Custom Bridge Cranes: Tailoring Capacities for Specialized Uses

Custom bridge cranes are designed to meet specific industrial needs, ensuring optimal capacity, performance, safety for specialized environments.

Custom Bridge Cranes: Tailoring Capacities for Specialized Industrial Applications

In today's industrial landscape, the demand for efficiency and precision has never been higher. For businesses operating in diverse sectors such as manufacturing, logistics, and construction, the ability to tailor equipment to specific needs can significantly impact productivity and operational costs. One crucial aspect of this customization lies in the capacity of bridge cranes, which play a pivotal role in material handling and logistics within large-scale facilities.

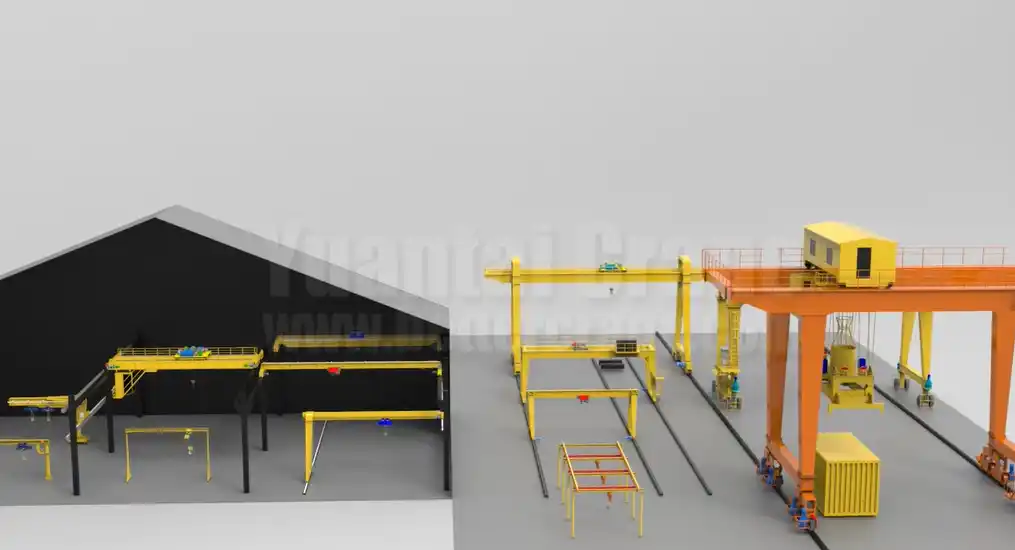

All types of bridge cranes for sale, tailored for specialized industrial uses and applications

Importance of Tailored Crane Capacities

Bridge cranes, also known as overhead cranes, are indispensable tools in industries where heavy lifting and precise material handling are routine tasks. The importance of selecting the right crane capacity cannot be overstated. A crane that is underpowered may struggle to lift required loads efficiently, leading to delays and potential safety hazards. Conversely, an overpowered crane not only wastes energy but also incurs unnecessary costs in terms of maintenance and initial investment.

- Meeting Unique Industrial Needs. Every industrial setting presents its own set of challenges and requirements. Whether it's the automotive industry needing to handle bulky car parts or the shipping industry managing containers of varying weights, each application demands a crane solution that can handle specific loads reliably. Tailoring crane capacities involves a careful assessment of the types of materials to be lifted, the frequency of lifts, and the operational environment.

- Enhancing Operational Efficiency. Customizing crane capacities goes beyond mere lifting capabilities. It directly impacts operational efficiency by ensuring that tasks are completed swiftly and safely. By matching the crane's capacity precisely to the demands of the workload, businesses can streamline their operations, reduce downtime, and optimize their overall production processes.

- Cost-Effectiveness and Safety. Investing in a crane with a tailored capacity isn't just about operational efficiency; it's also about cost-effectiveness and safety. A well-matched crane reduces the risk of accidents associated with overloading or underloading, thereby enhancing workplace safety. Moreover, it minimizes unnecessary wear and tear on equipment, extending its lifespan and reducing maintenance costs over time.

