Your Guide to Buying a 10 Ton Overhead Crane: Step-by-Step Instructions

Navigate the purchase of a 10-ton overhead crane confidently with our step-by-step guide, ensuring efficiency, safety, & optimal performance. Contact us!

Your Guide to Buying a 10 Ton Overhead Crane: Step-by-Step Instructions

In today’s industrial landscape, efficiency and safety are paramount. When it comes to handling heavy loads in warehouses, factories, or construction sites, investing in the right equipment is crucial. Among the many options available, the overhead crane stands out as a versatile and efficient solution for lifting and moving heavy objects with precision and ease.

Overhead cranes, also known as bridge cranes or suspended cranes, are a type of material handling equipment used to lift and transport heavy loads horizontally within a defined are Unlike mobile or forklift cranes, overhead cranes are stationary and typically mounted on rails attached to the ceiling or elevated structures. This configuration allows for maximum floor space utilization and precise load positioning.

Selecting the appropriate overhead crane for your application is crucial for several reasons. Firstly, the wrong crane may not have the necessary lifting capacity or reach to handle your loads safely and efficiently, leading to potential accidents or damage to the goods being lifted. Secondly, investing in an overhead crane that is too large or complex for your needs can result in unnecessary expenses and operational inefficiencies. Therefore, taking the time to assess your requirements and choose the right crane is essential for optimizing productivity and ensuring workplace safety.

Assessing Your Needs

Before embarking on the journey of purchasing a 10-ton overhead crane, it's essential to conduct a thorough assessment of your specific requirements. This step is crucial as it forms the foundation for selecting the right crane that meets your operational needs and safety standards.

Understanding Weight Requirements

The first consideration in assessing your needs is understanding the weight requirements of your lifting tasks. Take stock of the heaviest loads you anticipate handling regularly, ensuring to include any potential growth in load sizes over time. Remember that the rated capacity of the crane should not only accommodate the maximum load weight but also consider any additional factors such as load distribution and dynamic loading. By accurately determining your weight requirements, you can avoid under or over-specifying the crane’s capacity, ensuring safe and efficient lifting operations.

Determining Lift Height and Span

Next, determine the lift height and span required for your lifting operations. Measure the distance from the floor to the highest point where the load needs to be lifted (lift height) and the distance between the runway rails or support structures (span). Consider factors such as building height, obstructions, and clearance requirements when determining these dimensions. Additionally, account for any future changes or expansions in your facility that may affect the crane’s lift height and span requirements. By accurately assessing these parameters, you can select a crane that provides optimal coverage and accessibility for your lifting tasks.

Considering Environmental Factors

Environmental factors play a significant role in determining the suitability of an overhead crane for your facility. Evaluate factors such as ambient temperature, humidity levels, dust, and corrosive elements present in your workspace. These factors can impact the performance, longevity, and maintenance requirements of the crane. For example, if your facility operates in extreme temperatures or harsh environments, you may need to opt for specialized crane components with enhanced durability and corrosion resistance. By considering these environmental factors, you can ensure the longevity and reliability of your overhead crane in the specific conditions of your workplace.

By thoroughly assessing your needs in terms of weight requirements, lift height and span, and environmental factors, you can lay the groundwork for selecting the right 10-ton overhead crane that meets your operational needs and safety standards. This proactive approach will not only optimize your lifting operations but also enhance workplace safety and efficiency.

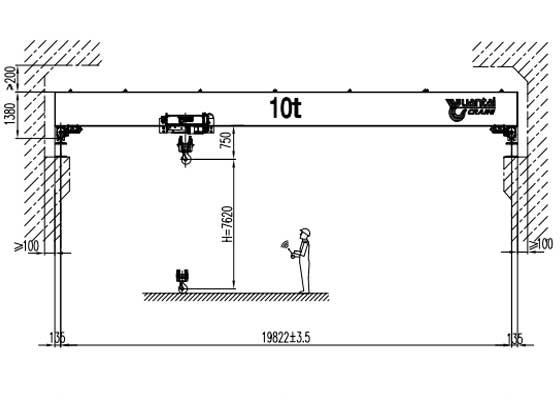

10 ton overhead crane drawing helps you to confirm your parameters and specifications

10 ton overhead crane drawing helps you to confirm your parameters and specifications

Researching Suppliers

Once you have a clear understanding of your overhead crane requirements, the next step is to research and identify reputable suppliers who can meet your needs. Choosing the right supplier is crucial as it ensures the quality, reliability, and support of your crane system throughout its lifecycle.

