What Factors Influence the Pricing of Bucket Grabs for Cranes?

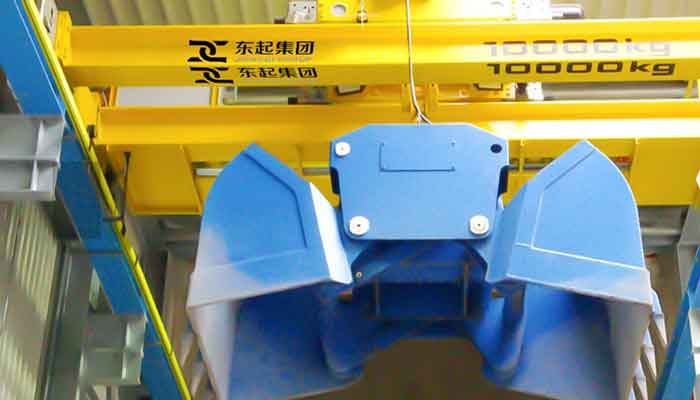

Bucket grabs are essential attachments for cranes, designed to handle bulk materials like sand, gravel, coal, and scrap metal. These versatile tools come in various designs, including clamshell and orange peel models, each suited for specific tasks. Their primary function is to improve the efficiency and safety of material handling operations, making them indispensable in industries such as construction, mining, and waste management.

The factors that influence the pricing of bucket grabs is crucial for several reasons. For businesses, it helps in budgeting and planning capital expenditures more effectively. It also ensures that purchasers can compare different products and manufacturers accurately, making informed decisions that balance cost with quality and functionality. Additionally, knowing these factors can help in negotiating better deals and avoiding overpayment for features that may not be necessary for specific applications.

clamshell grab bucket for cement handling

Material and Build Quality

Types of Materials Used (Steel, Aluminum, etc.)

The materials used in the construction of bucket grabs significantly influence their pricing. Common materials include:

- Steel: The most widely used material, known for its strength and durability. High-strength steel alloys, such as manganese steel, are often used to enhance wear resistance, especially in harsh environments.

- Aluminum: Lightweight and resistant to corrosion, aluminum is used in applications where weight reduction is crucial. However, it is generally more expensive than steel and may not offer the same level of durability under heavy loads.

- Specialty Alloys: In some cases, manufacturers use advanced alloys that combine different metals to achieve specific properties, such as increased toughness or corrosion resistance. These materials can significantly raise the cost due to their superior performance characteristics.

Impact of Material Quality on Durability and Cost

The quality of the materials directly affects the bucket grab's durability and lifespan. High-quality materials, while more expensive upfront, offer better resistance to wear and tear, reducing the need for frequent replacements and maintenance. This long-term durability can lead to cost savings over the equipment's operational life.

- High-Quality Steel: Offers excellent durability and resistance to impacts and abrasion, making it suitable for heavy-duty applications. The cost is higher, but the reduced downtime and maintenance expenses justify the investment.

- Lower-Grade Materials: While cheaper initially, these materials may wear out faster, leading to higher long-term costs due to more frequent repairs or replacements.

Role of Manufacturing Processes in Determining Price

The manufacturing process used to create bucket grabs also plays a crucial role in determining their final price. Advanced manufacturing techniques can improve the quality and performance of the product but may also increase production costs.

- Forging and Casting: Forging involves shaping metal using compressive forces, resulting in a stronger and more durable product. Casting, on the other hand, involves pouring molten metal into a mold. Forged bucket grabs typically cost more due to their superior strength and durability compared to cast versions.

- Heat Treatment: Processes like annealing, quenching, and tempering enhance the material's mechanical properties, such as toughness and hardness. These treatments add to the manufacturing cost but significantly improve the product's performance.

- Precision Machining: Ensures that components fit together perfectly, enhancing the grab's efficiency and lifespan. Precision machining requires advanced equipment and skilled labor, which can increase the price.

- Welding and Assembly: The quality of welding and assembly can impact the structural integrity of the bucket grab. High-quality welding techniques, such as robotic welding, provide consistent and strong joints but come at a higher cost.