- Choosing the Right Partner. Selecting the optimal crane capacity involves collaboration with experienced manufacturers and suppliers who understand the nuances of industrial applications. This partnership ensures that the chosen crane not only meets current operational needs but also accommodates future growth and changes in production requirements.

In conclusion, the importance of tailored crane capacities in industrial settings cannot be overstated. By investing in customized solutions that precisely match operational demands, businesses can achieve higher efficiency, lower costs, and improved safety standards. In the subsequent sections of this article, we will delve deeper into how bridge cranes can be customized for specific industrial applications, exploring modular designs, custom load handling attachments, and real-world case studies that highlight successful implementations across various industries. Stay tuned to discover how custom bridge cranes are shaping the future of industrial logistics and material handling.

Designing for Specific Applications: Customizing Bridge Cranes to Meet Unique Industrial Demands

In industrial environments, one size rarely fits all when it comes to equipment. Bridge cranes, essential for efficient material handling across various sectors, exemplify the need for customization to meet specific operational requirements.

Industries differ significantly in their material handling needs. For instance, automotive manufacturing requires lifting heavy vehicle components with precision, while warehouses managing diverse goods benefit from versatile crane capabilities. Customizing bridge cranes involves a detailed assessment of these unique demands, including load sizes, weights, frequencies, and spatial constraints within the facility.

- Tailored Solutions for Optimal Performance. The key to effective customization lies in designing bridge cranes that align seamlessly with operational workflows. This involves selecting the appropriate crane capacity, reach, and lifting mechanisms tailored to the specific tasks at hand. By integrating these tailored solutions, businesses can enhance operational efficiency, minimize downtime, and optimize resource utilization.

- Adapting to Industry Challenges. Each industry presents its own set of challenges that influence crane design. For example, in the steel industry, cranes must withstand high temperatures and harsh environments, while in food processing, hygiene and corrosion resistance are paramount. Customized bridge cranes address these challenges by incorporating specialized materials, protective coatings, and ergonomic features that ensure durability and compliance with industry regulations.

- Flexible Configurations for Varied Applications. Modular designs play a crucial role in customizing bridge cranes. They allow for flexibility in capacity adjustments, enabling businesses to adapt quickly to changing operational needs without extensive reconfiguration or downtime. Whether scaling up production or handling seasonal variations in workload, modular cranes offer versatility and cost-efficiency.

- Collaborative Approach to Customization. Successful customization requires collaboration between businesses and crane manufacturers who possess expertise in both engineering and industrial applications. This partnership ensures that the designed solutions not only meet immediate requirements but also anticipate future challenges and growth opportunities.

In essence, designing bridge cranes for specific industrial applications is about more than just lifting capabilities; it's about optimizing efficiency, ensuring safety, and future-proofing operations. The next sections of this article will delve deeper into modular designs, custom load handling attachments, and real-world case studies to illustrate how customized bridge cranes empower industries to achieve their operational goals effectively. Stay tuned as we explore these essential components in the realm of specialized industrial crane solutions.

