Questions to Ask Before Getting a Quote for a 10 Ton Overhead Crane

Before requesting a quote for a 10-ton overhead crane, ask about customization options, safety features, installation requirements, and after-sales support.

When it comes to investing in heavy equipment like a 10-ton overhead crane, asking the right questions can make all the difference. Whether you're a small business looking to expand your operations or a seasoned professional in the industry, understanding your needs and the specifications of the equipment is crucial. That's where we come in.

In this guide, we'll walk you through the essential questions you need to ask before requesting a quote for a 10-ton overhead crane. Our goal is simple: to empower you with the knowledge and insight necessary to make informed decisions and ensure you receive accurate quotes tailored to your requirements.

Understanding Your Material Handling Needs

Before diving into the process of requesting a quote for a 10-ton overhead crane, it's essential to have a clear understanding of your specific requirements.

- Assessing the specific requirements for the overhead crane: Start by evaluating the primary purpose of the crane. Will it be used for lifting heavy machinery in a manufacturing facility, loading and unloading cargo in a warehouse, or any other specific task? Consider factors such as the maximum weight capacity you'll need, the height of the lift, and any specialized lifting attachments required.

- Determining the intended use and operational environment: Understanding where and how the overhead crane will be used is crucial. Is it for indoor or outdoor use? Will it be exposed to harsh environmental conditions such as extreme temperatures or corrosive substances? Consider factors such as the available space for installation, the layout of the facility, and any potential obstacles that may affect the crane's operation.

- Evaluating any unique features or customization needed: Every business has its unique requirements when it comes to overhead cranes. Perhaps you need a crane with a specific span or lifting height to accommodate your facility's layout. Or maybe you require specialized features such as radio remote control, variable speed controls, or advanced safety systems. Take the time to identify any customization or special features that are essential for meeting your operational needs effectively.

By thoroughly assessing your needs in these areas, you'll be better equipped to communicate your requirements to potential suppliers and ensure that the quotes you receive are tailored to your specific needs. This proactive approach will help streamline the procurement process and ultimately lead to a more successful outcome for your business.

Related Qustions

1. What are the primary purposes for which you intend to use the 10-ton overhead crane?

2. What is the maximum weight capacity required for your overhead crane operations?

3. How high will the crane need to lift loads within your facility?

4. Will the overhead crane be used indoors or outdoors, and what environmental conditions will it be exposed to?

5. Do you have sufficient space available for installing the overhead crane, and are there any layout constraints to consider?

6. Are there any potential obstacles or obstructions that could affect the operation of the overhead crane?

7. Are there any specific customization or unique features required for the overhead crane to meet your operational needs effectively?

8. Do you require any specialized attachments or lifting mechanisms for your overhead crane?

9. Are there any safety or regulatory requirements that the overhead crane must adhere to in your operational environment?

10. What level of automation or control features do you require for the overhead crane, such as radio remote control or variable speed controls?

Safety and Compliance

Safety should always be a top priority when considering the purchase of a 10-ton overhead crane. Here's a closer look at what you need to consider:

Inquiring about safety standards and certifications: Before requesting a quote, it's essential to inquire about the safety standards and certifications that the overhead crane meets. Look for certifications such as CE (Conformité Européenne) for European standards or ANSI (American National Standards Institute) for American standards. These certifications indicate that the crane has undergone rigorous testing and meets the necessary safety requirements.

Ensuring compliance with local regulations and industry standards: In addition to international safety standards, it's crucial to ensure that the overhead crane complies with local regulations and industry-specific standards. Different regions may have specific safety requirements and regulations governing the operation of overhead cranes. Make sure to research and understand these regulations to ensure compliance and avoid any potential legal issues down the line.