In conclusion, the materials and manufacturing processes used in the production of bucket grabs are critical factors that influence their pricing. High-quality materials and advanced manufacturing techniques lead to more durable and reliable products, often justifying the higher initial cost through long-term performance and reduced maintenance needs.

Design and Specifications

Standard vs. Customized Designs

Bucket grabs come in both standard and customized designs, each affecting the pricing differently.

- Standard Designs: These are pre-engineered models that manufacturers produce in bulk. They are designed to meet the general requirements of a wide range of applications. Because they are mass-produced, standard bucket grabs benefit from economies of scale, resulting in lower costs. They are suitable for common tasks and are often available off-the-shelf, reducing lead times and overall expenses.

- Customized Designs: These bucket grabs are tailored to specific customer requirements. Customization can include unique shapes, specialized materials, or additional features to handle particular materials or operate in unique environments. While customized designs offer optimal performance for specific applications, they come with higher costs due to the need for bespoke engineering, specialized materials, and potentially longer production times.

Capacity and Size Variations

The capacity and size of a bucket grab are fundamental factors influencing its price.

- Capacity: This refers to the volume of material the bucket grab can handle in a single operation, usually measured in cubic meters or cubic yards. Larger capacity grabs require more materials for construction, leading to higher costs. Additionally, they may need stronger mechanisms and more robust structures to support the increased load, further driving up the price.

- Size: The physical dimensions of the bucket grab must be appropriate for the crane's lifting capacity and the nature of the material being handled. Larger bucket grabs, while capable of moving more material at once, are more expensive due to the increased material and engineering required. Conversely, smaller grabs are less costly but may not be as efficient for high-volume operations.

Influence of Design Complexity on Pricing

The complexity of the bucket grab's design is another crucial factor in its pricing.

- Simple Designs: Basic bucket grabs with straightforward mechanisms and fewer moving parts are generally less expensive. They are easier to manufacture, require less material, and involve simpler assembly processes. These designs are suitable for routine tasks with moderate requirements.

- Complex Designs: Advanced bucket grabs incorporate sophisticated features such as hydraulic systems, remote control operations, and enhanced gripping mechanisms. These designs improve efficiency, precision, and versatility but significantly increase the manufacturing costs. Complex designs often require specialized engineering, advanced materials, and more labor-intensive production processes.

- Special Features: Features such as reinforced edges, anti-wear liners, and high-performance coatings can add to the complexity and cost of the bucket grab. These enhancements improve durability and performance in demanding environments but come at a higher price.

In conclusion, the design and specifications of bucket grabs play a pivotal role in determining their pricing. Standard designs and simpler models are more cost-effective and readily available, while customized and complex designs offer tailored performance at a premium cost. Understanding these factors helps buyers choose the right bucket grab that balances cost with functionality and durability for their specific needs.

Technology and Features

Advanced Features (e.g., Remote Control, Automation)

Modern bucket grabs often incorporate advanced technologies that enhance their functionality and ease of use:

- Remote Control: Allows operators to control the bucket grab from a distance, improving safety and precision. Remote control systems typically involve wireless technology and electronic controls, which add to the cost of the bucket grab but provide significant benefits in terms of operator comfort and operational efficiency.

- Automation: Includes automated features like self-adjusting claws or programmed operation cycles. Automation reduces the need for manual intervention and can increase productivity by ensuring consistent performance and reducing human error. However, the integration of automation technology adds complexity and cost to the bucket grab.

- Sensor Technology: Some bucket grabs are equipped with sensors for load monitoring, material type detection, or position tracking. These sensors enhance operational safety and accuracy but increase the initial investment due to the advanced technology involved.

- Wear-Resistant Coatings: Specialized coatings can improve the bucket grab's resistance to abrasive materials, extending its lifespan. These coatings add to the manufacturing cost but offer long-term savings by reducing maintenance and replacement needs.

Technological Enhancements and Their Cost Implications

Technological enhancements can significantly impact the pricing of bucket grabs:

- Increased Production Costs: Integrating advanced technologies such as remote controls, automation, and sensors requires additional components, specialized engineering, and more intricate assembly processes. These enhancements lead to higher production costs, which are reflected in the final price of the bucket grab.