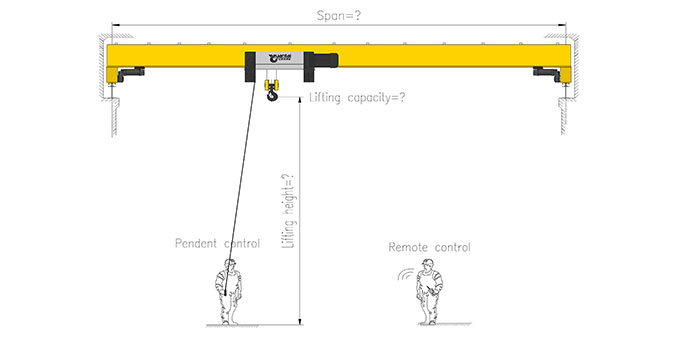

Single girder bridge crane main specification required to design for you

Single girder bridge crane main specification required to design for you

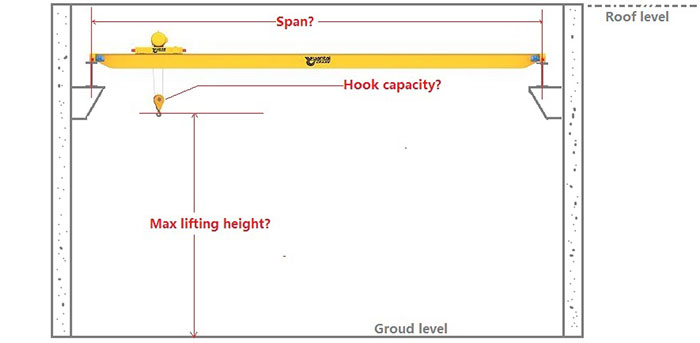

Double girder bridge crane main specification required to design for you

Double girder bridge crane main specification required to design for you

Modular Designs for Flexibility: How Modular Crane Designs Facilitate Adjustable Capacities

In the dynamic landscape of industrial operations, flexibility is a cornerstone of efficiency. Modular crane designs offer a strategic advantage by enabling adjustable capacities that can adapt to varying demands and operational scenarios.

- The Concept of Modular Design. Modular crane designs are characterized by their ability to be easily customized and reconfigured. Unlike traditional fixed designs, which may require extensive modifications to accommodate changes in capacity or operational needs, modular cranes utilize standardized components and interchangeable modules. This modular approach allows for swift adjustments in lifting capacity, span, height, and other critical parameters without compromising on performance or safety.

- Scalability and Adaptability. One of the primary advantages of modular crane designs is scalability. Businesses can scale their operations up or down as needed, whether due to seasonal fluctuations, changes in production volumes, or evolving business requirements. This scalability minimizes downtime and optimizes resource utilization, enhancing overall operational efficiency.

- Cost Efficiency and Return on Investment. By leveraging modular designs, businesses can achieve significant cost savings over the lifecycle of the crane. The ability to upgrade or expand capacity incrementally reduces upfront investment costs compared to purchasing a new crane for each capacity change. Additionally, modular cranes are easier to maintain and repair, further contributing to long-term cost efficiency and maximizing return on investment.

- Adaptive Solutions for Diverse Applications. Modular crane designs are versatile and adaptable to diverse industrial applications. Whether used in manufacturing facilities, warehouses, ports, or construction sites, these cranes can be tailored to meet specific operational challenges and environmental conditions. This adaptability ensures that businesses can deploy the right crane configuration for each task, optimizing productivity and safety across different work environments.

- Integration with Advanced Technologies. Advancements in technology, such as digital controls and automation, can be seamlessly integrated into modular crane designs. This integration enhances operational efficiency by providing real-time monitoring, predictive maintenance capabilities, and enhanced safety features. It also positions modular cranes as future-proof investments that can evolve alongside technological advancements in industrial automation.

- Collaborative Approach to Implementation.Successful implementation of modular crane designs requires collaboration between businesses and crane manufacturers with expertise in modular systems. This partnership ensures that the modular solutions not only meet current operational needs but also align with long-term business strategies and growth objectives.

In summary, modular crane designs offer unparalleled flexibility, scalability, and cost efficiency in meeting adjustable capacity requirements across diverse industrial applications. The following sections of this article will delve into the impact of custom load handling attachments, real-world case studies, and the collaborative design process, illustrating how modular crane solutions empower industries to achieve optimal performance and adaptability. Join us as we explore these essential components in the realm of specialized industrial crane solutions.