Asking about safety features and maintenance requirements: When requesting a quote, be sure to ask about the safety features included with the overhead crane. This may include features such as overload protection systems, emergency stop buttons, limit switches, and safety alarms. Additionally, inquire about the maintenance requirements for the crane to ensure that it remains in optimal working condition and continues to meet safety standards over time. Regular maintenance and inspections are essential for identifying and addressing any potential safety hazards before they escalate into serious issues.

By prioritizing safety and compliance in your procurement process, you can protect your workers, minimize the risk of accidents, and ensure the smooth and efficient operation of your facility. Don't hesitate to ask potential suppliers for detailed information about safety standards, certifications, and maintenance requirements to make an informed decision that prioritizes the well-being of your workforce.

Related Qustions

1. What safety standards and certifications should the 10-ton overhead crane meet, and how can I verify their compliance?

2. Are there any specific safety features included with the overhead crane, such as overload protection systems or emergency stop buttons?

3. How does the overhead crane manufacturer ensure compliance with local regulations and industry-specific standards in different regions?

4. What are the maintenance requirements for the overhead crane to ensure continued compliance with safety standards over time?

5. Can you provide documentation or proof of safety certifications, such as CE or ANSI, for the overhead crane?

6. Are there any additional safety training or certification programs available for crane operators to ensure safe and proper usage?

7. How frequently are safety inspections conducted on the overhead crane, and what is the process for addressing any identified safety hazards?

8. What measures are in place to address any potential safety concerns or issues that may arise during the operation of the overhead crane?

9. Can you provide references or case studies demonstrating the successful implementation of safety measures and compliance with regulations in similar operational environments?

10. How does the overhead crane manufacturer prioritize safety and compliance in their design, manufacturing, and maintenance processes?

Technical Specifications

Understanding the technical specifications of a 10-ton overhead crane is vital to ensure it meets your operational needs effectively. Here's what you need to consider:

Clarifying load capacity and lifting requirements: The load capacity of the crane refers to the maximum weight it can lift safely. When requesting a quote, be sure to clarify your specific lifting requirements, including the maximum weight of the loads to be lifted and any special considerations such as uneven weight distribution or delicate materials. This will help ensure that the crane you select is capable of handling your workload efficiently and safely.

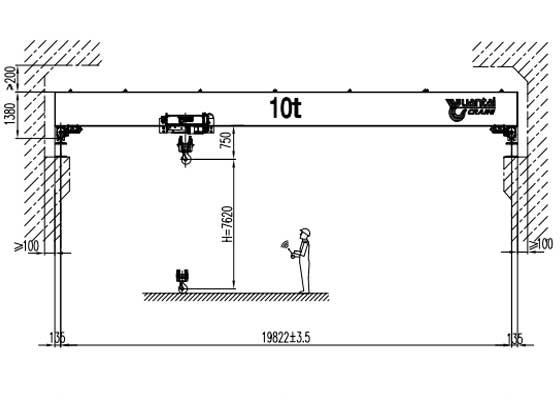

Understanding crane dimensions and space requirements: The dimensions of the overhead crane, including its span and lifting height, are essential factors to consider to ensure it fits within your facility's layout. Measure the available space for installation carefully and communicate these dimensions to potential suppliers when requesting a quote. Additionally, consider any height restrictions or obstacles that may affect the crane's operation and select a model that can accommodate your spatial limitations without compromising performance.

Inquiring about power supply and operational controls: Different overhead crane models may have varying power requirements and operational controls. Inquire about the power supply needed to operate the crane, including voltage, phase, and frequency, to ensure compatibility with your facility's electrical infrastructure. Additionally, ask about the operational controls available for the crane, such as pendant controls, radio remote controls, or cabin controls, and choose the option that best suits your operational preferences and safety requirements.

By clarifying the technical specifications of the overhead crane before requesting a quote, you can ensure that you select a model that meets your specific lifting needs, fits within your facility's layout, and operates seamlessly with your existing infrastructure. This proactive approach will help you make an informed decision and avoid any potential compatibility issues or operational challenges down the line.