Identifying Reliable Manufacturers

Start by compiling a list of reputable manufacturers known for producing high-quality overhead cranes. Look for manufacturers with a proven track record of delivering reliable and durable equipment that meets industry standards and regulations. Consider factors such as manufacturer reputation, years of experience, certifications, and adherence to quality assurance processes. Additionally, prioritize manufacturers who offer a wide range of crane configurations, customization options, and after-sales support services. By choosing a reliable manufacturer, you can have confidence in the performance and longevity of your overhead crane system. Yuantai Crane, Dongqi Group

Yuantai Crane, Dongqi Group

Reading Reviews and Testimonials

Once you have identified potential manufacturers, take the time to read reviews and testimonials from their customers. Online forums, industry publications, and social media platforms are valuable sources of unbiased feedback and insights into the customer experience. Pay attention to reviews that highlight factors such as product quality, reliability, customer service, and responsiveness to issues or concerns. Additionally, reach out to other businesses in your industry or network who have experience working with the manufacturer to gather firsthand feedback and recommendations. By leveraging the experiences of others, you can make a more informed decision when selecting a supplier for your overhead crane.

Comparing Prices and Features

After narrowing down your list of potential suppliers, it’s time to compare prices and features to find the best value for your investment. Request detailed quotes from each supplier, ensuring that they include all relevant costs such as equipment, installation, training, and ongoing maintenance. Pay attention to the specific features and capabilities offered by each crane system, such as hoist and trolley configurations, control systems, safety features, and customization options. Consider factors such as warranty coverage, lead times, and availability of spare parts when comparing suppliers. While price is an important consideration, prioritize overall value and long-term support when making your decision. By carefully comparing prices and features, you can ensure that you select an overhead crane system that meets your needs while staying within your budget.

By thoroughly researching suppliers, reading reviews and testimonials, and comparing prices and features, you can make an informed decision when selecting a supplier for your 10-ton overhead crane. This proactive approach will help you find a reliable partner who can deliver a high-quality crane system that meets your operational needs and exceeds your expectations.

Understanding Technical Specifications

Before finalizing your purchase decision, it’s crucial to have a comprehensive understanding of the technical specifications of the overhead crane system. These specifications will dictate the crane’s performance, capabilities, and compatibility with your specific application requirements.

Types of Overhead Cranes

There are several types of overhead cranes available, each designed for specific applications and lifting tasks. The most common types include:

- Single Girder Overhead Crane: Features a single bridge beam supported by end trucks, ideal for light to medium-duty lifting applications in workshops, warehouses, and manufacturing facilities.

- Double Girder Overhead Crane: Utilizes two bridge beams running parallel to each other, providing increased stability, lifting capacity, and height clearance for heavy-duty lifting tasks in industrial environments.

- Gantry Crane: Similar to an overhead crane but supported by legs that run on wheels or tracks on the ground, offering mobility and flexibility for outdoor or temporary lifting operations.

- Jib Crane: Consists of a horizontal boom mounted on a vertical mast, allowing for 360-degree rotation and precise positioning of loads within a limited area, commonly used in workshops and manufacturing cells.

Choosing the right type of overhead crane depends on factors such as load weight, lifting height, span, and workspace layout. Consider consulting with a crane expert or supplier to determine the most suitable type for your application.

