobility and flexibility in various environments.

Gantry cranes serve multiple purposes, primarily focusing on the efficient handling of heavy materials and equipment. They are crucial for tasks such as loading and unloading cargo in shipping yards, moving large components in manufacturing plants, and supporting construction projects by lifting materials to elevated positions.

In specialized industrial environments, such as aerospace, automotive, and construction, gantry cranes play a critical role tailored to specific operational needs. These environments often require cranes with customized features like precise control systems for delicate operations or heavy-duty structures capable of lifting substantial weights. Such specialized designs ensure safety, operational efficiency, and compliance with industry standards, addressing unique challenges posed by different sectors.

By adapting gantry crane designs to specific industrial requirements, businesses can optimize their workflow, enhance safety measures, and effectively manage logistics, thereby contributing to overall productivity and operational success.

Types of Specialized Industrial Environments

In today's industrial landscape, various sectors require gantry crane designs tailored to their specific operational demands. Understanding these specialized environments is crucial for designing cranes that optimize efficiency and safety.

Overview of Industries Requiring Specialized Gantry Crane Designs:

Gantry cranes are indispensable in several key industries, each with unique requirements:

- Aerospace:Precision is paramount in handling aircraft components such as engines, fuselage sections, and wings. Gantry cranes in aerospace must often support delicate parts while ensuring minimal disturbance to sensitive equipment.

- Automotive:From assembly lines to logistics centers, automotive industries rely on gantry cranes for lifting heavy car bodies, engines, and other components. These cranes facilitate efficient production processes and streamline material handling operations.

- Construction:Gantry cranes play a pivotal role in construction sites by lifting and positioning heavy materials like steel beams, concrete panels, and prefabricated structures. They are essential for vertical construction tasks and ensuring timely project completion.

- Shipping Yards:Container handling and bulk cargo operations in shipping yards require robust gantry cranes capable of lifting massive loads, often in challenging weather conditions and near water bodies. These cranes ensure smooth operations in loading and unloading vessels.

Specific Challenges and Requirements for Each Industry:

- Aerospace:Requires gantry cranes with precise control systems and lightweight yet durable materials to handle fragile aircraft parts without causing damage.

- Automotive:Needs gantry cranes with high load capacities and fast operational speeds to support the rapid pace of assembly lines while maintaining safety standards for workers.

- Construction:Demands gantry cranes that can operate effectively in rugged outdoor environments, with features like all-terrain mobility and robust lifting capabilities to handle heavy construction materials.

- Shipping Yards:Requires gantry cranes with corrosion-resistant materials and weatherproof designs capable of lifting and maneuvering heavy containers and cargo efficiently on docks and shipyards.

These specific challenges allows crane manufacturers to design and customize gantry cranes that meet the unique demands of each industry, enhancing operational efficiency, safety, and overall productivity.

Factors Influencing Gantry Crane Design

The design of gantry cranes is influenced by several critical factors that ensure their efficiency, safety, and compliance with industry standards. Understanding these factors is essential for developing gantry cranes tailored to specific operational environments.

Main parameters to get your custom gantry crane design for specialized industrial environment

Load Capacity and Size Considerations:

Gantry cranes are designed to handle a wide range of loads, from light to extremely heavy. Factors influencing load capacity and size considerations include:

- Payload Requirements:Determining the maximum weight the crane will lift regularly.

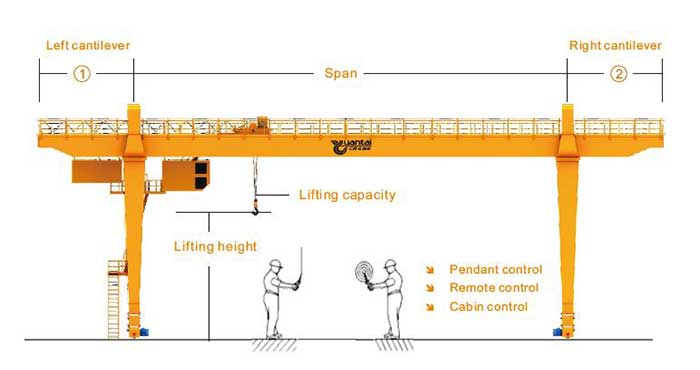

- Span and Height Requirements:Span refers to the distance between the legs of the crane, while height relates to the lifting capacity required.

- Clearance Requirements:Ensuring sufficient clearance for the crane to operate without obstruction.

Environmental Factors:

Environmental conditions significantly impact gantry crane design and performance. Key environmental factors include:

- Weather Conditions:Cranes used outdoors must withstand varying weather conditions such as wind, rain, and extreme temperatures.