Related Qustions

1. What is the maximum load capacity required for your lifting operations, and are there any specific considerations such as uneven weight distribution or delicate materials?

2. Can you provide the dimensions of the available space for installing the overhead crane, including span and lifting height restrictions?

3. What are the power supply requirements for operating the overhead crane, including voltage, phase, and frequency, and does your facility's electrical infrastructure meet these specifications?

4. Are there any height restrictions or obstacles in your facility that may affect the installation or operation of the overhead crane, and how can these be accommodated?

5. Do you have any preferences or requirements regarding the operational controls of the overhead crane, such as pendant controls, radio remote controls, or cabin controls?

6. What safety features are integrated into the overhead crane design to ensure safe and efficient operation, and how do these align with your safety protocols?

7. Are there any specific environmental factors in your facility, such as extreme temperatures or corrosive substances, that may affect the performance or durability of the overhead crane?

8. Can you provide details of any special lifting attachments or accessories required for your lifting operations, and how can these be accommodated in the crane design?

9. Are there any regulatory or compliance requirements that the overhead crane must meet in your industry or region, and how does the crane comply with these standards?

10. Can the supplier provide technical documentation and specifications for the overhead crane, including load charts, structural drawings, and operational manuals, for review?

Installation and Maintenance

Proper installation and regular maintenance are essential for the safe and efficient operation of a 10-ton overhead crane. Here's what you need to know:

Asking about installation procedures and requirements: Before purchasing a crane, inquire about the installation process and any specific requirements. This includes considerations such as the need for a concrete foundation, structural supports, and clearance space for installation. Understanding the installation procedures upfront will help you prepare your facility and ensure a smooth and timely installation process.

Inquiring about ongoing maintenance and service agreements: Regular maintenance is key to maximizing the lifespan and performance of your overhead crane. When requesting a quote, ask about the availability of maintenance and service agreements offered by the supplier. These agreements typically include scheduled inspections, preventive maintenance tasks, and timely repairs to address any issues that may arise. Investing in a comprehensive maintenance plan will help minimize downtime, reduce the risk of costly repairs, and prolong the life of your crane.

Understanding warranty coverage and support options: Inquire about the warranty coverage provided with the overhead crane and any additional support options available. This includes warranty periods for different components of the crane, such as the hoist, trolley, and bridge, as well as any exclusions or limitations. Additionally, ask about the supplier's after-sales support services, including technical assistance, spare parts availability, and emergency support. Choosing a supplier that offers robust warranty coverage and responsive support will provide you with peace of mind and assurance that your investment is protected in the event of any issues or malfunctions.

Related Qustions

1. What are the specific installation procedures and requirements for the 10-ton overhead crane, including considerations such as concrete foundation, structural supports, and clearance space?

2. Can the supplier provide guidance or assistance with the installation process, including recommendations for preparing the facility and coordinating logistics?

3. What maintenance and service agreements are available for the overhead crane, and what do these agreements typically include in terms of scheduled inspections, preventive maintenance tasks, and timely repairs?

4. How often are maintenance inspections conducted, and what is the process for scheduling and coordinating these inspections with your operational schedule?

5. What are the warranty coverage periods for different components of the overhead crane, and are there any exclusions or limitations to the warranty coverage?

6. Can the supplier provide information about the after-sales support services available, including technical assistance, spare parts availability, and emergency support?

7. Are there any additional support options or value-added services offered by the supplier, such as training programs for crane operators or online resources for troubleshooting common issues?

8. What measures does the supplier take to ensure timely response and resolution of maintenance and service requests, including any escalation procedures for urgent issues?

9. Can the supplier provide references or case studies demonstrating their track record in installation, maintenance, and support services for overhead cranes?

10. How does the supplier handle warranty claims and service requests, and what is the process for initiating and tracking these requests?