Capacity and Load Limitations

Capacity refers to the maximum weight that the crane can lift safely, while load limitations encompass factors such as load distribution, center of gravity, and dynamic loading. It’s essential to select a crane with sufficient capacity to handle your heaviest loads without exceeding its rated limits. Overloading a crane can compromise its structural integrity and lead to safety hazards or equipment failure. Additionally, consider factors such as load fluctuations, acceleration, and deceleration when assessing load limitations to ensure safe and efficient lifting operations.

built up hoist and trolley for your customized needs

Hoist and Trolley Configurations

The hoist and trolley configurations of an overhead crane determine its lifting and movement capabilities. Common configurations include:

- Wire Rope Hoist: Utilizes a wire rope or chain to lift and lower loads, offering high lifting speeds and precise load control.

- Electric Chain Hoist: Features a chain mechanism powered by an electric motor for lifting and lowering loads, suitable for lighter-duty applications with lower lifting heights.

- Manual Trolley: Requires manual operation for horizontal movement along the crane bridge, offering simplicity and cost-effectiveness for light-duty lifting tasks.

- Motorized Trolley: Equipped with a motorized mechanism for horizontal movement along the crane bridge, providing enhanced speed, control, and versatility for heavy-duty lifting operations.

Selecting the appropriate hoist and trolley configuration depends on factors such as load weight, lifting speed, precision requirements, and budget considerations.

Electrical Requirements

Overhead cranes require electrical power to operate their lifting and movement mechanisms. Understanding the electrical requirements of the crane system is essential for ensuring proper installation, operation, and safety. Consider factors such as voltage, phase, frequency, and power supply capacity when assessing electrical requirements. Additionally, consult with an electrician or crane specialist to ensure compliance with local electrical codes and regulations. Proper electrical installation and maintenance are critical for optimizing the performance and longevity of your overhead crane system.

By understanding the technical specifications of overhead cranes, including types, capacity, hoist and trolley configurations, and electrical requirements, you can make an informed decision when selecting a crane system that meets your specific application needs. Take the time to consult with crane experts and suppliers to ensure that you choose the right crane for safe and efficient lifting operations in your facility.

Budgeting and Financing

Investing in a 10-ton overhead crane is a significant decision that requires careful consideration of financial factors. From setting a realistic budget to exploring financing options and assessing the total cost of ownership, understanding the financial aspects of your crane purchase is essential for making a sound investment.

Setting a Realistic Budget

Before beginning your search for an overhead crane, it’s crucial to establish a realistic budget that aligns with your financial resources and operational needs. Consider factors such as the initial purchase price, installation costs, training expenses, and ongoing maintenance and repair costs. Be sure to account for any additional expenses such as upgrades, accessories, and regulatory compliance requirements. Consult with your finance department or financial advisor to determine a budget that balances your investment objectives with your financial constraints. Setting a realistic budget will help guide your purchasing decisions and prevent overspending or unexpected financial strain.

Exploring Financing Options

Once you have established a budget, explore financing options to fund your overhead crane purchase. Depending on your financial situation and creditworthiness, financing options may include:

- Equipment Loans: Traditional loans offered by banks or financial institutions specifically for purchasing equipment, such as overhead cranes. These loans typically require a down payment and fixed monthly payments over a predetermined term.

- Equipment Leasing: Leasing allows you to use the crane without owning it outright, making fixed monthly lease payments for a specified term. Leasing may offer tax advantages and flexibility in upgrading equipment at the end of the lease term.

- Equipment Financing: Financing options tailored for equipment purchases, offering flexible terms and repayment options. Equipment financing may be available through equipment manufacturers or specialized lenders.

- Government Grants and Incentives: Explore government programs, grants, or incentives aimed at promoting equipment purchases or upgrading to more efficient and environmentally friendly equipment. These programs may offer financial assistance or tax incentives to eligible businesses.

Evaluate each financing option carefully, considering factors such as interest rates, repayment terms, collateral requirements, and potential tax implications. Choose the option that best suits your financial goals and cash flow management strategy.

Considering Total Cost of Ownership

In addition to the initial purchase price, it’s essential to consider the total cost of ownership (TCO) when evaluating overhead crane options. TCO encompasses all costs associated with owning, operating, and maintaining the crane over its entire lifecycle. Factors to consider when assessing TCO include:

- Maintenance and Repair Costs: Estimate the cost of routine maintenance, inspections, and repairs over the crane’s lifespan. Consider factors such as warranty coverage, spare parts availability, and service agreements when budgeting for maintenance expenses.