- Temperature Extremes:Cranes operating in environments with high or low temperatures require materials and lubricants that can withstand these conditions without compromising performance.

- Corrosion Resistance:Especially important for cranes operating in marine environments or areas with high humidity, requiring corrosion-resistant materials and protective coatings.

Safety and Regulatory Requirements:

Ensuring the safety of operators and compliance with regulatory standards is paramount in gantry crane design:

- Structural Integrity:Designing cranes with robust structures and safety features to prevent accidents and ensure stable operation.

- Safety Devices:Incorporating safety devices such as limit switches, overload protection, emergency stop buttons, and warning alarms.

- Compliance:Adhering to local and international safety standards and regulations governing crane design, installation, and operation.

By carefully considering these factors during the design phase, crane manufacturers can create gantry cranes that not only meet operational requirements but also prioritize safety, durability, and efficiency in diverse industrial settings.

Key Design Features of Gantry Cranes for Specialized Environments

Gantry cranes designed for specialized environments incorporate specific features tailored to meet the unique demands of various industries. These features enhance efficiency, safety, and adaptability in challenging operational settings.

Heavy-duty Construction:

Gantry cranes in specialized environments are built with robust structural components and durable materials to withstand rigorous use and heavy loads:

- Structural Components and Materials:Utilization of high-strength steel or aluminum alloys ensures structural integrity and longevity.

- Reinforcement and Durability Features:Additional reinforcement in critical stress points and protective coatings to resist corrosion and wear, enhancing crane lifespan in demanding conditions.

Customized Controls and Automation:

Advanced control systems and automation play a crucial role in optimizing crane operations and enhancing safety:

- Remote Operation Capabilities:Enable operators to control cranes from a safe distance, improving visibility and maneuverability.

- Integration with Industrial IoT (Internet of Things):Sensors and data monitoring systems provide real-time information on crane performance, maintenance needs, and operational efficiency, facilitating predictive maintenance and operational insights.

Adaptability and Mobility:

Specialized gantry cranes offer flexibility and mobility to meet diverse operational requirements:

- Trackless Gantry Cranes:Designed with omnidirectional wheels or crawler tracks, allowing movement across various surfaces without fixed rails, ideal for dynamic work environments.

- Portability Options:Lightweight and modular designs enable easy assembly, disassembly, and relocation, supporting temporary installations or operations in multiple locations.

These key design features ensure that gantry cranes for specialized environments not only meet specific industry requirements but also optimize productivity, minimize downtime, and adhere to stringent safety standards, ultimately contributing to enhanced operational efficiency and cost-effectiveness.

Case Studies and Examples

Gantry cranes are integral to various industries, each requiring tailored designs to meet specific operational needs. Here are detailed examples of gantry crane applications in key sectors:

Automotive: Assembly Line and Logistics Support

Gantry cranes are essential in automotive manufacturing facilities, supporting assembly line processes and logistics operations. Key features include:

- High Load Capacities:Capable of lifting heavy car bodies, engines, and other components with speed and efficiency.

- Fast Operational Speeds:Designed for rapid material handling to maintain the pace of automotive production lines.

Gantry Crane designed for construction site

Construction: Heavy Material Handling at Construction Sites

In the construction industry, gantry cranes facilitate the lifting and movement of heavy materials at construction sites, enhancing efficiency and safety. These cranes are equipped with:

- Heavy-Duty Structures:Robust construction to handle bulky materials such as steel beams, concrete panels, and prefabricated structures.

- All-Terrain Mobility:Tracks or wheels suitable for rough terrain, allowing cranes to maneuver across construction sites with ease.

These case studies illustrate how gantry cranes are customized to meet the specific demands of aerospace, automotive, and construction industries, demonstrating their versatility and critical role in enhancing operational capabilities across diverse industrial applications.

Benefits of Specialized Gantry Crane Designs

Specialized gantry crane designs offer numerous advantages tailored to meet the unique challenges and requirements of various industries. Here are the key benefits:

Enhanced Operational Efficiency:

Specialized gantry cranes streamline operations by:

- Optimizing Workflow:Customized designs ensure seamless integration into specific industrial processes, enhancing productivity and minimizing bottlenecks.

- Faster Material Handling:High-speed operations and precise positioning capabilities reduce cycle times, accelerating production and assembly processes.

Reduction in Downtime and Maintenance Costs:

Designed with durability and reliability in mind, specialized gantry cranes contribute to:

- Extended Lifespan:Robust construction and use of high-quality materials minimize wear and tear, reducing the frequency of repairs and replacements.