By addressing installation and maintenance considerations upfront and choosing a supplier that offers comprehensive support services, you can ensure that your 10-ton overhead crane is installed correctly, maintained properly, and operates reliably throughout its lifespan. Don't hesitate to ask potential suppliers for detailed information about installation procedures, maintenance agreements, and warranty coverage to make an informed decision that prioritizes the long-term performance and durability of your crane.

Pricing and Additional Costs

Requesting a detailed breakdown of costs: When requesting a quote, ask for a detailed breakdown of all costs associated with the overhead crane. This should include the base price of the crane itself, as well as any additional costs for customization, special features, or optional accessories. Inquire about any taxes, fees, or surcharges that may apply, and request clarification on any items that are not clearly specified. Having a clear understanding of the total cost upfront will help you make an informed decision and avoid any unexpected expenses later on.

Inquiring about additional expenses such as shipping and installation: In addition to the cost of the crane itself, consider any additional expenses that may arise, such as shipping and installation fees. Ask the supplier for a breakdown of these costs and inquire about any factors that may affect them, such as the distance to your facility, the complexity of the installation process, or any special equipment needed for delivery. By understanding these additional expenses upfront, you can budget accordingly and avoid any surprises when it comes time to finalize the purchase.

Understanding payment terms and financing options: Discuss payment terms and financing options with the supplier to determine the most suitable arrangement for your budget and cash flow needs. Inquire about the possibility of financing the purchase through the supplier or a third-party financing provider, and ask about the terms and conditions of any financing agreements available. Additionally, clarify the accepted payment methods and any discounts or incentives that may apply for early payment or bulk orders. By exploring your payment and financing options upfront, you can choose the most cost-effective solution and ensure a smooth transaction process.

Related Qustions

1. Can you provide a detailed breakdown of all costs associated with the overhead crane, including the base price, customization fees, and optional accessories?

2. Are there any additional expenses such as taxes, fees, or surcharges that I should be aware of when considering the total cost of the crane?

3. What are the shipping and installation fees for delivering the overhead crane to my facility, and how are these costs calculated?

4. Are there any factors that may affect shipping and installation expenses, such as the distance to my facility or the complexity of the installation process?

5. Can you provide information about payment terms and financing options available for purchasing the overhead crane, including any third-party financing providers that you work with?

6. What are the terms and conditions of any financing agreements offered, including interest rates, repayment schedules, and eligibility criteria?

7. Do you offer any discounts or incentives for early payment or bulk orders, and if so, what are the terms and conditions?

8. What payment methods do you accept for purchasing the overhead crane, and are there any additional fees associated with certain payment methods?

9. Are there any warranty or maintenance plans available for the overhead crane, and if so, how do these factor into the overall cost of ownership?

10. Can you provide references or case studies demonstrating the total cost of ownership for similar overhead crane purchases, including all associated expenses and financing arrangements?

By thoroughly understanding the pricing and additional costs associated with acquiring a 10-ton overhead crane, you can make an informed decision that aligns with your budget and financial objectives. Don't hesitate to request a detailed breakdown of costs, inquire about additional expenses, and explore payment and financing options to ensure that you receive the best value for your investment.

Supplier Evaluation

Choosing the right supplier for your 10-ton overhead crane is essential for a successful acquisition process. Here's how to evaluate potential suppliers:

Researching the reputation and experience of potential suppliers: Start by researching the reputation and experience of potential suppliers in the industry. Look for suppliers with a proven track record of delivering high-quality products and excellent customer service. Check online reviews, industry forums, and business directories to gather feedback from other customers. Additionally, consider factors such as the supplier's years of experience in the industry, the size of their operation, and any certifications or awards they may have received.

Asking for references and customer testimonials: Don't hesitate to ask potential suppliers for references and customer testimonials. Contacting past or current customers can provide valuable insights into the supplier's reliability, professionalism, and ability to meet customer expectations. Ask specific questions about the quality of the products supplied, the level of customer service received, and any issues encountered during the purchasing process. Hearing directly from other customers can help you gauge whether the supplier is a good fit for your needs and expectations.