- Maintenance and Support: Advanced features often require specialized maintenance and support. For instance, automated systems and electronic controls may need periodic calibration or repair by trained technicians, adding to the ongoing operational costs.

- Energy Efficiency: Some technological improvements enhance energy efficiency, reducing operational costs over time. For example, advanced hydraulic systems can lower energy consumption, potentially offsetting the higher initial cost with long-term savings.

Impact of Innovation on Overall Pricing

Innovation in bucket grabs has a dual effect on pricing:

- Higher Initial Costs: Innovative features and advanced technologies generally come with a higher price tag. The development and integration of new technologies, such as automation and sophisticated control systems, increase the cost of manufacturing. Buyers will see this reflected in the upfront price of the bucket grab.

- Enhanced Performance and Efficiency: Despite the higher initial cost, innovative features can lead to greater operational efficiency, reduced labor costs, and increased safety. These benefits can result in long-term savings and improved productivity, making the higher price more justifiable in terms of overall value.

- Market Positioning: Companies that offer highly innovative bucket grabs may position themselves as premium suppliers, targeting markets that value cutting-edge technology and are willing to pay a premium for enhanced capabilities and performance.

In summary, the integration of advanced technology and features into bucket grabs can substantially influence their pricing. While the initial cost is higher due to the added complexity and advanced components, the potential benefits in terms of efficiency, safety, and long-term savings can make these innovations a worthwhile investment for many users.

Brand and Manufacturer

Reputation and Reliability of Different Brands

The reputation and reliability of bucket grab manufacturers play a significant role in determining their pricing. Established brands with a strong reputation for quality and reliability are often perceived as more trustworthy and can command higher prices. Here’s how brand reputation affects pricing:

- Quality Assurance: Leading brands invest heavily in quality control and rigorous testing to ensure their products meet high standards. This focus on quality often translates to higher prices, reflecting the cost of maintaining strict quality assurance processes.

- Customer Support: Reputable manufacturers provide robust customer support, including installation, maintenance, and troubleshooting. The added value of comprehensive support and service can justify higher prices.

- Track Record: Brands with a proven track record of durability and performance are often preferred, even if their products come at a premium. Buyers are willing to pay more for the assurance of reliability and reduced risk of operational issues.

Influence of Brand Value on Pricing

Brand value significantly influences the cost of bucket grabs, often leading to variations in pricing across different brands:

- Premium Pricing: Well-known brands with a reputation for excellence and innovation may charge higher prices. This premium reflects the perceived value and the brand’s commitment to high standards, advanced technology, and superior performance.

- Market Perception: Brand value can create a perception of higher quality, leading customers to believe that higher-priced products offer better performance and longevity. This perception can drive the pricing strategy of established brands.

- Warranty and Guarantees: Leading brands often offer extended warranties and guarantees, which add to the product's cost. These assurances provide added confidence in the product's longevity and performance.

Comparison of Pricing Among Top Manufacturers

Comparing pricing among top bucket grab manufacturers can reveal significant differences based on various factors:

- Product Range: Different manufacturers offer a range of products from basic to high-end models. Premium models from top manufacturers come with advanced features and higher price points compared to standard offerings.

- Customization Options: Some manufacturers provide extensive customization options, which can affect the price. Tailored solutions from well-known brands often cost more due to the additional engineering and design work involved.

- Regional Pricing Differences: Pricing can vary based on regional factors, such as local market conditions, import taxes, and distribution costs. Top manufacturers may have different pricing strategies depending on the region they serve.

- Total Cost of Ownership: When comparing prices, consider not only the initial purchase cost but also factors like maintenance, spare parts availability, and operational efficiency. A higher-priced product from a reputable manufacturer might offer better long-term value.

In conclusion, the brand and manufacturer of bucket grabs play a crucial role in determining their pricing. Established brands with a reputation for reliability and quality can command higher prices, reflecting the added value of their products and services. Comparing pricing among top manufacturers involves evaluating not just the initial cost but also the overall value, including support, durability, and performance.