- Energy Consumption: Evaluate the crane’s energy efficiency and power consumption to estimate long-term energy costs. Opt for energy-efficient components and technologies to minimize operating expenses and reduce environmental impact.

- Downtime and Productivity Losses: Factor in the cost of downtime and productivity losses associated with crane breakdowns or maintenance activities. Choose a crane with reliable performance and responsive support services to minimize downtime and maximize productivity.

- Residual Value: Consider the potential resale or trade-in value of the crane at the end of its useful life. Selecting a high-quality crane from a reputable manufacturer may help preserve its resale value and minimize depreciation costs.

By considering the total cost of ownership, including maintenance and repair costs, energy consumption, downtime, and residual value, you can make a more informed decision when selecting an overhead crane that offers the best long-term value for your investment. Be sure to conduct a thorough cost analysis and consult with financial experts to ensure that you have a clear understanding of the financial implications of your crane purchase.

Customization and Special Requirements

Every industrial setting has its unique challenges and requirements when it comes to overhead crane operations. Assessing specialized needs, exploring customization options, and ensuring compliance with safety regulations are essential steps in tailoring your overhead crane system to meet your specific application demands.

Assessing Specialized Needs

Before finalizing your overhead crane purchase, it’s crucial to assess any specialized needs or unique requirements specific to your industry or application. Consider factors such as:

- Load Characteristics: Evaluate the size, shape, weight distribution, and fragility of the loads to be lifted. Determine if specialized lifting attachments or custom rigging solutions are necessary to safely handle unique load types.

- Operational Environment: Consider environmental factors such as temperature extremes, humidity levels, corrosive substances, and airborne contaminants present in your facility. Select crane components and materials that can withstand these conditions to ensure optimal performance and longevity.

- Workspace Layout: Assess the layout and configuration of your workspace, including ceiling height, floor space, obstructions, and access points. Determine if modifications or adaptations are required to accommodate the crane system and ensure safe and efficient operation.

- Regulatory Requirements: Familiarize yourself with relevant safety regulations, codes, and standards governing overhead crane operations in your region or industry. Ensure that your crane system meets or exceeds these requirements to maintain compliance and mitigate safety risks.

By conducting a thorough assessment of specialized needs, you can identify potential challenges and opportunities for customization to optimize the performance and safety of your overhead crane system.

35 ton overhead crane with customized features for sale Qatar

Customization Options

Once you have identified your specialized needs, explore customization options available to tailor your overhead crane system to your specific requirements. Common customization options include:

- Lifting Attachments: Customize lifting attachments, such as hooks, slings, magnets, or grabs, to accommodate unique load shapes, sizes, and handling requirements.

- Control Systems: Choose from a variety of control options, including pendant controls, radio remote controls, or automated systems, to optimize operator efficiency and control precision.

- Crane Configuration: Customize the crane configuration, including bridge span, runway length, and runway height, to fit your workspace layout and operational requirements.

- Safety Features: Incorporate additional safety features such as anti-collision systems, overload protection devices, emergency stop buttons, and warning alarms to enhance workplace safety and compliance.

Collaborate closely with your crane supplier or manufacturer to explore customization options that address your specific needs while ensuring compatibility, reliability, and compliance with industry standards.

Safety Features and Compliance

Safety is paramount in overhead crane operations, and ensuring compliance with safety regulations and standards is essential to protect personnel, equipment, and property. Prioritize the integration of safety features and adherence to safety guidelines throughout the customization process. Key safety considerations include:

- Load Limit Devices: Install load limit devices to prevent overloading and protect against equipment damage or structural failure.

- Collision Avoidance Systems: Implement collision avoidance systems to prevent crane-to-crane, crane-to-structure, or crane-to-person collisions in busy work environments.

- Emergency Stop Controls: Install emergency stop controls at strategic locations to allow operators to quickly halt crane movement in case of emergencies or hazardous situations.

- Operator Training and Certification: Provide comprehensive training and certification programs for crane operators to ensure competency in safe crane operation, load handling techniques, and emergency procedures.