Inquiring about the supplier's after-sales support and responsiveness: Inquire about the supplier's after-sales support services and responsiveness to customer inquiries and concerns. Ask about the availability of technical support, spare parts, and maintenance services after the sale is complete. Additionally, assess the supplier's communication style and responsiveness during the initial inquiry and quoting process. A supplier who is attentive, responsive, and committed to providing excellent customer service is more likely to be a reliable partner for the long term.

Related Qustions

1. Can you provide information about your company's reputation and experience in the industry, including any certifications or awards received?

2. Do you have any references or customer testimonials that I can contact to learn more about your products and services?

3. How long have you been operating in the industry, and what is your level of experience with supplying 10-ton overhead cranes?

4. Can you describe your after-sales support services, including technical support, spare parts availability, and maintenance services?

5. How responsive is your company to customer inquiries and concerns, and what is your typical turnaround time for addressing customer issues?

6. Can you provide examples of how you have resolved customer issues or challenges in the past, demonstrating your commitment to customer satisfaction?

7. What communication channels do you offer for contacting your support team, and are there specific contact persons assigned to handle customer inquiries?

8. How do you ensure the quality and reliability of your products, and do you have any quality control processes in place?

9. Can you describe any specific instances where you have gone above and beyond to meet customer expectations or provide exceptional service?

10. What sets your company apart from other suppliers in the industry, and why should I choose you as my partner for purchasing a 10-ton overhead crane?

By thoroughly evaluating potential suppliers based on their reputation, customer feedback, and after-sales support, you can choose a partner who not only provides high-quality products but also delivers outstanding service and support throughout the entire lifecycle of your overhead crane. Take the time to research and gather information from multiple sources to make an informed decision that aligns with your needs and objectives.

Contact us to get your custom 10 ton overhead crane by leaving a message down below or contact us by email to [email protected] or WhatsApp: + 86 150 38346929.

Customization Options

Customization options for your 10-ton overhead crane can enhance its functionality and tailor it to your specific requirements. Here's what you need to know:

Exploring customization options to meet specific needs: Take the time to explore the customization options available to ensure that the overhead crane meets your unique needs and operational requirements. This may include customization of the crane's lifting capacity, span, lifting height, or operational controls. Consider factors such as the layout of your facility, the types of loads you'll be lifting, and any special considerations or challenges you may face. Working closely with the supplier to explore customization options will help you design a crane that maximizes efficiency and productivity in your operation.

Inquiring about additional features or accessories: In addition to basic customization options, inquire about additional features or accessories that can further enhance the functionality and performance of your overhead crane. This may include features such as remote control operation, variable speed controls, collision avoidance systems, or specialized lifting attachments. Discuss your specific requirements with the supplier and explore the availability of these additional features to ensure that the crane is equipped with everything you need to optimize your workflow.

Understanding the impact of customization on pricing and lead times: While customization can enhance the functionality of your overhead crane, it's essential to understand the potential impact on pricing and lead times. Customized features or modifications may incur additional costs and require longer lead times for design, engineering, and manufacturing. Work closely with the supplier to understand the pricing structure for customization and any associated lead time implications. By weighing the benefits of customization against the cost and lead time considerations, you can make an informed decision that balances your operational needs with your budget and timeline constraints.

Related Qustions

1. What customization options are available for the 10-ton overhead crane to tailor it to our specific operational requirements?

2. Can the lifting capacity, span, and lifting height of the overhead crane be customized to accommodate our facility layout and load requirements?

3. Are there options for customizing the operational controls of the crane, such as remote control operation or variable speed controls?

4. Can you provide information about additional features or accessories that can enhance the functionality and performance of the overhead crane, such as collision avoidance systems or specialized lifting attachments?

5. How do customization options affect the pricing of the overhead crane, and are there any additional costs associated with specific customization features?