Market Demand and Supply

Current Market Trends Affecting Pricing

Several market trends impact the pricing of bucket grabs:

- Increasing Demand for Efficiency: There is a growing demand for equipment that enhances operational efficiency and productivity. This trend drives the development of advanced bucket grabs with features like automation and remote control. As these innovations become more sought after, their prices may rise due to higher production costs and the value they offer.

- Sustainability and Environmental Concerns: With an increasing focus on sustainability, manufacturers are developing bucket grabs with eco-friendly materials and energy-efficient technologies. This shift can lead to higher prices for products that align with environmental standards, as they may require more expensive materials and technologies.

- Technological Advancements: As technology advances, new features and capabilities are incorporated into bucket grabs. While these innovations offer improved performance, they also contribute to higher prices due to the costs associated with developing and integrating new technologies.

Regional Variations in Demand and Supply

Pricing of bucket grabs can vary significantly based on regional demand and supply dynamics:

- Regional Demand: In areas with high construction or mining activity, the demand for bucket grabs may be higher, leading to increased prices due to greater competition and the need for more specialized equipment. Conversely, in regions with lower demand, prices may be more competitive.

- Supply Chain Factors: Regional supply chain conditions, including the availability of raw materials and manufacturing capabilities, affect pricing. In regions where raw materials are more readily available or manufacturing costs are lower, bucket grabs may be less expensive.

- Local Market Conditions: Economic conditions, labor costs, and regulatory environments can impact pricing. For example, in regions with high labor costs or stringent regulations, the cost of producing and delivering bucket grabs may be higher, resulting in increased prices.

Seasonal Factors Influencing Prices

Seasonal variations can also play a role in the pricing of bucket grabs:

- Construction and Mining Seasons: In regions where construction or mining activities are seasonal, such as during specific weather conditions or fiscal quarters, demand for bucket grabs may fluctuate. Prices may rise during peak seasons due to higher demand and fall during off-peak periods.

- Raw Material Availability: Seasonal factors can affect the availability of raw materials used in bucket grabs. For instance, if certain materials are in higher demand during specific seasons, their prices may increase, leading to higher costs for bucket grabs.

- Economic Cycles: Broader economic cycles, such as periods of economic growth or recession, can influence pricing. During times of economic expansion, demand for equipment may increase, driving up prices. Conversely, economic downturns may lead to reduced demand and lower prices.

In summary, market demand and supply dynamics, including current trends, regional variations, and seasonal factors, all play crucial roles in determining the pricing of bucket grabs. Understanding these factors helps buyers make informed decisions and anticipate how market conditions may impact the cost of their equipment.

Regulatory and Compliance Costs

Compliance with Safety and Industry Standards

Bucket grabs must adhere to various safety and industry standards to ensure their safe and effective operation. Compliance with these standards involves:

- Safety Regulations: Bucket grabs must meet stringent safety requirements to prevent accidents and protect operators. These regulations often include guidelines on structural integrity, load capacity, and safety features like emergency stops and warning systems. Ensuring compliance with these regulations involves additional design and testing efforts, which can increase manufacturing costs.

- Industry Standards: Different industries have specific standards for equipment performance and safety. For example, in construction or mining, equipment must meet standards set by organizations such as OSHA (Occupational Safety and Health Administration) or ISO (International Organization for Standardization). Meeting these industry-specific standards often requires additional engineering and documentation, impacting the overall price of the bucket grab.

Certification and Testing Requirements

Certifications and testing are crucial to verifying that bucket grabs meet safety and performance standards. These requirements include:

- Certification: Bucket grabs often need to be certified by recognized bodies or organizations to verify that they meet industry standards. Certification processes can be complex and costly, involving detailed inspections and documentation. The costs associated with obtaining and maintaining certifications are usually passed on to the customer.

- Testing: Comprehensive testing is required to ensure that bucket grabs can handle their rated loads and perform reliably under various conditions. This testing can include load tests, durability tests, and safety tests. The costs of these tests, along with any necessary modifications or retesting, contribute to the overall price of the equipment.