Enhancing Efficiency with Custom Load Handling: Impact of Bespoke Load Handling Attachments on Crane Performance

Efficiency in industrial operations hinges not only on the capacity and design of bridge cranes but also on the precision and versatility of their load handling capabilities. Custom load handling attachments play a pivotal role in optimizing crane performance to meet specific operational requirements.

Bespoke Load Handling Attachments

Bespoke or custom load handling attachments are specialized tools designed to enhance the functionality of bridge cranes. These attachments are tailored to the unique needs of various industries and specific tasks within those industries. They can range from simple hooks and lifting beams to more complex grabs, magnets, and vacuum lifters, each designed to securely grasp, transport, and position materials of varying sizes, shapes, and weights.

Key Benefits of Custom Load Handling Attachments

- Improved Efficiency: Custom attachments streamline material handling processes by allowing cranes to lift and maneuver loads more efficiently. This efficiency translates into reduced cycle times, increased throughput, and enhanced overall productivity within industrial operations.

- Enhanced Safety: Custom attachments are engineered with safety in mind, ensuring secure handling of materials to minimize the risk of accidents, damage to goods, and injuries to personnel. They provide precise control over load positioning, reducing the likelihood of load slippage or instability during lifting and transport.

- Versatility and Adaptability: By customizing load handling attachments, businesses can adapt crane operations to handle a wide range of materials and operational scenarios. Whether lifting delicate components in the automotive industry or heavy machinery parts in manufacturing, these attachments can be tailored to meet specific application requirements effectively.

- Cost Efficiency: Custom attachments optimize resource utilization by reducing manual labor requirements and material wastage. They also contribute to longer equipment lifespan and lower maintenance costs, resulting in improved cost efficiency over time.

Integration with Crane Systems

Effective integration of custom load handling attachments requires collaboration between businesses and crane manufacturers to ensure seamless compatibility and operational effectiveness. This partnership enables the development of tailored solutions that maximize the performance and longevity of bridge cranes while meeting stringent industry standards and regulatory requirements.

Case Studies in Custom Load Handling

Real-world examples illustrate the transformative impact of custom load handling attachments across diverse industries. From specialized grabs for waste management facilities to precision lifting tools for aerospace manufacturing, these case studies highlight how customized solutions optimize operational workflows, improve safety outcomes, and drive business success.

In conclusion, the integration of bespoke load handling attachments enhances the operational efficiency, safety, and versatility of bridge cranes in meeting the unique demands of industrial applications. The subsequent sections of this article will explore the collaborative design process and showcase real-world case studies, providing further insights into the strategic advantages of customizing bridge cranes for specialized industrial environments. Join us as we delve deeper into these essential components of specialized industrial crane solutions.

Collaborative Design Process: Steps in Collaborating with Manufacturers for Customized Solutions

The achieving optimized bridge crane solutions tailored to specific industrial needs involves a collaborative effort between businesses and experienced crane manufacturers. This collaborative design process ensures that the final crane configuration not only meets but exceeds operational expectations.

Collaboration begins with a thorough assessment of the industrial application requirements and operational challenges. This initial phase sets the foundation for designing a crane system that integrates seamlessly into existing workflows while addressing unique operational demands.

Key Steps in the Collaborative Design Process:

- Initial Consultation and Needs Assessment:The process kicks off with an in-depth consultation where businesses articulate their specific operational challenges, performance goals, and environmental constraints. Manufacturers leverage their expertise to analyze these requirements comprehensively.

- Conceptual Design and Proposal:Based on the needs assessment, manufacturers develop conceptual designs and proposals that outline potential crane configurations, including capacity specifications, ergonomic considerations, safety features, and integration with custom load handling attachments.

- Engineering and Design Development:Upon approval of the conceptual design, the collaborative effort shifts towards detailed engineering and design development. This phase involves refining structural calculations, selecting materials, and incorporating advanced technologies to optimize crane performance and reliability.