6. What is the lead time for implementing customization options, and how does this affect the overall delivery timeline for the overhead crane?

7. Can you provide examples of past customization projects or modifications that you have implemented for other customers?

8. How does the customization process work, from initial design discussions to final implementation and testing?

9. Are there any limitations or restrictions on the types of customization options available for the overhead crane?

10. How do you ensure that customized features or modifications meet our specific requirements and adhere to industry standards and safety regulations?

By exploring customization options, inquiring about additional features, and understanding the impact on pricing and lead times, you can design a 10-ton overhead crane that is perfectly tailored to your specific needs and operational requirements. Collaborate closely with the supplier to explore all available options and ensure that the final design meets your expectations for performance, efficiency, and safety.

Future Expansion and Scalability

Planning for the future is essential when investing in a 10-ton overhead crane. Here's how to ensure scalability and long-term value:

Considering future needs and scalability options: Anticipate future growth and evolving needs within your operation when selecting an overhead crane. Consider factors such as increasing production volumes, expanding product lines, or changes in workflow processes. Choose a crane that offers scalability options, such as the ability to increase load capacity, span, or lifting height as your needs change over time. By selecting a crane with scalability in mind, you can minimize the need for costly replacements or upgrades in the future and ensure that your investment continues to meet your evolving needs effectively.

Inquiring about upgrade possibilities and compatibility with existing infrastructure: When evaluating overhead crane options, inquire about upgrade possibilities and compatibility with your existing infrastructure. Ask the supplier about the availability of upgrade kits or retrofit options that allow you to enhance the functionality or performance of the crane as needed. Additionally, ensure that the crane is compatible with your facility's layout, structural supports, and electrical infrastructure to avoid compatibility issues or costly modifications down the line. Choosing a crane that seamlessly integrates with your existing infrastructure will facilitate future upgrades and minimize disruption to your operations.

Understanding the long-term value and return on investment: Evaluate the long-term value and return on investment of the overhead crane beyond the initial purchase price. Consider factors such as reliability, durability, maintenance requirements, and energy efficiency when assessing the overall value proposition. Calculate the total cost of ownership over the crane's expected lifespan, taking into account factors such as maintenance costs, energy consumption, and potential downtime. By understanding the long-term value and return on investment of the overhead crane, you can make an informed decision that maximizes the benefits to your operation and delivers a positive ROI over time.

Related Qustions

1. How does the overhead crane accommodate future growth and evolving needs within our operation, such as increasing production volumes or expanding product lines?

2. Are there scalability options available for the overhead crane, such as the ability to increase load capacity, span, or lifting height as our needs change over time?

3. Can you provide information about upgrade possibilities or retrofit options that allow us to enhance the functionality or performance of the overhead crane in the future?

4. How compatible is the overhead crane with our existing infrastructure, including structural supports, electrical infrastructure, and layout constraints?

5. What measures are in place to ensure seamless integration of the overhead crane with our existing infrastructure and minimize disruption to our operations during installation or upgrades?

6. How does the overhead crane contribute to long-term value and return on investment beyond the initial purchase price?

7. Can you provide an estimate of the total cost of ownership for the overhead crane over its expected lifespan, including maintenance costs, energy consumption, and potential downtime?

8. What factors contribute to the reliability and durability of the overhead crane, and how do these factors impact its long-term value proposition?

9. Are there any energy efficiency features or options available for the overhead crane to minimize operating costs and environmental impact over time?

10. Can you provide references or case studies demonstrating the long-term value and return on investment of the overhead crane for other customers with similar operational requirements?

By considering future needs, inquiring about upgrade possibilities, and understanding the long-term value and return on investment, you can select a 10-ton overhead crane that not only meets your current requirements but also provides scalability, flexibility, and long-term value for your operation. Take the time to assess your future needs and evaluate the potential benefits and costs associated with different crane options to make a decision that aligns with your strategic objectives and investment goals.