Regularly inspect, maintain, and test safety features to ensure proper functionality and compliance with regulatory requirements. By prioritizing safety features and compliance with safety standards, you can create a safer work environment and mitigate the risk of accidents and injuries associated with overhead crane operations.

By assessing specialized needs, exploring customization options, and prioritizing safety features and compliance, you can tailor your overhead crane system to meet your specific application requirements while ensuring optimal performance, efficiency, and safety. Collaborate closely with your crane supplier or manufacturer to design a customized solution that addresses your unique challenges and enhances productivity in your workplace.

Requesting and Evaluating Quotes

Once you have identified potential suppliers for your overhead crane system, the next step is to request and evaluate detailed quotes to make an informed purchasing decision. This process involves gathering comprehensive information from suppliers, assessing quotes based on predetermined criteria, and seeking clarification on terms and conditions to ensure transparency and alignment with your requirements.

Requesting Detailed Quotes from Suppliers

When requesting quotes from suppliers, provide detailed information about your specific overhead crane requirements to ensure accurate pricing and compatibility. Key information to include in your request for quotes (RFQ) may include:

- Crane Specifications: Provide detailed specifications such as lifting capacity, lift height, span, and any customization requirements based on your assessment of specialized needs.

- Installation Requirements: Specify any site-specific considerations such as ceiling height, floor space, structural support, and electrical requirements that may impact crane installation and operation.

- Additional Services: Request information on additional services such as installation, commissioning, training, maintenance, and support to evaluate the full scope of offerings from each supplier.

- Pricing Breakdown: Ask for a detailed breakdown of pricing, including equipment costs, installation fees, taxes, and any other relevant charges to understand the total cost of the crane system.

Ensure that your RFQ is clear, concise, and comprehensive to facilitate accurate and timely responses from suppliers. Request quotes from multiple suppliers to compare options and negotiate favorable terms.

Evaluating Quotes Based on Criteria

Once you receive quotes from suppliers, carefully evaluate each quote based on predetermined criteria to assess the value and suitability of the proposed crane system. Key criteria to consider when evaluating quotes may include:

- Price: Compare the total cost of each quote, including equipment, installation, and any additional services, to ensure competitiveness and alignment with your budget.

- Equipment Specifications: Assess the compatibility of the proposed crane system with your application requirements, including lifting capacity, lift height, span, and customization options.

- Quality and Reputation: Consider the reputation and track record of each supplier, including their experience, reliability, and customer satisfaction ratings, to gauge the quality of their products and services.

- Support Services: Evaluate the availability and quality of support services such as installation, training, maintenance, and technical support to ensure ongoing reliability and performance of the crane system.

- Warranty and Terms: Review the warranty coverage, payment terms, delivery lead times, and any other contractual terms and conditions to identify potential risks or limitations associated with each quote.

By evaluating quotes based on predetermined criteria, you can objectively compare options and identify the best fit for your overhead crane requirements. Consider consulting with procurement professionals or crane experts to help streamline the evaluation process and negotiate favorable terms with suppliers.

Seeking Clarification on Terms and Conditions

Before finalizing your decision, seek clarification on any ambiguous or unclear terms and conditions included in the quotes from suppliers. Schedule meetings or discussions with representatives from each supplier to address any questions or concerns and ensure mutual understanding and agreement on key aspects such as:

- Delivery Schedule: Confirm the expected delivery lead times and installation timelines to align with your project schedule and operational needs.

- Payment Terms: Clarify the payment terms, including deposit requirements, milestone payments, and final payment due dates, to avoid any misunderstandings or delays in the purchasing process.

- Warranty Coverage: Seek clarification on the scope of warranty coverage, including duration, coverage limits, exclusions, and procedures for warranty claims and repairs.

- Compliance Requirements: Ensure that the proposed crane system meets all relevant safety standards, regulatory requirements, and industry certifications to maintain compliance and minimize risks.

Document any agreements or clarifications reached during discussions with suppliers to create a record of understanding and mitigate potential disputes in the future.