- Prototype Development and Testing:Prototyping plays a crucial role in validating the proposed crane solution. Manufacturers build and test prototypes to assess functionality, durability, and adherence to performance criteria. This iterative process ensures that any design refinements are implemented before full-scale production.

- Production and Installation:Once the prototype meets all specifications and undergoes rigorous testing, production commences. Manufacturers oversee the fabrication and assembly of components, ensuring quality control measures are upheld throughout the manufacturing process. Installation at the client's facility follows stringent safety protocols and operational guidelines.

- Commissioning and Training:Post-installation, manufacturers conduct thorough commissioning procedures to ensure the crane operates efficiently and safely within its intended environment. Training sessions are provided to operators and maintenance personnel to familiarize them with the crane's features, controls, and maintenance requirements.

- Ongoing Support and Maintenance:The collaborative relationship extends beyond installation with manufacturers offering ongoing support, maintenance, and periodic inspections to uphold crane performance and longevity. This proactive approach minimizes downtime, optimizes operational uptime, and enhances overall reliability.

Benefits of Collaborative Design

The collaborative design process fosters innovation and customization, enabling businesses to deploy crane solutions that not only meet immediate operational needs but also align with long-term strategic objectives. By leveraging manufacturers' expertise and technological advancements, businesses gain access to cutting-edge solutions that enhance productivity, safety, and efficiency across diverse industrial sectors.

In summary, collaboration with experienced crane manufacturers is pivotal in developing customized solutions that optimize bridge crane performance for specialized industrial applications. The subsequent sections of this article will showcase real-world case studies and delve deeper into the impact of collaborative design on operational outcomes. Join us as we explore how strategic partnerships and tailored crane solutions are reshaping industrial logistics and material handling practices.

Case Studies: Examples of Successful Custom Crane Deployments Across Industries

Examples demonstrate the transformative impact of custom bridge crane solutions in enhancing operational efficiency, safety, and productivity across diverse industrial applications.

Automotive Manufacturing: Precision Handling of Vehicle Components

In the automotive industry, a leading manufacturer faced challenges with lifting and maneuvering heavy vehicle components on their assembly lines. Working closely with a crane manufacturer, they customized bridge cranes with precision lifting capabilities and specialized load handling attachments. These cranes not only improved workflow efficiency by reducing cycle times but also enhanced worker safety by ensuring secure handling of delicate and heavy parts.

Aerospace Industry: High-Precision Manufacturing

An aerospace facility required crane systems capable of lifting and positioning large aircraft components with utmost precision. By collaborating with crane experts, they developed custom bridge cranes equipped with advanced automation features and specialized sensors for accurate positioning. These bespoke solutions optimized production processes, minimized assembly errors, and supported stringent quality control standards in aerospace manufacturing.

Logistics and Warehousing: Versatile Material Handling

In a bustling logistics center, flexibility and efficiency were paramount. Customized bridge cranes were deployed with modular designs that allowed for rapid adjustments in lifting capacities and operational configurations. This versatility enabled the warehouse to manage diverse cargo types, from bulky pallets to fragile goods, with minimal downtime and maximum throughput. The integration of custom load handling attachments further enhanced operational agility and safety.

Steel Industry: Endurance in Extreme Environments

A steel manufacturing plant required robust crane systems capable of withstanding high temperatures, heavy loads, and corrosive environments. Through collaborative design and engineering, they implemented custom bridge cranes featuring specialized coatings, heat-resistant materials, and enhanced structural integrity. These tailored solutions not only improved operational reliability but also extended equipment lifespan, reducing maintenance costs and downtime associated with equipment failures.

Construction Sector: Adaptive Solutions for Dynamic Projects

In the construction sector, where project timelines and site conditions vary widely, customized bridge cranes played a pivotal role in streamlining material handling operations. By partnering with crane manufacturers, construction firms implemented modular crane designs that could be swiftly reconfigured to meet changing project demands. These adaptive solutions enhanced construction efficiency, optimized resource allocation, and contributed to timely project delivery.