Impact of Regulatory Costs on Pricing

Regulatory and compliance costs have a significant impact on the pricing of bucket grabs:

- Increased Production Costs: Compliance with safety regulations and industry standards requires additional resources, such as advanced materials, specialized engineering, and rigorous testing. These factors increase the production costs, which are reflected in the final price of the bucket grab.

- Documentation and Certification Costs: The process of obtaining certifications and maintaining compliance involves administrative costs, including documentation, application fees, and periodic renewals. These costs are often incorporated into the price of the equipment.

- Liability and Risk Management: Ensuring compliance with regulations helps reduce the risk of legal issues and accidents. While this risk management adds to the initial cost, it ultimately protects both the manufacturer and the buyer from potential liabilities and associated costs.

In summary, regulatory and compliance costs play a crucial role in determining the pricing of bucket grabs. Compliance with safety and industry standards, along with certification and testing requirements, contributes to higher production costs. These costs are typically passed on to the customer, reflecting the added value of ensuring safe, reliable, and legally compliant equipment.

Additional Services and Warranties

Availability of After-Sales Services and Support

After-sales services and support are essential components of the overall value offered by bucket grab manufacturers. These services include:

- Installation and Training: Many manufacturers provide installation services and operator training to ensure that the bucket grab is set up correctly and used efficiently. This support helps minimize operational issues and extends the equipment’s lifespan. The cost of these services is often factored into the overall price of the bucket grab.

- Technical Support: Access to technical support for troubleshooting, repairs, and maintenance inquiries is crucial for minimizing downtime. Manufacturers with robust support systems offer assistance through various channels, such as phone, email, or on-site visits. The availability and quality of this support can influence the pricing of the bucket grab.

- Parts and Repairs: The availability of spare parts and repair services is another critical factor. Manufacturers that stock and provide genuine parts and offer repair services contribute to higher costs but ensure that the equipment remains in optimal working condition.

Impact of Warranty Terms on Pricing

Warranty terms significantly impact the cost of bucket grabs:

- Length of Warranty: Longer warranty periods typically come with higher prices. A comprehensive warranty often includes coverage for parts, labor, and potential defects, providing peace of mind but adding to the initial cost.

- Coverage: Warranties that cover a wide range of issues, including structural defects, performance failures, and component malfunctions, are more expensive. The cost of offering extensive warranty coverage is reflected in the price of the bucket grab.

- Extended Warranties: Manufacturers may offer extended warranties or service contracts for an additional fee. These extended terms provide longer coverage beyond the standard warranty period, increasing the total cost of ownership.

Importance of Maintenance and Service Packages

Maintenance and service packages are vital for ensuring the long-term performance and reliability of bucket grabs:

- Preventive Maintenance: Regular maintenance is essential to prevent breakdowns and extend the equipment’s lifespan. Service packages that include scheduled maintenance, inspections, and minor repairs can help keep the bucket grab in optimal condition. The cost of these packages is often included in the pricing or offered as an additional option.

- Cost Savings: Investing in a service package can lead to cost savings over time by reducing the frequency of major repairs and minimizing downtime. These packages often provide prioritized service and discounts on parts and labor, making them a valuable addition for businesses with high equipment usage.

- Overall Value: Maintenance and service packages enhance the overall value of the bucket grab by ensuring reliable performance and reducing unexpected repair costs. The availability and quality of these packages can influence the pricing of the equipment, as manufacturers may offer bundled services to attract customers.

In conclusion, additional services and warranties play a crucial role in determining the pricing of bucket grabs. After-sales support, warranty terms, and maintenance packages contribute to the overall cost but also provide significant benefits in terms of equipment reliability, performance, and peace of mind. Understanding these factors helps buyers assess the true value of their investment and make informed purchasing decisions.

Economic Factors

Raw Material Price Fluctuations

The prices of raw materials used in the production of bucket grabs can vary significantly, impacting the overall cost of the equipment:

- Material Costs: The cost of essential materials such as steel, aluminum, and specialty alloys can fluctuate based on supply and demand dynamics, production levels, and geopolitical factors. When raw material prices rise, manufacturers often pass these costs on to buyers, leading to higher prices for bucket grabs.