By seeking clarification on terms and conditions, you can ensure transparency and alignment with your expectations and requirements, ultimately facilitating a smooth and successful procurement process for your overhead crane system. Collaborate closely with suppliers to address any concerns and finalize a mutually beneficial agreement that meets your needs and objectives.

Making the Purchase

Once you've thoroughly evaluated quotes from suppliers and made your decision, it's time to move forward with finalizing the purchase of your 10-ton overhead crane system. This phase involves completing the necessary paperwork, ensuring warranty and service agreements are in place, and planning for the delivery and installation of the crane.

Finalizing the Deal

Contract Negotiation: Review the terms and conditions of the proposed contract with your chosen supplier. Negotiate any necessary revisions or modifications to ensure that the agreement accurately reflects the agreed-upon specifications, pricing, and terms.

Sign Contract: Once both parties are satisfied with the terms, sign the contract to formalize the purchase agreement. Ensure that all parties involved receive copies of the signed contract for their records.

Deposit Payment: Make any required deposit payment as stipulated in the contract to secure the order and initiate the procurement process. Verify the accepted payment methods and instructions provided by the supplier.

Ensuring Warranty and Service Agreements

- Warranty Coverage: Confirm the warranty coverage provided by the manufacturer for the overhead crane system. Review the warranty terms, duration, and coverage limits to understand your rights and responsibilities in case of defects or malfunctions.

- Service Agreements: Discuss and finalize service agreements with the supplier to ensure ongoing maintenance, inspection, and support for the crane system. Clarify the scope of services, response times, and contact procedures for requesting assistance or repairs.

- Documentation: Obtain copies of the warranty certificate and service agreements from the supplier for your records. Keep these documents in a safe and accessible location for future reference and warranty claims.

Planning for Delivery and Installation

- Delivery Schedule: Coordinate with the supplier to establish a delivery schedule for the crane system. Confirm the expected delivery date and make arrangements to receive the equipment at your facility.

- Site Preparation: Prepare the installation site in accordance with the specifications provided by the supplier. Ensure that the installation area is clear, accessible, and meets any structural or electrical requirements specified for the crane system.

- Installation Supervision: Supervise the installation process to ensure that it is carried out safely, efficiently, and in accordance with manufacturer guidelines and industry standards. Address any issues or concerns that may arise during installation promptly to avoid delays or complications.

- Training: Schedule training sessions for crane operators and maintenance personnel to familiarize them with the operation, safety procedures, and maintenance requirements of the overhead crane system. Ensure that all relevant personnel receive comprehensive training to optimize crane performance and minimize risks.

By carefully finalizing the purchase deal, ensuring warranty and service agreements are in place, and planning for the delivery and installation of the crane, you can ensure a smooth and successful transition to operational use of your new 10-ton overhead crane system. Maintain open communication with the supplier throughout the process to address any questions or concerns and facilitate a positive purchasing experience.

Training and Maintenance

After the successful installation of your 10-ton overhead crane, it’s essential to focus on training operators, establishing maintenance procedures, and ensuring ongoing support from the supplier. These steps are critical for optimizing crane performance, enhancing workplace safety, and maximizing the longevity of your investment.

Organizing Training for Operators

- Identify Training Needs: Assess the skill levels and training requirements of your crane operators. Determine if any additional training is needed to familiarize them with the specific features, controls, and safety procedures of the overhead crane system.

- Operator Training Program: Develop a comprehensive training program that covers topics such as crane operation, load handling techniques, safety protocols, emergency procedures, and equipment maintenance. Incorporate hands-on training sessions to provide practical experience and reinforce learning objectives.

- Training Resources: Utilize training materials provided by the crane manufacturer or seek out third-party training providers specializing in overhead crane operation and safety. Ensure that training materials are up-to-date, relevant, and compliant with industry standards and regulations.

- Schedule Training Sessions: Coordinate training sessions with certified instructors or trainers to accommodate the availability of crane operators and minimize disruption to workflow. Schedule refresher training sessions periodically to reinforce knowledge and skills and address any emerging training needs.