Electric hoist trolley for double girder bridge crane for sale Philippines

Crane type: Double girder bridge crane with electric hoist trolley European style

Crane capacity: 35t/5 ton

Crane span: 49m

Crane lifting height: 10m

Crane power supply: 400V60HZ/3Phase

Project location: Philippines

Crane Type: Open Winch Double Girder Overhead Crane

Crane Capacity: 45 Ton

Crane Span: 22.785 m

Crane Lifting Height: 15 m

Crane Power Supply: 415V50HZ3P

Crane Control: Joystick Remote Control

European style double girder bridge crane 40 ton for sale America

Crane specification:

Overhead bridge crane capacity: 40 ton,

Bridge crane span: 22.25m

Crane lifting height:10.688m.

Quantity; 2 sets

Application: Indoor use for die and mold handling

These case studies underscore the strategic advantage of customizing bridge cranes to align with specific industrial requirements. By leveraging collaborative design processes and innovative engineering solutions, businesses across industries can optimize operational workflows, improve safety standards, and achieve sustainable growth. The success stories of custom crane deployments highlight the transformative impact of tailored solutions in reshaping industrial logistics and material handling practices.

Conclusion: Recap of Key Insights and the Importance of Selecting Optimal Crane Capacities

Throughout this exploration into custom bridge cranes, we've delved into the critical importance of tailoring crane capacities to meet specific industrial needs. Here's a recap of key insights and the significance of selecting optimal crane configurations:

Key Insights:

- Customization Enhances Efficiency: Customizing bridge cranes allows businesses to optimize operational efficiency by aligning crane capacities with specific material handling requirements. Whether it's precision lifting in automotive manufacturing or versatile handling in logistics, tailored solutions streamline workflows and minimize downtime.

- Safety and Reliability: Selecting the right crane capacity is crucial for ensuring workplace safety and equipment reliability. Overloaded or underloaded cranes pose safety risks and can lead to operational disruptions. Customized crane solutions with appropriate load handling capabilities mitigate these risks and enhance operational safety.

- Flexibility with Modular Designs: Modular crane designs offer unparalleled flexibility, enabling businesses to adapt quickly to changing operational needs. Whether scaling production volumes or adjusting to seasonal fluctuations, modular cranes facilitate seamless adjustments in lifting capacities and configurations without extensive downtime.

- Collaborative Design Process: Successful deployment of custom bridge cranes involves a collaborative approach between businesses and crane manufacturers. This partnership ensures that crane solutions are meticulously tailored to meet specific operational challenges, incorporate advanced technologies, and comply with industry standards.

Importance of Selecting Optimal Crane Capacities:

Choosing the optimal crane capacity goes beyond mere operational efficiency. It impacts overall business performance, cost-effectiveness, and employee welfare. By investing in custom crane solutions that precisely match operational demands, businesses can:

- Maximize Productivity: Ensure smoother operations with minimal disruptions and improved throughput.

- Reduce Costs: Minimize maintenance expenses, energy consumption, and downtime associated with improper crane capacity.

- Enhance Safety: Mitigate risks of accidents and injuries by maintaining safe load handling practices.

- Future-Proof Operations: Anticipate future growth and technological advancements with adaptable crane systems that support long-term business strategies.

In conclusion, the selection of optimal crane capacities is a strategic decision that drives efficiency, safety, and profitability across industrial sectors. By embracing customization and leveraging collaborative partnerships with crane manufacturers, businesses can navigate complex operational challenges effectively and achieve sustainable growth in today's competitive landscape.

We hope this journey through the realm of custom bridge cranes has provided valuable insights and inspiration for optimizing material handling practices within your industry. For more information on tailored crane solutions or to explore specific applications further, feel free to contact us or consult with experienced crane professionals. Thank you for joining us in exploring the transformative potential of custom bridge cranes.