- Supply Chain Disruptions: Disruptions in the supply chain, such as shortages or delays in raw material delivery, can drive up costs. Manufacturers may face increased costs for acquiring and transporting materials, which can affect the final price of the bucket grabs.

- Commodity Market Trends: The prices of raw materials are influenced by global commodity markets. Trends in commodity prices, such as those driven by market speculation or changes in mining and production levels, can lead to fluctuations in the cost of materials used in bucket grabs.

Impact of Global Economic Conditions on Pricing

Global economic conditions play a significant role in determining the pricing of bucket grabs:

- Economic Growth: In periods of economic expansion, demand for construction and industrial equipment, including bucket grabs, typically increases. Higher demand can drive up prices as manufacturers and suppliers respond to the increased need for equipment.

- Economic Recessions: During economic downturns, demand for industrial equipment may decrease, leading to lower prices. However, manufacturers may still face higher costs due to reduced economies of scale or financial instability, which can impact pricing strategies.

- Inflation and Interest Rates: Inflation can lead to increased production costs for raw materials, labor, and manufacturing processes. Additionally, rising interest rates can affect financing costs for both manufacturers and buyers, influencing the overall cost of bucket grabs.

Currency Exchange Rates and Their Influence on International Pricing

Currency exchange rates can significantly impact the pricing of bucket grabs, especially in international transactions:

- Exchange Rate Fluctuations: For manufacturers and buyers involved in international trade, fluctuations in currency exchange rates can affect the cost of bucket grabs. A weaker domestic currency relative to the currency of the country where materials are sourced or equipment is purchased can increase costs.

- Import and Export Costs: Exchange rates influence the cost of importing raw materials or exporting finished bucket grabs. A stronger domestic currency can reduce the cost of imports, while a weaker currency can increase export costs for foreign buyers.

- Pricing Strategies: Manufacturers may adjust their pricing strategies based on currency fluctuations to maintain competitiveness and protect profit margins. This can result in varying prices for bucket grabs depending on the currency exchange rate at the time of purchase.

In summary, economic factors such as raw material price fluctuations, global economic conditions, and currency exchange rates play a crucial role in determining the pricing of bucket grabs. Understanding these factors helps buyers anticipate potential cost changes and make informed decisions when purchasing equipment.

Customization and Special Requirements

Costs Associated with Bespoke Solutions

Customizing bucket grabs to meet specific requirements involves several cost factors:

- Design and Engineering: Creating bespoke solutions requires specialized design and engineering efforts. This includes modifying existing designs or developing entirely new ones to meet unique specifications. The cost of this customized design work is reflected in the final price of the bucket grab.

- Material Costs: Custom bucket grabs may require unique materials or advanced alloys that are not standard in off-the-shelf models. These materials often come with higher costs due to their specialized properties or limited availability.

- Production and Assembly: Customizations often necessitate alterations to the production and assembly processes. This may include the use of specialized machinery or additional labor, contributing to increased manufacturing costs.

- Testing and Certification: Bespoke bucket grabs often undergo additional testing to ensure they meet specific performance and safety standards. The costs of these tests and any required certifications are added to the overall price.

Influence of Specific Industry Requirements on Pricing

Different industries have unique requirements that impact the cost of customized bucket grabs:

- Construction: In the construction industry, bucket grabs might need to handle a wide range of materials, including heavy and abrasive substances. Customizations may involve reinforcing the grab's structure or incorporating features to enhance its durability and performance. These industry-specific requirements can drive up the cost.

- Mining: Mining operations often require bucket grabs with high capacity and durability to handle large quantities of ore or rocks. Custom solutions for mining applications may involve additional strengthening and specialized components, increasing the overall price.

- Waste Management: In waste management, bucket grabs may need to accommodate varying types of waste, including hazardous materials. Custom designs for these applications often include features for safe handling and containment, which can affect the pricing.