- Predictive Maintenance:Integration with IoT technologies allows for proactive monitoring of crane performance, enabling timely maintenance interventions to prevent breakdowns and downtime.

Improved Safety Protocols and Compliance with Industry Standards:

Enhanced safety features in specialized gantry cranes ensure:

- Risk Mitigation:Advanced safety systems such as overload protection, emergency stop buttons, and proximity sensors enhance operator safety and prevent accidents.

- Adherence to Regulations:Compliance with stringent industry standards and regulations ensures safe crane operation, mitigating liability risks and ensuring workplace safety.

By focusing on these benefits, specialized gantry crane designs not only optimize operational efficiency but also contribute to cost savings, safety enhancement, and regulatory compliance in diverse industrial environments.

Challenges and Considerations

Specialized gantry cranes, while offering significant benefits, also present specific challenges and considerations that need careful attention in their design and operation:

Maintenance Requirements for Specialized Components:

Maintaining specialized gantry cranes involves:

- Unique Components:Components such as precision control systems and specialized materials require specific maintenance procedures and expertise.

- Scheduled Inspections:Regular inspections to detect wear, corrosion, and other potential issues early, ensuring continued reliability and performance.

- Availability of Parts:Ensuring availability of spare parts for timely repairs and replacements to minimize downtime.

Training Needs for Operators in Specific Environments:

Operators of specialized gantry cranes require:

- Technical Expertise:Training in the operation of advanced control systems and specialized features unique to the crane design.

- Safety Protocols:Understanding and adherence to stringent safety protocols tailored to the operational environment.

- Emergency Procedures:Preparedness in handling emergency situations and troubleshooting technical issues promptly.

Addressing these challenges through proactive maintenance practices and comprehensive operator training programs is crucial to maximizing the efficiency, safety, and longevity of specialized gantry cranes in various industrial applications.

Conclusion

Specialized gantry crane designs play a pivotal role in enhancing operational efficiency, ensuring safety, and meeting the unique demands of diverse industrial environments. As highlighted throughout this discussion, these cranes are meticulously tailored to specific industries such as aerospace, automotive, and construction, each requiring customized features to optimize performance and productivity.

Specialized gantry cranes offer tailored solutions that:

- Enhance Efficiency:By optimizing workflow, reducing downtime, and accelerating material handling processes.

- Ensure Safety:Through advanced safety features and compliance with stringent industry standards.

- Meet Industry Requirements:Addressing specific challenges such as precision handling in aerospace or heavy-duty operations in construction.

As industries evolve and demand for efficiency and safety grows, specialized gantry crane designs will continue to evolve, offering solutions that not only meet but exceed the expectations of modern industrial applications. By embracing innovation and addressing emerging challenges, specialized gantry cranes will remain indispensable tools for enhancing productivity and operational excellence across various sectors.

Questions and Answers on Gantry Crane Designs

Here are some frequently asked questions (FAQs) related to choosing and implementing specialized gantry crane designs:

Q1: What factors should I consider when choosing a specialized gantry crane design for my industry?

A1: When selecting a specialized gantry crane, consider factors such as the specific operational requirements (e.g., load capacity, environmental conditions), safety features, maintenance needs, and compliance with industry regulations.

Q2: How can specialized gantry crane designs improve operational efficiency?

A2: Specialized gantry cranes are designed to optimize workflow and reduce downtime through features like faster material handling, advanced control systems for precise operations, and integration with IoT for predictive maintenance.

Q3: What are the maintenance requirements for specialized gantry crane components?

A3: Maintenance of specialized gantry cranes involves regular inspections of unique components such as precision control systems and specialized materials. Scheduled maintenance ensures reliability and extends the crane's lifespan.

Q4: How can operators be trained to handle specialized gantry cranes effectively?

A4: Operator training should cover technical aspects of operating advanced control systems, adherence to safety protocols specific to the crane's design, and emergency procedures. Ongoing training ensures competent and safe crane operation.

Q5: What are the future trends in specialized gantry crane designs?

A5: Future innovations may include advancements in automation, such as AI-driven operations and remote monitoring, development of lightweight yet robust materials, and enhancements in environmental adaptability to expand crane usage in diverse conditions.

Q6: How can specialized gantry crane designs contribute to workplace safety?

A6: Specialized gantry cranes enhance safety through features like advanced safety systems (e.g., overload protection, emergency stop buttons), compliance with rigorous industry standards, and ergonomic designs that prioritize operator safety.

These FAQs provide insights into the considerations and benefits of choosing and implementing specialized gantry crane designs, ensuring efficient and safe operations across various industrial applications.