Establishing Maintenance Procedures

- Maintenance Schedule: Develop a maintenance schedule outlining routine inspection, lubrication, and servicing tasks to keep the overhead crane system in optimal working condition. Schedule maintenance activities based on manufacturer recommendations, operational usage, and environmental factors.

- Inspection Checklist: Create a comprehensive inspection checklist that covers all critical components and systems of the crane, including structural integrity, electrical components, hoist mechanisms, brakes, and safety features. Conduct regular inspections to identify and address any signs of wear, damage, or malfunction promptly.

- Preventive Maintenance: Implement a preventive maintenance program to proactively address potential issues before they escalate into costly repairs or downtime. Perform preventive maintenance tasks such as belt tension adjustments, bearing replacements, and gear lubrication according to the recommended intervals.

- Record-Keeping: Maintain detailed records of maintenance activities, inspections, and repairs conducted on the overhead crane system. Keep track of maintenance schedules, service history, parts replacements, and compliance documentation to ensure accountability and traceability.

Ensuring Ongoing Support from Supplier

- Technical Support: Establish a direct line of communication with the crane supplier or manufacturer to access technical support and assistance as needed. Ensure that you have contact information for technical support representatives who can address any questions, troubleshooting issues, or technical inquiries promptly.

- Spare Parts Inventory: Maintain an inventory of essential spare parts and components for the overhead crane system to minimize downtime and expedite repairs. Work with the supplier to identify critical spare parts and establish a replenishment strategy to ensure availability when needed.

- Service Agreements: Leverage existing service agreements or maintenance contracts with the supplier to access ongoing support services, including scheduled inspections, emergency repairs, and troubleshooting assistance. Ensure that service agreements are renewed as needed and align with your maintenance requirements and budget.

- Continuous Improvement: Foster a collaborative relationship with the crane supplier to explore opportunities for continuous improvement and optimization of crane performance. Share feedback, suggestions, and lessons learned from your experience operating the crane to inform future product enhancements or service offerings.

By organizing training for operators, establishing maintenance procedures, and ensuring ongoing support from the supplier, you can maximize the safety, reliability, and efficiency of your 10-ton overhead crane system. Invest in training and maintenance initiatives as valuable investments that contribute to the long-term success and productivity of your operations.

Conclusion

As you reach the conclusion of your journey to purchase a 10-ton overhead crane, it's essential to reflect on the key steps taken, emphasize the importance of diligence throughout the purchase process, and look ahead to the efficient operations enabled by your new overhead crane system.

Recap of Key Steps

Throughout this guide, we've covered a comprehensive process for buying a 10-ton overhead crane, including:

Assessing Your Needs: Understanding weight requirements, lift height, span, and environmental factors.

Researching Suppliers: Identifying reliable manufacturers, reading reviews, and comparing prices and features.

Understanding Technical Specifications: Exploring crane types, capacity, hoist configurations, and electrical requirements.

Budgeting and Financing: Setting a realistic budget, exploring financing options, and considering total cost of ownership.

Customization and Special Requirements: Assessing specialized needs, exploring customization options, and ensuring safety compliance.

Requesting and Evaluating Quotes: Soliciting detailed quotes, evaluating based on criteria, and seeking clarification on terms.

Making the Purchase: Finalizing the deal, ensuring warranty and service agreements, and planning for delivery and installation.

Training and Maintenance: Organizing training for operators, establishing maintenance procedures, and ensuring ongoing support from the supplier.

The process of buying a 10-ton overhead crane requires careful planning, research, and attention to detail. Diligence in assessing your needs, researching suppliers, understanding technical specifications, and evaluating quotes is essential for making an informed decision and securing the right crane system for your operation. By investing time and effort upfront, you can avoid costly mistakes, ensure compatibility with your requirements, and maximize the value of your investment over the long term.

In conclusion, purchasing a 10-ton overhead crane is a significant investment that requires careful planning and execution. By following the steps outlined in this guide and remaining diligent throughout the purchase process, you can acquire a crane system that meets your needs, enhances your operations, and contributes to the success of your business. Here's to efficient operations and continued success with your new overhead crane!