Examples of Customization Impacting Price

Here are a few examples of how customization can impact the price of bucket grabs:

- Heavy-Duty Reinforcements: For applications involving particularly abrasive or heavy materials, bucket grabs may be customized with reinforced edges, thicker plates, or special wear-resistant coatings. These custom features add to the cost due to the additional materials and engineering required.

- Specialized Gripping Mechanisms: Bucket grabs designed to handle specific materials, such as delicate or irregularly shaped items, may include customized gripping mechanisms or additional hydraulic systems. The complexity of these custom features can significantly increase the price.

- Enhanced Safety Features: In industries with stringent safety regulations, bucket grabs may be customized with advanced safety features, such as enhanced visibility systems, automatic safety locks, or additional sensors. Implementing these features involves extra costs for both materials and technology.

- Size and Capacity Adjustments: Custom bucket grabs with modified sizes or capacities to meet specific operational requirements may require changes in design and production. These adjustments can lead to higher costs due to the need for custom engineering and production adjustments.

In summary, customization and special requirements have a substantial impact on the pricing of bucket grabs. The costs associated with bespoke solutions, industry-specific requirements, and examples of customization highlight how these factors contribute to the overall price of the equipment. Understanding these aspects helps buyers assess the value of customized solutions and make informed decisions based on their specific needs.

Conclusion

Summary of Key Factors Influencing the Pricing of Bucket Grabs

The pricing of bucket grabs is influenced by a range of factors that can vary significantly depending on the specific needs and circumstances of each buyer. Key factors include:

- Material and Build Quality: The choice of materials and the quality of construction directly impact the durability and cost of bucket grabs. Higher-quality materials and more robust construction lead to increased costs but offer greater reliability and longevity.

- Design and Specifications: Whether opting for standard or customized designs, and the variations in capacity and size, all affect pricing. Complex designs and custom features generally lead to higher costs.

- Technology and Features: Advanced technologies such as remote controls, automation, and sensors contribute to higher prices due to the additional costs of integrating and maintaining these features.

- Brand and Manufacturer: The reputation and reliability of different brands can significantly influence pricing. Established brands with a track record of quality often command higher prices.

- Market Demand and Supply: Fluctuations in demand and supply, including regional variations and seasonal factors, affect pricing. Economic conditions and raw material price fluctuations also play a role.

- Regulatory and Compliance Costs: Compliance with safety and industry standards, along with certification and testing requirements, impacts the pricing of bucket grabs due to the associated costs.

- Additional Services and Warranties: The availability of after-sales services, warranty terms, and maintenance packages contribute to the overall cost of bucket grabs, reflecting the value of additional support and protection.

- Customization and Special Requirements: Bespoke solutions and specific industry requirements lead to increased costs due to custom design, materials, and production processes.

Importance of Considering Multiple Factors When Evaluating Pricing

When evaluating the pricing of bucket grabs, it is crucial to consider all relevant factors to make a well-informed decision:

- Comprehensive Assessment: A thorough evaluation of material quality, design specifications, technological features, and brand reputation helps in understanding the true cost and value of the equipment.

- Long-Term Value: Beyond the initial price, considering factors such as durability, maintenance needs, and operational efficiency provides a clearer picture of the total cost of ownership.

- Customization Needs: Assessing the need for customization and its impact on pricing ensures that the chosen bucket grab meets specific requirements without overpaying for unnecessary features.

Final Thoughts and Recommendations for Buyers

- Evaluate Your Needs: Clearly define the specific requirements and operational needs for your bucket grab to ensure that you select a model that offers the best value for your application.

- Research and Compare: Compare different models, brands, and manufacturers, considering their pricing, features, and reputation. Look at reviews and seek recommendations to make an informed choice.

- Consider Total Cost of Ownership: Factor in not just the purchase price but also the costs of maintenance, support, and any additional services or warranties. This will help in assessing the overall value and ensuring that the investment is worthwhile.

- Consult with Experts: Engage with manufacturers or industry experts to gain insights into the best options for your specific needs and to understand the implications of various customization and technological features on pricing.

By carefully considering these factors, buyers can make informed decisions and select a bucket grab that balances cost with functionality, quality, and long-term performance.